Professional Documents

Culture Documents

D6R Series III Track Type Tractor Power Train System

Uploaded by

IH MedranoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D6R Series III Track Type Tractor Power Train System

Uploaded by

IH MedranoCopyright:

Available Formats

B

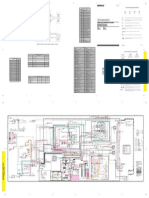

COMPONENT LIST No.

1 2 3 4 5 6 7 8 9 10 11 12 13 14

C D

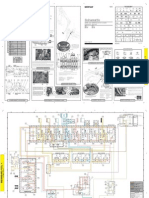

The screened main suction manifold (A) for the power train oil pump is located at the right front of the main case, near the bottom. The three-section gear-type power train oil pump (B) is mounted to the front of the main case, at the upper right. The electronic brake valve (C) is located on top of the main case, to the left of center. The torque converter inlet relief valve and the lube distribution manifold are both incorporated into one housing (D). These two components are mounted to the left front of the main case, near the bottom.

RENR7954-01 June 2006

FLUID POWER SYMBOLS

BASIC COMPONENT SYMBOLS

MAIN AUX.

PUMP or MOTOR

FLUID CONDITIONER

SPRING

CONTROL VALVES

RESTRICTION

Schematic Location

C-4 A-5 E-5 E-4 N/A D-3 B-1 C-4 E-5 F-6 A-6 B-2 N/A N/A

Part Number

226-3902 235-5812 213-1308 263-9949 9G-5127 220-1418 238-1116 231-4166 220-1429 231-5969 231-5990 232-6207 241-5635 223-9039

LINE RESTRICTION (FIXED)

2-SECTION PUMP

PUMP: VARIABLE and PRESSURE COMPENSATED

Description

POWER TRAIN OIL PUMP (3 SECTION) POWER TRAIN OIL FILTERS ELECTRONIC BRAKE CONTROL VALVE LUBE DIST. / TC INLET RELIEF MANIFOLD BREATHER TORQUE CONVERTER OUTLET RELIEF VALVE OIL COOLER PUMP INLET SCREEN / HOUSING GP. TRANSMISSION AR. LEFT DRIVE / BRAKE GP. RIGHT DRIVE / BRAKE GP. TORQUE CONVERTER / HOUSING GP. DIPSTICK OIL FILL TUBE

VARIABILITY

SPRING (ADJUSTABLE)

LINE RESTRICTION (VARIABLE)

PRESSURE COMPENSATION

HYDRAULIC PNEUMATIC ENERGY TRIANGLES

LINE RESTRICTION

VARIABLE and PRESSURE COMPENSATED

ATTACHMENT

VALVE ENVELOPES

VALVES

VALVE PORTS

ONE POSITION

TWO POSITION

THREE POSITION

TWO-WAY

THREE-WAY

FOUR-WAY

CONTROL VALVES

AB AB

CHECK VALVES

P T NORMAL POSITION

P T SHIFTED POSITION

INFINITE POSITION

BASIC SYMBOL

SPRING LOADED

SHUTTLE

PILOT CONTROLLED

The power train oil pump draws oil for the torque converter charging circuit and for the transmission charging circuit from a screened suction manifold that connects to the pump at the pump inlet (E). The torque converter charging section (F) of the power train oil pump supplies approximately 145 L/min. (38.3 US gal./min.) of oil to the torque converter circuit for operation of the torque converter and for lubrication purposes.

PRESSURE

MEASUREMENT

ROTATING SHAFTS

TEMPERATURE

FLOW

UNIDIRECTIONAL

BIDIRECTIONAL

G

Tap Locations

Tap Number

ER1 B P M N L2 L1 LB1 LB2 CL1 CL2 CL3 CL4 CL5 AA BB

The transmission charging section (G) of the power train oil pump supplies approximately 54 L/min. (14.3 US gal./min.) of oil to the transmission and brakes circuit.

