Professional Documents

Culture Documents

Manual Overlay Welding

Uploaded by

carlmac61Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Overlay Welding

Uploaded by

carlmac61Copyright:

Available Formats

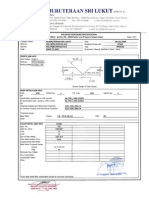

SAUDI ARAMCO WELDING PROCEDURE SPECIFICATIONS

WPS No. Application BASE METAL P-No.

OL-3

WPS Revision No.

PQR No. Service Sour FILLER METAL

OL-3

PQR Revision No. Inconel 625

Corrosion-Resistant Overlay

Welding Material

BM Thickness Range

6.0 mm - unlimited

Spec. No. (SFA) AWS No. (Class.) Size of Filler Metal SAW Electrode-Flux (Class.)

A5.11 ENiCrMo-3 3.2 N/A Inconel 112 20-484-340

Material Specification (typical) Other carbon steel

A516, A283, A515, API 5L Gr. B, A36

WELD METAL Chem. Elem. 0.15 max. C, 38 min. Ni, 12 min. Cr, 6 min. Mo, 40 max. Fe 1.6 mm minimum

Electrode / Flux Trade Name SAMS S/N PREHEAT Preheat Temp. Interpass Temp. 10 C 177 C

Deposit Thickness JOINT SKETCH

weld overlay 1 layer only 30-50% bead overlap

A

POST WELD HEAT TREATMENT Temperature Range Time Range Heating Rate Cooling Rate POSITION Position GAS Shielding Gas (Type) Flow Rate N/A N/A N/A N/A N/A None

All

Welding Progression

V-UP

TECHNIQUE & ELECTRICAL CHARACTERISTICS Tungsten Electrode Size and Type String or Weave Bead Stringer Brushing & Grinding N/A Orifice or Gas Cup Size Multiple or Single Layer N/A Single

Initial & Interpass cleaning (Brushing, Grinding, etc.) FILLER METAL ENiCrMo-3

LAYER 1

PROCESS SMAW

SIZE 3.2

POLARITY DCRP

AMP 65-90

VOLT 22-26

TRAVEL SPEED

SEQUENCE/COMMENTS use only 3.2 mm dia. electrode

SPECIFIC INSTRUCTIONS & DETAILS 1. Single layer only 2. For improved corrosion resistance, use procedure OL-4 (two layer technique).

Department

Consulting Services Department

Revision Date

November 24, 1998

Approval Restrictions

None

CopyrightSaudi Aramco 2009. All rights reserved.

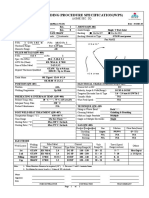

SAUDI ARAMCO WELDING PROCEDURE SPECIFICATIONS

WPS No. Application BASE METAL P-No.

OL-4

WPS Revision No.

PQR No. Service Sour FILLER METAL

OL-4

PQR Revision No. Inconel 625

Corrosion-Resistant Overlay

Welding Material

BM Thickness Range

6.0 mm - unlimited

Spec. No. (SFA) AWS No. (Class.) Size of Filler Metal SAW Electrode-Flux (Class.)

A5.11 ENiCrMo-3 3.2 N/A Inconel 112 20-484-340

Material Specification (typical) Other carbon steel

A516, A283, A515, API 5L Gr. B, A36

WELD METAL Chem. Elem. 0.10 max. C, 50 min. Ni, 17 min. Cr, 8 min. Mo, 20 max. Fe 3.0 mm minimum

Electrode / Flux Trade Name SAMS S/N PREHEAT Preheat Temp. Interpass Temp. 10 C 177 C

Deposit Thickness JOINT SKETCH

weld overlay 2 layers minimum 30-50% bead overlap

A

POST WELD HEAT TREATMENT Temperature Range Time Range Heating Rate Cooling Rate POSITION Position GAS Shielding Gas (Type) Flow Rate N/A N/A N/A N/A N/A None

All

Welding Progression

V-UP

TECHNIQUE & ELECTRICAL CHARACTERISTICS Tungsten Electrode Size and Type String or Weave Bead Stringer Brushing & Grinding N/A Orifice or Gas Cup Size Multiple or Single Layer N/A Single

