Professional Documents

Culture Documents

Automotive Wiring and Circuit Diagrams

Uploaded by

Quangvu HoangCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automotive Wiring and Circuit Diagrams

Uploaded by

Quangvu HoangCopyright:

Available Formats

CM-CH04

6/4/02

2:57 PM

Page 91

C H A P T E R

Wiring and Circuit Diagrams

Upon completion and review of this chapter, you should be able to: Explain when single-stranded or Explain how temperature affects multistranded wire should be used. resistance and wire size selection. Explain the purpose and use of printed Explain the use of resistive wires in a circuits. circuit. Explain why wiring harnesses are used Describe the construction of spark plug and how they are constructed. wires. Explain the purpose of wiring diagrams. Explain how wire size is determined by Identify the common electrical symbols the American Wire Gauge (AWG) and that are used. metric methods. Explain the purpose of the component Describe how to determine the correct locator. wire gauge to be used in a circuit.

Introduction

Todays vehicles have a vast amount of electrical wiring that, if laid end to end, could stretch for half a mile or more. Todays technician must be proficient at reading wiring diagrams in order to sort though this great maze of wires. Trying to locate the cause of an electrical problem can be quite difficult if you do not have a good understanding of wiring systems and diagrams. In this chapter, you will learn how wiring harnesses are made, how to read the wiring diagram, how to interpret the symbols used, and how terminals are used. This will reduce the amount of confusion you may experience when repairing an electrical circuit. It is also important to understand how to determine the correct type and size of wire to carry the anticipated amount of current. It is possible to cause an electrical problem by simply using the wrong gauge size of wire. A technician must understand the three factors that cause resistance in a wirelength, diameter, and temperatureto perform repairs correctly.

Automotive Wiring

Primary wiring is the term used for conductors that carry low voltage. The insulation of primary wires is usually thin. Secondary wiring refers to wires used to carry high voltage, such as ignition spark plug wires. Secondary wires have extra thick insulation. Most of the primary wiring conductors used in the automobile are made of several strands of copper wire wound together and covered with a polyvinyl chloride (PVC) insulation (Figure 4-1). Copper has low resistance and can be connected to easily by using crimping connectors or soldered connections. Other types of conductor materials used in automobiles include silver, gold, aluminum, and tin-plated brass.

AUTHORS NOTE: Copper is used mainly because of its low cost and availability.

Primary wiring refers to smaller wire with light insulation.

Secondary wiring refers to larger wire or cable with heavier insulation.

91

CM-CH04

6/4/02

2:57 PM

Page 92

PVC insulation

Stranded conductor

Figure 4-1 Stranded primary wire.

Stranded wire means the conductor is made of several individual wires that are wrapped together. A ballast resistor reduces the current flow through the ignition coil to increase the life of the coil. The resistance value of the ballast resistor is usually between 0.8 and 1.2 ohms. Resistance wire is designed with a certain amount of resistance per foot. Spark plug wires are often referred to as television-radiosuppression (TVRS) cables.

Stranded wire is used because it is very flexible and has less resistance than solid wire. This is because electrons tend to flow on the outside surface of conductors. Since there is more surface area exposed in a stranded wire (each strand has its own surface), there is less resistance in the stranded wire than in the solid wire (Figure 4-2). The PVC insulation is used because it can withstand temperature extremes and corrosion. PVC insulation is also capable of withstanding battery acid, antifreeze, and gasoline. The insulation protects the wire from shorting to ground and from corrosion.

AUTHORS NOTE: General Motors has used single-stranded aluminum wire in limited applications where no flexing of the wire is expected. For example, it is used in the taillight circuits.

A ballast resistor is used by some manufacturers to protect the ignition primary circuit from excessive voltage. It reduces the current flow through the coils primary windings and provides a stable voltage to the coil. Some automobiles use a resistance wire in the ignition system instead of a ballast resistor. This wire is called the ballast resistor wire and is located between the ignition switch and the ignition coil (Figure 4-3) in the ignition RUN circuit. Spark plug wires are also resistance wires. The resistance lowers the current flow through the wires. By keeping current flow low, the magnetic field created around the wires is kept to

Electrons

Electrons

Conductors (A) Stranded wire (B) Single strand wire

Conductor

Figure 4-2 Stranded wire provides flexibility and more surface area for electron flow than a single-strand solid wire.

92

CM-CH04

6/4/02

2:57 PM

Page 93

Battery

Switch

Starting bypass

Ballast (primary resistor) Coil primary winding Coil secondary winding

Figure 4-3 Ballast resistor used in some ignition primary wiring circuits.

a minimum. The magnetic field needs to be controlled because it causes radio interference. The result of this interference is noise on the vehicles radio and all nearby radios and televisions. The noise can interfere with emergency broadcasts and the radios of emergency vehicles. Because of this concern, all ignition systems are designed to minimize radio interference; most do so with resistance-type spark plug wires. Spark plug wires are targeted because they carry high voltage pulses. The lower current flow has no adverse effect on the firing of the spark plug. Most spark plug wire conductors are made of nylon, rayon, fiberglass, or aramid thread impregnated with carbon. This core is surrounded by rubber (Figure 4-4). The carbon-impregnated core provides sufficient resistance to reduce RFI, yet does not affect engine operation. As the spark plug wires wear because of age and temperature changes, the resistance in the wire will change. Most plug wires have a resistance value of 3,000 to 6,000 per foot. However, some have between 6,000 and 12,000 . The accepted value when testing is 10,000 per foot as a general specification. Because the high voltage within the plug wires can create electromagnetic induction, proper wire routing is important to eliminate the possibility of cross-fire. To prevent cross-fire, the plug wires must be installed in the proper separator. Any two parallel wires next to each other in the firing order should be positioned as far away from each other as possible (Figure 4-5). When induction cross-fire occurs, no spark is jumped from one wire to the other. The spark is the result of induction from another field. Cross-fire induction is most common in two parallel wires that fire one after the other in the firing order.

Cross-fire is the electromagnetic induction spark that can be transmitted in another wire close to the wire carrying the current.

Glass and cotton braid Insulation Core Jacket hypalon normal silicon high temperature

Figure 4-4 Typical spark plug wire.

93

CM-CH04

6/4/02

2:57 PM

Page 94

Cable bracket

Plug cables 7 and 8 separated in cable bracket 7 8 Left bank engine cylinders

Firing orders and cylinder numbering vary among the different engines

Example: firing order 1-5-4-2-6-3-7-8

Figure 4-5 Proper spark plug wire routing to prevent cross-fire. (Reprinted with the permission of Ford Motor Company)

Wire Sizes

An additional amount of consideration must be given for some margin of safety when selecting wire size. There are three major factors that determine the proper size of wire to be used: 1. The wire must have a large enough diameter, for the length required, to carry the necessary current for the load components in the circuit to operate properly. 2. The wire must be able to withstand the anticipated vibration. 3. The wire must be able to withstand the anticipated amount of heat exposure. Wire size is based on the diameter of the conductor. The larger the diameter, the less the resistance. There are two common size standards used to designate wire size: American Wire Gauge (AWG) and metric. The AWG standard assigns a gauge number to the wire based on its diameter. The higher the number, the smaller the wire diameter. For example, 20-gauge wire is smaller in diameter than 10-gauge wire. Most electrical systems in the automobile use 14-, 16-, or 18-gauge wire. Some high current circuits will also use 10- or 12-gauge wire. Most battery cables are 2-, 4-, or 6-gauge cable. Both wire diameter and wire length affect resistance. Sixteen-gauge wire is capable of conducting 20 amperes for 10 feet with minimal voltage drop. However, if the current is to be carried for 15 feet, 14-gauge wire would be required. If 20 amperes were required to be carried for 20 feet, then 12-gauge wire would be required. The additional wire size is needed to prevent voltage drops in the wire. The illustration (Figure 4-6) lists the wire size required to carry a given amount of current for different lengths. Another factor to wire resistance is temperature. An increase in temperature creates a similar increase in resistance. A wire may have a known resistance of 0.03 ohms per 10 feet at 70F. When exposed to temperatures of 170F, the resistance may increase to 0.04 ohms per 10 feet. Wires that are to be installed in areas that experience high temperatures, as in the engine compartment, must be of a size such that the increased resistance will not affect the operation of the load component. Also, the insulation of the wire must be capable of withstanding the high temperatures. In the metric system, wire size is determined by the cross-sectional area of the wire. Metric wire size is expressed in square millimeters (mm2). In this system the smaller the number, the smaller the wire conductor. The approximate equivalent wire size of metric to AWG is shown (Figure 4-7).

