Professional Documents

Culture Documents

Drilling Fluids Manual

Uploaded by

ParaZzzitOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drilling Fluids Manual

Uploaded by

ParaZzzitCopyright:

Available Formats

ava Drilling Fluids & Services

Drilling Fluids

Manual

ava S.p.A.

Via Salaria, 1313/C

00138 Rome, Italy

Tel: +39 06 8856111

Email: avaspa@avaspa.it

Internet: www.avaspa.it

Version 1

November 2004

RETURN TO MENU

This manual is provided without warranty of any kind, either expressed or

implied. The information contained in this manual is believed to be

accurate, however AVA S.p.A, Newpark Drilling Fluids, LLC and any of its

affiliates, will not be held liable for any damages, whether direct or indirect

which result from the use of any information contained herein. Furthermore,

nothing contained herein shall be construed as a recommendation to use any

product in conflict with existing patents covering any materials or uses.

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 1 -

TABLE OF CONTENTS

CHAPTER 1 GENERAL DUTIES AND FUNCTIONS OF DRILLING FLUIDS

CHAPTER 2 BASIC CHEMISTRY

CHAPTER 3 GEOLOGY

CHAPTER 4 CLAY CHEMISTRY AND PROPERTIES

CHAPTER 5 POLYMER CHEMISTRY

CHAPTER 6 FLUID LOSS CONTROL

CHAPTER 7 WATER BASED FLUIDS

CHAPTER 8 OIL BASED FLUIDS

CHAPTER 9 BOREHOLE STABILITY

CHAPTER 10 FLUID DESIGN

CHAPTER 11 SOLIDS CONTROL

CHAPTER 12 UNDERBALANCED DRILLING AND FOAM

CHAPTER 13 RHEOLOGY

CHAPTER 14 PRODUCTION ZONE DRILLING

CHAPTER 15 CORROSION

CHAPTER 16 PROBLEM SOLVING WITH DRILLING FLUIDS

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 2 -

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 3 -

CHAPTER 1

GENERAL RIG DUTIES AND FUNCTIONS OF DRILLING FLUIDS

1.1 KEY POINTS AND SUMMARY

1.2 ROTARY DRILLING TECHNIQUE - INTRODUCTION TO DRILLING FLUIDS

1.3 PRINCIPLE FUNCTIONS OF DRILLING FLUIDS

1.3.1 Improve Cuttings Removal Rates

1.3.2 Control Sub-surface Pressures

1.3.3 Suspend and Release Solids

1.3.4 Maintain Borehole Stability

1.3.5 Protect Producing Formations

1.3.6 Control Corrosion Rates

1.3.7 Seal the Wall of the Borehole

1.3.8 Aid in Maximizing Penetration Rates

1.3.9 Aid in the Retrieval and Interpretation of Formation Data

1.3.10 Cool and Lubricate the Bit and Drill String

1.3.11 Other Functions

1.4 COMPOSITION OF DRILLING FLUIDS

1.5 PROPERTIES OF DRILLING FLUIDS

1.6 DUTIES AND RESPONSIBLITIES OF A MUD ENGINEER

REFERENCES

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 4 -

1.1 KEY POINTS AND SUMMARY

Drilling Fluids Technology is continually changing and improving. These changes are usually

initiated by the need to improve drilling and production economics. Today many types of

specialized fluids exist, which perform a diverse number of functions. The physical properties

and chemical constituents of these fluids are designed, monitored and altered to suit one or more

function at a time. These functions may be prioritized - either by design or when a solution to a

specific situation is required.

Drilling fluids usually contain a fluid phase and a solid phase. The fluid phase may consist of air,

oil or water or a combination of these. The solid phase may consist of formation material and

solid materials added to contribute to a certain function.

1.2 ROTARY DRILLING TECHNIQUE - INTRODUCTION TO DRILLING FLUIDS

The application of Science and Technology to boring holes through the earths crust is a dynamic

process. Documentation suggests that rotary drilling rigs with circulating systems were being

used as early as the mid-nineteenth century.

1

Since then, improving the economics of petroleum

production has been a driving force behind the advancement of drilling technology. More

recently, concerns regarding the safety of personnel and the protection of the environment have

played an equal role in this technology.

Today, the process of rotary drilling still has some similarities to the methods used over a century

ago. A cutting head or bit is attached to a series of connected hollow pipes. The outside

diameter of the pipe is smaller than that of the bit. This configuration is suspended from a set of

traveling blocks such that it can be run partly in compression and partly in tension. The part in

compression (the lower part) supplies the force on the bit. The bit is rotated clockwise as viewed

from above. Drilling fluid is pumped down the inside of the pipe and through the bit. As the bit

cuts through the rock, the cuttings are flushed away by the drilling fluid. The fluid continues to

transport the cuttings to the surface through the annular space between the pipe and the wall of

the hole. At the surface, the cuttings are separated and discarded. The Drilling Fluid is cleaned,

and treated with chemicals before being pumped down the pipe again. The general arrangement

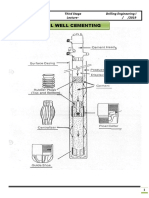

of a drilling rig, mud pits, drill pipe, bit and casing is shown in Figure 1.1.

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 5 -

Figure 1.1. Circulating System cross section

1 Pump 10 Cased Annulus

2 Shock Hose / Standpipe 11 Guide Base

3 Swivel / Top Drive 12 Blow Out Prevention Stack

4 Kelly / Drillpipe 13 Riser

5 Bottom Hole Assembly 14 Flowline

6 Bit 15 Diverter

7 Open hole annulus 16 Diverter Line

8 Casing Shoe 17 Shaker

9 Casing 18 Mud Pits

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 6 -

A drilling operation can usually be divided into three distinct parts. The first involves drilling to

the targeted depth or pay-zone. This is done in a series of intervals of decreasing diameter.

The objective is to complete this part as quickly as possible, therefore the Drilling Fluid is

designed to aid to this end. Steel casing is lowered and cemented into place at the end of each

interval. While waiting for the cement to set, the physical or chemical properties of the Drilling

Fluid may be adjusted to suit the conditions and demands presented by the next sequence of

formations to be penetrated.

The second part of the drilling operation begins once the potential pay zone is reached. Here the

objective changes. It becomes essential to minimize formation damage caused by

contaminated Drilling Fluids. Specialized drill-in fluids may be used to aid in hydrocarbon

detection or to protect potential production zones.

The final stage occurs when the well is completed. The casing and cement are perforated.

The hydrostatic forces exerted on the formation are reduced enough to allow the fluids in the

formation to flow to surface, or a pump is installed or steam is injected etc. The fluids used in this

stage can have a significant influence on the productivity of the formation. Many operators are

using various types of completion fluids regularly.

As exploration and production costs increase, greater emphasis is placed on the role of drilling

and completion fluids. The Petroleum Industry recognizes that both the design and management

of Drilling Fluid systems play an important role in the success of a drilling operation. This is the

case in terms of reduced drilling time and in increased productivity. Thus, Drilling Fluid

technology continues to be a dynamic and multi-disciplinary science.

1.3 PRINCIPLE FUNCTIONS OF DRILLING FLUIDS

Drilling Fluid was probably first used to aid in the transport of drilled cuttings to the surface.

2

As

the drilling industry evolved, additional functions became both apparent and necessary. Today,

Drilling Fluid serves several principle functions.

The chemical and physical properties of any Drilling Fluid depend on its components. The

composition of a fluid may be altered or designed, in order to improve the efficiency of a

certain function. When this is done it is likely that other properties or functions will also be

affected. The efficiency of some functions can be affected by more than one property. An

example of this is the influence of both density and viscosity on the rate of penetration.

The functions of Drilling Fluids do have a practical order of importance. It is generally accepted

that the transport of cuttings and the control of sub-surface pressures are essential functions.