Initial & Interpass cleaning (Brushing, Grinding, etc.) FILLER METAL ENiCrMo-3 ENiCrMo-3

LAYER 1 2

PROCESS SMAW SMAW

SIZE 3.2 3.2

POLARITY DCRP DCRP

AMP 65-90 65-90

VOLT 22-26 22-26

TRAVEL SPEED

SEQUENCE/COMMENTS use only 3.2 mm dia. electrode

SPECIFIC INSTRUCTIONS & DETAILS

Department

Consulting Services Department

Revision Date

November 24, 1998

Approval Restrictions

None

CopyrightSaudi Aramco 2009. All rights reserved.

SAUDI ARAMCO WELDING PROCEDURE SPECIFICATIONS

WPS No. Application BASE METAL P-No.

OL-6

WPS Revision No.

PQR No. Service Sour FILLER METAL

OL-6

PQR Revision No.

Corrosion-Resistant Overlay

Welding Material

316L Stainless Steel

BM Thickness Range

6.0mm-unlimited

Spec. No. (SFA) AWS No. (Class.) Size of Filler Metal SAW Electrode-Flux (Class.)

A5.4 E316L 3.2 N/A N/A 20-484-698

Material Specification (typical) Other carbon steel

A516, A283, A515, API 5L Gr. B, A36

WELD METAL Chem. Elem. 16 min. Cr, 10 min. Ni, 2 min. Mo

Electrode / Flux Trade Name SAMS S/N

Deposit Thickness JOINT SKETCH

3.0 mm minimum

PREHEAT Preheat Temp. Interpass Temp. 10 C 177 C

weld overlay 2 layers minimum 30-50% bead overlap

A

POST WELD HEAT TREATMENT Temperature Range Time Range Heating Rate Cooling Rate POSITION Position GAS Shielding Gas (Type) Flow Rate N/A N/A N/A N/A N/A None

All

Welding Progression

V-UP

TECHNIQUE & ELECTRICAL CHARACTERISTICS Tungsten Electrode Size and Type String or Weave Bead Stringer Brushing & Grinding N/A Orifice or Gas Cup Size Multiple or Single Layer N/A Single

Initial & Interpass cleaning (Brushing, Grinding, etc.) FILLER METAL E316L E316L

LAYER 1 2

PROCESS SMAW SMAW

SIZE 3.2 3.2

POLARITY DCRP DCRP

AMP 70-100 70-100

VOLT 22-26 22-26

TRAVEL SPEED

SEQUENCE/COMMENTS use only 3.2 mm dia. electrode

SPECIFIC INSTRUCTIONS & DETAILS

Department

Consulting Services Department

Revision Date

November 24, 1998

Approval Restrictions

None

CopyrightSaudi Aramco 2009. All rights reserved.

SAUDI ARAMCO WELDING PROCEDURE SPECIFICATIONS

WPS No. Application BASE METAL P-No.

OL-8

WPS Revision No.

PQR No. Service Sour FILLER METAL

OL-8

PQR Revision No. Stellite 6

Hardfacing Overlay

Welding Material

BM Thickness Range

6.0-25.4mm

Spec. No. (SFA) AWS No. (Class.) Size of Filler Metal

A5.13 ECoCr-A 3.2 N/A Stellite 6 20-117-315

Material Specification (typical) Other WELD METAL Chem. Elem.

304, 304L, 316, 316L stainless steel

SAW Electrode-Flux (Class.) 0.7 min. C, 40 min. Co, 20 min. Cr, 3 min. W, 25 max. Fe, 3 max. Ni 1.6 mm minimum Electrode / Flux Trade Name SAMS S/N PREHEAT Preheat Temp. Interpass Temp. 10 C 250 C

Deposit Thickness JOINT SKETCH

weld overlay 1 layer only 30-50% bead overlap

A

POST WELD HEAT TREATMENT Temperature Range Time Range Heating Rate Cooling Rate POSITION Position GAS Shielding Gas (Type) Flow Rate N/A N/A N/A N/A N/A None

