Professional Documents

Culture Documents

Rapid Range Technical Information Sheet

Uploaded by

graham4877Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rapid Range Technical Information Sheet

Uploaded by

graham4877Copyright:

Available Formats

CAMBS. R.F.D. No.

97

THEOBEN ENGINEERING WEST NEWLANDS SOMERSHAM CAMBS. PE28 3EB ENGLAND theoben@zetnet.co.uk Tel : 01487 740744 Fax : 01487 740040

http://www.theoben.co.uk

RAPID RANGE TECHNICAL INFORMATION SHEET

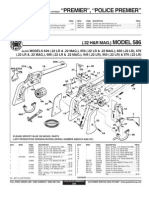

New Bolt - Jan 2000 24+ 9s 9r 9a 9 9h 9e 8b 8 9a 9f 9n 9k 9d 9c 9b 6d 7c 7d 6l 6c 9c 9k 9d 9b 16a 16 8d 8c

An exploded diagram of the Rapid Range

7b

7g

7a

7f

6a

2 15d 15m 15c 15r 15e 15n 13a 15 1

Black Valve

6m/n

Metal Valve

6 6e

13

15l 15k 15f 15t

15g

6k 6g 11a 12 11 11b

6k

6g

6h

6f

1 2 2b 3a 3b 3d 4a 4f 6 6a 6b 6c 6d 6e 6f 6g 6h 6j 6k 6l 6m 6n 6p 7 7a 7b

Body 7c Inertia Weight 9e Bolt Circlip Bottle Inlet Adaptor 7d Inertia Spring 9f Dog Inlet Adaptor o-ring (BS015) 7f M6 Washer 9g Dog Screw 280cc Bottle Neck 7g Hammer Spring Guide (std) 9h Bolt Plate 280cc Schrader Valve (HP9914) 7l Hammer Spring (.177/Elan) 9j Bolt Plate Screw 280cc Bottle o-ring (BS111) 7m Int. Hammer Spring (.177/Elan) 9k Spring Washer 400cc Bottle Neck 7n Spring Guide (.177/Elan) 9l Probe (.20 cal) 400cc Bottle o-ring (BS111) 8 16 inch Barrel (.22 cal) 9m Probe (.25 cal) Metal Valve Body 8b Barrel Location Screw 9n Crinkle Washer (shim) Blanking Screw 8c Barrel Clamp & Screw 9o Probe (.177 cal) Blanking Screw o-ring (015) 8e 16 inch Barrel (.20 cal) 9r Bolt Adjustment Rod Valve Spring 8h 16 inch Barrel (.177 cal) 9s Bolt Adlustment Screw Valve Stem 9 Bolt Handle 11 Front Stock Screw ( UNF) Metal Valve Cap 9a Bolt Body 11a Rear Stock Screw (2ba) Theoben 008 seal 9b Probe (.22cal) 11b Blacked M6 Washer Valve o-ring (011) 9c Probe Stem (specify calibre) 12 Trigger Guard Valve o-ring (013) 9d Bolt Spring 13 Rear (sporter) Trigger Boss Valve Location Screw Valve o-ring (4.1 x 1.6) Valve Stem o-ring (607) 7d Black Valve 38 7m 7l 7n 7f 7 Elan Black Valve The Elan hammer set up. Elan Valve Spring Hammer The rest of the parts in the Elan are the same as the parts in the Rapid Range Progressive Hammer Spring Rear Screw Cap as shown in the top diagram.

13a 15 15a 16 16a 25+ 27

Star Washer Trigger Assembly (Sporter) Trigger Pin Blips (pair) Blip Screws Gold Medal Trigger (GMT) GMT Hammer

30 35a 36+ 36d 37+ 38

Rear (GMT)Trigger Boss Bottle Neck Adaptor (Elan) Charging Union (Elan) Dowty Seal (Elan) Charging Hose (Elan) Inertia Weight (Elan) FAC parts not listed

8 6g 6n 6l 6d 6p 6a

36d

35a

35

6b 36+

An exploded diagram of the Elan showing the valve, bottle and charging union.