Other functions may take precedent at certain stages of the drilling program. Minor or inherent

functions are listed in section 1.3.11.

1.3.1 Improve Cuttings Removal Rates

As drilling proceeds, a great deal of emphasis is placed on the Drilling Fluids ability to remove

the drilled cuttings. The term hole cleaning is used frequently and the cuttings returning to

surface are observed continuously. Any changes in the size, shape, consistency, or the net

volume of cuttings are noted. If the material returning to surface contains cavings or

sloughings, adjustments to fluid properties are considered.

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 7 -

The cuttings must be removed as quickly as possible to prevent annular blockage. This can

become more complicated in deviated wells where the cuttings tend to form a cuttings bed on

the low side of the hole. Further, the cuttings generated in some formations tend to be reactive in

water-based solutions. They may chemically degrade or disperse as a function of time. Usually

mechanical degradation occurs also. Cuttings may degrade to beyond the point of capture by the

solids removal equipment on surface, contributing to rheological or density-associated problems.

Several properties and parameters influence cuttings removal rates. The primary ones are the

viscosity and velocity of the transporting fluid. The viscosity may be expressed in terms of

funnel viscosity, yield point, consistency index, plastic viscosity, apparent viscosity, effective

viscosity and annular viscosity - depending on the specific application and the mathematical

model used. An accurate prediction of a fluids ability to transport cuttings can be quite

complicated, since most Drilling Fluids are non-Newtonian or shear thinning. In non-Newtonian

fluids, the effective viscosity decreases as the shear rate (velocity in this case) is increased. By

using mathematical models for a given fluid, its behavior under various dynamic conditions may

be predicted. Thus the correct combination of velocity and viscosity may be applied.

Other parameters affect the cuttings removal rate. These include the density of both the fluid and

the cuttings, and the size and shape of the cuttings. The mathematical modeling of fluid behavior

and the mechanisms of cuttings transport are discussed in detail in the section on Rheology.

1.3.2 Control Sub-surface Pressures

The prediction, detection and control of sub-surface pressures are an integral part of any drilling

operation. Safety and environmental concerns are the main motives for devoting attention to sub-

surface pressures.

As depth increases, the weight of the overlaying rock exerts increased pressure on the formation

being penetrated. Usually the pore size in the rocks is reduced. The bulk or net density of the

formation increases and any liquid or gas trapped in the rocks is subjected to increasing

pressure. The pressure profile of a well (pore pressure vs. depth) can be predicted through

seismic or extrapolated from offset well data. Unfortunately, pressure prediction is not always

accurate and pressure profiles are seldom linear. For the sake of simplicity, pressures may be

reported as the equivalent fluid density required to balance the formation pressure. The

pressure profile of a well or an interval may also be expressed in terms of its relationship to a

column of fresh water of equal height. That is; over, under, or normally pressured. Two

mechanisms may contribute to problems associated with drilling with an underbalanced fluid

column.

The first is related to stress relief and may result in borehole collapse. In tertiary or plastic

formations the symptoms are evident as squeezing. Often the remedy is mechanical - wiping the

hole. At times it is necessary to revert to increasing the fluid density to contain squeezing.

The second is related to the pressure exerted on the connate fluids. If the pressure exerted by

the Drilling Fluid doesn't exceed the pore pressure, formation fluids will flow into the well bore.

The results of an uncontrolled, flowing well can be disastrous. In competent formations, over

pressured shales may enter the wellbore at an excessive rate. Increased flowline gas levels may

accompany this phenomenon. In this case the usual remedy is also to increase the fluids

density.

Both the value of the density and the fluid constituents contributing to that value are monitored

closely during drilling operations. Several problems may result if the density is too high (over-

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 8 -

balanced). These include borehole fracturing, slower penetration rates and rheological

problems caused by the build-up and size degradation of the fluids solid phase.

Rheological properties are also important when considering the effective density of the fluid

column. Changing the viscosity can alter the equivalent circulating density and increase the

surge / swab effect when reciprocating pipe. The effect of fluid density on various drilling

parameters is discussed during Rheology, Hole Stability and Problem Solving.

1.3.3 Suspend and Release Solids

Since most Drilling Fluids consist of materials in suspension as well as in solution, it is imperative

that particles composing the solid phase remain suspended. If particle settling is adverse, the

result can be costly. Problems such as barite settling on packers, or fill and bridges after trips or

while logging take time to correct. When circulation is stopped, certain constituents of the fluid

should form a greater degree of structure and gelation should occur. The degree to which this

happens is a function of time and is defined as the thixotropic properties of the fluid - indicated

by the fluids gel strengths. Thixotropic properties should be controlled. They shouldn't be so

excessive that circulation cant be resumed easily. They should be reversible such that after

shearing for a reasonable time, the fluid returns to its original viscosity. This is necessary

because at surface the fluid must have the ability to release the cuttings and high viscosity

impairs the efficiency of the solids removal equipment. Thixotropic properties of Drilling Fluids

are discussed in the chapters on Clay Chemistry and Rheology.

1.3.4 Maintain Borehole Stability

Problems involving the stability of the borehole always require time and expense to correct.

Occasionally a drilling operation fails when the problem can't be rectified in a timely manner. The

cause or combinations of causes to this problem vary and the solutions are diverse. Drilling

successfully through a problem formation may be entirely dependant on the Drilling Fluids

formulation, maintenance and modification.

Contributing factors to borehole instability include easily erodible formations such as evaporates

or permafrost. Or, the formation might be fractured - with a weak matrix - unable to withstand

overburden stresses. Many shales are hydratable and / or swelling, with a tendency to slough

after a certain time of exposure to drilling fluid. Effects of over pressured shales are sometimes

extremely difficult to correct and they may contain dangerous levels of gas. Overburden or

tectonic forces may cause wells to squeeze making it difficult to pull pipe, log or run casing.

There are several Drilling Fluid properties that can contribute to the maintenance of borehole

stability. The treatment and mechanisms vary depending on the cause or the potential cause.

An adjustment to the viscosity might alter the annular flow regime enough to prevent erosion.

Raising the specific gravity may be the only requirement for successful drilling through over

pressured zones. A wide range of inhibitive fluids has been developed. In some, the ionic

content of the liquid phase has been altered with various salts. The effects of these fluids may

be beneficiated with encapsulating polymers. In many areas, operators have found that drilling

with oil-based fluids has proven to be by far the best solution to borehole stability problems.

Drilling Fluid testing procedures and reporting formats are designed to monitor the particular

properties and parameters that contribute to the maintenance of borehole stability. This volume

contains a chapter on Borehole Stability.

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 9 -

1.3.5 Protect Producing Formations

As production costs rise, increasing emphasis is placed on protecting producing formations from

potential damage caused by contact with borehole fluids. This protection can at times, be a

primary function of the fluid. Specialized drill-in, completion, and work over fluids are

designed and used in specific and localized applications.

Usually formation damage is attributed to the reduction in size, or the plugging of the rocks

natural porosity. Generally the mechanisms that cause damage may be classified into two

groups: Plugging associated with solids (including precipitates) and plugging associated with

fluid filtrate.

3

Fluid properties that may influence the success of a non-damaging fluid application include,

density, solids content, fluid loss and filtrate characteristics, viscosity, and the fluids ability to limit

corrosion. The background, theory and design parameters of non-damaging fluids are discussed

later in the manual.

1.3.6 Control Corrosion Rates

All metal components including drilling tools, casing and rig components must perform in a

corrosive environment. The results of excessive corrosion include casing failure, damage to

surface equipment and failure of down hole production tools.

Corrosion mechanisms encountered in drilling operations are usually related to dissolved

oxygen, carbon dioxide or hydrogen sulfide. Occasionally all three may be present. Usually

the fluid is maintained in an alkaline state to help impede corrosion rates. A broad range of

chemical additives is available to combat specific corrosion related problems. Corrosion is

discussed later in the course.