All

Welding Progression

V-UP

TECHNIQUE & ELECTRICAL CHARACTERISTICS Tungsten Electrode Size and Type String or Weave Bead Stringer Brushing & Grinding N/A Orifice or Gas Cup Size Multiple or Single Layer N/A Single

Initial & Interpass cleaning (Brushing, Grinding, etc.) FILLER METAL ECoCr-A

LAYER 1

PROCESS SMAW

SIZE 3.2

POLARITY DCRP

AMP 90-130

VOLT 22-26

TRAVEL SPEED

SEQUENCE/COMMENTS use only 3.2 mm dia. electrode

SPECIFIC INSTRUCTIONS & DETAILS

Department

Consulting Services Department

Revision Date

November 24, 1998

Approval Restrictions

None

CopyrightSaudi Aramco 2009. All rights reserved.

SAUDI ARAMCO WELDING PROCEDURE SPECIFICATIONS

WPS No. Application BASE METAL P-No.

OL-9

WPS Revision No.

PQR No. Service Sour FILLER METAL

OL-9

PQR Revision No. 309 Stainless Steel

Corrosion-Resistant Overlay

Welding Material

BM Thickness Range

6.0 mm - unlimited

Spec. No. (SFA) AWS No. (Class.) Size of Filler Metal SAW Electrode-Flux (Class.)

A5.4 E309 3.2 N/A N/A 20-485-410

Material Specification (typical) Other carbon steel

A516, A283, A515, API 5L Gr. B, A36

WELD METAL Chem. Elem. 20 min. Cr, 11 min. Ni

Electrode / Flux Trade Name SAMS S/N

Deposit Thickness JOINT SKETCH

3.0 mm minimum

PREHEAT Preheat Temp. Interpass Temp. 10 C 177 C

weld overlay 2 layers minimum 30-50% bead overlap

A

POST WELD HEAT TREATMENT Temperature Range Time Range Heating Rate Cooling Rate POSITION Position GAS Shielding Gas (Type) Flow Rate N/A N/A N/A N/A N/A None

All

Welding Progression

V-UP

TECHNIQUE & ELECTRICAL CHARACTERISTICS Tungsten Electrode Size and Type String or Weave Bead Stringer Brushing & Grinding N/A Orifice or Gas Cup Size Multiple or Single Layer N/A Single

Initial & Interpass cleaning (Brushing, Grinding, etc.) FILLER METAL E309 E309

LAYER 1 2

PROCESS SMAW SMAW

SIZE 3.2 3.2

POLARITY DCRP DCRP

AMP 65-90 65-100

VOLT 22-26 22-26

TRAVEL SPEED

SEQUENCE/COMMENTS use only 3.2 mm dia. electrode

SPECIFIC INSTRUCTIONS & DETAILS

Department

Consulting Services Department

Revision Date

November 24, 1998

Approval Restrictions

None

CopyrightSaudi Aramco 2009. All rights reserved.

SAUDI ARAMCO WELDING PROCEDURE SPECIFICATIONS

WPS No. Application BASE METAL P-No.

P1-BU1

WPS Revision No.

PQR No. Service

Sour

P1-9

PQR Revision No.

E7018

Weld Build-Up

Welding Material

FILLER METAL BM Thickness Range

4.8mm-203mm

Spec. No. (SFA) AWS No. (Class.) Size of Filler Metal SAW Electrode-Flux (Class.)

A5.1 E7018 3.2, 4.0

Material Specification (typical) Other

A105, A350, A694, A707 L3 & L5, A216 WCB

all carbon steel materials (garde B through X60)

WELD METAL Chem. Elem.

N/A

N/A

N/A 20-483-071/074

Electrode / Flux Trade Name SAMS S/N

Deposit Thickness JOINT SKETCH

203 mm maximum

PREHEAT Preheat Temp. Interpass Temp.