94

The number assigned to a wire to indicate its size is referred to as gauge.

CM-CH04

6/4/02

2:57 PM

Page 95

Total Approximate Circuit Amperes 12 V 1.0 1.5 2 3 4 5 6 7 8 10 11 12 15 18 20 22 24 30 40 50 100 150 200 3 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 16 12 10 10

Wire Gauge (for Length in Feet) 5 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 16 16 14 12 10 8 7 18 18 18 18 18 18 18 18 18 18 18 18 18 16 16 16 16 16 14 12 10 8 8 10 18 18 18 18 18 18 18 18 18 18 18 18 18 16 16 16 16 14 12 12 10 8 6 15 18 18 18 18 18 18 18 18 18 16 16 16 14 14 14 12 12 10 10 10 6 4 4 20 18 18 18 18 18 18 18 18 16 16 16 16 14 14 12 12 12 10 10 10 6 4 4 25 18 18 18 18 18 18 16 16 16 16 14 14 12 12 10 10 10 10 8 8 4 2 2 30 18 18 18 18 16 16 16 16 16 14 14 14 12 12 10 10 10 10 8 8 4 2 2 40 18 18 18 18 16 16 16 14 14 12 12 12 12 10 10 10 10 10 6 6 4 2 1

Note: 18 AWG as indicated above this line could be 20 AWG electrically. 18 AWG is recommended for mechanical strength.

Figure 4-6 The distance the current must be carried is a factor in determining the correct wire gauge to use.

Metric Size (mm2) 0.5 0.8 1.0 2.0 3.0 5.0 8.0 13.0 19.0

AWG (Gauge) Size 20 18 16 14 12 10 8 6 4

Ampere Capacity 4 6 8 15 20 30 40 50 60

Figure 4-7 Approximate AWG to metric equivalents.

95

CM-CH04

6/4/02

2:57 PM

Page 96

Terminals and Connectors

Shop Manual Chapter 4, page XX

To perform the function of connecting the wires from the voltage source to the load component reliably, terminal connections are used. Todays vehicles can have as many as 500 separate circuit connections. The terminals used to make these connections must be able to perform with very low voltage drop. Terminals are constructed of either brass or steel. Steel terminals usually have a tin or lead coating. A loose or corroded connection can cause an unwanted voltage drop that results in poor operation of the load component. For example, a connector used in a light circuit that has as little as 10% voltage drop (1.2V) may result in a 30% loss of lighting efficiency. Terminals can be either crimped or soldered to the conductor. The terminal makes the electrical connection and it must be capable of withstanding the stress of normal vibration. The illustration (Figure 4-8) shows several different types of terminals used in the automotive electrical system. In addition, the following connectors are used on the automobile:

1. Molded connector: These connectors usually have one to four wires that are

Shop Manual Chapter 4, page XX

molded into a one-piece component (Figure 4-9). Although the connector halves separate, the connector itself cannot be taken apart.

2. Multiple-wire hard-shell connector: These connectors usually have a hard plastic

Shop Manual Chapter 4, page XX

shell that holds the connecting terminals of separate wires (Figure 4-10). The wire terminals can be removed from the shell to be repaired.

3. Bulkhead connectors: These connectors are used when several wires must pass

through the bulkhead (Figure 4-11).

4. Weather-Pack Connectors: These connectors have rubber seals on the terminal

Shop Manual Chapter 4, page XX

ends and on the covers of the connector half (Figure 4-12). They are used on computer circuits to protect the circuit from corrosion, which may result in a voltage drop.

Ring terminal Three-way Y connector

Spade terminal Snap plug terminal Hook terminal

Butt splice

Quick disconnect terminal

Figure 4-8 Primary wire terminals used in automotive applications.

96

CM-CH04

6/4/02

2:57 PM

Page 97

Figure 4-9 Molded connectors cannot be disassembled to replace damaged terminals.

5. Metri-Pack Connectors: These are like the weather-pack connectors but do not

have the seal on the cover half (Figure 4-13).

6. Heat Shrink Covered Butt Connectors: Recommended for air bag applications by

Shop Manual Chapter 4, page XX

some manufacturers. Other manufacturers allow NO repairs to the circuitry, while still others require silver-soldered connections. To reduce the number of connectors in the electrical system, a common connection can be used (Figure 4-14). If there are several electrical components that are physically close to each other, a single common connection (splice) eliminates using a separate connector for each wire.

Printed Circuits

Most instrument panels use printed circuit boards as circuit conductors. A printed circuit is made of a thin phenolic or fiberglass board that copper (or some other conductive material) has been deposited on. Portions of the conductive metal are then etched or eaten away by acid. The remaining strips of conductors provide the circuit path for the instrument panel illumination lights, warning lights, indicator lights, and gauges of the instrument panel (Figure 4-15). The printed circuit board is attached to the back of the instrument panel housing. An edge connector joins the printed circuit board to the vehicle wiring harness. Whenever it is necessary to perform repairs on or around the printed circuit board, it is important to follow these precautions: 1. When replacing light bulbs, be careful not to cut or tear the surface of the printed circuit board.

Common connections are used to share a source of power or a common ground and are often called a splice. Printed circuit boards are used to simplify the wiring of the circuits they operate. Other uses of printed circuit boards include the inside of radios, computers, and some voltage regulators.

97

CM-CH04

6/4/02

2:57 PM

Page 98

Amp connector Shoulder Locking tab Socket contact Bridge Locking tab Pin contact

Locking wedge connector Groove Retaining finger Wedge

Latching leg Tang connector T Plastic spring

Groove

Shoulder Wedge Locking tang Latching tongue Latching tongue Latching tongue

Blade connector

Internal locking finger connector

Locking finger Socket contact

Socket contact T-shaped T slots Locking fingers Cut-out notch Locking finger Pin contact Cut-out notch

Blade contact

Printed circuit connector

Locking finger

Finger notch Contact finger

Locking finger

Figure 4-10 Multiple-wire hard shell connectors.

98

CM-CH04

6/4/02

2:57 PM

Page 99

Figure 4-11 Bulkhead connector. (Courtesy of DaimlerChrysler Corporation)

Figure 4-12 Weather-pack connector is used to prevent connector corrosion.

Figure 4-13 Metri-pack connector.

Light switch 0.8 Blk 150

Brake pressure switch 0.8 Blk 150

Instrument panel printed circuit 0.8 Blk 0.8 Blk 150 150

Audio alarm assembly 0.8 Blk 150

Heater A/C switch light 0.8 Blk 150

Radio 0.8 Blk

Ashtray light 0.8 Blk

150

C219 0.8 Blk 150 Common connections S205 150 0.8 Blk G200 150 Clock Cigarette lighter

Common ground

Figure 4-14 Common connections (splices) are used to reduce the amount of wire and connectors.

2. Do not touch the surface of the printed circuit with your fingers. The acid present in

normal body oils can damage the surface. 3. If the printed circuit board needs to be cleaned, use a commercial cleaning solution designed for electrical use. If this solution is not available, it is possible to clean the board by lightly rubbing the surface with an eraser.

A B I T O F H I S T O R Y

The printed circuit board was developed in 1947 by the British scientist J. A. Sargrove to simplify the production of radios.

3 Blk

99

150

CM-CH04

6/4/02

2:57 PM

Page 100

Flexible printed circuit Gauge connector clips

Fuel level dampening module

Bulb assemblies (16 maximum)

Wiring harness connector locations

Fuel level dampening module located here on optional tachometer cluster

Figure 4-15 Printed circuits eliminate bulky wires behind the instrument panel.