1.3.7 Seal the Wall of the Borehole

Drilling Fluids usually have a specific gravity sufficient to offset or counter-balance formation

pressures. This aids in supporting the rock and preventing formation fluids from entering the

wellbore. When the fluid column is overbalanced usually some fluid is lost to the formation.

The degree of loss depends on the pressure differential, the size of the pores in the rock and the

size and type of particles or bridging agents in the fluid.

If fluid is lost to the formation, several adverse affects may result. Whole fluid losses can be

expensive - especially in the case of oil-based fluids. Kick detection becomes hampered if

losses are continual while drilling. When the liquid phase or filtrate of the fluid is lost to the

formation, the solid phase becomes deposited as a cake on the wall of the hole. This cake may

be of sufficient consistency to cause the pipe to become stuck. Filtrate invasion may also affect

other Drilling Fluid functions, including the influence of the fluid on borehole stability or the

protection of producing formations.

The main methods of gauging the filtration characteristics of a Drilling Fluid include conducting

API filtration or high temperature / high-pressure filtration tests on the fluid. Other more involved

tests may be employed if required. The results of these tests are reported in volume of filtrate per

time unit, and cake thickness. The actual characteristics of the cake may be vitally important in

problem formations.

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 1 0 -

Many different materials are available to effectively seal the wall of the borehole. They range in

sized from colloidal clays to golf-ball and larger sized materials. Their application depends on the

severity of the problem, and type of Drilling Fluid used. Fluid Loss Control is studied in detail in a

chapter of this volume.

1.3.8 Aid in Maximizing Penetration Rates

For years, substantial research has been directed at maximizing the Rate of Penetration (ROP)

while drilling. Several factors, including bit design, Bottom Hole Assembly design, bit hydraulics,

force on the bit, RPM, and Drilling Fluid properties have all proven to affect the ROP. The

justification for the research is mainly economical. Drilling time is reduced and interval lengths

can be increased.

Numerous studies have been conducted and models examined in an attempt to correlate Drilling

Fluid properties with changes to penetration rates. The fluids spurt loss

4

, certain filtration

characteristics

5

, solids characteristics and density all have an effect on the ROP. Several Drilling

Fluid properties are involved in a graphical model, called chip hold-down pressure. It attempts to

correlate the pressure differential between the Drilling Fluid column and the formation pore

pressure with drilling rates. Certain fluid properties are also considered when optimizing the

Hydraulic Horsepower at the bit. The effect of various fluid properties on penetration rates is

discussed throughout this volume.

1.3.9 Aid in the Retrieval and Interpretation of Formation Data

Many methods for evaluating production potential exist. Some are conducted while drilling, while

others are carried out when an interval is complete. The proper adjustment and maintenance of

Drilling Fluid properties may aid most evaluation techniques. The rheological properties are

important in terms of cuttings transport if accurate analysis of formation tops is to be made. The

particle size distribution of various solid phase components should also be considered when

running telemetry equipment or while coring. The thixotropic properties should be controlled -

both to allow for accurate flowline gas detection and to prevent solids settling while testing or

logging. The fluids ionic content may be adjusted to aid electric logging results. Tracer

elements may be incorporated into the fluid to aid in evaluation of recovered formation fluids after

drill stem testing. The minimization of formation damage caused by fluids remains the area of

greatest concern when considering the topic of retrieval and interpretation of formation data. This

function is an important part of Drilling Fluids design.

1.3.10 Cool and Lubricate the Bit and Drill String

While drilling ahead, a considerable amount of heat is generated by the frictional forces of the

rotating bit and drill string. This heat cannot be totally absorbed by the formation and must be

conducted away by the drilling fluid. A quantity of heat is then lost at the surface.

Lubrication is to a limited extent provided by the liquid phase and solids deposited on the wall as

a filter cake. However, when drilling conditions become adverse, operators rely on improved

Drilling Fluids formulation to aid in extending their engineering parameters. Wells are becoming

deeper, hotter and more deviated - sometimes horizontal or "S" shaped. The Drilling Fluid should

have the ability to minimize the influence of rotary torque and hole drag on well design. Various

friction-reducing Drilling Fluid additives have been developed and several methods are

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 1 1 -

available to test their effectiveness on given fluids. Rotary torque and hole drag are discussed in

greater detail in the chapter on Problem Solving with Drilling Fluids.

1.3.11 Other Functions

There are several other functions or roles which Drilling Fluids may serve. Although they are

considered in drilling program design, fluid properties are not usually altered to enhance them.

They include; contributing to drill string buoyancy, driving downhole motors and telemetry

equipment, and the transport of data such as MWD and pore pressure data to surface.

Areas which are not functions but extremely important considerations, include the impact of a

particular Drilling Fluid system or its components on the safety and protection of personnel and

the environment. In most areas of the world these considerations take precedent over the benefit

of any other functions of Drilling Fluids.

1.4 COMPOSITION OF DRILLING FLUIDS

Drilling Fluids usually consists of two components; the fluid phase and the solid phase.

The fluid phase may consist of either a single fluid, or two immiscible fluids (an emulsion or

foam). If two fluids are used they are usually formulated to contain a discontinuous or dispersed

phase within a continuous phase. A general classification of Drilling Fluids based on their fluid

phase is outlined in table 1.1.

TABLE 1.1 CLASSIFICATION OF DRILLING FLUIDS SYSTEMS BASED ON THEIR FLUID

PHASE

Fluid Phase

Gas Water Oil

Gas

Foam

Water

Direct

Emulsion

Oil

Invert

Emulsion

Air or gas

alone

Air or gas

with water

and/or oil to

form foam

Oil free

water/brine

fluids

Continuous

water/brine

phase with

emulsified oil

Water free oil

fluid

Continuous oil

phase with

emulsified

water/brine

Various materials (solutes) may be dissolved in the fluid phase to change or control certain

properties of the fluid. A general classification of Drilling Fluids solutes is given in table 1.2.

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 1 2 -

TABLE 1.2 DRILLING FLUIDS SOLUTES

a

Solute

Function

Solute

Function

Salts/Ionic Compounds

Increase density

(completion brines)

Aid inhibition

Prevent solution of

evaporites

Used as tracers

Adjust water activity

Polymers

Control fluid

loss

Deflocculation

Flocculation

Encapsulation

Control

viscosity

Alkaline Compounds Inhibit corrosion

Solubilize polymers

Alter charges on clays

Aid inhibition

Surfactants Corrosion

control

Emulsion

stabilization

Prevent bit

balling

Acids Cement contamination

treatment

Clay dispersion

Asphaltic derivatives Control fluid

loss

Suspension

properties

a) Note that not all substances are soluble in both oil and water

The benefit of gas-based fluid systems is realized in rapid penetration rates. Its application is

limited to competent, low-pressured formations. As formations become wet, mist, foam or stable

foam must be used.

Water is the most commonly used continuous phase due to its low cost and availability. Because

water is a polar medium it has the advantage of being able to dissolve many different substances.

This feature may also contribute to undesirable effects. Water dissolves gases, which cause

corrosion. The ionic compounds, which make up evaporate formations, are easily dissolved by

water - sometimes resulting in severe hole erosion. Most formation clays have an affinity for

water. The expansion forces generated when they adsorb water are often strong enough to

contribute to borehole instability.

To overcome these effects, various solutes may be incorporated into the water phase. These

have led to a general classification and nomenclature of water-based fluids systems, many of

which have been designed with some form of inhibition in mind. Water-Based Fluids and their

components are discussed later in this course.