20 C if WT<25mm, 121 C if WT>25mm 315 C

weld buildup 1 or 2 layers (as required) grind smooth

A

POST WELD HEAT TREATMENT Temperature Range Time Range Heating Rate Cooling Rate POSITION Position GAS Shielding Gas (Type) Flow Rate N/A N/A N/A N/A N/A None

All

Welding Progression

V-UP

TECHNIQUE & ELECTRICAL CHARACTERISTICS Tungsten Electrode Size and Type String or Weave Bead Stringer Brushing & Grinding N/A Orifice or Gas Cup Size Multiple or Single Layer N/A

Single or multiple

Initial & Interpass cleaning (Brushing, Grinding, etc.) FILLER METAL

E7018 E7018

LAYER

1, 2 alt.

PROCESS SMAW

SMAW

SIZE 3.2

4.0

POLARITY DCRP

DCRP

AMP

90-120 120-160

VOLT 22-26

22-26

TRAVEL SPEED

SEQUENCE/COMMENTS

SPECIFIC INSTRUCTIONS & DETAILS

Grind flush and smooth with contour of the original surface.

Department

Consulting Services Department

Revision Date

March 28, 2000

Approval Restrictions

None

CopyrightSaudi Aramco 2009. All rights reserved.

SAUDI ARAMCO WELDING PROCEDURE SPECIFICATIONS

WPS No. Application BASE METAL P-No.

8

P8-BU1

WPS Revision No.

PQR No. Service

Sour

P*04

PQR Revision No.

316L Stainless Steel

Weld Build-Up

Welding Material

FILLER METAL BM Thickness Range

316, 316L Stainless Steel 4.8mm-50.8mm

Spec. No. (SFA) AWS No. (Class.) Size of Filler Metal

A5.4 E316L 3.2

Material Specification (typical) Other WELD METAL Chem. Elem.

SAW Electrode-Flux (Class.)

Cr 17% min, Ni 11% min.

N/A

N/A 20-484-698

Electrode / Flux Trade Name SAMS S/N

Deposit Thickness JOINT SKETCH

40 mm maximum

PREHEAT Preheat Temp. Interpass Temp.

20 C if WT<25mm, 121 C if WT>25mm 315 C

weld buildup 1 or 2 layers (as required) grind smooth

A

POST WELD HEAT TREATMENT Temperature Range Time Range Heating Rate Cooling Rate POSITION Position GAS Shielding Gas (Type) Flow Rate N/A N/A N/A N/A N/A None

All

Welding Progression

V-UP

TECHNIQUE & ELECTRICAL CHARACTERISTICS Tungsten Electrode Size and Type String or Weave Bead Stringer Brushing & Grinding N/A Orifice or Gas Cup Size Multiple or Single Layer N/A

Single or multiple

Initial & Interpass cleaning (Brushing, Grinding, etc.) FILLER METAL

E8018-C1 E8018-C1

LAYER

1, 2 alt.

PROCESS SMAW

SMAW

SIZE 3.2

4.0

POLARITY DCRP

DCRP

AMP

90-120 120-160

VOLT 22-26

22-26

TRAVEL SPEED

SEQUENCE/COMMENTS

SPECIFIC INSTRUCTIONS & DETAILS

Grind flush and smooth with contour of the original surface.

Department

Consulting Services Department

Revision Date

February 23, 2000

Approval Restrictions

None

CopyrightSaudi Aramco 2009. All rights reserved.

SAUDI ARAMCO WELDING PROCEDURE SPECIFICATIONS

WPS No. Application BASE METAL P-No.

P1-BU2

WPS Revision No.

PQR No. Service

Non-Sour

P1-21

PQR Revision No.

E8018-C1

Weld Build-Up

Welding Material

FILLER METAL BM Thickness Range

A333 Gr 6, A537 Cl. 1 & 2 4.8mm-203mm

Spec. No. (SFA) AWS No. (Class.) Size of Filler Metal

A5.5 E8018-C1 3.2, 4.0

Material Specification (typical) Other WELD METAL Chem. Elem.

N/A

SAW Electrode-Flux (Class.) Electrode / Flux Trade Name SAMS S/N

N/A

N/A 20-483-541/543

Deposit Thickness JOINT SKETCH

203 mm maximum

PREHEAT Preheat Temp. Interpass Temp.

