Professional Documents

Culture Documents

EEP305 Electric Drives Laboratory PDF

Uploaded by

Amit SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EEP305 Electric Drives Laboratory PDF

Uploaded by

Amit SinghCopyright:

Available Formats

EEP305 Electric Drives Laboratory Jan-May 2013 List of Experiments CYCLE1 1.

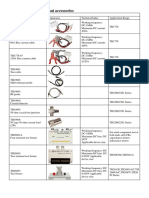

DC shunt motor braking Dynamic braking and low voltage plugging. Get the parameters of the DC machine and also simulate the braking performance in a digital computer. 2. Three-phase Induction motor starting- Record the starting current and speed transients for Y- , auto transformer and DOL starting. Simulate the performance of DOL starting in a digital computer. 3. Three-phase Induction motor braking (a) low voltage plugging (b) low voltage DC dynamic braking (c) Diode braking (d) capacitor braking. Simulate the plugging performance with a large rotor resistance in a digital computer. 4. Rectifier fed DC motor Drive. Observing Current and Voltage waveforms in the AC as well as DC side through current and voltage sensors for two different load conditions. Also study the harmonic spectrum in the current in the AC side for these load conditions. 5. Rotor resistance control of 3-phase slip ring induction motor simulation and experiment CYCLE 2

6. VSI fed 3-phase induction motor drive. Study the speed regulation at different load conditions for a given frequency setting. Observe input and output voltage and current waveforms. Simulate the same in SIMULINK. 7. Pole changing of 3-phase induction motors Experimentally study the pole changing configurations of the motor in the laboratory and simulation of speed-torque characteristics 8. Chopper fed DC motor drive 9. Performance characteristics of PMSM drive 10. Performance characteristics of PMBLDC motor drive NOTE:-Please make sure that you learn abo ut the experiment that you are going to perform and read the hand outs before you come for the actual laboratory class. Please submit the reports along with the results and inference in the following week itself. T he report submitted (one per subgroup) should contain: Title of the experiment, Name of the person writing the report, Names of the members o f the subgroup, Date of submissio n, Date on which the experiment was conducted, Aim, Apparatus required, Circuit d iagram, Theory, Procedure, Observatio ns, Inference, Precautions to be taken while conducting the experiment, graphs (if any), answers for quiz questions, simulation models, results of simulatio n and additional remarks/comments.

(G.Bhuvaneswari) Course co-ordinator

Hand out EXPERIMENT NO-1 DC Shunt Motor Braking

Braking in any electrical machine is accomplished mainly by three methods: 1.Regenerative braking 2. Dynamic braking 3. Plugging or reverse current braking. Regenerative braking allows feeding back of the stored energy in the m/c back to the supply and hence it is the most energy efficient method of braking. In dynamic braking, the generated power in the machine is dissipated in an external resistance. In plugging, the stored kinetic energy in the machine as well as the energy supplied from the source both are wasted in the form of heat in the external resistance. In this experiment, two methods of braking namely dynamic braking and plugging are to be implemented and tested for the given DC motor. The plugging is to be done at a reduced voltage so that the current through the machine is limited to its Full-Load value. The computer simulation of plugging operation is also to be carried out using a dynamic model for the DC machine. PROCEDURE: As there is no starter provided for the given DC shunt machine, an external rheostat has to be used in series with the armature so that the starting current is within the set limit. Keep Rext in maximum resistance position and switch on the DC supply to the motor by closing the DPDT in 11 position. As the m/c picks up the external resistance can be cut down. When the machine has gone up to its rated speed, throw the switch in position 22, so that the dynamic braking takes effect. Note down the time taken by the machine to stop completely after dynamic braking is initiated.

Plugging has to be done at reduced voltage; otherwise the machine might unduly get heated up. The connections are exactly similar to dynamic braking condition except that along with RB, a DC supply of reverse polarity has to be connected in series and this voltage has to be about 30 to 50V. Note that the field should be excited separately. Plugging voltage should be varied from 25 to 50V and the time taken by the m/c to stop should be recorded. S. No. Reverse Voltage Braking Time 1 2

NOTE: Field to be separately excited during braking. Finally the parameters of machine are to be measured Ra, La etc. and J has to be measured by retardation test (please refer to S.K.PILLAI). Field coil resistance can also be measured. Simulation of plugging can be done as follows: (i) During running, initial current Ia is known. Speed is known. If is also known. (ii) Ra .Ia + La dIa/dt + Rb.Ia = Eb + V during braking where Eb= KIf = initial speed If = Eb / Rf J d/dt = TL = -- KIfIa -- (Ia2 Rb)/ Solve these two simultaneous differential equation and obtain and Ia vs. Time. Compare this braking time with the actual one that was obtained from the experiment. Comment on the discrepancies. QUIZ: (1) Can a series motor be braked by regenerative braking. Why? (2) Plugging causes a heavy current to flow through the m/c .Why? (3) Dynamic braking is more effective in separately excited m/c compared to shunt m/c. Why?