Oil-based fluids have been commercially available since the 1940's. The disadvantages

inherent in water-based fluids may be overcome when oil becomes the continuous phase. This is

due to the non-polar nature of oil. It will not solubilize salts or react with clays. Most oil-based

fluids are an emulsion, with brine making up the dispersed phase. Oil-based fluids may be

formulated with diesel oil, or a more environmentally compatible low toxicity oil. Oil-based fluids

and their components are presented following the chapter on Water-Based Fluids.

The solid phase of Drilling Fluids consist of particles held in suspension by the liquid phase.

There are several ways of classifying solids in Drilling Fluids:

1. By size; colloidal to gravel sized.

2. By surface charge; reactive or inert.

3. By how they entered the fluid; drilled solids or "commercial solids".

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 1 3 -

4. By their specific gravity; high or low gravity solids.

Drilled solids are derived from the formation. Although the presence of drilled solids may

improve filtration, viscosity or density characteristics, other additives perform these functions

more efficiently. Drilled solids are usually low gravity solids. Excessive concentrations of drilled

solids are undesirable (contaminants) as they contribute to abrasiveness and make rheological

properties difficult to control. The degree of tolerance a fluids system has for drilled solids

depends on the concentration of "commercial solids" and the availability of deflocculants within

the system. Commercial solids are non-soluble materials that are added purposely to a fluid

system to control a property. They may be broadly classified into five different functional groups

as outlined in table 1.3. The impact of the solid phase of Drilling Fluids is discussed throughout

both volumes of this manual.

TABLE 1.3 FUNCTIONS OF SOLID PHASE ADDITIVES

GROUP

FUNCTION

EXAMPLES

a

Weighting agents

Increase specific gravity

Barite, Hematite

Clays Increased viscosity, aid in

bridging, increase lubricity

Montmorillonite, Sepiolite

Bridging agents Seal porosity Fiber, Flakes, Resins,

Salts

Solid phase torque reducers Reduce rotary torque & hole drag Graphite, Teflon beads,

Bentonite

Hole stabilization additives Plug microfractures Asphalts, Gilsonite

a

Note: The examples given do not constitute a complete list.

1.5 PROPERTIES OF DRILLING FLUIDS

The properties of Drilling Fluids may be divided into two groups: physical properties and

chemical properties. The physical properties of a Drilling Fluid are usually influenced to some

degree by both the liquid and solid phases of the fluid. The chemical properties, which are

considered important, are influenced by constituent solutes including ionic species, polymers and

other dissolved compounds.

Various physical and chemical properties are incorporated into fluid design, monitored and

reported - especially when they pertain to a specific application or problem. These applications

include formation damage, high pressures, hole stability, high temperatures, contaminating

formations and friction.

Generally the properties applicable to the majority of fluids systems include specific gravity and

viscosity characteristics. Properties particular to specific fluids are outlined in Volume II of this

manual. The procedures for testing these properties are also outlined in Volume II.

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 1 4 -

1.6 DUTIES AND RESPONSIBLITIES OF A MUD ENGINEER

The purpose of this section is to discuss the various aspects of the day-to-day activities of an Ava

Drilling Fluids Mud Engineer. As a representative of Ava, the most important skill you must

possess is the ability to communicate with all the stakeholders (e.g. Office operations, technical

service, sales; truckers; rig supervisors; crews).

An open discussion of the points below will give you an idea of the issues a Mud Engineer from

Ava S.p.A. will deal with on a daily basis.

1. Safety

Driving

Night driving

Hours on the road

Conditions

Defensive driving

On the rig

Mud tanks

Product stockpile/warehouse

PPE

Safety Certification(s)

Duties

Testing equipment

HTHP

Chemicals

Pipettes

Laboratory

Samples/shipping

Warehouse/Products

MSDS

ADR

Product Data Sheets

Cellular phone

Hands Free

Timing/Duration

2. Communication

Cellular phone

Hands Free

Timing/Duration

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 1 5 -

Weekly Reports

Monday/Thursday

Problems

ASAP with information!

Truckers

Loads/timing

Road Conditions

Directions

Special Instructions

Engineer/Drilling Foreman/Toolpush

Mud Program

Drilling Program

Troubleshooting

Special Operations

Loads/timing

Derrickman/Rig Crew

Current mud properties/operations

Obstacles/Questions/Concerns

Mud Program Implementation

Drilling Program pre-planning

Troubleshooting

Special Operations cementing, logging, coring, running casing

Loads/timing OBM/WBM/Special additives

Mixing Instructions verbal/written

MSDS

ADR

3. Communication

Technical Services/Sales

Current mud properties/operations

Obstacles/Questions/Concerns

Mud Program Implementation

Drilling Program pre-planning

Troubleshooting Vital link to Ava customers

Samples product/mud/solids

Special Operations cementing, logging, coring, running casing

Loads/timing OBM/WBM/Special additives

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 1 6 -

4. Logistics

Programmed products

Rig suitability

Availability

Quantities

Customer expectations

Warehouse inventory

Availability

Quantities

Ordering

Timing warehouse/rig

Pre-planning

Substitutions

Weights/clays

Polymers PHPAs, Xanthan, FLC, other

LCM

Lubricants

Defoamers

Crisis management

Lost circulation

Pressure control

Critical Sour operations

5. Reporting

Mud reports

Copies

Floppy disk(s)/downloads

Required Information

Summaries

Timing

Contents

AVA Software

Practice

Ask

Suggest

Telephone

Timing/timeliness/duration

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 1 7 -

Timing/Frequency

Crisis communications

ASAP with information

Customer expectations

Ava Operations/sales expectations

6. Testing

Per instructions in Ava Mud Manual or as defined by various API

Bulletins

Timing/timeliness/frequency

Location

Samples

Pilot testing/laboratory analysis

7. Discussion

Safety

Personal

Rig

Fatigue

Driving

Moving violations

Tickets

Other

Hot Shots/Deliveries

Insurance

ADR

Duties

Organization - planning/Notes - records

Rig

Hauling

Service

Define/discuss

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 1 8 -

References

1 H.C.H. Darley & George R. Gray, Composition and Properties of Drilling and Completion

Fluids, 5th ed. (Houston: Gulf Publishing Company, 1988), 38 ; all subsequent citations

are to this edition.

2 Darley and Gray, Composition and Properties, 38.

3 Thomas O. Allen and Allan P. Roberts, Production Operations, 3rd ed. (Tulsa: Oil and

Gas Consultants International, 1989), 2: 68, 69; All subsequent citations are to this

edition.

4 Darley & Gray, Composition and Properties, 416.

5 Darley & Gray, Composition and Properties, 422.

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 1 9 -

CHAPTER 2

BASIC CHEMISTRY

2.1 KEY POINTS AND SUMMARY

2.2 BASIC DEFINITIONS

2.2.1 The Fundamental Units of Substances

2.2.2 Quantifying these Units

2.2.3 Chemical Formulas and Equations

2.3 CHEMICAL BONDING

2.3.1 Electron Shells, Ions and Valency

2.3.2 Ionic Bonding

2.3.3 Covalent and Mixed Bonding

2.3.4 Other Atomic Influences

2.4 SOLUTIONS

2.4.1 Types of Solutions

2.4.2 The Hydration of Ions

2.4.3 Water Solubility

2.4.4 Oil Solubility

2.4.5 Dispersions and Dispersability

2.4.6 Colloidal Systems and Suspensions

2.4.7 Equilibrium and Precipitation

2.4.8 Drilling Fluids: Multi-phase Homogenates

2.5 CHEMICAL CALCULATIONS

2.5.1 Molarity and Normality

2.5.2 Concentrations in Solutions and Suspensions

2.5.3 Converting and Calculating

2.6 ACIDS AND BASES

2.6.1 pH

2.6.2 Ionization Constant

2.6.3 Acids and Bases

2.6.4 Practical pH

2.6.5 Alkaline Drilling Mud's

2.7 SURFACE CHEMISTRY

2.7.1 Surfaces

2.7.2 Surface Tension

2.7.3 Emulsion and Foam

2.7.4 Surface Charges

2.7.5 Other Surface Phenomena

2.7.6 Semi permeable Membranes and Osmotic Pressure

2.7.7 Altering Surface Chemistry

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 2 0 -

2.1 KEY POINTS AND SUMMARY

Ava Drilling Fluids has included this chapter to serve as an introduction to petroleum and mud

chemistry, and should be used as a review, or as a quick reference. As with any science it would

be impossible to include every facet of chemistry within this short introduction. Therefore, for the

sake of succinctness, mainly the concepts and terms that apply to drilling fluids are addressed

here. Some concepts are expanded upon later in the manual, as required for a better

understanding of specific chemical phenomena.