SETTING THE POWER

These calculations are approximate, based on the most accurate pellet not the most powerful. Formula to convert feet per second to foot pounds energy

To regulate, fill bottle Calibre to . . . for most accurate reading 1900psi 1900psi 2500psi 3000psi 2500psi 3000psi 3200psi 3200psi 1700psi 1700psi

Power

Pellet

Shots Weight FPS Based on a Full 400cc bottle Pressure (grns) 7.9 10.5 14.3 14.3 14.3 21 24.5 27 14.3 15.3 825 715 610 930 610 800 830 815 610 594 170 170 270 40 300 50 30 30 50 50 2900psi 2900psi 3000psi 3200psi 3000psi 3200psi 3200psi 3200psi 2700psi 2700psi

.177 .20 .22 .25 Elan

.22

12 ft/lbs Crosman Premier FAC Crosman Premier 12 ft/lbs Crosman Premier FAC Crosman Premier 12 ft/lbs Crosman Premier FAC Bisley Magnum FAC FAC 12ft/lbs 12ft/lbs Crosman Premier H & N Rampoint Crosman Premier H & N FT Trophy

FPS x FPS x Grns 450240 = Muzzle Energy

WARNING - Changing the rifle from the manufacturers setting could take the rifle over the legal limit. This is an offence and could result in rifle confiscation or prosecution.

METAL VALVE SERVICE KIT

O-RING KIT

Contains: Full Instructions Molykote 33 Grease (pack) 1 Theoben 008 white seal 6F 2 111 o-ring (buddy bottle) 3G 2 015 o-ring 6B 1 013 o-ring 6H 1 011 o-ring 6G 1 4.1 x 1.6 o-ring 6K 1 607 o-ring 6L 1 Collet 1 Rod

Contains: Full Instructions Molykote 33 Grease (pack) 2 Theoben 008 white seal 6F 4 111 o-ring (buddy bottle) 3G 4 015 o-ring 6B 2 013 o-ring 6H 2 011 o-ring 6G 2 4.1 x 1.6 o-ring 6K 2 607 o-ring 6L 1 Allen key 3/16 1 Allen key 5/32 1 Allen key 1/8 This service kit contains everything neccesary to 1 Allen key 3/32 do 2 services on your Rapid with a metal valve 1 Allen key 1/16 including a collet and rod needed for the job. 1 Collet This o-ring kit contains the basic items required to 1 Rod do 1 service on your Rapid with a metal valve.

COMPLETE VALVE SERVICING AND O-RING KITS ARE AVAILABLE FROM THEOBEN

BLACK VALVE SERVICE KIT O-RING KIT

Contains: Full Instructions Contains: Molykote 33 Grease (pack) Full Instructions 1 111 o-ring (buddy bottle) 3G Molykote 33 Grease (pack) 2 015 o-ring 6B 1 Assembled Plastic Valve 6M 1 013 o-ring 6H 4 111 o-ring (buddy bottle) 3G 1 607 o-ring 6L 4 015 o-ring 6B 1 + 1 013 o-ring 6H 2 607 o-ring 6L 1 Allen key 3/16 This service kit contains a completely new and 1 Allen key 5/32 ready to fit black valve & the neccesary o-rings for 2 services, including the tools needed for the job. 1 Allen key 1/8 1 Allen key 3/32 This o-ring kit contains the basic items required 1 Allen key 1/16 to do 1 service of your black valve.

Black Acetal Valves are fitted in all current Rapids and over 90% produced since January 1998. Although service kits and replacement o-rings for the original Metal valve will be available for some time after this. Rifles built originally with metal valves are able to have the new style black valves fitted. These valves are easier to service and are more resistant to the type of damage that can cause failure. If your rifle needs servicing and you have never done it before, we recommend that you fit the new black valve even if your rifle is currently fitted with a metal valve. Please Note; Elans,12ft/lbs and FAC Rapids are fitted with different size valves. When ordering please quote rifle type. Elan Service Kit is also available. Please specify the type of kit you require and for which type of Rapid.