F E

D6R Series III Track-Type Tractor Power Train System

GJB1-UP WCB1-UP HDC1-UP RFC1-UP TBC1-UP JEK1-UP HCD1-UP HKE1-UP WRG1-UP MTJ1-UP DMK1-UP LGP1-UP JDL1-UP DLM1-UP LFM1-UP EXL1-UP DPS1-UP EXW1-UP GMT1-UP MRT1-UP

FLUID STORAGE RESERVOIRS

VENTED

PRESSURIZED

RETURN ABOVE FLUID LEVEL

RETURN BELOW FLUID LEVEL

COMBINATION CONTROLS

Schematic Location

C-1 E-6 D-8 E-4 D-3 E-2 C-8 E-6 A-6 C-6 C-7 D-7 D-7 D-6 A-4 A-5

Description

ENGINE SPEED TRANS. GEAR P/T OIL TYPE PTO SUMP OIL TEMP BRAKE PRESSURE TRANS. MAIN RELIEF T/C SUPPLY PRESSURE T/C OUTLET PRESSURE FLYWHEEL LUBE PRESSURE TRANS. LUBE PRESSURE L BRAKE LUBE PRESSURE R BRAKE LUBE PRESSURE TRANS. CLUTCH 1 PRESSURE TRANS. CLUTCH 2 PRESSURE TRANS. CLUTCH 3 PRESSURE TRANS. CLUTCH 4 PRESSURE TRANS. CLUTCH 5 PRESSURE PTO SAMPLING PORT (SOS) PTO PRESSURE

The transmission and torque converter scavenge section (H) of the power train oil pump draws approximately 125 L/min. (33 US gal./min.) from the torque divider case, and the transmission case.

SOLENOID

SOLENOID or MANUAL

SOLENOID and PILOT

SOLENOID and PILOT or MANUAL

SERVO

THERMAL

DETENT

The scavenge oil is used for lubrication of the steering differential. The power train oil temperature sensor (I) provides main sump oil temperature information to the Machine ECM. This is the temperature sensor that is considered when performing power train calibrations, such as brake touch-ups and transmission clutch fill calibrations.

MANUAL CONTROL SYMBOLS

PUSH-PULL LEVER

MANUAL SHUTOFF

GENERAL MANUAL

PUSH BUTTON

PEDAL

SPRING

PILOT CONTROL SYMBOLS

RELEASED PRESSURE REMOTE SUPPLY PRESSURE

The torque converter inlet relief valve (J) and the lube distribution manifold (L) are both contained in one housing. Oil from the torque converter charging section of the power train oil pump is supplied to the torque converter inlet relief valve through the upper hose (K). The torque converter inlet relief valve is installed in the housing. Excess oil flows past the inlet relief valve into the main sump through a port in the front of the case, and behind the housing. Oil flow to the torque converter inlet is through the hose on the right (N). Cooled oil from the power train oil cooler is directed to the lube distribution manifold (L) through the hose on the left (M). The smaller hose (P) is the line leading to the remote pressure test port for torque converter inlet pressure ( M ). This remote pressure test port is located inside the front compartment on the right fender

EXTERNAL RETURN

INTERNAL RETURN

SIMPLIFIED

COMPLETE

INTERNAL SUPPLY PRESSURE

ACCUMULATORS

CROSSING AND JOINING LINES

HYDRAULIC AND PNEUMATIC CYLINDERS

SPRING LOADED

GAS CHARGED

LINES CROSSING

LINES JOINING

SINGLE ACTING

DOUBLE ACTING

HYDRAULIC PUMPS

FIXED DISPLACEMENT VARIABLE DISPLACEMENT NON-COMPENSATED

HYDRAULIC MOTORS

FIXED DISPLACEMENT VARIABLE DISPLACEMENT NON-COMPENSATED

INTERNAL PASSAGEWAYS

INFINITE POSITIONING THREE POSITION TWO POSITION

UNIDIRECTIONAL

UNIDIRECTIONAL

FLOW IN ONE DIRECTION PARALLEL FLOW CROSS FLOW FLOW ALLOWED IN EITHER DIRECTION

BIDIRECTIONAL

BIDIRECTIONAL

Power Train Oil Pump 1

2006 Caterpillar All Rights Reserved

Printed in U.S.A.