EXPERIMENT NO-2 Induction Motor Starting Transients There are various methods of starting of an induction motor: (a) Direct on line starting (DOL) (b) Star Delta starting (c) Auto transformer starting As most of the squirrel-cage induction motors draw 6 to 7 times Full-Load current while starting direct on line, it is desirable to have some mechanism to bring down this starting current. Please refer M. G. SAY for starting methods.

Speed and current transients are observed from all the three types of starters by using the tacho and current sensors and feeding these signals to the CRO. Record these transients,observe how long its takes for the machine to come up to its rated speed using each of these methods when it is running on no-load. Conduct free running test, blocked rotor test and retardation test on the induction motor to find out its parameters like r1, x1, r2, x2, Xm, Rc and J. The equation governing induction motor dynamics are as follows:

where V = Va - Vb - Vc V = 0 + 3/2Vb - 3/2 Vc Vd = 0 Vq = 0

where Va , Vb, Vc are the stator applied voltages( per phase) instantaneous values & Vq,, Vd are rotor voltages. This result is obtained by transforming 3-phase stator and rotor to their 2-phase equivalents and then transforming all the rotor quantities to stationary reference frame.(Please refer to Unified Theory of Electrical Machines by C. V. JONES) L1 = M + l1 Mutual + leakage inductance of stator L2 = M + l2 Mutual + leakage inductance of rotor r = instantaneous rotor speed These four simultaneous differential equations allow us to solve for currents for the given m/c parameters and i/p voltages. T = -M i iq + M i id = Electromagnetic torque Te - TL = J dr / dt From which r (instantaneous rotor speed) can be solved for. Thus all these five simultaneous differential equations can be solved and hence the response of the m/c can be obtained.(Please refer to a book on Numerical methods for differential equation solution using Runge - Kutta method). Quiz: 1. What are the methods of starting IM using solid-state controllers? 2. Are they better than the conventional starting methods? Justify.

EXPERIMENT NO-3 Induction Motor Braking The different type of braking have already been discussed in experiment no-1. In this experiment, braking of a 3-phase induction motor will be implemented using the following four methods: (a) capacitor braking (b) DC dynamic braking (c) Diode braking (d) Plugging For all these methods of braking, please refer to the book on Fundmanetals of Electric drives by G .K . Dubey (from Narosa). For diode braking, the students are encouraged to dig out the research papers and study them. In capacitor braking, the induction machine will be disconnected from the supply and connected to a capacitor bank connected in Star or Delta. So, now the excitation would be provided by the capacitor and the machine will start acting like a generator (Why?). The generated electric power will be dissipated in the inherent resistance of the windings and thus braking is accomplished . In DC dynamic braking, the 3-phase supply to the stator is cut off and a low voltage DC is applied to the stator windings. This causes stator magnetic field to be stationary and hence s < r.This causes generator action and the energy is dissipated in winding resistances. Diode braking is almost similar to the DC dynamic braking. In plugging the phase sequence of the stator supply is reversed but very low voltage is applied; (Why?).This causes braking because of the reversed direction of the revolving magnetic field. PROCEDURE: The induction motor is started by using an Auto transformer and brought up to Full speed. The circuit diagram for different types of braking are shown below: Capacitor Braking:

S. No.

Capacitor value

Braking Time

DC Dynamic Braking:

S. No.

DC Voltage

Braking Time

Diode Braking:

S. No.

Voltage

Time for stopping

Plugging:

S. No.

Voltage

Time for stopping

SIMULATION: The simulation can be done by using the model of induction motor. In the previous experiment, the simulation of the machine during starting was done. The final results of that could be taken as the initial conditions. For plugging operation, only the forcing function has to be changed from ABC to BAC and rest of the things remain the same. In this experiment also, it is necessary to do retardation test and free running & blocked rotor test to get the parameters of the machine. In the simulation , Speed vs Torque, Current vs Time, Speed vs Time are to be obtained. QUIZ: (1) Is regenerative braking feasible in an induction m/c? (2) Analyse DC dynamic braking for the two cases: (a) one phase open (b) two stator phases started and DC supply applied between the other terminal and short-circuited terminal. (3) Draw the drive characteristics for motoring, plugging and regenerative braking in a single torque-speed plane. (4) It is always necessary to have a centrifugal switch during plugging operation to detect zero speed and switch off the supply. If this switch malfunctions, what will happen?