Wiring Harness

A wire harness is an assembled group of wires that branch out to the various electrical components.

Most manufacturers use wiring harnesses to reduce the amount of loose wires hanging under the hood or dash of an automobile. The wire harness provides for a safe path for the wires of the vehicles lighting, engine, and accessory components. The wiring harness is made by grouping insulated wires and wrapping them together. The wires are bundled into separate harness assemblies that are joined together by connector plugs. The multiple-pin connector plug may have more than 60 individual wire terminals. There are several complex wiring harnesses in a vehicle, in addition to the simple harnesses. The engine compartment harness and the under dash harness are examples of complex harnesses (Figure 4-16). Lighting circuits usually use a more simple harness (Figure 4-17). A complex harness serves many circuits. The simple harness services only a few circuits. Some individual circuit wires may branch out of a complex harness to other areas of the vehicle. Most wiring harnesses now use a flexible conduit to provide for quick wire installation (Figure 4-18). The conduit has a seam that can be opened to accommodate the installation or removal of wires from the harness. The seam will close once the wires are installed, and will remain closed even if the conduit is bent.

100

CM-CH04

6/4/02

2:57 PM

Page 101

Stereo wiring Radio wiring Ash tray lamp Glove box lamp

Printed circuit board connectors

To door T courtesy switch To heater blower T motor resistor To A/C blower T motor resistor To right front T door resistor Headlamp switch Heated rear window switch and lamp Rear wipe and wash switch and lamp L body M-Z 44 Lamp Lifegate release L body M-Z24 Ground Fuse block To stereo T speakers MZ24 To left door T speakers To left door courtesy T switches T rear wipe wash To To heated rear window T To hatch release T To body wiring T Bulkhead disconnect

Heater blower motor feed Cigarette lighter To key-in buzzer T To key-lamp T To wiper switch T To ignition switch lamp T To intermittent wipe T T turn signal switch To

To accessory lamps T To headlamp T dimmer switch To ignition T switch To stop lamp switch T To speed control switch wiring T To speed control brake wiring T To speed control clutch switch T To speed control servo T

Figure 4-16 Complex wiring harness. (Courtesy of DaimlerChrysler Corporation)

Figure 4-17 Simple wiring harness. (Courtesy of DaimlerChrysler Corporation)

Figure 4-18 Flexible conduit used to make wiring harnesses.

101

CM-CH04

6/4/02

2:57 PM

Page 102

Retainer Tubing

TY strap Boot

Clip Tie strap Sleeve

Figure 4-19 Typical wire protection devices. (Courtesy of DaimlerChrysler Corporation)

Wiring Protective Devices

Often overlooked, but very important to the electrical system, are proper wire protection devices (Figure 4-19). These devices prevent damage to the wiring by maintaining proper wire routing and retention. Special clips, retainers, straps, and supplementary insulators provide additional protection to the conductor over what the insulation itself is capable of providing. Whenever the technician must remove one of these devices to perform a repair, it is important that the device be reinstalled to prevent additional electrical problems. Whenever it is necessary to install additional electrical accessories, try to support the primary wire in at least 1-foot intervals. If the wire must be routed through the frame or body, use rubber grommets to protect the wire.

Shop Manual Chapter 4, page XX

Wiring Diagrams

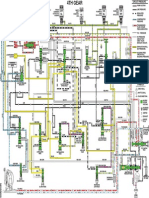

One of the most important tools for diagnosing and repairing electrical problems is a wiring diagram. These diagrams identify the wires and connectors from each circuit on a vehicle. They also show where different circuits are interconnected, where they receive their power, where the ground is located, and the colors of the different wires. All of this information is critical to proper diagnosis of electrical problems. Some wiring diagrams also give additional information that helps you understand how a circuit operates and how to identify certain components (Figure 4-20). Wiring diagrams do not explain how the circuit works; this is where your knowledge of electricity comes in handy. A wiring diagram can show the wiring of the entire vehicle (Figure 4 -21) or a single circuit (Figure 4-22). These single circuit diagrams are also called block diagrams. Wiring diagrams of the entire vehicle tend to look more complex and threatening than block diagrams. However, once you simplify the diagram to only those wires, connectors, and components that belong to an individual circuit, they become less complex and more valuable. Wiring diagrams show the wires, connections to switches and other components, and the type of connector used throughout the circuit. Total vehicle wiring diagrams are normally spread out over many pages of a service manual. Some are displayed on a single large sheet of paper that folds out of the manual. A system wiring diagram is actually a portion of the total vehicle diagram. The system and all related circuitry are shown on a single page. System diagrams are often easier to use than vehicle diagrams simply because there is less information to sort through.

A wiring diagram is an electrical schematic that shows a representation of actual electrical or electronic components (by use of symbols) and the wiring of the vehicles electrical systems.

102

CM-CH04

6/4/02

2:57 PM

Page 103

Fuses Gives fuse amperage and fuse cavity. Circuit identification code, circuit code, wire size, and color code. A shows its a power feed, and it has 14-gauge black wire. You can follow the black wire to a single connector. You see what the connector looks like, and notice it has fusible link wire on the other side of the connector. The connector location is also indicated. The fusible link wire, is a finer gauge with a lower melting point than the wire its connected to. Here its 20-gauge orange between the 14-gauge black and 14-gauge pink wires A splice symbol indicates the junction of the fusible link with the standard wire in the circuit. The bulkhead connector symbol tells you the pink wire goes to cavity # 31. Circuit direction. You are directed to page 47 for the rest of the A-3 circuit. NOTE: THE CONNECTOR CAVITY MAY BE IDENTIFIED ON SOME DIAGRAMS WITH THE OLDER SYSTEM USING S.C. (FOR SERVICE CONNECTOR). This circuit code shows a tracer symbol (*) but not color. Here you would look for a 14-gauge pink wire with a tracer which will be black or white. Tracer color is indicated. Here tracer is/RD/ 12BK/RD*.

Q2 16BK Fuse # 13 (5 amp) A1 Grd J2 14DB J2 14DB # 10 To starter system (see page 11)

*Use cavity # 14

(6 amp) circuit breaker

To ignition switch (see page 29) J2 2

A2 10GBK

20DB

Left headlight ground (left fender shield-rear of battery)

J2 14DB Black

A2 6GBK

J2 14DB

A1 Grd

G5

+ Battery (front of car left side)

J2 14DB

+ Red

J2 14DB

J2

J2 14DB A3 14BK A1 6BK

A7 6GBK (Rear of battery) To heated rear window (see page 82) C13 12BK/RD

20DB

G5

(Rear of battery)

Q2 16BK

*

A3 20DB C13 12BK/RD

*

Fusible link (Hypalon wire) (left side shield-front) C13 20DB

75 Amp

# 36

To rear wash wipe (see page 77) To speed control (see page 30) To G5 splice # 31

A3 14PK

To lift gate release (see page 75)

A1 8RD

To deck lid release (see page 79)

A1 Grd Fusible link (Hypalon wire) (rear of battery)

(see page 30.51)

To hazard flasher (see page 471)

Figure 4-20 Wiring diagrams provide the technician with necessary information to accurately diagnose the electrical systems. (Courtesy of DaimlerChrysler Corporation)

Remember that electrical circuits need a complete path in order to work. A wiring diagram shows the insulated side of the circuit and the point of ground. Also, when lines (or wires) cross on a wiring diagram, this does not mean they connect. If wires are connected, there will be a connector or a dot at the point where they cross. Most wiring diagrams do not show the location of the wires, connectors, or components in the vehicle. Some have location

A3 14PK

103

CM-CH04

6/4/02

2:57 PM

Page 104

Component and connector location is giving on wiring diagram. Wire separated from component shows connector or terminal that is connected to that component. Ground symbol indicates body or engine ground connection.