Electrical Symbols Table

AA

P

Transmission Charge Circuit Accumulator Transmission Lube Temperature Sensor

BB

AA

BB

Hydraulic Symbols (Electrical)

G

Transducer (Fluid) Transducer (Gas / Air) Generator

M

Electric Motor

CL1 CL2 CL3 CL4 CL5 P L1

10

LB1

12

L1

CL4

CL5

CL3

CL2

CL1

Pressure Switch

Pressure Switch (Adjustable)

Temperature Switch

Electrical Symbols (Electrical)

T

L1

RENR7954-01

Electrical Wire

Pressure Symbol

CL4

Temperature Symbol

Level Symbol

Flow Symbol

CL5

ECPC XMSN Clutch Valves

Wire Number Identification Codes

M N

CL3

Electrical Schematic Example

Current Standard

Harness identification code This example indicates wire 135 in harness "AG". Wire

Hydraulic Schematic Example

Current Standard

11

LB2

AA

CL2

Opening the top door of the forward compartment on the right fender gains access to the combination power train oil fill tube and dipstick (Q). Transmission Lube Temperature Sensor Transmission Housing Opening the front door of the forward compartment on the right fender gains access to the power train oil filter (S). This spin-on type canister contains a replaceable 6-micron filter element. The filter base contains a filter bypass switch (R). This is a normally open switch that is held closed by the filter bypass valve spool. The bypass valve opens, allowing the switch to open, when the difference in pressure between the filter inlet and the filter outlet becomes great enough (approximately 50 psi). The switch is monitored by the Caterpillar Monitoring System and alerts the operator to the filter bypass condition. The filter base also contains the power train oil sampling (AA) and a pressure test port (BB) for the transmission charging circuit. The pressure test port is situated downstream from the filter. The power train oil sampling port is situated upstream, or before the filter.

13 14

CL1

Circuit Number Identification

Wire Color

CL1 CL2 CL3 CL4 CL5 P L1

325-AG135 PK-14 325-PK

Circuit Identification Number Wire Color Wire Gauge

5 13 14

AA

Located at the rear of the machine, on top of the the transmission case are the following service points: 1. Transmission main relief pressure test port (P) 2. Transmission lube pressure test port (L1) 3. Transmission lube temperature sensor Pressure test ports for each of the five transmission clutches remain on the transmission cover. These pressure test ports are: (CL1). Transmission clutch (reverse clutch) (CL2). Transmission clutch (forward clutch) (CL3). Transmission clutch (speed 3) (CL5). Transmission clutch (speed 1) (CL4). Transmission clutch (speed 2) Clutch engagement pressure calibrations are no longer required, with the common top pressure strategy. Proper adjustment of the transmission main relief valve will set the proper pressure for the operation of all five transmission clutches and the brakes. It is still necessary to perform transmission clutch fill calibrations and to perform brake touch-up calibrations.

Also located in the forward compartment on the right fender and inboard from the power train oil filter canister are the following service points: (T). remote power train breather (M). remote pressure test port for torque converter inlet pressure (N). remote pressure test port for torque converter outlet pressure

Previous Standard

Wire Wire Color

325-PK-14

Power Train Oil Filter Group 2

B

Circuit Number Identification Wire Gauge

(EXAMPLE VALVE)

Engine Oil Cooler The transmission charge circuit accumulator is mounted beneath the fuel tank and located above the transmission case. This accumulator is pre-charged to approximately 1724 kPa (250 psi). It is used to help maintain transmission charge circuit pressure for short periods of time, such as when transmission clutches are filling (shifts) or at other times when the pressure in the transmission charging circuit may become too low (cold oil, low idle, etc.). Power Train Oil Cooler

11 10

LB1 LB2

12

CL4

CL5

Right Side

CL2

CL3

ECPC XMSN Clutch Valves

Left Side

Transmission Charge Circuit Accumulator

Below and to the rear of the engine oil cooler is the oil-to-water type power train oil cooler.