Experiment No. 4. Rectifier Fed DC Motor Drive Study of Rectifier fed DC Motor coupled to induction generator (a) Run at two different loads (two different firing angles) (i) observe & trace the waveforms of voltage and current in the i/p and o/p side by using voltage/current sensors. (ii) Record harmonics in the AC side current and THD Using a power analyzer. Study the manual as to what kind of controls are used for firing etc. Solid state control of DC drives could be done using converters or choppers. If the incoming supply is AC, controlled converters are used to adjust DC level that is inputted to the drive. The drive characteristics should match with the load characteristics and this can be done by controlling the converter appropriately. In the present experiment we are considering the case of armature voltage control. EXPERIMENTAL SETUP:

Here the DC machine whose speed is to be controlled acts like a prime mover and the induction generator is the load on the DC machine. When the induction generator is not loaded and when the capacitors are not connected to the m/c, then the DC motor is on No-Load. The reference speed is set using a POT on the panel of the drive unit. On No-Load, the current drawn by the DC motor and the voltage across the armature can be noted down. The current and voltage waveforms in the CRO can be traced. In the AC side, the 3-phase power analyzer (the connection is similar to a 3-phase wattmeter) can be used to note down the harmonic contents in the currents, THD and power factor of the drive unit. Now, the excitation to the induction generator could be turned on and the load can be applied on to the generator. For two different loads (if the current output from generator is within its Full-Load limit), the readings taken during No-Load could be taken. These can be repeated for different speed settings on the POT.

S.No.

Load Current

DC motor Current Voltage

AC side harmonics 1 5 7 11 13 THD PF

Wave form Traces

1 2 3 QUIZ:1. 2. 3. 4.

Could you observe commutation overlap in these waveforms? Why? What is the effect of overlap? Is the current continuous all the time in the DC side? What is the effect of discontinuity in current?

Experiment No. 5 Rotor Resistance Control of Wound Rotor Induction Motor

Motivation The main advantage of slip ring induction motor over the squirrel cage motor is that it offers one more degree of freedom to the Engineers for starting & speed control. Slip ring Induction Motor is used where the load requirements are high starting toque & variable speed, or where the motor is to be started under heavy load. Typical applications of these motors are crane & hoist control. Resister controllers in the rotor circuit are used to achieve smooth start & speed control. Resent investigations have shown that certain desired torque speed characteristics can be achieved by insertion of relatively simple passive frequency sensitive networks. Careful selection of network parameters leads to highly reduced starting current & & improved torque/ current ratio. To understand the industrial systems incorporating the Slip ring Induction Motors it is therefore necessary to study the effect of rotor impedance on the performance of Induction Motors. Objective The objective of this experiment is to determine the performance (speed, torque, current, efficiency, and power-factor) of Slip ring Induction Motor for a) Various values of rotor circuit resistance b) Various values of series combination of resistance & capacitance in the rotor circuit. Theory The per phase equivalent circuit of a polyphase Induction Motor is shown in Fig.1. Passive two terminal network is connected externally to each rotor phase. The external network can be represented as impedance Z(s) = R(s) + JX(s) At slip s.. The rotor impedance when referred to stator side becomes Z(s)/S as shown in Fig.1. To simplify the circuit Thevenins equivalent of the circuit is taken across the air gap. The thevenins equivalent circuit is shown in Fig.2 where Re = C^2 Rs, Xe = C . Xs, Ee = C . E

We know that the internal torque of Induction Motor is T = Pg/Ws watts/phase Pg = Airgap power Ws= synchronous speed in rad/sec. Also Pg = Ir^2. (Rr + Rs)/S Let (Rr + Rs)/S = R & Xr + X(s)/S = X Combine these =ns we get T. Ws = R. E^2/[(R+Re)^2 + (X + Xe)^2] ...............(A) The above =n gives the torque slip relation for an Induction Motor with external rotor impedance. Now the effect of different network parameters will be examined. (1) Resistance Control