(Rear of battery)

Voltage regulator (right side shield)

R3 18OG J2 14DB

J2 14DB

J3 18DG G

Power feed circuit information works both waysyou can trace the

R3 18DG Generator (right side forward of engine)

J2 18DG

here by going to the pages indicated, or you may be directed back to this point as you check the circuits on pages 11, 13, 14, 28, 29, 33 and 34. This splice symbol indicates that all these wires are joined to the A1-1 feed circuit splice.

J2 14DB

To low oil T pressure switch (see page 32)

J2 14DB R2 60BK

R9 8BK

R6 8BK

Note:

R9

C29 18BK

R1 12RD

To starter T system (see page 11) R6 14RD R6 8BK

J2 14DBL

Fusable link (Hypalon wire) (left side shield-front) C13 20OR C26 20OR R1 8RD J10 18GY C26 14GY J10 12PK (left side shield-front) J1 12RD To air conditioning T and heater system (see page 33,34) To ignition switch (see page 29)

*

#4

J10 12PK

J2 14DBL These points do not connect J2 14DBL

1 R1

J1 20OR

J1 12RD # 37

Fusable link (Hypalon wire) (left side shield-front) R6 18GY

J1 14PK # 35 R6 12BK R6 12BK

To electronic spark advance system

J2 14DBL

T To

R6

Splice

(see page 28)

Figure 4-20 (continued)

104

J2 14DBL

Air pump bracket mounting bolt

R9 60BK

C9 12BK

To air T conditioning and heater system (see page 33)

(Rear of battery)

This is a splice

CM-CH04

6/4/02

2:57 PM

Page 105

Figure 4-21 A wiring diagram that covers the complete electrical systems of a vehicle. (Courtesy of American Honda Motor Co., Inc.)

105

CM-CH04

6/4/02

2:57 PM

Page 106

Figure 4-21 (continued)

106

CM-CH04

6/4/02

2:57 PM

Page 107

Figure 4-21 (continued)

107

CM-CH04

6/4/02

2:58 PM

Page 108

Figure 4-21 (continued)

108

CM-CH04

6/4/02

2:58 PM

Page 109

Figure 4-21 (continued)

109

CM-CH04

6/4/02

2:58 PM

Page 110

Figure 4-21 (continued)

110

CM-CH04

6/4/02

2:58 PM

Page 111

Figure 4-21 (continued)

111

CM-CH04

6/4/02

2:58 PM

Page 112

Figure 4-21 (continued)

112

CM-CH04

6/4/02

2:58 PM

Page 113

Figure 4-21 (continued)

113

CM-CH04

6/4/02

2:58 PM

Page 114

Figure 4-22 Wiring diagram illustrating only one specific circuit for easier reference. This is also known as a block diagram. (Courtesy of American Honda Motor Co., Inc.)

114

CM-CH04

6/4/02

2:58 PM

Page 115

reference numbers displayed by the wires. After studying the wiring diagram, you will know what you are looking for. Then you move to the car to find it. In addition to entire vehicle and system specific wiring diagrams, there are other diagrams that may be used to diagnose electricity problems. An electrical schematic shows how the circuit is connected. It does not show the colors of the wires or their routing. Schematics are what have been used so far in this book. They display a working model of the circuit. These are especially handy when trying to understand how a circuit works. Schematics are typically used to show the internal circuitry of a component or to simplify a wiring diagram. One of the troubleshooting techniques used by good electrical technicians is to simplify a wiring diagram into a schematic. Installation diagrams show where and how electrical components and wiring harnesses are installed in the vehicle. These are helpful when trying to locate where a particular wire or component may be in the car. These diagrams also may show how the component or wiring harness is attached to the vehicle (Figure 4-23).

Installation diagrams provide a more accurate duplication of where the wire harness, connectors, and components are found on the vehicle.

Electrical Symbols

Most wiring diagrams do not show an actual drawing of the components. Rather they use electrical symbols to represent the components. Often the symbol displays the basic oper-

In place of actual pictures, a variety of electrical symbols are used to represent the components in the wiring diagram.

Figure 4-23 A typical installation diagram. (Reprinted with the permission of Ford Motor Company)

115

CM-CH04

6/4/02

2:58 PM

Page 116

ation of the component. Many different symbols have been used in wiring diagrams through the years. Figure 4-24 shows some of the commonly used symbols. Recently, most manufacturers have begun to use some new style symbols (Figure 4-25). The reason for the change is because most manufacturers are going to electronic media instead of paper forms of service manuals. Some of the older symbols are not distinguishable when viewed on a monitor. You need to be familiar with all of the symbols; however, you dont need to memorize all of the variations. Wiring diagram manuals include a legend that helps you interpret the symbols.

B I T

O F

H I S T O R Y

The service manuals for early automobiles were hand drawn and labeled. They also had drawings of the actual components. As more and more electrical components were added to cars, this became impractical. Soon schematic symbols replaced the component drawings.

Color Codes and Circuit Numbering

Nearly all of the wires in an automobile are covered with colored insulation. These colors are used to identify wires and electrical circuits. The color of the wires is indicated on a wiring diagram. Some wiring diagrams also include circuit numbers. These numbers, or letters and numbers, help identify a specific circuit. Both types of coding makes it easier to diagnose electrical problems. Unfortunately, not all manufacturers use the same method of wire identification. Figure 4-26 shows common color codes and their abbreviations. Most wiring diagrams list the appropriate color coding used by the manufacturer. Make sure you understand what color the code is referring to before looking for a wire. In most color codes, the first group of letters designates the base color of the insulation. If a second group of letters is used, it indicates the color of the tracer. For example, a wire designated as WH/BLK would have a white base color with a black tracer.

Ford uses four methods of color coding its wires (Figure 4-27):

A tracer is a thin or dashed line of a different color than the base color of the insulation.

1. Solid color. 2. Base color with a stripe (tracer). 3. Base color with hash marks. 4. Base color with dots.

DaimlerChrysler uses a numbering method to designate the circuits on the wiring diagram (Figure 4-28). The circuit identification, wire gauge, and color of the wire are included in the wire number. DaimlerChrysler identifies the main circuits by using a main circuit identification code that corresponds to the first letter in the wire number (Figure 4-29). General Motors uses numbers that include the wire gauge in metric millimeters, the wire color, the circuit number, splice number, and ground identification (Figure 4-30). In this example, the circuit is designated as 100, the wire size is 0.8 mm2, the insulation color is black, the splice is numbered S114, and the ground is designated as G117. Most manufacturers also number connectors and terminals for identification.

116

CM-CH04

6/4/02

2:58 PM

Page 117

Positive Negative Ground Fuse Circuit breaker Capacitor

Connector Male connector Female connector Multiple connector Denotes wire continues elsewhere Splice

2 2

Ohms Resistor Variable resistor V Series resistor Coil Step up coil Open contact Closed contact Open switch Closed switch Closed ganged switch Open ganged switch Two pole single T throw switch Pressure switch Solenoid switch Mercury switch Diode or rectifier Bi directional zener diode

Splice identification Wiring g with Optional Wiring without Thermal element bimetal strip Y Windings Digital readout Single filament lamp Dual filament lamp LED light emitting diode Thermistor Gauge

Timer

M

Timer Motor Armature and brushes Denotes wire goes through grommet Denotes wire goes through 40 way disconnect Denotes wire goes through 25 way steering column connector Denotes wire goes through 25 way instrument panel connector

Steering column

Instrument panel

Figure 4-24 Common electrical symbols used in wiring diagrams. (Courtesy of DaimlerChrysler Corporation)

117

CM-CH04

6/4/02

2:58 PM

Page 118

or

Resistor

Wire connector, detachable

Soldered or welded wire splice

or

Variable V resistor

Semiconductor diode

16

Wiring cross section (gauge) Toggle or rocker T switch (manually operated)

Or

Electrically operated valve

Electromagnetic relay

Spark plug

Alternator

Hydraulically operated switch

Fuse

Motor

Solid-state relay Thermally operated (bimetallic) switch Manually operated multiposition switch

Light bulb or One filament in a multifilament light bulb

Wire junction, detachable

Wire crossing (no connection)

Heating element

Wire junction, permanent + Battery Shielded conductors

Solid-state circuitry

Mechanlcally operated switch

Manually operated switch

Meter or gauge

Horn

Figure 4-25 Electrical symbols used in more recent manuals.