It is recommended that any reader who has an additional interest in basic chemistry, turn to a first

year text book such as Chem One by Waser, Trueblood and Knobles, published by McGraw-Hill.

2.2 BASIC DEFINITIONS

2.2.1 Fundamental Units of Substances

If you put a cube of sugar in your hand it will have a specific amount of weight associated with it,

or in scientific terms, the cube of sugar has a specific mass (for argument sake its weight or

mass = 1 gram). The term mass refers to the quantity of matter contained in a particle or body.

On the other hand, the term matter refers to anything that has mass or occupies space. The

constituents and the behavior of matter are of concern and interest to scientists and lay-people

alike.

Matter exists in three generally accepted states solids, liquids and gases. There are several ways

to classify matter. One simple method is to group matter by particle size as outlined in Table 2.1.

Table 2.1

Name Example Size Visibility

Sub Atomic Protons, Neutrons,

Electrons

<<1x10

-12

meters Inference by high

speed bombardment

Atoms Elements <1x10

-9

meters X-rays

Molecules Groups of atoms <1x10

-8

meters Electron microscopes

Compounds/materials Groups of molecules 1x10

-8

meters to

visible

Microscopes to the

human eye

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 2 1 -

Fig 1 & 2 are both high powered microscopic pictures of some common materials, notice the

ordered structure of the Plexiglas compared to the random order of the emulsion.

Fig. 1. A picture of Plexiglas. Each particle is 2x10

-6

meters in length.

Fig. 2. A picture of oil in water or an emulsion.

In the 19

th

& 20

th

Century, scientists have come to understand what constitutes the basic building

blocks of matter. Today, some of the smallest particles known are quarks, anti-quarks and

gluons. Combinations of these particles give rise to mesons, baryons, and combinations of these

particles give rise to neutrons, protons, and electrons and before you know it you have a cube of

sugar in your hand.

For interest sake, Quarks, discovered in 1969, exist in at least six different flavors: up, down,

strange, charm, top and bottom. Each flavor comes in three colors, red, green and blue

1

.

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 2 2 -

Protons, Electrons and Neutrons

At a sub-atomic level matter is made up of three particles, protons, electrons and neutrons. If you

picture an atom as a small sphere, the core of that sphere is made up of neutrons (n, neutral,

atomic mass unit (AMU) = 1.009), protons (p, positive charge, AMU = 1.0) and orbiting that core

(like satellites) are electrons (e, negative charge, AMU = 0.0005). An atom with a specific number

of protons is classified as an element. The element carbon (C) has six protons, six electrons and

6 neutrons for an atomic weight of 12.011.

An atom has equal numbers of protons and electrons (net charge = 0), but can vary in the

number of neutrons present in the core. Elements that have extra neutrons but the same number

of protons are called isotopes. Isotopes have similar chemical properties but differ in mass.

Carbon-14 (

14

C, AMU = 14, used in archeology to carbon date artifacts) is an isotope of carbon

with two additional neutrons. Carbon has 7 different isotopes.

Neutrons and protons are held together by nuclear forces. Of interest is the removal or addition

of electrons to an atom. By adding an electron (-1) to an atom, we would have a negative (1)

charge, i.e. a negative ion (anion). If we took an electron away, the atom would have a net

positive (+1) charge, i.e. a positive ion (cation). This is important, as this is the foundation to

understanding the interactions between clays, rocks and mud systems.

There are currently 111 known elements. It is believed that all of the matter in the universe is

composed of these elements. Theoretical physicists believe that the lightest elements were

formed in less than half an hour, from a primordial mixture of neutrons and electromagnetic

radiation.

Table 2.2 lists the known elements in an order that groups elements of like properties together

and it is called the Periodic Table of the Elements.

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 2 3 -

Table 2.2: Periodic table of the Elements (Mendeleev)

Alkaline metals: Group I (1A)

Alkaline earth metals: Group II (2A)

Transition metals: Groups 3B, 4B, 5B, 6B, 7B, 8, 1B, 2B

Non metals: Groups III, IV, V, VI, VII (3A, 4A, 5A, 6A, 7A)

Halogens: Group VII (7A)

Noble gas: Group VIII (8A)

Lanthanides: From Cerium to Lutetium

Actinides: From Thorium to Lawrencium

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 2 4 -

Chemicals

Two or more elements may combine chemically to form a molecule (or compound). A molecule

can be as simple as two hydrogen atoms H

2

(hydrogen gas, fig. 3) or as complex as C

10

H

14

N

2

(nicotine, fig. 4). A molecule consists of differing atoms (elements) arranged in a specific order

and are represented by a chemical formula. Chemical formulas can be visualized by drawing out

chemical structures based on the known geometry of the atoms and how they interact with each

other. With 111 elements, the possible numbers of molecules are limitless.

H H

N

N

CH

3

Fig 3. Hydrogen gas

Fig 4. Nicotine

Bonds hold atoms together; these bonds are complex interactions between the protons and

electrons of both atoms. To make a bond between two atoms you must add energy to the two

atoms, force them close together and a bond will form. A bond between two atoms contains a lot

of energy, although orders of magnitude lower than the energy holding an atom together. Think

about the difference between breaking a chemical bond (TNT explosion) and an atom (an atom

bomb explosion)!

Most reactions are reversible so if you add enough energy you will be able to break the bond

between the two elements, which will release the energy stored in the bond (usually released as

heat). If more energy is required to break a bond than is released by the bond the reaction is

called endothermic i.e. a thermal cracker adds energy to break apart hydrocarbons. If more

energy is released when the bond breaks than is required to break the bond then the reaction is

called exothermic i.e. conventional explosives.

An exothermic reaction can also be as simple as dissolving a bag of caustic soda in water. The

heat required to break apart the ionic lattice (lattice energy) is less than the energy given off as

water rushes to hydrate the ions (hydration energy); therefore caustic or caustic potash will give

off large amounts of energy in the form of heat when dissolved in water. Salt on the other hand is

endothermic when dissolved in water i.e. the lattice energy is greater than the hydration energy.

See fig. 5.

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 2 5 -

Figure 5

Energy comes in many different forms, chemical reactions (stored energy), heat, light, sound or

an electric current. An example of a chemical reaction is the formation of water. A liquid formed

by the combination of two elements, hydrogen and oxygen (which are gasses) in the presence of

heat. Water can be reacted back into hydrogen and oxygen by adding energy in the form of an

electric current (electrolysis).