In this case R(s) = Rext. / S & X = Xr Hence =n (A) becomes T * Ws = (Ee)^2 . ( Rr + Rext .) / S . . (B) {Re + (Rr + Rext)/S}^2 + (Xe + Xr) ^2 In =n (B) Ee, Re, Xe.Xr are constants therefore the torque developed (internal) is a function of rotor resistance & rotor .speed. It shows that the value of the torque can be varied for a particular speed of the rotor by varying the external resistance rotor resistance. The value of the maximum torque is independent of the rotor resistance & the speed at which the Tmax occurs can be adjusted using the rotor resistance. The starting torque also increases.

(2) Series RC Control In this case R(S) = Rext/S X(s) = -j 1/SWs C Now, T. Ws = . (Ee)^2. ( Rr + Rext .) / S . . (C) {Re + (Rr + Rext)/S}^2 + (Xe + Xr 1/S^2 WsC) ^2 The value of C is such that for a particular value of Slip S = S1 Xe + Xr = 1/S1^2 Ws C = 0 At S = S1 the peak torque occurs Hence at S = S1 =n (C) becomes T . Ws = (Ee)^2 . ( Rr + Rext .) / S1 .(D) {Re + (Rr + Rext)/S1}^2 As, (Rr + Rext)/S1>>Re, =n (D) becomes T. Ws = (Ee)^2 . .(E) (Rr + Rext)/S1 It is evident that the value of external resistance decides the peak the peak value of the torque. From the above discussion it is clear that the value of series resistance decides the value of maximum torque & the series capacitance decides the speed at which maximum torque occurs. Equipments & Components:(1) Three phase slip ring Induction Motor coupled to a DC dynamo motor with torque measuring devices. (2) Three phase autotransformers (3) DC machine coupled to an Induction Motor / DC motor to make Ward Leonard system. (4) Two field rheostats (5) High current resistances (6) Two single phase or one three phase wattmeters (7) AC voltmeter (Two) (8) DC voltmeter (9) AC ammeter (10) DC ammeter(three)

(11) Double pole single throw knife switch

Experimental Procedure (1) Decide the values & ranges of rheostats & measuring devices from the machine name plate ratings. (2) Conduct light running test & blocked rotor tests to determine the equivalent circuit parameters. Measure the rotor resistance. (3) Make connections as shown in Fig.(3).Check the direction of rotation of test machine & Ward Leonard prime mover. Check the polarity of the voltage generated by DC generator. (4) Short circuit the rotor of the test motor. Run the rotor at reduced voltage(preferably half the rated voltage & using the Ward Leonard take observations starting from low speed to determine the characteristics of INDUCTION MOTOR. (5) Choose value of external resistance & connect the resistance to the rotor terminals of the test motor .Run the motor and take observations to determine the characteristics. (6) Repeat the experiment for various values of rotor resistances. (7) From equivalent circuit parameters choose an approximate value of series capacitance & resistance .Determine Xe & Re & for a particular value of slip Find out the value of C. Run the motor to determine the its characteristics with series RC in rotor circuit. (8) Repeat the experiment with various values of series s RC in rotor circuit. (9) The full experiment should be performed at half the rated voltage as at low speed current level is high. Impedance Control OBSERVATION TABLE:

Sl.No Motor I/P Current I(ac) Input Power(W1,W2) Speed N Torque T DC voltage Vdc DC current Idc field current (If)M Field current I(f)D

jXs Rs R(s)/S Re

jXe

jXr

R(s)/S

jXm E1

Z(s)/S

Z(s)/S

Fif(1)

Fig(2)

W 1

L A

Iac

Idc A

AUTO TRAN SFOR MER

V Vab

TEST IM

Vbc

DC M/C

L M W2 A If1

IM

DC M/C

A Fig (3) + Vf -

If2

You might also like

- Retardation TestDocument5 pagesRetardation TestAnkit Shetty100% (1)

- Special Electrical Machines Ee2403 PDFDocument16 pagesSpecial Electrical Machines Ee2403 PDFsamyramu100% (3)

- Electric Drive Lab Laboratory Manual: Dev Bhoomi Institute Chakrata Road, Navgaoun Manduwala, UttarakhandDocument15 pagesElectric Drive Lab Laboratory Manual: Dev Bhoomi Institute Chakrata Road, Navgaoun Manduwala, Uttarakhandjaya mishraNo ratings yet