Color

Aluminum Black Blue (Dark) Blue Blue (Light) Brown Glazed Gray Green (Green) Green (Light) Maroon Natural Orange Pink Purple Red Tan Violet White Yellow AL BLK BLU DK BLU BLU LT BRN GLZ GRA GRN DK GRN LT MAR NAT ORN PNK PPL RED TAN VLT WHT YEL

Abbreviations

BK DB B LB BR GL GR DG LG M N O PK PR R T V W Y B DK BLU L LT BLU BN G DK GRN LT GRN ORG P RD TN WH YL

Figure 4-26 Common color codes used in automotive applications.

118

CM-CH04

6/4/02

2:58 PM

Page 119

Solid color Striped Hashmarked Dotted (D) Dot (H) Hashmark Stripe is understood Examples: BKSolid black BRY Brown with yellow stripe BKY H Black with yellow hashmarks OBK D Orange with black dots

Figure 4-27 Four methods that Ford uses to color code their wires. (Reprinted with the permission of Ford Motor Company)

J Main circuit identification

2A 18 BL/Y* Color of wire (Blue with yellow tracer) Gage of wire (18 Gage)

Part of main circuit (Varies V depending on equipment)

Figure 4-28 DaimlerChryslers wiring code identification. (Courtesy of DaimlerChrysler Corporation)

Main Circuit Identification Codes

A B C D E F G H I J K L M BATTERY FEED (i.e. Fuselink Feeds, Starter Feeds, Starter Relay) Brakes Climate Control (A/C, Heater, E.B.L. and Heated Mirror Related Circuits) Diagnostic Circuits Dimming Illumination Circuits Fused Circuits (Non-Dedicated MultiSystem Feeds) Monitoring Circuits (Gages, Clocks, Warning Devices) **OPEN** Not used as a circuit designator **OPEN** Engine Logic Module Control Circuits Exterior Lighting Circuits Interior Lighting Circuits (Dome, Courtesy Lamps, Cargo Lamps) N O P ESA Module Electronic Circuits Not used as a circuit designator Power Options (Battery Feed) (i.e. Seats, Door Locks, Mirrors, Deck Lid Release, etc.) Q Power Options (Ignition Feed) (i.e. Windows, Power Top, Power Sun Roof, etc.) R Passive Restraint S Suspension and Steering Circuits T Transmission/Transaxle, Differential, Transfer Case and Starter System Circuits U **OPEN** V Speed Control and Wash Wipe Circuit W **OPEN** X Sound Systems (i.e. Radio and Horn) Y **OPEN** Z Grounds (B)

Figure 4-29 DaimlerChryslers circuit identification codes. (Courtesy of DaimlerChrysler Corporation)

119

CM-CH04

6/4/02

2:58 PM

Page 120

0.8 Blk S114 100 0.8 Blk G117

0.8 Blk

Figure 4-30 GMs method of circuit and wire identification.

DIN is the abbreviation for Deutsche Institut fer Normung (German Institute for Standardization) and is the recommended standard for European manufacturers to follow.

Standardized Wiring Designations. The Society of Automotive Engineers (SAE) is attempting to standardize the circuit diagrams used by the various manufacturers. The system that is developed may be similar to the DIN used by import manufacturers. DIN assigns certain color codes to a particular circuit as follows: Red wires are used for direct battery-powered circuits and also ignition-powered circuits. Black wires are also powered circuits controlled by switches or relays. Brown wires are usually the grounds. Green wires are used for ignition primary circuits. A combination of wire colors is used to identify subcircuits. The base color still identifies the circuits basic purpose. In addition to standardized color coding, DIN attempts to standardize terminal identification and circuit numbering.

Component Locators

A component locator is used to determine the exact location of several of the electrical components.

The wiring diagrams in most service manuals may not indicate the exact physical location of the components of the circuit. In another section of the service manual, or in a separate manual, a component locator is provided to help find where a component is installed in the vehicle. The component locator may use both drawings and text to lead the technician to the desired component (Figure 4-31). Many electrical components may be hidden behind kick panels, dash boards, fender wells, and under seats. The use of a component locator will save the technician time in finding the suspected defective unit.

Summary

Terms to Know Ballast resistor Bulkhead connectors Common connections Component locator Cross-fire DIN

Most of the primary wiring conductors used in the automobile are made of several strands of copper wire wound together and covered with a polyvinyl chloride (PVC) insulation. Stranded wire is used because of its flexibility and current flows on the surface of the conductors. Because there is more surface area exposed in a stranded wire, there is less resistance in the stranded wire than in the solid wire. There are three major factors that determine the proper size of wire to be used: (1) The wire must be large enough diameterfor the length requiredto carry the necessary current for the load components in the circuit to operate properly, (2) The wire must be able to withstand the anticipated vibration, and (3) The wire must be able to withstand the anticipated amount of heat exposure.

120

CM-CH04

6/4/02

104 105 102 101 107 109 M52 M53 M56 M54 C17 M103 M101 C11 C05 C04 4 C03 C C02 C15 C07 CR01 M48 C21 M46 MC01 MC02 M47 (Passive only) M46 (Passive only) M60 C22 C19 M49-A M49-B C20 C08 C09 C23 M70 MR103 MR102 MR101 M61 C18 C06 C010 C13 M55 MR02 MR01 ( (G04) M51 M45 M47 7 M52 C01 C 01 M62 M59 106 C12 108 1 103

2:58 PM

M57

Page 121

C14

M45 M46 M47 M48 M49 M50 M51 M52 Instrument cluster

Glove box switch Glove box lamp Air conditioner extension wire Front door speaker extension wire (RH) Blower motor Heater resister Digital clock Front door speaker (LH) Front door speaker (RH) Tailgate opener switch (passive seat belt only) T Seat belt extension wire (passive seat belt only) Seat belt switch (passive seat belt only) Radio fuse Rear speaker extension wire Rear wiring connector

121

M57 M58 M59 M60 M61 M62 M70 101 102

103 Stop lamp switch Seat belt timer 104 Chime bell 105 Diode connector 106 F.B.C. unit F 107 Multifunction switch 108 Door opening switch 109 Ignition switch Relay box (M53 HTD, M54 Idle up, M55 Flasher, M56 5-T T M) M102 Diode connector M103 Heated timer C01 Courtesy lamp extension wire C02 Fuse box C03 Tailgate opener switch T C04 Sun roof extension wire C05 Lock up control unit C06 Defogger switch C07 Cluster illumination lamp C08 C09 C10

C11 C12 C13 Cluster illumination lamp C14 Air conditioner switch C15 Rear wiper switch (except 4 door) C16 Rear washer switch (except 4 door) C17 C18 Instrument extension wire connector C19 C20 Rheostat switch C21 Rheostat and intermittent wiper illumination lamp C22 Intermittent wiper relay C23 Blower switch CR01 Audio MR01 Front door speaker extension wire (LH) MR02 Ash tray illumination lamp Cigar lighter Cigar lighter Heater control illumination switch

Figure 4-31 The component locator is used to find the actual location of a component. (Courtesy of Hyundai Motor America)

CM-CH04 6/4/02

I-MARK Component & Location Page NO. 11

I-MARKContinued Component & Location

2:58 PM

Fig. No.