20 C if WT<25mm, 121 C if WT>25mm 315 C

weld buildup 1 or 2 layers (as required) grind smooth

A

POST WELD HEAT TREATMENT Temperature Range Time Range Heating Rate Cooling Rate POSITION Position GAS Shielding Gas (Type) Flow Rate N/A N/A N/A N/A N/A None

All

Welding Progression

V-UP

TECHNIQUE & ELECTRICAL CHARACTERISTICS Tungsten Electrode Size and Type String or Weave Bead Stringer Brushing & Grinding N/A Orifice or Gas Cup Size Multiple or Single Layer N/A

Single or multiple

Initial & Interpass cleaning (Brushing, Grinding, etc.) FILLER METAL

E8018-C1 E8018-C1

LAYER

1, 2 alt.

PROCESS SMAW

SMAW

SIZE 3.2

4.0

POLARITY DCRP

DCRP

AMP

90-120 120-160

VOLT 22-26

22-26

TRAVEL SPEED

SEQUENCE/COMMENTS

SPECIFIC INSTRUCTIONS & DETAILS

Grind flush and smooth with contour of the original surface.

Department

Consulting Services Department

Revision Date

March 28, 2000

Approval Restrictions

None

CopyrightSaudi Aramco 2009. All rights reserved.

You might also like

- WPS, PQR & WPQ - Duplex 2205Document20 pagesWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- Ferrite Testing ProcedureDocument8 pagesFerrite Testing ProcedureMuthuselvam Thanaselvam100% (1)

- Design Strip FootingDocument12 pagesDesign Strip FootingHenra HalimNo ratings yet

- WPS PQR A36.20Document5 pagesWPS PQR A36.20gchaves504100% (2)

- WPS-PQR (Er309l Mo)Document4 pagesWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- Wps Repair WorDocument1 pageWps Repair WorMajdi JerbiNo ratings yet

- Procedure For Post Weld Heat Treatment (PWHT PROCEDURE)Document10 pagesProcedure For Post Weld Heat Treatment (PWHT PROCEDURE)Senthil Kumaran100% (2)

- Draw WorkDocument5 pagesDraw WorkriobmNo ratings yet

- Manual Overlay WeldingDocument8 pagesManual Overlay Weldingaamirtec301100% (2)

- Super Duplex Stainless SteelDocument1 pageSuper Duplex Stainless SteelUma Shankar100% (1)

- KSL Wps PQR 012 DuplexDocument33 pagesKSL Wps PQR 012 DuplexJunaidi Minhat100% (6)

- PT BM 183 DC 00007 PWHT ProcedureDocument7 pagesPT BM 183 DC 00007 PWHT Procedureeldobie3100% (1)

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- 625 Overlay WeldingDocument9 pages625 Overlay Weldingdaviesgang360100% (2)

- WPS FormatDocument1 pageWPS FormatAbdullah AnsariNo ratings yet

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- Welding Procedure Specification for SMAW of Carbon Steel Butt JointsDocument2 pagesWelding Procedure Specification for SMAW of Carbon Steel Butt JointstayyabNo ratings yet

- Welding Procedure Specification "WPS": O O O ODocument1 pageWelding Procedure Specification "WPS": O O O OAli MoosaviNo ratings yet

- Welder Certification ProcedureDocument28 pagesWelder Certification ProcedureAnant Rubade100% (1)

- WpsDocument2 pagesWpssamer8saifNo ratings yet

- P91 Repair With NiCrDocument76 pagesP91 Repair With NiCrElias KapaNo ratings yet

- WPS PQR 12Document9 pagesWPS PQR 12Ranjan KumarNo ratings yet

- Weld Overlay Procedure For InconelDocument3 pagesWeld Overlay Procedure For InconelArash Mohamadi100% (2)

- 2.2.2 Technical Requirements For Weld Overlay, Cladding & HardfacingDocument6 pages2.2.2 Technical Requirements For Weld Overlay, Cladding & Hardfacingim4uim4uim4u100% (4)