- AC DC DrivesDocument13 pagesAC DC Drives322399mk7086No ratings yet

- DC Machines Lab ManualDocument56 pagesDC Machines Lab ManualRockstar RichNo ratings yet

- Drives and Control Lab ManualDocument36 pagesDrives and Control Lab ManualKabilanNo ratings yet

- Direct Torque Control On BLDC Motor For Electric VehicleDocument10 pagesDirect Torque Control On BLDC Motor For Electric VehicleIJRASETPublicationsNo ratings yet

- Experiment - 12: Power Angle Curve of Syncronous MachineDocument3 pagesExperiment - 12: Power Angle Curve of Syncronous MachinesanjuNo ratings yet

- V and Inverted V Curves of Synchronous MotorDocument7 pagesV and Inverted V Curves of Synchronous Motorkarthikeyan249No ratings yet

- Experiment No.5-Determination of XD and XQ of Synchronous Machine by Slip TestDocument3 pagesExperiment No.5-Determination of XD and XQ of Synchronous Machine by Slip Test61EEPrabhat PalNo ratings yet

- Hopkinson Test On DC Shunt MotorDocument5 pagesHopkinson Test On DC Shunt MotorVarun VadluriNo ratings yet

- Power Electronics Lab Manual1Document72 pagesPower Electronics Lab Manual1Harish SvNo ratings yet

- 2 - To Study The Speed Control of DC Shunt Motor by Armature Control and Field Control MethodDocument4 pages2 - To Study The Speed Control of DC Shunt Motor by Armature Control and Field Control Methodbhavesh1863100% (1)

- Power Electronics Lab Manual PDFDocument41 pagesPower Electronics Lab Manual PDFSudhakar MarojuNo ratings yet

- Power Electronics Lab ManualDocument89 pagesPower Electronics Lab ManualPartha DewriNo ratings yet

- Machies Singly ExcitedDocument15 pagesMachies Singly ExcitedMohamed ElfekyNo ratings yet

- EquivalEquivalent Circuit of Single-Phase Induction Motorent Circuit of Single-Phase Induction MotorDocument13 pagesEquivalEquivalent Circuit of Single-Phase Induction Motorent Circuit of Single-Phase Induction Motoraili_avinashNo ratings yet

- PSIM MANUAL For StudentsDocument23 pagesPSIM MANUAL For StudentsSomnath Khamaru75% (4)

- MMME2104 Synchronous Generators Electrical ComponentsDocument38 pagesMMME2104 Synchronous Generators Electrical ComponentsMd Rodi BidinNo ratings yet

- Closed Loop Control of Separately Excited DC MotorDocument13 pagesClosed Loop Control of Separately Excited DC MotorJAIRAJ MIRASHINo ratings yet

- Ac Machines Lab ManualDocument102 pagesAc Machines Lab ManualAshwin Gopinath100% (3)

- Single Phase Half Controlled Converter With R LoadDocument3 pagesSingle Phase Half Controlled Converter With R LoadB ANIL KUMARNo ratings yet

- SSSC PPT (Autosaved)Document14 pagesSSSC PPT (Autosaved)shubham bansalNo ratings yet

- Four Quadrant Operation of DC Drives: - Dual ConvertersDocument12 pagesFour Quadrant Operation of DC Drives: - Dual ConvertersDr.K.Krishna Veni ProfessorNo ratings yet

- Solid State Controller of Drives - ExperimentDocument37 pagesSolid State Controller of Drives - ExperimentRakesh Singh LodhiNo ratings yet

- AKT - Cycloconverter CDocument19 pagesAKT - Cycloconverter CDrAshok Kumar TiwariNo ratings yet

- Government Polytechnic Muzaffarpur: Name of The Lab: Power Electronics & DrivesDocument18 pagesGovernment Polytechnic Muzaffarpur: Name of The Lab: Power Electronics & DrivesVK DNo ratings yet

- PX7203-Special Electrical Machines PDFDocument11 pagesPX7203-Special Electrical Machines PDFvaishnavisriNo ratings yet

- Assignment Induction MotorsDocument3 pagesAssignment Induction MotorsMallikarjunBhiradeNo ratings yet

- Injection of EMF in The Rotor CircuitDocument3 pagesInjection of EMF in The Rotor CircuitAbhishekGuptaNo ratings yet