2H

2

O H

2

+ O

2

e

-1

Pt

H

2

+ O

2

Spark

All of the chemicals added to drilling fluids are molecules or chemical compounds; some of the

more common ones are listed in Table 2.3

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 2 6 -

Table 2.3

Name Chemical formula Common Name

Aluminum sulfate Al

2

(SO

4

)

3

Barium sulfate BaSO

4

Barite

Calcium bromide CaBr

2

Calcium chloride CaCl

2

Calcium carbonate CaCO

3

Limestone

Calcium hydroxide Ca(OH)

2

Hydrated lime

Calcium oxide CaO Quick lime

Calcium sulfate CaSO

4

Anhydrite

Calcium sulfate bis-hydrate CaSO

4

2H

2

O Gypsum

Hydrochloric acid HCl

Potassium chloride KCl Potash

Potassium hydroxide KOH Caustic Potash

Sodium bicarbonate NaHCO

3

Bicarb

Sodium bromide NaBr

Sodium carbonate Na

2

CO

3

Soda ash

Sodium chloride NaCl Salt

Sulfuric acid H

2

SO

4

Zinc bromide ZnBr

Notice in this list of chemical compounds that they are all salts of some kind! This gives us an

important distinction. Compounds or molecules that have no carbon/hydrogen in them are

classified as inorganic compounds; a common example of an inorganic compound would be

table salt. Compounds that have a carbon/hydrogen atoms contained within the molecule are

classified as organic compounds of which oil would be a common example.

Molecules have very different properties from each other and when they group together they tend

to form into structures that are common to us; compare a sugar cube, a coffee cup and water.

Sugar molecules in large quantities stack together (like CDs stacked in a tower) in the form of a

crystal. Styrene Fig. 6 is chemically reacted together to give polystyrene (plastic cup), a

macromolecule.

Styrene

Int.

x

Polystyrene

Fig 6

Water molecules at room temperature are clustered together and randomly float around bumping

into each other. This gives us a property we recognize as liquid water. These three compounds

all have very different states from each other.

What if we bring the temperature of the water down to 20C, then what happens? The water

molecules slow down enough to stack together and crystallize to give ice. A structure similar to

the sugar cube. Almost all compounds have the three physical states associated with them

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 2 7 -

(liquid, solid, gas), water is one which we all have experience with. Most other types of chemicals

require extreme conditions to change there phase from liquid to gas or solid. One of the ways to

make sodium metal and chlorine gas is to heat table salt past 430C to melt it. If you bring air

down to 177C then it would turn into a liquid.

Other common terms of solids classification a drilling engineer will use are crystals (above),

colloids and macromolecules. Colloids can be described as compounds that are held in a liquid

by their interaction with the surrounding fluid, a common colloid is blood. In drilling muds clays

are colloids. Drilling fluid polymers are macromolecules, and they consist of many thousands if

not millions of repeating molecules put together in a chain. Geologists define a mineral as a

naturally occurring, inorganic crystalline solid that has a definite chemical composition and

possesses characteristic physical properties. Molecules often combine in an ordered, repeating

structures to form crystals, the normal form of the solid state of matter. The arrangement of the

ions, atoms, or molecules in a crystal comprises a definite pattern called a lattice (see fig 5).

2.2.2 Quantifying these Units

Atoms and elements may be categorized by several different methods. The Periodic Table is

one way of classifying elements which most of us are familiar with. The chief function of the

periodic table is to serve as a fundamental framework for the systematic organization of

chemistry. Figure 7 depicts the key to a simple rendition of the periodic table shown in Table 2.2.

The top number 6 represents the atomic number of carbon, the C is the symbol of carbon and the

12.01 is the atomic weight.

Fig. 7

Other varieties of the periodic table provide a much more in-depth description of the

characteristics and properties of elements. The elements are sometimes classified as either

metals or non-metals. Metals are described as elements whose compounds form positive ions in

solution and whose oxides form hydroxides rather than acids with water.

The atomic number is simply the number of protons of each atom of an element. It is the main

identity parameter of each element. (Each element has a different number of protons and hence,

a different atomic number). Since atoms are electrically neutral, the atomic number is also the

same as the number of negatively charged electrons orbiting the nucleus of that atom.

The atomic weight of an element refers to the total mass of all the constituents of each of its

atoms, including protons, neutrons and electrons. The mass of one proton is equal to one atomic

mass unit (AMU). The mass of a neutron is 1.009 AMU and an electron is 0.000544 AMU. Since

the mass of an electron is so minute and the mass of a neutron is almost 1, one would think that

the atomic weight of an element would be a whole number. A look at Table 2.2 shows this is not

true. The reason is, that the atomic weight is an average of the weights of all of the isotopes or

species of atoms of an element.

The atoms of individual elements all have the same atomic number, equal to the number of

protons in the nucleus. In most cases each atoms nucleus has an equal number of neutrons. An

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 2 8 -

isotope of an element is composed of atoms with one or more extra neutrons in their nuclei. This

gives the isotope a larger atomic weight, increasing the average atomic weight of the element;

hence the atomic weight can be a fraction.

Twenty-one elements have no isotopes, each consisting of only one kind of atom. The remaining

natural elements have from 2 to 10 isotopes each. The

12

C is the international standard of atomic

weight. Its nucleus has 6 protons and 6 neutrons. When 7 neutrons are present, its atomic weight

becomes 13 and the element is called carbon 13 with the abbreviation denoted by a superscript

(

13

C). Radioactive isotopes decay, emitting energy in the form of particles. Ultimately a new, more

stable element is formed. Tritium is a man-made radioactive isotope of hydrogen, used

occasionally in drilling fluids. Because it decays at a known rate (a 12.5 year life) and

concentrations are identified easily, it makes a good tracer.

The term molecular weight is used regularly in this manual. It is a chemical term, which simply

refers to the sum of the atomic weights of the atoms in a molecule. The molecular weight of the

common natural gas methane (CH

4

) is 16.043, the atomic weight being

C=12.011

4H=4x1.0079

H H

H

H

CH

4

16.04

16.031300

C 74.87% H 25.13%

2.2.3 Chemical Formulas & Equations

Several types of formulas serve to designate chemical compounds, each type conveying different

information. The empirical formula of a compound is the ratio of moles of each element present

in the compound, expressed in the form of small whole numbers. The empirical formula of any

compound can be expressed as small whole numbers because atoms are indivisible. If the ratio

of moles were 1Fe:1.5O, as it is in iron (III) oxide, the empirical formula would be written as

Fe

2

O

3

.

Structural formulas provide information on the detailed atomic arrangement in a compound. The

ensuing text shows structural formulas when explaining covalent bonding. The structural formula

for acetylene is...

C C H H or H H

fig 8

Chemical equations are used to show the reactions of substances in terms of their formulas,

relative numbers of reactants and the products involved. By definition chemical equations should

be balanced. They should show the same number of each atom on both sides and the net charge

should be the same on both sides. Balancing an equation can mean re-arranging it to fit this

definition. For example, an unbalanced equation:

C

3

H

8

O + O

2

CO

2

+ H

2

O

heat

The simplest procedure is to first balance an atomic species that appears in only one compound

on each side, starting with C.

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 2 9 -

C

3

H

8

O + O

2

3CO

2

+ H

2

O

heat

H also appears in only one compound on each side. H can be balanced by putting 4H

2

O on the

right.

C

3

H

8

O + O

2

3CO

2

+ 4H

2

O

heat

Since there are now 10 oxygen atoms on the right there must be 10 on the left. There is already

one atom of O in each molecule of C

3

H

8

O, therefore:

C

3

H

8

O + 4.5O

2

3CO

2

+ 4H

2

O

heat

Fractional coefficients are acceptable.

2.3 CHEMICAL BONDING

The preceding text explained that a compound is a combination of two or more elements

combined chemically. A chemical bond is an attractive force between atoms, which is strong

enough to permit the combined aggregate to function as a unit. In simple terms, a bond is formed

when protons from the other atom are sharing electrons from the other atom. There are three

principal types of chemical bonds that are important. These include: ionic, covalent, and hydrogen

bonds.