CL1

Component and Tap Locations

Transmission Group 9

Power Train Oil Cooler 7

24 Page

L1

LB1

CLUTCH/BRAKES

10

CL4 CL1

LUBE BRAKE

LEFT BRAKE PRESSURE PORT

9

CL5 CL3 CL2

E

EB BRAKE VALVE

L2 M

FLYWHEEL HOUSING

B

PROPORTIONAL VALVE XMSN LUBE

3

MAIN RELIEF 2ND 3RD 1ST

IMPLEMENT PUMP

ENGINE

CL4

CL3

CL5

PROPORTIONAL VALVE

D

DIFF STEER BEVEL & TRANSFER GEAR LUBE

P

PROPORTIONAL VALVE PROPORTIONAL VALVE

6

TORQUE CONVERTER

PROPORTIONAL VALVE PROPORTIONAL VALVE VENT LINE

XL, XW, LGP 200 NET HP STD 185 NET HP AT 1850 RPM

C9

ECPC XMSN CLUTCH VALVES

RENR7954-01

CL2

FWD

CL1

REV

PTO TEMP. SENSOR

ER1

SUCTION SCREEN

24 Page, Color 2

L1

TRANS. LUBE TEMP. SENSOR

SCREEN

DRIVESHAFT

SCAV

SCAVENGE OUTPUT AND DIFF STEER LUBE TRANSMISSION CONTROL VALVE

TRANS B

T/C C

12

POWERTRAIN OIL COOLER

7

B B

BRAKE

LUBE

11

RIGHT BRAKE PRESSURE PORT

AA

CLUTCH/BRAKES

LB2

BB

LINE PATTERNS

Pressure Line Pilot / Load Sensing Pressure Drain / Return Lines Component Group

2

A

NOTES: (A) TRANSMISSION AND CONVERTER SCAVENGE PUMP (B) TRANSMISSION CHARGE PUMP (C) TORQUE CONVERTER CHARGE PUMP

HYDRAULIC CIRCUIT COLOR DESCRIPTIONS

Brakes. Supply Line. Drain / Return Line. Transmission Charge Pump. Transmission and Torqueconverter Scavenge Pump Torque Converter Charge Pump and Powertrain Oil Cooler

Attachment Air Line

CALLOUTS

YY

Taps (Pressure, Sampling,Sensor) by letter Components by number

THIS SCHEMATIC IS FOR THE D6R TRACK-TYPE TRACTOR

PART #: 270-8369 CHG 01

Components are shown installed on a fully operable machine with the key and engine off and transmission shifter in neutral. Refer to the appropriate Service Manual for Troubleshooting, Specifications and Systems Operations

52

You might also like

- Transmision Electronica (D6R)Document51 pagesTransmision Electronica (D6R)A Ramos Gaby96% (27)

- Plano Electrico Cat D6RDocument9 pagesPlano Electrico Cat D6Redhuam86% (14)

- Curso Cat d6r III STMGDocument73 pagesCurso Cat d6r III STMGSilas F Pimenta89% (19)

- Kel 4. C-D6R TextsDocument22 pagesKel 4. C-D6R TextsGregk Dirgantara100% (3)

- CalibrationXmsn - Testing AdjustingDocument44 pagesCalibrationXmsn - Testing AdjustingGustavo Alonso100% (4)

- D5MDocument42 pagesD5MPlaneamiento Mecanico90% (21)

- Manual Electronic Control System Caterpillar d5m d6m d6r Track Type Tractors Components Sensors ValvesDocument14 pagesManual Electronic Control System Caterpillar d5m d6m d6r Track Type Tractors Components Sensors ValvesRoussel Florez Zuloaga92% (13)

- Caterpillar D6R Tractor (Electronic Clutch Brake) Electrical System PDFDocument2 pagesCaterpillar D6R Tractor (Electronic Clutch Brake) Electrical System PDFdothao78% (9)