- Unit 3Document5 pagesUnit 3Narasimman DonNo ratings yet

- VTU Guide Measures Resistance Using Wheatstone BridgeDocument18 pagesVTU Guide Measures Resistance Using Wheatstone Bridgevnyshreyas100% (2)

- Solid State Drives Short BookDocument48 pagesSolid State Drives Short BookGomathi Raja MNo ratings yet

- Flexible AC Transmission SystemDocument3 pagesFlexible AC Transmission SystemSatya SahaNo ratings yet

- Brake Test On 3 Phase Slip Ring Induction MotorDocument5 pagesBrake Test On 3 Phase Slip Ring Induction MotorRajeev Sai0% (1)

- Synchronous Generators - 2 Marks Questions and AnswersDocument3 pagesSynchronous Generators - 2 Marks Questions and AnswersJoseph Harindranath67% (3)

- Sem QuestionsDocument11 pagesSem QuestionsRojaNo ratings yet

- Power System Stability - Unit 4 PSOCDocument57 pagesPower System Stability - Unit 4 PSOChareesh.makesuNo ratings yet

- IDA - QuesbankDocument10 pagesIDA - QuesbankKavitha KaviNo ratings yet

- Design & Fabrication of 1-Ph Induction Motor Starter MANUALDocument5 pagesDesign & Fabrication of 1-Ph Induction Motor Starter MANUALSreenidhi SrungaramNo ratings yet

- 360 Topic 6 DC MachineDocument33 pages360 Topic 6 DC MachineAchsan ArfandiNo ratings yet

- DC MachinesDocument52 pagesDC MachinesArun Kumar100% (1)

- Scott Connection of Transformers TitleDocument6 pagesScott Connection of Transformers TitleSheri Abhishek ReddyNo ratings yet

- III Eee 05 Ee8501 Psa Unit 1Document37 pagesIII Eee 05 Ee8501 Psa Unit 1BALAKRISHNANNo ratings yet

- BrakingDocument19 pagesBrakingMohammad Umar RehmanNo ratings yet

- MA-415 Industrial Drives Lab IndexDocument19 pagesMA-415 Industrial Drives Lab IndexMayankJainNo ratings yet

- DC Shunt Motor Change DrictionDocument4 pagesDC Shunt Motor Change Drictionnved01No ratings yet

- ED LAB ManualDocument31 pagesED LAB Manualmanoj kumar100% (1)

- Dcmotors and Their RepresentationDocument61 pagesDcmotors and Their RepresentationSoeprapto AtmariNo ratings yet

- Lab#3A: Full-Wave Bridge Rectifier Circuit Without and With FilterDocument6 pagesLab#3A: Full-Wave Bridge Rectifier Circuit Without and With FilterSadil BatafNo ratings yet

- Power Electronics Converters and their Control for Renewable Energy ApplicationsFrom EverandPower Electronics Converters and their Control for Renewable Energy ApplicationsArezki FekikNo ratings yet

- PS Lab ManualDocument25 pagesPS Lab ManualPhani PhaniNo ratings yet

- Induction MatlabDocument12 pagesInduction Matlabgrido002No ratings yet

- EM2 - Lab - 10 - Synchronous Motor Part I - STD PDFDocument7 pagesEM2 - Lab - 10 - Synchronous Motor Part I - STD PDFneonNo ratings yet

- Analysis of Self Excited Induction Generator Delta Connected Resistive LoadDocument24 pagesAnalysis of Self Excited Induction Generator Delta Connected Resistive LoadHemant KumarNo ratings yet

- Lab Report: Engineering Analysis and Design (EEN 206)Document6 pagesLab Report: Engineering Analysis and Design (EEN 206)saksham mahajanNo ratings yet

- Speed Control of DC Motor by Armature Resistance ControlDocument8 pagesSpeed Control of DC Motor by Armature Resistance ControlKosigar ChelladoraiNo ratings yet

- Braking Schemes of TractionDocument7 pagesBraking Schemes of TractionSuraj BhushanNo ratings yet

- Experiment No: 2 19BEE069 Date:-18/01/2022Document5 pagesExperiment No: 2 19BEE069 Date:-18/01/2022R.D SutariyaNo ratings yet

- Three Phase Inductioin Motor Test AhmedDocument9 pagesThree Phase Inductioin Motor Test Ahmedmearggebremedhin2013No ratings yet

- Plant specification and bill of quantityDocument4 pagesPlant specification and bill of quantitylewgne08No ratings yet