- Scan Preheat and PWHT ProcedureDocument11 pagesScan Preheat and PWHT ProcedureGandhi Kusuma100% (1)

- Weld OverlayDocument4 pagesWeld OverlayInfoNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Metrode Welding Duplex & Superduplex Stainless SteelsDocument18 pagesMetrode Welding Duplex & Superduplex Stainless SteelsClaudia Mms50% (2)

- p91 Pwht. AwsDocument4 pagesp91 Pwht. AwssantyagoNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- Welding Procedure Specification for Vertical Storage TanksDocument6 pagesWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- PQRDocument2 pagesPQRalokbdasNo ratings yet

- Hastelloy C-276 WeldingDocument4 pagesHastelloy C-276 WeldingClaudia MmsNo ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- P 91 - Welding WPSDocument2 pagesP 91 - Welding WPSSuhailshah123475% (4)

- Welding of P91Document37 pagesWelding of P91nishant361100% (4)

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- Weld Repair Procedure SummaryDocument10 pagesWeld Repair Procedure SummaryRAMAKRISHNANo ratings yet

- 3-Piping Repair Weld Procedure - PR003Document5 pages3-Piping Repair Weld Procedure - PR003mohd as shahiddin jafriNo ratings yet

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDocument2 pagesElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (1)

- FCAW Overlay WPSDocument2 pagesFCAW Overlay WPSAsad Bin Ala Qatari100% (1)

- Repair ProcedureDocument6 pagesRepair ProcedureTomy GeorgeNo ratings yet

- ASME SECTION IX INTERPRETATIONSDocument95 pagesASME SECTION IX INTERPRETATIONSnizam1372No ratings yet

- ConocoPhillips Welding Procedure SpecificationDocument18 pagesConocoPhillips Welding Procedure SpecificationAgus Budiono100% (5)

- Metrode - P92 WPS PDFDocument3 pagesMetrode - P92 WPS PDFXing ChenNo ratings yet

- PWHT Procedure A2Document15 pagesPWHT Procedure A2Raja Thakur100% (4)

- PMI Just in Case: Measurement of Ferrite Content in Austenitic & Duplex SteelDocument7 pagesPMI Just in Case: Measurement of Ferrite Content in Austenitic & Duplex Steelmahi1437100% (1)

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- SAIC-W-2006 Rev 0Document4 pagesSAIC-W-2006 Rev 0philipyap100% (2)

- Specification For Welding of Duplex Stainless Steel Pipelines AmendmentsSupplements To API STD 1104Document54 pagesSpecification For Welding of Duplex Stainless Steel Pipelines AmendmentsSupplements To API STD 1104Ajesh Kumar Muraleedharan100% (1)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- WPS D1.6 Annex m1 PDFDocument1 pageWPS D1.6 Annex m1 PDFbollascribdNo ratings yet

- PREQUALIFIED STRUCTURAL WELDING PROCEDURE SPECIFICATIONSDocument12 pagesPREQUALIFIED STRUCTURAL WELDING PROCEDURE SPECIFICATIONSwalitedisonNo ratings yet

- WPSDocument1 pageWPSNidhinkorothNo ratings yet

- PQR For 32 MM PlateDocument1 pagePQR For 32 MM PlateMuhammed MubeenNo ratings yet

- p22MNVMB MN Gtaw+Smaw (Pipe)Document2 pagesp22MNVMB MN Gtaw+Smaw (Pipe)abidaliabid1No ratings yet

- Fab-Wps-002sfasf Asfh Fhjsafgjha Sfsa FSDocument2 pagesFab-Wps-002sfasf Asfh Fhjsafgjha Sfsa FSabidaliabid1100% (1)

- WPS Asme IxDocument4 pagesWPS Asme Ixjcarlosherrerac7100% (1)

- SAND ProductionDocument18 pagesSAND Productionali100% (1)

- Sheet Metal Forming: Deep Drawing of Rectangular and Asymmetric PartsDocument17 pagesSheet Metal Forming: Deep Drawing of Rectangular and Asymmetric PartsBachLeCaoNo ratings yet