- d7r Solenide de ControlDocument12 pagesd7r Solenide de ControlDavid Ceron100% (6)

- Alert Indicator Description: Systems OperationDocument28 pagesAlert Indicator Description: Systems OperationEd Calhe100% (4)

- Cat 12H Motor Grader: Standard TypeDocument22 pagesCat 12H Motor Grader: Standard Typestopaferreira80% (5)

- Electronic Control Module (Power Train) ... 120H, 12H, 135H, 140H, 143H, 160H and 163H Motor Graders Caterpillar - Spare PartsDocument11 pagesElectronic Control Module (Power Train) ... 120H, 12H, 135H, 140H, 143H, 160H and 163H Motor Graders Caterpillar - Spare Partsbrahim50% (2)

- Manual Caterpillar d5m d6m d6r Track Type Tractors Power Train Control System Components Diagrams PDFDocument12 pagesManual Caterpillar d5m d6m d6r Track Type Tractors Power Train Control System Components Diagrams PDFBruno Cecatto86% (21)

- 12H, 140H, and 160HDocument2 pages12H, 140H, and 160HMarvin Melendez Vanegas100% (6)

- D5M D6M D6R Tractor Control System GuideDocument42 pagesD5M D6M D6R Tractor Control System GuideJulio CR100% (16)

- Sistema Control Trans 140hDocument7 pagesSistema Control Trans 140hFernando Ortiz86% (7)

- Serv1852 02 TXT2 PDFDocument24 pagesServ1852 02 TXT2 PDFابو احمد100% (13)

- Manual Completo d8rDocument151 pagesManual Completo d8redgardo-ehq91% (54)

- D6R Error CodeDocument7 pagesD6R Error CodeRajan Mullappilly100% (4)

- D6R Schematic ElectricDocument30 pagesD6R Schematic ElectricAgung Ardhana71% (7)

- Plano Hidraulico Cat D6MDocument2 pagesPlano Hidraulico Cat D6Medhuam75% (4)

- Electric 120H 5FM PDFDocument2 pagesElectric 120H 5FM PDFrprim100% (2)

- Cat D6R Hydr.&.Elec - Diagram PDFDocument11 pagesCat D6R Hydr.&.Elec - Diagram PDFMaxwell Carrasco Santi83% (6)

- Plano Hidraulico Motoniveladora 12h-140h CatDocument2 pagesPlano Hidraulico Motoniveladora 12h-140h CatJulio CR78% (9)

- 966F & 966F Series II Wheel Loaders Hydraulic SystemDocument2 pages966F & 966F Series II Wheel Loaders Hydraulic SystemAhmed Nahrawy100% (7)

- Transmision d6mDocument8 pagesTransmision d6mTeresa Marina Peralta100% (5)

- Transmision Electronica D6RDocument51 pagesTransmision Electronica D6Rmohamed100% (2)

- 320C Hydraulic Excavator Electrical SchematicDocument2 pages320C Hydraulic Excavator Electrical Schematicluiscampos7792% (12)

- D8R Electrical SystemDocument2 pagesD8R Electrical Systemwtn201389% (9)

- Hydraulic Schematic 320dlDocument2 pagesHydraulic Schematic 320dlIsaque Mateus67% (3)

- 120H CatDocument2 pages120H CatAnonymous QXT0YIj4yJ71% (7)

- Presiones de Transmision d6r IIDocument5 pagesPresiones de Transmision d6r IITeo Deustch100% (5)

- Differential Steering System : SMCS Code: 4005 4010Document18 pagesDifferential Steering System : SMCS Code: 4005 4010Balikpapan City75% (4)

- 140h Sist. Electrico - SisDocument2 pages140h Sist. Electrico - SisRodrigo Chacca100% (4)

- Cat 14h Sistema HidraulicoDocument2 pagesCat 14h Sistema HidraulicoJuan Pablo Barron Marin100% (3)

- D PWT D6riii PDFDocument2 pagesD PWT D6riii PDFDennis Olaya100% (1)