RAPID TROUBLE SHOOTING

Power failure 1 Buddy bottle not charged correctly i.e. overfilled or underfilled. 2 BS111 NI90 o-ring on bottle neck must be greased (Molykote 33) and at all times protected from dirt. Even a hair across an o-ring will cause leakage. 3 Metal valve main seal damaged (Theoben 008). This can happen if dirt is allowed into the charging system from bottles or via inlet adaptor on rifle. Seal will need replacing. 4 Black valve face damaged. May need replacing. 5 It is unlikely but possible that other o-rings in rifle assembly could fail. These can be changed using replacements from the service kit. Low power 1 Rear cap (item 7B) needs turning clockwise to increase hammer spring pressure, thus increasing power. (Always use a chronograph). 2 Buddy bottles either over or under pressure. 3 Hammer and floating inertia not assembled correctly. (See diagram overleaf). 4 Oil in/on the hammer. It should run dry of lubricant. 5 Theoben 008 main valve seal flattened and surface enlarged, therefore slowing the flow of air. Remedy: change Theoben 008 main seal described on service sheet . Accuracy 1 Wrong calibre silencer fitted 2 Dirty or leaded up barrel, See cleaning the barrel 3 Change rifle scope 4 Not using the recommended pellets i.e. .177 STD Crosman Premier 7.9grain FAC Crosman Premier 10.5grain .20 STD Crosman Premier 14.3 grain FAC Crosman Premier 14.3 grain .22 STD Crosman Premier 14.3 grain FAC Bisley Magnum 21 grain .25 FAC Bisley Superfield 24.5 grain FAC H & N Rampoint 27 grain Magazine - 7 shot (.22 cal only), 12 shot (.20, .22, . 25 cals) & 17 Shot (.177 cal only) 1 Dust, grit, pocket fluff and fragments of lead will cause the magazine fail. 2 Do not put any lubrication - oil, WD40 etc inside the mag as it will have a negative effect. 3 Magazines can be returned to the factory and serviced; 7 shot magazine .................. 7 (replacement parts included) 12 & 17 shot magazines ...... 5 (cost of major replacement parts not included) 4 If the magazine doesnt fit in the rifle - check there is clearance from the scope. Check barrel position. If the rifle has been dropped on the barrel end, the barrel could be moved too far into the magazine slot on the rifle body. NOTE - MAGAZINES ARE NOT COVERED BY GUARANTEE.

Barrel Removing the barrel is achieved by unscrewing top grub screw (8b), located under front scope mount and barrel clamp assembly. Barrel must be relocated in the body precisely for smooth operation of magazine and correct lock down of the bolt. Barrel Cleaning - Theoben supply barrel cleaning kits and spare Napier cloth. Kits come with instructions for use. We only recommend Napier cloth. Trigger (sporter) The only engagement adjustment is with the grub screw behind trigger pull. Turn outwards (anticlockwise) for more engagement. Test for safe operation by flicking off bolt from its back position. If set properly the trigger will hold the hammer back and prevent the rifle from firing off. Safety catch failure can only be caused by pushing the catch foreword beyond its normal position. This bends the spring located on the trigger assembly. This can be rectified by straightening the spring so that it relocates in the safety catch notches. It is not necessary to completely remove the trigger to do this. If the trigger is removed from the body (not advisable because the whole assembly flies apart) the trigger and must be built up using 5/8 long slave pin. The whole assembly is then lined up in the Rapid body and the 1 long pin pushed through, thereby pushing the slave pin out.

Diagram/instructions for both the field target & the sporter trigger are available from Theoben.

NOTE: TRIGGER SHOULD BE TESTED FOR SAFE OPERATION WITH THE BOTTLE AND THE MAGAZINE REMOVED. Bolt (from January 2000) This new design is easily adjusted to make a metal to metal seal between the probe and the barrel. This is factory set but over time and use the lockdown may ease. So using a 1/16 inch allen key adjust a 1/8 or 1/4 of a turn at a time - in for harder, out for easier. Adjustment is only required if a 'puff' of air is felt from the side of the magazine. * * * * * * If your rifle is pre Jan 2000 and for whatever reason you purchase a new bolt assembly, you will also need to buy a new bolt handle, dog and dog screw. * * * * * * Bolt (pre January 2000) This assembly is shimmed to achieve metal to metal seal between probe and barrel. Air blasting out from the side of the magazine is wasted air! Check barrel position. More usually a shim (crinkle washer) is needed behind probe assembly. Remove the bolt from the action, then remove circlip and all components. Place extra crinkle washer (.010) at the bottom of the blind hole. Reassemble. To remove bolt it is necessary to remove bolt handle and hammer assembly. Do not forget the square dog has to be removed from the underside of the bolt assembly. Make sure when this is refitted it is the correct way round.