- BDA37401-Lab Sheet Engineering Mechanic Laboratory IIDocument70 pagesBDA37401-Lab Sheet Engineering Mechanic Laboratory IIkfodskfoNo ratings yet

- Basics of Foundation Design PDFDocument433 pagesBasics of Foundation Design PDFGnkdsNo ratings yet

- Getting A Good Fit: Selecting The Right Shaft and Housing ToleranceDocument2 pagesGetting A Good Fit: Selecting The Right Shaft and Housing Toleranceeng13No ratings yet

- V2607-DI-T-E3B: Kubota 07 SeriesDocument2 pagesV2607-DI-T-E3B: Kubota 07 SeriesRodrigoThuLokithoPkmz0% (1)

- Dex39 1540 - REV 01Document1 pageDex39 1540 - REV 01Navneet RankNo ratings yet

- Drying solids fundamentals and equipment selectionDocument30 pagesDrying solids fundamentals and equipment selectionArfel Marie FuentesNo ratings yet

- Unfired Pressure VesselDocument30 pagesUnfired Pressure VesselSrinivasan RajenderanNo ratings yet

- Structural Optimization Procedure of A Composite Wind Turbine Blade For Reducing Both Material Cost and Blade WeightDocument20 pagesStructural Optimization Procedure of A Composite Wind Turbine Blade For Reducing Both Material Cost and Blade WeightNasser ShelilNo ratings yet

- Catalog Echipamente de Gresat Si Transfer Ulei PressolDocument104 pagesCatalog Echipamente de Gresat Si Transfer Ulei PressolvalentinNo ratings yet

- Bevel ExplanationDocument4 pagesBevel ExplanationVarun VaidyaNo ratings yet

- Hydraulic Pressure TestDocument4 pagesHydraulic Pressure TestBola AdelNo ratings yet

- Electric Pumps Cat 2006 ScreenDocument258 pagesElectric Pumps Cat 2006 ScreenNicolasNo ratings yet

- CAT 385CLRE ElectricalDocument17 pagesCAT 385CLRE ElectricalGeorge Zormpas100% (1)

- 1104D-E44T and 1104D-E44TA Industrial Engine Electrical SystemDocument2 pages1104D-E44T and 1104D-E44TA Industrial Engine Electrical SystemGerman E.100% (1)

- Sp329a PRIMAAX EX For Mack HDT PDFDocument6 pagesSp329a PRIMAAX EX For Mack HDT PDFJonathan Smith Vargas torresNo ratings yet

- LPG Carbon Dioxide Fire Suppression System Installation Manual .Document50 pagesLPG Carbon Dioxide Fire Suppression System Installation Manual .hrhgk100% (1)

- Well DiagramDocument2 pagesWell DiagramSanjay KapoorNo ratings yet

- Model XQ140/12A Hydraulic Power Tong Operation ManualDocument61 pagesModel XQ140/12A Hydraulic Power Tong Operation ManualNgwe Min TheinNo ratings yet

- Kumera-848027c - Installation and Maintenance - en - 2015-08 PDFDocument40 pagesKumera-848027c - Installation and Maintenance - en - 2015-08 PDFgilbertogatoNo ratings yet

- STB S19 00 Datenblatt - Scalpac - EN - v01 PDFDocument2 pagesSTB S19 00 Datenblatt - Scalpac - EN - v01 PDFAnastasia PošaracNo ratings yet

- Astm A788Document10 pagesAstm A788Lucas Prezotto Puertas ErnandesNo ratings yet

- PortfolioDocument10 pagesPortfolioapi-550329398No ratings yet

- Elektrisk (Katalog - Ermax)Document267 pagesElektrisk (Katalog - Ermax)ionel1987No ratings yet

- 2014 Miteebite Catalog WebDocument40 pages2014 Miteebite Catalog WebDonald NeislerNo ratings yet

- XtraVac Multihead Packaging Lines-LRDocument5 pagesXtraVac Multihead Packaging Lines-LRMohammad SalamaNo ratings yet

- VXN150 Vixion Radiator & Hose PDFDocument1 pageVXN150 Vixion Radiator & Hose PDFHarris Jum'aniandaNo ratings yet