- Plano de Transmision D6TDocument2 pagesPlano de Transmision D6TronaldNo ratings yet

- D 8 TDocument2 pagesD 8 TAlberjose Sanchez RuizNo ratings yet

- RENR8305RENR8305-04 - SIS 777f 1Document4 pagesRENR8305RENR8305-04 - SIS 777f 1gadolineo100% (1)

- Sistema de Tren de PotenciaDocument2 pagesSistema de Tren de PotenciaJHOSMAR_22No ratings yet

- Diagrama Hidraulico 777FDocument4 pagesDiagrama Hidraulico 777Ffabioalbor100% (1)

- D10T Track-Type Tractor Power Train System: Rjg1-UpDocument2 pagesD10T Track-Type Tractor Power Train System: Rjg1-UpJHOSMAR_22No ratings yet

- D10TDocument2 pagesD10TjoseluisyalicoNo ratings yet

- Diagrama Hidraulico 420E CATERPILLARDocument4 pagesDiagrama Hidraulico 420E CATERPILLARjulio cesar100% (6)

- Diagrama Hidraulico D9TDocument2 pagesDiagrama Hidraulico D9TCristian Valencia100% (1)

- D10T Track-Type Tractor Hydraulic System: Dozer Control Valve 5Document2 pagesD10T Track-Type Tractor Hydraulic System: Dozer Control Valve 5Roberto Antonio Chihuaihuan Araya100% (2)

- Cat 450E Backhole Loader Hydraulic SystemDocument4 pagesCat 450E Backhole Loader Hydraulic Systemwords2zhigang_612545100% (3)

- 950H Wheel Loader Hydraulic SystemDocument2 pages950H Wheel Loader Hydraulic Systemwtn2013100% (16)

- Diagrama Hidraulico 962g CaterpillarDocument4 pagesDiagrama Hidraulico 962g CaterpillarRonald Gareca Rueda100% (1)

- 777F MG SistemasDocument118 pages777F MG SistemasDenerMendozaLayza100% (6)

- Bronze Master Exam Theory Question PaperDocument64 pagesBronze Master Exam Theory Question Paperjithinnambiar1392% (39)

- GE CF34 Engine Training DocumentDocument18 pagesGE CF34 Engine Training DocumentMadhan Ganesan100% (1)

- Plano Power Train D8TDocument2 pagesPlano Power Train D8Talexander_1985100% (3)

- 950H, 962H and IT62H Wheel Loader Hydraulic System: Command Control SteeringDocument2 pages950H, 962H and IT62H Wheel Loader Hydraulic System: Command Control SteeringRodrigo Chacca100% (2)

- Renr8879renr8879-04 Sis PDFDocument2 pagesRenr8879renr8879-04 Sis PDFMAQUINARIAPESADA100% (1)

- Diagrama Hidraulico de Power Train d8t InteractivoDocument14 pagesDiagrama Hidraulico de Power Train d8t InteractivoVeimar Gutierrez100% (1)

- Tr7-8fi ManualDocument82 pagesTr7-8fi ManualClint CooperNo ratings yet

- At DiagnosisDocument502 pagesAt Diagnosisvixentd100% (2)

- Component Locations: 777F and 777F OEM Off-Highway Truck Hydraulic SystemDocument4 pagesComponent Locations: 777F and 777F OEM Off-Highway Truck Hydraulic SystemMScLxNo ratings yet

- 777D Off Highway Truck: Service Training MalagaDocument17 pages777D Off Highway Truck: Service Training MalagaMAQUINARIAPESADA100% (4)

- S01 General Pre-Start Check List ES PDFDocument4 pagesS01 General Pre-Start Check List ES PDFIH MedranoNo ratings yet

- S00 Maintenance Frontpage General PDFDocument26 pagesS00 Maintenance Frontpage General PDFIH MedranoNo ratings yet

- S00 FrontPage Service 4101 - SP PDFDocument2 pagesS00 FrontPage Service 4101 - SP PDFIH MedranoNo ratings yet