Only use Theoben recommended lubricants. DO NOT USE silicone Oil/grease as it seriously impedes the correct operation of our rifles and accessories.

RIFLES, MAGAZINES AND BOTTLES MAY BE RETURNED TO THE FACTORY FOR SERVICING.

CONVERT YOUR RAPID TO FAC SPECIFICATION - except the Rapid Elan

If you have an Rapid in .20 or .22 calibre it can be converted at the factory to FAC for only 76 plus postage. This price does not include conversion to a 19 inch barrel, but using your existing 16 inch barrel. Some efficiency will be lost compared with the 19 inch barrel FAC version Rapid, but you can still expect about 26 ft/lbs for .20 calibre and 28 ft/lbs for .22 cal. However the benefit is a shorter, lighter rifle for easier use. If you wish to convert your .177 cal a 19 barrel must be purchased. Exchange of your 16 barrel to 19 is only possible if the barrel is immaculate. If the barrel is damaged the cost is 105 for a new barrel. We can also de-rate Rapids from FAC to under 12 ft/lbs. Please note that barrel size must be reduced to 16. FAC conversion - up rate FAC barrel exchange FAC up rate inc barrel exchange Complete 17/17 FAC up rate 12ft/lbs conversion - de rate 76.00 74.00 150.00 150.00 76.00

H. F. Taylor & D. R. Theobald

r7_tech 04/00

V.A.T. No. GB 360 0324 05

You might also like

- Rapid Range Servicing InstructionsDocument2 pagesRapid Range Servicing Instructionsgraham4877No ratings yet

- Stripping and Servicing The Theoben Rapid 7111Document8 pagesStripping and Servicing The Theoben Rapid 7111graham487775% (4)

- Barrel RemovalDocument2 pagesBarrel Removalgraham4877No ratings yet

- Cleaning Your Barrel With A Pull ThroughDocument1 pageCleaning Your Barrel With A Pull Throughgraham4877No ratings yet

- Rapid Bolt Assembly InstuctionsDocument1 pageRapid Bolt Assembly Instuctionsgraham4877No ratings yet

- Rapid Mk1 Pressure IndicatorDocument1 pageRapid Mk1 Pressure Indicatorgraham4877No ratings yet

- RAPIDID TRIGGER Standard Sporter Trigger For The Rapid RangeDocument1 pageRAPIDID TRIGGER Standard Sporter Trigger For The Rapid Rangegraham48770% (1)

- Rapid MK 2 SpecsDocument1 pageRapid MK 2 Specsgraham4877No ratings yet

- Rapid Field Target SpecsDocument1 pageRapid Field Target Specsgraham4877No ratings yet

- Rapid Rifle Numbers and Approximate AgesDocument1 pageRapid Rifle Numbers and Approximate Agesgraham4877No ratings yet

- QB78 TuneDocument11 pagesQB78 TuneSadBoiH0urs 1100% (1)

- BSA Scorpion & T10Document2 pagesBSA Scorpion & T10Pera DjetlicNo ratings yet

- Valmet M-88Document12 pagesValmet M-88aki009No ratings yet

- CQC Online ManualDocument14 pagesCQC Online Manualnabeelmerchant01No ratings yet

- Budischowsky Tp-70Document5 pagesBudischowsky Tp-70JustinNo ratings yet

- QB78 Rifle Tune and Modifications GuideDocument11 pagesQB78 Rifle Tune and Modifications GuideMirosław Jurczyszyn100% (1)

- The GOLD MEDAL TRIGGER The Field Target Trigger For The Rapid RangeDocument1 pageThe GOLD MEDAL TRIGGER The Field Target Trigger For The Rapid Rangegraham4877No ratings yet

- HS 2000 Manual Title Under 40Document6 pagesHS 2000 Manual Title Under 40LUGAS KHALIQ PANGABDINo ratings yet

- 5 8366 PDFDocument68 pages5 8366 PDFguillermoNo ratings yet

- SHTF 50Document6 pagesSHTF 50Tonyf6188No ratings yet

- Instruction Manual Slavia 634 enDocument14 pagesInstruction Manual Slavia 634 enzeniek50% (2)

- 870 Detent Staking PunchDocument1 page870 Detent Staking PunchZardoz1090No ratings yet