................ 49 ................ 50 ................ 23 ................ 24 ................ 49 ................ 50 ................ 23 ................ 49 ................ 21 ................ 22 ................ 47 ................ 48 ................ 21 ................ 22 ................ 47 ................ 48 ................ 21 ................ 22 ................ 47 ................ 48 ................ 21 ................ 22 ................ 47 ................ 48 ................ 21 ................ 22 ................ 47 ................ 48 ................ 21 ................ 22 ................ 47 ................ 48 ................ 21 ................ 22 ................ 47 ................ 48

Page 122

122

Page Fig. NO. 11 No. A/C Relay (1987 Turbo): Behind LH Side Of I/P ................... 53 ................ 25 A/C Relay (1987 Turbo): RH Side Of Cowl ........................... 36 ............... 6 A/C Relay (1987): Behind LH Side Of I/P ............................. 36 ............... 7 A/C Relay (1988 Turbo): Behind LH Side Of I/P ................... 56 ................ 33 A/C Relay (1988 Turbo): RH Side Of Cowl ........................... 55 ................ 31 A/C Relay (1988): Behind LH Side Of I/P ............................. 55 ................ 32 AIR Vacuum Switching Valve (1987 Turbo):RH Side Of Cowl ..................................................................... 38 ................ 12 AIR Vacuum Switching Valve (1988 Turbo): RH Side Of Cowl ..................................................................... 62 ................ 42 Alternator (1987 Exc. Turbo): RH Side Of Engine ............... 39 ................ 14 Alternator (1987 Turbo): RH Side Of Engine ........................ 41 ................ 16 Alternator (1988 Exc. Turbo): RH Side Of Engine ................ 57 ................ 37 Alternator (1988 Turbo): RH Side Of Engine ........................ 59 ................ 39 Auto Choke Relay (1987 Exc. Turbo): RH Side Of Cowl ...... 36 ................ 5 Auto Choke Relay (1988 Exc. Turbo): RH Side Of Cowl ...... 55 ................ 30 Canister Vacuum Switching Valve (1988 Turbo): RH Side Of Cowl ..................................................................... 38 ................ 12 Canister Vacuum Switching Valve (1988 Turbo): RH Side Of Cowl ..................................................................... 62 ................ 42 Car Speed Sensor (1987 Turbo): Inside Speedometer ........ 38 ................ 11 Car Speed Sensor (1987 Turbo): Inside Speedometer ........ 38 ................ 12 Car Speed Sensor (1988 Turbo): Inside Speedometer ........ 61 ................ 41 Car Speed Sensor (1988 Turbo): Inside Speedometer ........ 62 ................ 42 Carburetor (1987 Exc. Turbo): On Intake Manifold ............... 37 ................ 10 Carburetor (1988 Exc. Turbo): On Intake Manifold ............... 60 ................ 40 Condenser Fan Relay (1987 Turbo): RH Render Apron ....... 36 ................ 6 Condenser Fan Relay (1988 Turbo): RH Fender Apron ....... 55 ................ 31 Connector A1 (1987 Exc. Turbo): Behind Center Of I/P ....... 49 ................ 23 Connector A1 (1987 Turbo): Behind Center Of I/P ............... 51 ................ 24 Connector A1 (1988 Exc. Turbo): Behind Center Of I/P ....... 70 ................ 49 Connector A1 (1988 Turbo): Behind Center Of I/P ............... 72 ................ 50 Connector A2 (1987 Exc. Turbo): Behind Center Of I/P ....... 49 ................ 23 Connector A2 (1987 Turbo): Behind Center Of I/P ............... 51 ................ 24 Connector A2 (1988 Exc. Turbo): Behind Center Of I/P .................................................................................. 70 ................ 49 Connector A2 (1988 Turbo): Behind Center Of I/P ............... 72 ................ 50 Connector A3 (1987 Exc. Turbo): Behind Center Of I/P .................................................................................. 49 ................ 23 Connector A3 (1987 Turbo): Behind Center Of I/P ............... 51 ................ 24 Connector A3 (1988 Exc. Turbo): Behind Center Of I/P .................................................................................... 70 Connector A3 (1988 Turbo): Behind Center Of I/P .............. 72 Connector A4 (1987 Exc. Turbo): Behind Center Of I/P ................................................................................ 49 Connector A4 (1987 Turbo): Behind Center Of I/P .............. 51 Connector A4 (1988 Exc. Turbo): Behind Center Of I/P ................................................................................ 70 Connector A4 (1988 Turbo): Behind Center Of I/P .............. 72 Connector A5 (1987 Exc. Turbo): Behind Center Of I/P ................................................................................ 49 Connector A5 (1988 Exc. Turbo): Behind Center Of I/P ...... 70 Connector C1 (1987 Exc. Turbo): LH Side Of Cowl ............. 46 Connector C1 (1987 Turbo): LH Side Of Cowl ..................... 47 Connector C1 (1988 Exc. Turbo): LH Side Of Cowl ............. 67 Connector C1 (1988 Turbo): LH Side Of Cowl ..................... 68 Connector C2 (1987 Exc. Turbo): LH Side Of Cowl ............. 46 Connector C2 (1987 Turbo): LH Side Of Cowl ..................... 47 Connector C2 (1988 Exc. Turbo): LH Side Of Cowl ............. 67 Connector C2 (1988 Turbo): LH Side Of Cowl ..................... 68 Connector C3 (1987 Exc. Turbo): LH Side Of Cowl ............. 46 Connector C3 (1987 Turbo): LH Fender Apron .................... 47 Connector C3 (1988 Exc. Turbo): LH Side Of Cowl ............. 67 Connector C3 (1988 Turbo): LH Fender Apron .................... 68 Connector C4 (1987 Exc. Turbo): LH Side Of Cowl ............. 46 Connector C4 (1987 Turbo): LH Side Of Cowl ..................... 47 Connector C4 (1988 Exc. Turbo): LH Side Of Cowl ............. 67 Connector C4 (1988 Turbo): LH Side Of Cowl ..................... 68 Connector C5 (1987 Exc. Turbo): LH Side Of Cowl ............. 46 Connector C5 (1987 Turbo): LH Side Of Cowl ..................... 47 Connector C5 (1988 Exc. Turbo): LH Side Of Cowl ............. 67 Connector C5 (1988 Turbo): LH Side Of Cowl ..................... 68 Connector C6 (1987 Exc. Turbo): LH Side Of Cowl ............. 46 Connector C6 (1987 Turbo): LH Side Of Cowl ..................... 47 Connector C6 (1988 Exc. Turbo): LH Side Of Cowl ............. 67 Connector C6 (1988 Turbo): LH Side Of Cowl ..................... 68 Connector C7 (1987 Exc. Turbo): LH Fender Apron ............ 46 Connector C7 (1987 Turbo): LH Fender Apron .................... 47 Connector C7 (1988 Exc. Turbo): LH Fender Apron ............ 67 Connector C7 (1988 Turbo): LH Fender Apron .................... 68

Figure 4-31 (continued)

CM-CH04

6/4/02

2:58 PM

Page 123

Wire size is based on the diameter of the conductor. Factors that affect the resistance of the wire include the conductor material, wire diameter, wire length, and temperature. Terminals can be either crimped or soldered to the conductor. The terminal makes the electrical connection and it must be capable of withstanding the stress of normal vibration. Printed circuit boards are used to simplify the wiring of the circuits they operate. A printed circuit is made of a thin phenolic or fiberglass board that copper (or some other conductive material) has been deposited on. A wire harness is an assembled group of wires that branch out to the various electrical components. It is used to reduce the amount of loose wires hanging under the hood or dash. It provides for a safe path for the wires of the vehicles lighting, engine, and accessory components. The wiring harness is made by grouping insulated wires and wrapping them together. The wires are bundled into separate harness assemblies that are joined together by connector plugs. A wiring diagram shows a representation of actual electrical or electronic components and the wiring of the vehicles electrical systems. The technicians greatest helpmate in locating electrical problems is the wiring diagram. Correct use of the wiring diagram will reduce the amount of time a technician needs to spend tracing the wires in the vehicle. In place of actual pictures, a variety of electrical symbols are used to represent the components in the wiring diagram. Color codes and circuit numbers are used to make tracing wires easier. In most color codes, the first group of letters designates the base color of the insulation. If a second group of letters is used, it indicates the color of the tracer. A component locator is used to determine the exact location of several of the electrical components.