- S05 Drillling Compartment PDFDocument60 pagesS05 Drillling Compartment PDFIH MedranoNo ratings yet

- S02 Rock Drill PDFDocument14 pagesS02 Rock Drill PDFIH MedranoNo ratings yet

- S01 General Pre-Start Check List ESDocument4 pagesS01 General Pre-Start Check List ESIH MedranoNo ratings yet

- S00 Maintenance Frontpage GeneralDocument26 pagesS00 Maintenance Frontpage GeneralIH MedranoNo ratings yet

- S06 Drilling Hydraulic Components PDFDocument26 pagesS06 Drilling Hydraulic Components PDFIH MedranoNo ratings yet

- S00 FrontPage Service 4101 - SP PDFDocument2 pagesS00 FrontPage Service 4101 - SP PDFIH MedranoNo ratings yet

- S08 Diesel Power Pack PDFDocument166 pagesS08 Diesel Power Pack PDFIH MedranoNo ratings yet

- Control Valve Parts ListDocument8 pagesControl Valve Parts ListIH MedranoNo ratings yet

- S04 Boom PDFDocument76 pagesS04 Boom PDFIH MedranoNo ratings yet

- Front Page Spare Parts 4101 PDFDocument42 pagesFront Page Spare Parts 4101 PDFIH MedranoNo ratings yet

- S00 Front Page 4101 PDFDocument4 pagesS00 Front Page 4101 PDFIH MedranoNo ratings yet

- S03 Drill Feed PDFDocument20 pagesS03 Drill Feed PDFIH MedranoNo ratings yet

- Elec QuasarDocument30 pagesElec QuasarIH MedranoNo ratings yet

- Hydraulic Cartridges Seal Kit DiagramsDocument22 pagesHydraulic Cartridges Seal Kit DiagramsIH MedranoNo ratings yet

- S18 Hydraulic HosesDocument2 pagesS18 Hydraulic HosesIH MedranoNo ratings yet

- MACHINESERIALDocument92 pagesMACHINESERIALIH MedranoNo ratings yet

- S19 Special EquipmentsDocument2 pagesS19 Special EquipmentsIH MedranoNo ratings yet

- Applications electrical diagramDocument7 pagesApplications electrical diagramIH MedranoNo ratings yet

- S17 OptionalDocument2 pagesS17 OptionalIH MedranoNo ratings yet

- Elec QuasarDocument30 pagesElec QuasarIH MedranoNo ratings yet

- Elec QuasarDocument12 pagesElec QuasarIH MedranoNo ratings yet

- Manual Del Operador - 78493697 PDFDocument92 pagesManual Del Operador - 78493697 PDFIH MedranoNo ratings yet

- Esquemas Electricos - 78114052 - ELECDocument18 pagesEsquemas Electricos - 78114052 - ELECIH MedranoNo ratings yet

- Elec QuasarDocument7 pagesElec QuasarIH MedranoNo ratings yet

- Ansul A101 Fire Suppression ManualDocument66 pagesAnsul A101 Fire Suppression Manualtincho_0026100% (3)

- Manual Del Operador - 78493697Document259 pagesManual Del Operador - 78493697IH MedranoNo ratings yet

- 9852 2654 01 Transport Instructions MT2010 CabinDocument2 pages9852 2654 01 Transport Instructions MT2010 CabinIH Medrano100% (1)

- Considerations on Using Airlift Pumps in Sewage TreatmentDocument7 pagesConsiderations on Using Airlift Pumps in Sewage TreatmentvladmmuresanNo ratings yet

- 718 ManualDocument36 pages718 Manualanon_670402309No ratings yet

- CATERPILAR3516 1550-2200 BHPDocument6 pagesCATERPILAR3516 1550-2200 BHPNadia AnandaNo ratings yet

- ALLWEILER - Volute Casing Centrifugal Pumps of Inline DesignDocument16 pagesALLWEILER - Volute Casing Centrifugal Pumps of Inline DesignHamza AbdelhamidNo ratings yet