Table 2.4 Summary of Chemical Bonds

Bond Type Length (nm) Strength (kcal/mole) in water

Covalent 0.15 90

Ionic 0.25 3

Hydrogen 0.30 1

2.3.1 Electron Shells, Ions and Valency (oxidation state)

A simplified method for understanding the way in which electron orbitals are arranged around an

atomic nucleus is to consider the valence-bond (VB) model. Electrons are arranged in shells (s,

p, d or f), orbits or electron clouds around the nucleus. Figure 9 shows an s orbital and the p

orbitals, the most important in forming ionic or covalent bonds. These figures represent the

theoretical pathways the electrons follow.

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 3 0 -

s orbital

1p orbital

1 s orbital

& 1 p oribtal

2p orbitals 3p orbitals

fig 9

The closest or first shell, s has the lowest energy level and may contain a maximum of 2

electrons. The energy levels increase with the distance from the nucleus. The next orbital p may

contain a maximum of 6 electrons one in each lobe. Table 2.5 helps to explain the arrangement

of electrons in the first twenty elements.

Table 2.5

Electron orbitals in the first 20 elements

Number of electrons per orbital

Element Atomic number 1 s 2 s 2 p 3 s 3 p 4 s Valence electrons

Hydrogen 1 1 1

Helium 2 2 0

Lithium 3 2 1 1

Beryllium 4 2 2 2

Boron 5 2 2 1 3

Carbon 6 2 2 2 4

Nitrogen 7 2 2 3 5

Oxygen 8 2 2 4 6

Fluorine 9 2 2 5 7

Neon 10 2 2 6 0

Sodium 11 2 2 6 1 1

Magnesium 12 2 2 6 2 2

Aluminum 13 2 2 6 2 1 3

Silicon 14 2 2 6 2 2 4

Phosphorus 15 2 2 6 2 3 5

Sulfur 16 2 2 6 2 4 6

Chlorine 17 2 2 6 2 5 7

Argon 18 2 2 6 2 6 0

Potassium 19 2 2 6 2 6 1 1

Calcium 20 2 2 6 2 6 2 2

When electrons arrange themselves around a nucleus, the innermost shells are always filled first.

Electrons also have a tendency to try to keep the other shells of an atom full. Table 2.5 shows

that these shells are not always filled. Sodium (Na) for example, has 2 electrons in the first s

shell, 2 in the second s shell, 6 in the second p shell, but only 1 in the third s shell.

Islands of Stability

Three elements in table 2.4 have zero valence electrons, helium, neon, and argon. These

elements are called noble gases and are known to be the most inert elements in the universe.

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 3 1 -

The reason for this inertness has to do with the electrons surrounding these elements. The

orbitals surrounding the noble gases are completely full. Hence the electronic charges of these

elements are entirely balanced and utterly un-reactive towards other electrons. With this

knowledge we can look at every other element and say in a generalized way that (octet rule) all

other elements will lose or gain only enough electrons to get that element to a noble state or

every element wants to be a noble element! In terms of electrons every element wants to fill the s

orbitals (2 electrons) and the p orbitals (6 electrons).

In simple terms we can look at sodium and say it wants to get to neon so it will lose one electron

and become a Na

+

cation. The energy required to remove that electron is called the ionization

potential (IP), fig 10. The IP for sodium = 118 Kcal/mole

Fig. 10

Na Na

+

+ e

-1

H

o

=IP

Elements in the first row are known to have low IPs and are known to be electropositive

elements. Elements to the far right of the periodic table (halogens) are known to be

electronegative. These elements have an electron affinity (EA) i.e. they love electrons because

it makes them have a noble type electronic structure fig 11. The EA for fluorine to go to a fluorine

anion = 78.3 Kcal/mole.

Fig. 11

F + e

-1

F

-1

H

o

=EA

Electropositive (alkali metals) and electronegative (halogen) elements tend to lose and gain

electrons so easily they form pairs of ions. This type of bonding is described as ionic bonding.

For compounds in the middle of the table the energy required to lose or gain enough electrons to

get to a noble state is high, for carbon to have an electronic state similar to He the IP = 1480

Kcal/mole!

Fig. 12

C C

4+

+ 4e

-1

H

o

=1480.7Kcal/mole

Consequently these elements get to their octet (2+6) state by sharing electrons. Bonds in which

two (or more) electrons are shared are described as covalent bonds.

Fig. 13

+ 4H C H

H

H C

H

Carbon thinks that it is neon and hydrogen thinks it is helium, and the molecule is very stable.

Elements that have the greatest electronegativity are in the far top right of the periodic table;

those with the weakest are in the lower left of the periodic table. This is important because when

you have two elements joined together by a covalent bond, the more electronegative atom will

concentrate more of the electron density to itself. This creates a dipole moment and can be used

to visualize where a charge potential resides on a molecule.

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 3 2 -

Fig. 14

C F C O Al C B Cl

dipole moment

(+) (-)

These are not full +/- charges more like hints of charges (). But these hints can be powerful

enough to create viscosity in a drilling mud.

2.3.2 Ionic Bonding

An ionic bond results from the electrostatic attraction between oppositely charged ions. This bond

may be thought of as the transfer of an electron from one atom to another such that two

oppositely charged ions result. The energy of these bonds varies depending on where the

element is in the periodic table top right or bottom left. Thus it requires more energy to break an

ionic bond between two small ions (top of table). Ionic crystals are substances in which oppositely

charged ions are packed together in a highly regular three-dimensional array, held together

chiefly by ionic bonds. In sodium chloride crystals, equal numbers of Na

+

ions and Cl

-

ions occur

in an intermittent regular pattern. It is important to realize that sodium chloride crystals do not

contain actual NaCl molecules, but only Na

+

and Cl

-

ions. This applies also to molten sodium

chloride or an aqueous solution of sodium chloride. These properties are applicable to all ionic

compounds. The compounds listed in Table 2.3 are all ionic compounds.

Fig. 15

O

S

O

O

-1 -1

O

Sulfate (SO

4

-2

) (fig 15) is called a divalent anionic compound because it is a compound with a

net, double negative charge. Sodium (Na

+

) is a monovalent cation.

2.3.3 Covalent and Mixed Bonding

Lewis first proposed the idea that covalent bonds involved shared pairs of electrons in 1916.

However, it was not until the development of Quantum Mechanics (the theory developed from

Planks Quantum Principle and Heisenbergs Uncertainty Principle) that a clear understanding of

covalent bonding became possible. Because of its simplicity, the Lewis model is still commonly

used today. This section does not consider Quantum Mechanics.

Like ionic bonding, the effect of covalent bonding is to satisfy the atoms tendency to obtain a full

electron shell. A single bond involves the sharing of 2 electrons. Double and triple bonds share 4

and 6 electrons respectively. Bonds of intermediate multiplicity also exist. When a molecule is

depicted on paper using a structural formula, these bonds are described using single, double or

triple lines between atoms. Unshared outer electrons are sometimes represented by dots:

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 3 3 -

Fig. 16

CH

3

CH

2

O

H

CH

2

CH CH

CH

2

C C H H

Ethanol Butadiene

Acetylene

H

2

N

NH

2

1,6-diamniohexane

When electron pairs are shared by two nuclei, the bonding electrons are relatively localized in the

region of the two nuclei. Frequently a degree of delocalization occurs when the shared electrons

have a choice of orbitals.

In a covalently bonded molecule, the center of the positive charge may not coincide with the

center of the negative charge (this depends on the electronegativity of the two atoms). When this

occurs, the molecule retains electric dipole moments. When the dipole moments are permanent,

the molecule is said to be polar. Water is a polar molecule. The end with the oxygen atom has an

overall net negative charge, while the end with the two hydrogen atoms has an overall net

positive charge. (The center of the positive charge is halfway between the two H atoms). The

effect is as though the oxygen was keeping the hydrogens electrons for longer than its fair share

of time. This electrical effect helps many ionic compounds such as salts; dissolve in covalent

compounds like water (see fig 5). Oil is an example of a non-polar liquid.