- Constant Log BCJR Turbo Decoder With Pipelined ArchitectureDocument5 pagesConstant Log BCJR Turbo Decoder With Pipelined ArchitectureInternational Journal of Scientific Research and Engineering StudiesNo ratings yet

- Electrical ConduitsDocument8 pagesElectrical ConduitsFrisco Gabriel100% (1)

- Learning Element 3Document17 pagesLearning Element 3niel lunaNo ratings yet

- Rockwell-Samsung RC1 Controller ManualDocument330 pagesRockwell-Samsung RC1 Controller ManualTấn Hồ0% (1)

- Justin Snyder ResumeDocument1 pageJustin Snyder Resumeapi-437591351No ratings yet

- Problem 2.87Document5 pagesProblem 2.87Eric Castillo MartínezNo ratings yet

- TSSN Question Bank Ece IV NRCMDocument17 pagesTSSN Question Bank Ece IV NRCMbooks babu100% (1)

- Crydom DC60 DataSheetDocument6 pagesCrydom DC60 DataSheetJose Carlos SoaresNo ratings yet

- GPCB Late Fees CircularDocument2 pagesGPCB Late Fees CircularChirag JainNo ratings yet

- Electrical Machines-I Lab ManualDocument62 pagesElectrical Machines-I Lab ManualRaviNo ratings yet

- To Design and Simulate Priority EncoderDocument6 pagesTo Design and Simulate Priority EncoderShubham GargNo ratings yet

- HIGH SPEED NETWORK Final Exam (A)Document2 pagesHIGH SPEED NETWORK Final Exam (A)Hussein A. AlsameeNo ratings yet

- Bandwidth Enhancement Using Microstrip Patch Antenna - Project Phase-1Document104 pagesBandwidth Enhancement Using Microstrip Patch Antenna - Project Phase-1Rbalaji BeeceNo ratings yet

- Full-Color Micro-LED Display With CsPbBr3 Perovskite and CdSe Quantum Dots As Color Conversion LayersDocument6 pagesFull-Color Micro-LED Display With CsPbBr3 Perovskite and CdSe Quantum Dots As Color Conversion Layers18maxwell61No ratings yet

- Change Over Socomec ATYS-PMDocument2 pagesChange Over Socomec ATYS-PMHrvoje DubravaNo ratings yet

- Transition From MELSEC-A&QnA (Large Type) Series To Q Series Handbook (Fundamentals) L08043enggDocument298 pagesTransition From MELSEC-A&QnA (Large Type) Series To Q Series Handbook (Fundamentals) L08043enggAym BrNo ratings yet

- Electrical Transformer Losses GuideDocument4 pagesElectrical Transformer Losses GuidesauravNo ratings yet

- Selection Guide of Tonghui Accessories 20181227Document17 pagesSelection Guide of Tonghui Accessories 20181227prasadNo ratings yet

- Inspiron 24 5400 Aio - Service Manual - en UsDocument73 pagesInspiron 24 5400 Aio - Service Manual - en Ussimplu649No ratings yet

- Amba Axi ProtocolDocument30 pagesAmba Axi Protocolanon_82531963No ratings yet

- Methods of Protection - Flameproof ExdDocument2 pagesMethods of Protection - Flameproof ExdSyam DevNo ratings yet

- Ece Smart QuillDocument21 pagesEce Smart QuillRajanikant UpadhyeNo ratings yet

- APC Symmetra PX-2Document8 pagesAPC Symmetra PX-2drastir_777No ratings yet

- Railway Track Crack DetectionDocument24 pagesRailway Track Crack Detectionraghuveertrilochan100% (1)

- Mallory Installation InstructionsDocument4 pagesMallory Installation Instructionssantacruz08aNo ratings yet

- TSI Media 48 230 Inverter Data Sheet Version 02Document2 pagesTSI Media 48 230 Inverter Data Sheet Version 02Morne PelserNo ratings yet

- 15 Panel FabricationDocument36 pages15 Panel FabricationhkshahNo ratings yet

- Input Filter Compensation For Switching Regulators by S S KelkarDocument371 pagesInput Filter Compensation For Switching Regulators by S S KelkarshrikrisNo ratings yet

- EEE363 (Exp 5) Study of The Different Loading Conditions of AlternatorDocument5 pagesEEE363 (Exp 5) Study of The Different Loading Conditions of Alternatorsalad.ass420420No ratings yet