- Manuale CZ200Document11 pagesManuale CZ200gatto61No ratings yet

- Silent-Sr Sound Suppressor: Instruction Manual ForDocument12 pagesSilent-Sr Sound Suppressor: Instruction Manual Forblazerman3No ratings yet

- 45 Colt OldDocument1 page45 Colt OldCOLONEL ZIKRIA100% (1)

- Product Instructions - Flat Bending Jig InstructionsDocument34 pagesProduct Instructions - Flat Bending Jig InstructionsDale WadeNo ratings yet

- Ifle ASIX, Inc.: Instruction Sheet For Rifle Basix Cz-52 CZ 452 Bolt Action Rimfire RiflesDocument1 pageIfle ASIX, Inc.: Instruction Sheet For Rifle Basix Cz-52 CZ 452 Bolt Action Rimfire Riflesjean.phNo ratings yet

- Mossberg 151k PDFDocument6 pagesMossberg 151k PDFmikey_tipswordNo ratings yet

- Hushpower CatalogueDocument10 pagesHushpower CataloguepbayersNo ratings yet

- Winchester Model 1885Document0 pagesWinchester Model 1885carlosfanjul1No ratings yet

- Thompson/Center Arms Co., Inc. P.O. Box 5002 Rochester, New Hampshire 03866Document28 pagesThompson/Center Arms Co., Inc. P.O. Box 5002 Rochester, New Hampshire 03866johndoneNo ratings yet

- Brownells-2 5LB1911TriggerPullDocument4 pagesBrownells-2 5LB1911TriggerPullRyan ShanksNo ratings yet

- H&R Handgun Parts CatalogDocument2 pagesH&R Handgun Parts CatalogJames MckeanNo ratings yet

- Safety Manual for CZ 805 BREN S1 RifleDocument19 pagesSafety Manual for CZ 805 BREN S1 RifledeckahmNo ratings yet

- VZ 58 Shell DeflectorDocument15 pagesVZ 58 Shell DeflectoromikamiNo ratings yet

- Yugo M24 47 DisassemblyDocument30 pagesYugo M24 47 Disassemblyziehenbenzin100% (1)

- Glock Manual - UserDocument31 pagesGlock Manual - UserthomasmpbetressNo ratings yet

- CZ 40PDocument14 pagesCZ 40PpreceptiveinquirerNo ratings yet

- Uzi Carbine Fixed Stock InstallationDocument4 pagesUzi Carbine Fixed Stock Installationelvergonzalez1No ratings yet

- m14 Maintenance 3Document4 pagesm14 Maintenance 3entomophileNo ratings yet

- United States Patent 1111 3,595,128Document9 pagesUnited States Patent 1111 3,595,128rte678No ratings yet

- Crosman Model Series 761XLDocument6 pagesCrosman Model Series 761XLjayNo ratings yet

- CZ 200 PCP Air Rifle Manual PDFDocument18 pagesCZ 200 PCP Air Rifle Manual PDFErikNo ratings yet

- Rem 1911 r1Document18 pagesRem 1911 r1Mark PlattnerNo ratings yet

- BSASupertenDocument11 pagesBSASupertenapi-3695814No ratings yet

- Pump Shotgun: Instruction ManualDocument5 pagesPump Shotgun: Instruction ManualJustinNo ratings yet

- Vepr Bullet Guide IntstallDocument2 pagesVepr Bullet Guide IntstallTawnee Rae HallNo ratings yet

- KMR QRF MCMR: Bravo Company MFG®Document3 pagesKMR QRF MCMR: Bravo Company MFG®Matt KienertNo ratings yet

- Aerodynamic Characteristics of .22LR Match AmmunitionDocument76 pagesAerodynamic Characteristics of .22LR Match Ammunitionwlou100% (3)

- Patented June 1, 1901. No. 675,999.: L. HellfritzschDocument4 pagesPatented June 1, 1901. No. 675,999.: L. HellfritzschСлэйтер Строительная компанияNo ratings yet

- TM 9-1005-206-14P4 22 LR Target RiflesDocument47 pagesTM 9-1005-206-14P4 22 LR Target RiflesSteve Johnson100% (1)

- Mossberg YearsDocument14 pagesMossberg YearsClaude Malo100% (1)

- German 7.9-mm Dual Purpose Machine Gun MG34: TM EO-206A (German)Document72 pagesGerman 7.9-mm Dual Purpose Machine Gun MG34: TM EO-206A (German)canadiangrizzer100% (1)