Terms to Know (Continued) Electrical symbols Gauge Installation diagrams Primary wiring Printed circuit boards Resistance wire Schematic Secondary wiring Stranded wire Tracer Wire harness Wiring diagram

Review Questions

Short Answer Essays

1. Explain the purpose of wiring diagrams. 2. Explain how wire size is determined by the American Wire Gauge (AWG) and

metric methods.

3. Explain the purpose and use of printed circuits. 4. Explain the purpose of the component locator. 5. Explain when single-stranded or multistranded wire should be used.

123

CM-CH04

6/4/02

2:58 PM

Page 124

6. Explain how temperature affects resistance and wire size selection. 7. List the three major factors that determine the proper size of wire to be used. 8. List and describe the different types of terminal connectors used in the automotive

electrical system.

9. What is the difference between a complex and a simple wiring harness? 10. Describe the methods the three domestic automobile manufacturers use for wiring

code identification.

Fill-in-the-Blanks

1. There is ___________________ resistance in the stranded wire than in the

solid wire.

2. ___________________ ___________________ is the electromagnetic induction spark that

can be transmitted in another wire that is close to the wire carrying the current.

3. Wire size is based on the ___________________ of the conductor. 4. In the AWG standard, the ___________________ the number, the smaller the wire

___________________.

5. An increase in temperature creates a ___________________ ___________________

in resistance.

6. ___________________ connectors are used when several wires must pass through

the bulkhead.

7. ___________________ ___________________ ___________________ are used

to prevent damage to the wiring by maintaining proper wire routing and retention.

8. A wiring diagram is an electrical schematic that shows a ___________________ of actual

electrical or electronic components (by use of symbols) and the ___________________ of the vehicles electrical systems.

9. In most color codes, the first group of letters designates the ___________________

___________________ of the insulation. The second group of letters indicates the color of the ___________________.

10. A ___________________ ___________________ is used to determine the exact location of

several of the electrical components.

124

CM-CH04

6/4/02

2:58 PM

Page 125

Multiple Choice

1. Automotive wiring is being discussed. 6. Terminal connectors are being discussed.

Technician A says most primary wiring is made of several strands of copper wire wound together and covered with an insulation. Technician B says the types of conductor materials used in automobiles include copper, silver, gold, aluminum, and tin-plated brass. Who is correct? A. A only C. Both A and B B. B only D. Neither A nor B

2. Stranded wire use is being discussed.

Technician A says good terminal connections will resist corrosion. Technician B says the terminals can be either crimped or soldered to the conductor. Who is correct? A. A only C. Both A and B B. B only D. Neither A nor B

7. Wire routing is being discussed.

Technician A says there is less exposed surface area for electron flow in a stranded wire. Technician B says there is more resistance in the stranded wire than in the same gauge solid wire. Who is correct? A. A only C. Both A and B B. B only D. Neither A nor B

3. Spark plug wires are being discussed.

Technician A says to install additional electrical accessories it is necessary to support the primary wire in at least 10-foot intervals. Technician B says if the wire must be routed through the frame or body, use metal clips to protect the wire. Who is correct? A. A only C. Both A and B B. B only D. Neither A nor B

8. Printed circuit boards are being discussed.

Technician A says RFI is controlled by using resistances in the conductor of the spark plug wire. Technician B says all late model ignition systems use resistance wires to control RFI. Who is correct? A. A only C. Both A and B B. B only D. Neither A nor B

4. Spark plug wire installation is being discussed.

Technician A says printed circuit boards are used to simplify the wiring of the circuits they operate. Technician B says care must be taken not to touch the board with bare hands. Who is correct? A. A only C. Both A and B B. B only D. Neither A nor B

9. Wiring harnesses are being discussed.

Technician A says there is little that can be done to prevent cross-fire. Technician B says the spark plug wires must be installed in the proper separator and any two parallel wires next to each other in the firing order should be positioned as far away from each other as possible. Who is correct? A. A only C. Both A and B B. B only D. Neither A nor B

5. The selection of the proper size of wire to be used is

Technician A says a wire harness is an assembled group of wires that branches out to the various electrical components. Technician B says most underhood harnesses are simple harnesses. Who is correct? A. A only C. Both A and B B. B only D. Neither A nor B

10. Wiring diagrams are being discussed.

being discussed. Technician A says the wire must be large enough, for the length required, to carry the amount of current necessary for the load components in the circuit to operate properly. Technician B says temperature has little effect on resistance and it is not a factor in wire size selection. Who is correct? A. A only C. Both A and B B. B only D. Neither A nor B

Technician A says wiring diagrams give the exact location of the electrical components. Technician B says a wiring diagram will indicate what circuits are interconnected, where circuits receive their voltage source, and what color of wires are used in the circuit. Who is correct? A. A only C. Both A and B B. B only D. Neither A nor B

125

CM-CH04

6/4/02

2:58 PM

Page 126

You might also like

- Automotive Ignition SystemsDocument174 pagesAutomotive Ignition SystemsCharles Simo100% (12)

- Automotive SensorsDocument39 pagesAutomotive SensorsMomentum Press100% (16)

- Wiring Headlight RelaysDocument20 pagesWiring Headlight RelaysFloris van EnterNo ratings yet

- How To Diagnose and Repair Automotive Electrical SystemsDocument135 pagesHow To Diagnose and Repair Automotive Electrical Systemsgeorge74% (19)

- Automotive Relay Circuits FREE E-BookDocument34 pagesAutomotive Relay Circuits FREE E-BookMANUELAMAYA222519100% (4)

- Autotec Guide Key & Remote CodingDocument78 pagesAutotec Guide Key & Remote Codingmhcscribd67% (3)

- Automotive BasicsDocument146 pagesAutomotive BasicsSamuel Premkumar85% (20)

- Automotive Cable and Wiring SystemDocument20 pagesAutomotive Cable and Wiring SystemBala100% (1)

- Sensor Communication Auto MotivesDocument34 pagesSensor Communication Auto MotivesAkhil Sharma100% (2)

- Automotive Electrical SystemsDocument101 pagesAutomotive Electrical SystemsMos CraciunNo ratings yet

- Prentice Hall: Automotive Technology: Principles, Diagnosis and Service 3rd Edition © 2009 (Halderman/Mitchell)Document51 pagesPrentice Hall: Automotive Technology: Principles, Diagnosis and Service 3rd Edition © 2009 (Halderman/Mitchell)sorin grecuNo ratings yet

- Automotive Diag CAN NIDocument334 pagesAutomotive Diag CAN NIHector Sanchez100% (11)

- Wiring DiagramDocument281 pagesWiring Diagramchinzoo1275% (20)

- Electronic Engine ControlDocument19 pagesElectronic Engine ControlSohail Bashir97% (31)

- Automotive Sensors/Actuators: Sensor - Input Actuator - OutputDocument23 pagesAutomotive Sensors/Actuators: Sensor - Input Actuator - Outputcbatawala100% (2)

- Anti Theft SystemDocument13 pagesAnti Theft Systemsonny123460% (5)

- Troubleshooting Automotive Computers, Sensors & Network PDFDocument97 pagesTroubleshooting Automotive Computers, Sensors & Network PDFاحمد ابو عبدالله100% (11)

- Ford WiringDocument6 pagesFord WiringGilberto Dipiento100% (1)

- Automotive Sensors & Actuators - PreconferenceDocument68 pagesAutomotive Sensors & Actuators - PreconferenceSiddharth Narayanan ChidambareswaranNo ratings yet

- Automotive SensorsDocument49 pagesAutomotive SensorsStefan Burbulea79% (14)

- Automotive Power ElectronicsDocument80 pagesAutomotive Power Electronicslusthawk100% (9)

- LabScopes Introductory& AdvancedDocument78 pagesLabScopes Introductory& AdvancedMr.P100% (3)

- General Motor Relearn ProceduresDocument8 pagesGeneral Motor Relearn Procedurescherokewag86% (7)

- Wide Band O2 Sensors: DiagnosingDocument2 pagesWide Band O2 Sensors: DiagnosingMax Bike MartinezNo ratings yet