Fig. 17

H

O

H

2

+

O

H

Dipole in water

Electron orbitals in water

Covalent bonds provide strong attraction between the atoms comprising a molecule (see table

2.4). However, the forces between individual molecules are not necessarily as ridged in covalent

compounds as ionic compounds. Therefore covalent compounds usually retain less structure

than ionic compounds. That is, they tend to be liquids or gases at normal temperatures. In most

cases, covalent compounds with higher molecular weights have higher boiling points. The degree

of polarity of a compound can also influence its boiling point, since a greater attraction between

molecules impedes thermally induced random molecular motion. This is why the H

2

S is a gas,

even though it is heavier than H

2

O, a liquid.

Mixed-bonding is fairly common in nature. The term refers to a molecule whose components have

both ionic bonds and covalent bonds. CaCO

3

is an example; CO

3

is a covalent molecule ionically

bonded to a calcium 2 plus cation. Table 2.3 gives some examples.

2.3.4 Other Atomic Influences

Van der Waals forces and hydrogen bonds play an important role in both clay chemistry and

polymer chemistry.

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 3 4 -

Weak attractive forces may exist between uncharged atoms or molecules even in the absence of

any tendency to form covalent bonds. Collectively these are known as Van der Waals forces. Van

der Waals forces are of very short range compared to the range of electrostatic forces between

ions. Van der Waals forces act as attractive forces between the unit layers in clay suspensions.

One example is the forces, which act between molecules with permanent dipoles - polar

molecules.

Another example is an attractive force called the Dispersion Force or London Force. This force

can act on atoms and molecules with no permanent dipoles or charge distribution. It results when

two atoms or molecules come close enough to deform the electronic charge distribution of the

given atom or molecule. This induces dipole moments in them.

A hydrogen bond is an attractive force or bridge occurring in polar compounds such as water.

Here, a hydrogen atom of one molecule is attracted to two unshared electrons of another. The

hydrogen atom is the positive end of one polar molecule. It forms a linkage with the electro

negative end of another such molecule. In the formula below, the hydrogen atom in the center is

the bridge.

Fig. 18

Hydrogen bonds are much weaker than covalent bonds, but they have a pronounced effect on

the properties in which they occur

2

. This pertains to melting points, boiling points and crystal

structure. Hydrogen bonding contributes to the viscosification characteristics of Xanthan gum and

the encapsulating characteristics of PHPA polymers.

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 3 5 -

A metallic bond is found in metals: valence electrons of each atom are not bonded to atoms but

belongs to the overall metal; they function as glue that holds together all the atoms of the solid.

2.4 SOLUTIONS

2.4.1 Types of Solutions

A solution may be defined as a uniformly dispersed mixture at the molecular or ionic level.

(Sometimes a solution is incorrectly referred to as a homogeneous mixture, but in its strict sense

the term homogeneous refers to the chemical constitution of a compound or element.)

In a true solution one or more substances called solutes are uniformly dispersed in one or more

other substances called the solvent. Solutes may be present in water, usually in the form of

molecules (sugars) or ions (salts). Solutes may also be gaseous or liquid. When two liquids

exhibit mutual solvency they are said to be miscible. Solvents can either be polar or non-polar.

The most common solvent is water. It is highly, polar, whereas hydrocarbon solvents are non-

polar.

The proportion of substances in a solution depends on their limits of solubility. The solubility of

one substance in another is the maximum amount that can be dissolved at a given temperature

and pressure. A solution containing such a maximum amount of solute is said to be saturated. A

state of super-saturation can be created i.e. by heating water more sugar can be dissolved in the

water. Such solutions are unstable in practical use because if the temperature changes drastically

the solute may spontaneously precipitate or settle out as small, particulate solid compounds.

Supersaturated salt solutions are used as completion fluids with the salt particles acting as pore

plugging agents. Saturation is discussed again in the subsection, Water Solubility.

A solute, which imparts ionic conductivity when dissolved in water, is called an electrolyte. A

familiar example is sodium chloride. In the solid state it exists as an ionic compound. But when

dissolved in water, individual Cl

-

and Na

+

ions separate and the water becomes a better electric

conductor see Fig 5. Non-electrolytic substances usually dissolve as chargeless molecules. The

resultant solution does not efficiently conduct a current.

2.4.2 The Hydration of Ions

The term hydration refers to the solvation of ions in water. The strong affinity of water molecules

for dissociated ions causes them to acquire a film of highly bound water molecules as depicted in

Fig 5.

The density of the charge on the ion affects the strength of the bond. Some salts, especially those

with multi-valent ions such as calcium are called hydrous; they actually adsorb water from the

atmosphere. If the water is removed by heating, the crystals are called anhydrous. The size of

the ion also contributes to the strength of attachment of water molecules, increasing with

decreasing size.

Hydration increases the effective diameter of an ion. The exact number of water molecules

associated with any given ion is difficult to specify, especially if the number of free or available

H

2

O molecules are limited. Many uncharged molecules in aqueous solutions can be hydrogen

bonded to water molecules, for example NH

3

.

RETURN TO MENU

Drilling Fluids & Services

A New par k Compan y

- 3 6 -

2.4.3 Water Solubility

The solubility of molecules is a complex subject in which the principles of electrolytic dissociation,

diffusion and thermodynamics play controlling roles. For our purposes it is worthwhile to note the

following points.

An important generalization is that substances with similar intermolecular attractive forces tend to

be soluble in one another. Like dissolves like. That is, many non-polar substances are soluble in

non-polar solvents and many ionic compounds are soluble in polar solvents.

Because water is highly polar, it is an excellent solvent. Many ionic compounds are soluble in

water. The hydration energies of these compounds (their affinity for water) are greater than their

lattice energy (the strength of the bond holding the ion in place, within the crystal). Stated in

another way: a substance will dissolve in water if the forces of attraction between water

molecules and the ions (or ionic compounds) in the solid are greater than the forces of attraction

between oppositely charged ions in the crystal.

Table 2.7: Relative Water Solubilities of Some Common Compounds Containing Ionic Bonds

Water Solubility Cation Anion Compound Water Solubility Cation Anion Compound

Soluble Na

+

OH

-

NaOH Slightly Soluble Mg

2+

HCO

3

-

Mg(HCO

3

)

2

Na

+

Cl

-

NaCl Mg

2+

S

2-

MgS

Na

+

HCO

3

-

NaHCO

3

Ca

2+

OH

-

Ca(OH)

2

Na

+

CO

3

2-

Na

2

CO

3

Ca

2+

HCO

3

-

Ca(HCO

3

)

2

Na

+

SO

4

2-

Na

2

SO

4

Ca

2+

SO

4

2-

CaSO

4

Na

+

S

2-

Na

2

S Ca

2+

S

2-

CaS

K

+

OH

-

KOH Ba

2+

HCO

3

-

Ba(HCO

3

)

2

K

+

Cl

-

KCl

K

+

HCO

3

-

KHCO

3

Insoluble Mg

2+

OH

-

Mg(OH)

2

K

+

CO

3

2-

K

2

CO

3

Mg

2+

CO

3

2-

MgCO

3

K

+

SO

4

2-

K

2

SO

4

Ca

2+

CO

3

2-

CaCO

3

K

+

S

2-

K

2

S Ba

2+

CO

3

2-

BaCO

3

Mg

2+

Cl

-

MgCl

2

Ba

2+

SO

4

2-

BaSO

4

Mg

2+

SO

4

2-

MgSO

4

Zn

+2

S

-2

ZnS

Ca

2+

Cl

-

CaCl

2

Fe

+2

S

-2

FeS

Ba

2+

OH

-

Ba(OH)

2

Ag

+

Cl

-

AgCl

Ba

2+

Cl

-

BaCl

2

Ba

2+

S

2-

BaS

Al

3+

SO

4

2-