- Owners Manual For: Ar-10A® & Ar-10B® Rifles and CarbinesDocument59 pagesOwners Manual For: Ar-10A® & Ar-10B® Rifles and CarbinesVictor LuisNo ratings yet

- Tap & Drill Chart W - Decimal Inch & MetricDocument10 pagesTap & Drill Chart W - Decimal Inch & MetricGanesh NatarajanNo ratings yet

- Punching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesFrom EverandPunching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesNo ratings yet

- Churchills Mauser C96: Notes on -The blow-up in Sydney Street- from the London DecameroneFrom EverandChurchills Mauser C96: Notes on -The blow-up in Sydney Street- from the London DecameroneNo ratings yet

- MSA Cylinder ValveDocument13 pagesMSA Cylinder ValveTammanurRaviNo ratings yet

- Technical Information - S-RF3 Three Speed HubDocument4 pagesTechnical Information - S-RF3 Three Speed Hubdupazbita11No ratings yet

- Sturmey-Archer SRF3 User ManualDocument4 pagesSturmey-Archer SRF3 User Manualksjack100% (1)

- DIY 1000 Watt Wind TurbineDocument9 pagesDIY 1000 Watt Wind Turbinegraham4877No ratings yet

- Crosman 2240 2250Document1 pageCrosman 2240 2250graham4877No ratings yet

- C2250B EvpDocument2 pagesC2250B Evpgraham4877No ratings yet

- Alternator ManualDocument16 pagesAlternator Manualgraham4877No ratings yet

- The GOLD MEDAL TRIGGER The Field Target Trigger For The Rapid RangeDocument1 pageThe GOLD MEDAL TRIGGER The Field Target Trigger For The Rapid Rangegraham4877No ratings yet

- Basic Blacksmithing - David Harries PDFDocument132 pagesBasic Blacksmithing - David Harries PDFMichele Perrone FilhoNo ratings yet

- Bandsaw ManuleDocument17 pagesBandsaw Manulegraham4877No ratings yet

- Arkara Single Bay Data SheetDocument2 pagesArkara Single Bay Data Sheetgraham4877No ratings yet

- Auto Arc WelderDocument4 pagesAuto Arc Weldergraham4877No ratings yet

- ARKARA Single Bay User ManualDocument35 pagesARKARA Single Bay User Manualgraham4877No ratings yet

- Panasonic SDR s50Document36 pagesPanasonic SDR s50Daniel MerrillNo ratings yet

- ALSAT Manual 0430Document11 pagesALSAT Manual 0430graham4877No ratings yet

- Rapid MFR InfoDocument2 pagesRapid MFR Infograham4877No ratings yet

- Rapid Rifle Numbers and Approximate AgesDocument1 pageRapid Rifle Numbers and Approximate Agesgraham4877No ratings yet

- Rapid MK 2 SpecsDocument1 pageRapid MK 2 Specsgraham4877No ratings yet

- Rapid Mk1 Pressure IndicatorDocument1 pageRapid Mk1 Pressure Indicatorgraham4877No ratings yet

- Rapid MFRDocument1 pageRapid MFRgraham4877No ratings yet

- Rapid MK 1 SpecsDocument1 pageRapid MK 1 Specsgraham4877No ratings yet

- Rapid Mag StripDocument1 pageRapid Mag Stripgraham4877No ratings yet

- Rapid Range Technical Information SheetDocument2 pagesRapid Range Technical Information Sheetgraham487767% (3)

- RAPIDID TRIGGER Standard Sporter Trigger For The Rapid RangeDocument1 pageRAPIDID TRIGGER Standard Sporter Trigger For The Rapid Rangegraham48770% (1)

- Rapid Field Target SpecsDocument1 pageRapid Field Target Specsgraham4877No ratings yet

- New Rapid TriggersDocument1 pageNew Rapid Triggersgraham4877No ratings yet

- Match Grade Trigger MFRDocument1 pageMatch Grade Trigger MFRgraham4877No ratings yet

- Form-HSE-TMR-006 Compressor, Genzet, Water Jet InspectionDocument2 pagesForm-HSE-TMR-006 Compressor, Genzet, Water Jet Inspectionkenia infoNo ratings yet