- Project Final Phase - 1Document81 pagesProject Final Phase - 1NishantShahNo ratings yet

- HP Series Portable Manual & PartsDocument72 pagesHP Series Portable Manual & Partsseko33No ratings yet

- Marine Product Guide: Twin Disc Family of ProductsDocument57 pagesMarine Product Guide: Twin Disc Family of ProductsAnonymous hlPPOmxXB7No ratings yet

- HASS Manual Chapter 2Document18 pagesHASS Manual Chapter 2Victor Kim100% (1)

- D1146 - De08 Inject Pump ReplaceDocument8 pagesD1146 - De08 Inject Pump ReplacevarthotNo ratings yet

- Machines Hydraulics TOC CH 4-7Document4 pagesMachines Hydraulics TOC CH 4-7xan mianNo ratings yet

- CJI's Supply Chain Expansion for Great Lakes ContractDocument5 pagesCJI's Supply Chain Expansion for Great Lakes ContractTherese Chiu0% (1)

- Axial Piston Variable Pump A15VSO/A15VLODocument60 pagesAxial Piston Variable Pump A15VSO/A15VLOJesus CortesNo ratings yet

- Viron P320 XT Variable Speed Pump: DescriptionDocument1 pageViron P320 XT Variable Speed Pump: DescriptionSenghy MaoNo ratings yet

- 9A01402 Hydraulics and Hydraulic MachineryDocument4 pages9A01402 Hydraulics and Hydraulic MachinerysivabharathamurthyNo ratings yet

- 123959707-Intermix Concrete Mixers TransmissionsDocument53 pages123959707-Intermix Concrete Mixers TransmissionsFilippos100% (1)

- "L10" Drive End: Operation - Assembly Instructions and Parts List ForDocument7 pages"L10" Drive End: Operation - Assembly Instructions and Parts List ForACCA PumpsNo ratings yet

- LPG Centrifugal Spray Dryer Operation InstructionDocument9 pagesLPG Centrifugal Spray Dryer Operation InstructionM BJNo ratings yet

- Drilling ReportDocument64 pagesDrilling ReportWon-young Seo100% (2)

- HYDRA 1242 Crane Specs and FeaturesDocument2 pagesHYDRA 1242 Crane Specs and FeaturesPanchdev KumarNo ratings yet

- Whitelegg CatalogDocument208 pagesWhitelegg Cataloggigih priyandokoNo ratings yet

- DL1200 Val DR45 Om-R5Document12 pagesDL1200 Val DR45 Om-R5FAVIONo ratings yet

- Operating Manual: LKH-110, - 120 Multi-Stage Centrifugal PumpDocument24 pagesOperating Manual: LKH-110, - 120 Multi-Stage Centrifugal Pumppablo ortizNo ratings yet

- Air Operated Chassis Pump: A & A Hydraulic 800-992-9898Document16 pagesAir Operated Chassis Pump: A & A Hydraulic 800-992-9898JustinNo ratings yet

- Wilo Datasheet - International - en - 2161331 - Cronoline Il 150 325 37 4 s1 Ie3Document5 pagesWilo Datasheet - International - en - 2161331 - Cronoline Il 150 325 37 4 s1 Ie3suwono radukNo ratings yet

- PC130F-7 02 PDFDocument7 pagesPC130F-7 02 PDFMeka PratamaNo ratings yet

- K3V112DT Instruction Manual OverviewDocument40 pagesK3V112DT Instruction Manual Overviewjuanchis650100% (7)

- Steam Jet RefrigerationDocument3 pagesSteam Jet RefrigerationParag ParekhNo ratings yet

- Emerson Air Compressor VISSION 20 - 20Document80 pagesEmerson Air Compressor VISSION 20 - 20Edgar Joel Torres OlórteguiNo ratings yet

- Lars Specifications 1655476794 1655476998Document7 pagesLars Specifications 1655476794 1655476998adrian luthfiNo ratings yet

- BPCL Report MechanicalDocument44 pagesBPCL Report MechanicalritikaNo ratings yet