- 17012EDocument7 pages17012EAVINASHRAJNo ratings yet

- Sl1000 MLT User Guide v1 Key TelephoneDocument24 pagesSl1000 MLT User Guide v1 Key TelephoneRavi Sudharsan0% (1)

- Explosion Proof Control Device SpecificationsDocument12 pagesExplosion Proof Control Device SpecificationsAnonymous IErc0FJNo ratings yet

- Synopsis Mobile Banking AdministrationDocument24 pagesSynopsis Mobile Banking AdministrationRaj BangaloreNo ratings yet

- TM 1001 AVEVA Plant 12 1 PDMS Foundations Rev 3 0 PDFDocument153 pagesTM 1001 AVEVA Plant 12 1 PDMS Foundations Rev 3 0 PDFPolarogramaNo ratings yet

- Answer Key Workbook Academic Plan DynEd Pro Certification B1 1Document22 pagesAnswer Key Workbook Academic Plan DynEd Pro Certification B1 1Dendel Ciprado EbioNo ratings yet

- 80305a PDFDocument7 pages80305a PDFlorisseNo ratings yet

- Terminals of Ecm: For M/TDocument4 pagesTerminals of Ecm: For M/TTdco SonicoNo ratings yet

- Low-cost DIY ECG Patient Simulator for under $20Document3 pagesLow-cost DIY ECG Patient Simulator for under $20cv bayariNo ratings yet

- Generador de Vapor Cu360Document36 pagesGenerador de Vapor Cu360Jonatan medran ochoaNo ratings yet

- Engine and vehicle parameter monitoringDocument170 pagesEngine and vehicle parameter monitoringAlejandro Samuel100% (2)

- Design of Water Cooled Electric Motors Using CFD and Thermography TechniquesDocument6 pagesDesign of Water Cooled Electric Motors Using CFD and Thermography TechniquesNicolas JerezNo ratings yet

- TENDERSCHEDULE309532Document2 pagesTENDERSCHEDULE309532heavens indiaNo ratings yet

- Digital Vision Installation PDFDocument2 pagesDigital Vision Installation PDFnikola5nikolicNo ratings yet

- Sap Abap Programming SyllabusDocument5 pagesSap Abap Programming SyllabusSURAJ KUMAR SAHUNo ratings yet

- Atmos GIGA N 32-160Document1 pageAtmos GIGA N 32-160Efril dilen franciscoNo ratings yet

- ICC ES Report: Barsplice Products, IncDocument6 pagesICC ES Report: Barsplice Products, IncXiomara Muñoz MendozaNo ratings yet

- Company Profile - QuosphereDocument5 pagesCompany Profile - QuosphereDivya Rao100% (2)

- Track The 5 Most Important Call Center MetricsDocument3 pagesTrack The 5 Most Important Call Center Metricssalesforce.comNo ratings yet

- Hydraulic Excavator GuideDocument9 pagesHydraulic Excavator Guidewritetojs100% (1)

- AT-8600 Series Switch: Hardware ReferenceDocument30 pagesAT-8600 Series Switch: Hardware ReferenceSubbuNo ratings yet

- What Is A Project in Project ManagementDocument3 pagesWhat Is A Project in Project ManagementSamuel AntobamNo ratings yet

- ASME B31.3 2020 CambiosDocument10 pagesASME B31.3 2020 CambiosJosé Juan Jiménez AlejandroNo ratings yet

- Class B BiosolidsDocument9 pagesClass B BiosolidsGissmoNo ratings yet

- Perencanaan Produksi Dan Kebutuhan Material: Modul 4Document48 pagesPerencanaan Produksi Dan Kebutuhan Material: Modul 4Ivanca Earltina Miranda SimanungkalitNo ratings yet

- Practice Exam - CXC CSEC English A Exam Paper 1 - CaribExams2Document6 pagesPractice Exam - CXC CSEC English A Exam Paper 1 - CaribExams2Sam fry0% (1)

- HS1L DatasheetDocument8 pagesHS1L DatasheetBlAdE 12No ratings yet

- True/False: List of Attempted Questions and AnswersDocument15 pagesTrue/False: List of Attempted Questions and AnswersDeepak Kumar VermaNo ratings yet

- CV Template ReceptionistDocument2 pagesCV Template ReceptionistMuhammad Waqas LatifNo ratings yet