- Automotive Electrical Systems - Part 1 Explained SimplyDocument22 pagesAutomotive Electrical Systems - Part 1 Explained SimplykabiaNo ratings yet

- Make Your Own Diagnostic Equipment Mandy Concepcion PDFDocument129 pagesMake Your Own Diagnostic Equipment Mandy Concepcion PDFtonyeld92% (12)

- Ford DTCDocument10 pagesFord DTCmarcioe10005034100% (7)

- AUS Holden Vehicle Communication Software ManualDocument90 pagesAUS Holden Vehicle Communication Software ManualnigilbertoNo ratings yet

- Automotive Electrical Diagnosis CourseDocument304 pagesAutomotive Electrical Diagnosis CoursePaul100% (14)

- Automotive Oscilloscopes PosterDocument1 pageAutomotive Oscilloscopes PosterFernando Díaz Pérez100% (2)

- Painless Wiring Harness Install InstructionsDocument60 pagesPainless Wiring Harness Install InstructionsNick MarinoNo ratings yet

- Key Programming AppsDocument121 pagesKey Programming Appssimon_someone21774% (19)

- Pico Scope Vehicle DiagnosticsDocument36 pagesPico Scope Vehicle DiagnosticsMohamed Mohamed Abdulhay100% (6)

- Drive Belt Replacement: Removal ProcedureDocument55 pagesDrive Belt Replacement: Removal ProceduremohhizbarNo ratings yet

- Automotive Electronics - Vol 2Document40 pagesAutomotive Electronics - Vol 2Victor Balas100% (14)

- Obd2 DiagnosticsDocument59 pagesObd2 Diagnosticsgustavus diagnosis100% (10)

- Ford Wiring DiagramsDocument59 pagesFord Wiring DiagramsSkidanje Uputstava72% (145)

- Automotive Engine ElectronicsDocument5 pagesAutomotive Engine Electronicsmachine tunisieNo ratings yet

- Ford Fusion Hybrid Workshop Repair and Service ManualDocument1 pageFord Fusion Hybrid Workshop Repair and Service Manualerwin_teichmannNo ratings yet

- Ignition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.From EverandIgnition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Rating: 3 out of 5 stars3/5 (4)

- Automotive Wiring and Electrical Systems Vol. 2: ProjectsFrom EverandAutomotive Wiring and Electrical Systems Vol. 2: ProjectsRating: 4.5 out of 5 stars4.5/5 (4)

- Automotive Vehicle Strategies and ECM ModesFrom EverandAutomotive Vehicle Strategies and ECM ModesRating: 4 out of 5 stars4/5 (7)

- Automotive Diagnostic Systems: Understanding OBD-I & OBD-II RevisedFrom EverandAutomotive Diagnostic Systems: Understanding OBD-I & OBD-II RevisedRating: 4 out of 5 stars4/5 (3)

- How to Repair Automotive Air-Conditioning & Heating SystemsFrom EverandHow to Repair Automotive Air-Conditioning & Heating SystemsRating: 5 out of 5 stars5/5 (5)

- Automotive Master Technician: Advanced Light Vehicle TechnologyFrom EverandAutomotive Master Technician: Advanced Light Vehicle TechnologyRating: 5 out of 5 stars5/5 (1)

- Certified General Automobile Mechanic (ASE): Passbooks Study GuideFrom EverandCertified General Automobile Mechanic (ASE): Passbooks Study GuideNo ratings yet

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- Automotive Equipment Usage and Repair StrategiesFrom EverandAutomotive Equipment Usage and Repair StrategiesRating: 5 out of 5 stars5/5 (1)

- Automotive Actuators and EVAP System TestingFrom EverandAutomotive Actuators and EVAP System TestingRating: 4.5 out of 5 stars4.5/5 (4)

- Automotive Sensor Testing and Waveform AnalysisFrom EverandAutomotive Sensor Testing and Waveform AnalysisRating: 4.5 out of 5 stars4.5/5 (13)

- Hossay P. Automotive Innovation. The Science and Engineering.2020Document322 pagesHossay P. Automotive Innovation. The Science and Engineering.2020ngelectronic5226No ratings yet

- Microautobox Iii - Designed To Bring Your Vision To The RoadDocument39 pagesMicroautobox Iii - Designed To Bring Your Vision To The RoadAlNo ratings yet

- Ae 202004Document53 pagesAe 202004ngelectronic5226No ratings yet

- Scalar Wave PDFDocument7 pagesScalar Wave PDFBibiz999No ratings yet

- ThesisteslaDocument96 pagesThesisteslangelectronic5226No ratings yet

- RelativityDocument78 pagesRelativityngelectronic5226No ratings yet

- Manual - Macromedia - Flash MXDocument90 pagesManual - Macromedia - Flash MXrare2109100% (31)

- A Theory of Independent Fuzzy Probability For System ReliabilityDocument9 pagesA Theory of Independent Fuzzy Probability For System Reliabilityngelectronic5226No ratings yet

- Learning Kernel Classifiers. Theory and AlgorithmsDocument371 pagesLearning Kernel Classifiers. Theory and Algorithmsngelectronic5226100% (2)

- Longitudinal Wave Experiment After Nikola Tesla: of Professor Dr. Dr.-Ing. Konstantin MeylDocument9 pagesLongitudinal Wave Experiment After Nikola Tesla: of Professor Dr. Dr.-Ing. Konstantin MeylFernando MolinaNo ratings yet

- A Course in Mathematics For Students in EngineeringDocument432 pagesA Course in Mathematics For Students in EngineeringVincent SantamariaNo ratings yet

- MPEG Video Compression An Introduction ToDocument16 pagesMPEG Video Compression An Introduction Tongelectronic5226No ratings yet

- The Configuration of Can BitDocument10 pagesThe Configuration of Can BitPOWERBASENo ratings yet

- Windows 7 Product GuideDocument140 pagesWindows 7 Product GuideFirli RasyiidNo ratings yet

- VB 2008 Step by StepDocument1 pageVB 2008 Step by Stepngelectronic5226No ratings yet

- ABS System - Bosch ABS 5.3Document16 pagesABS System - Bosch ABS 5.3ngelectronic5226100% (1)

- ABS System - Bosch 2E ABSDocument14 pagesABS System - Bosch 2E ABSngelectronic5226100% (1)

- Ebook - How To Make Bio-DieselDocument5 pagesEbook - How To Make Bio-Dieseltravking100% (1)

- Handbook: Handbook FST + CAN-BUS 1Document35 pagesHandbook: Handbook FST + CAN-BUS 1ngelectronic5226No ratings yet

- Front Catalytic ConverterDocument1 pageFront Catalytic Converterngelectronic5226No ratings yet

- High Voltage 2xs FL 2y A2xs FL 2y 123kv Power CableDocument3 pagesHigh Voltage 2xs FL 2y A2xs FL 2y 123kv Power CableShailendra Kumar VermaNo ratings yet

- CTC PICC Catalogue 2022Document9 pagesCTC PICC Catalogue 2022Navaneetha KrishnanNo ratings yet

- MCQ ElectricalDocument8 pagesMCQ ElectricalKashyap Dubey0% (1)

- Specification For 33 KV PTDocument7 pagesSpecification For 33 KV PTPapun Scribd100% (1)

- GE - ESP BrochureDocument16 pagesGE - ESP Brochureandreé VillalobosNo ratings yet

- Electrical Operating ProceduresDocument35 pagesElectrical Operating ProceduresSuprapto DesmosediciNo ratings yet

- 8DH10 Katalog enDocument40 pages8DH10 Katalog enjosuem250No ratings yet

- Single Core Cables - 600/1000 V: Dimensions & WeightsDocument5 pagesSingle Core Cables - 600/1000 V: Dimensions & WeightsMohan KNo ratings yet

- Developing More Compact 22-kV Distribution Systems and SwitchgearDocument7 pagesDeveloping More Compact 22-kV Distribution Systems and SwitchgearDave ChaudhuryNo ratings yet

- New Guide To Installlation of PV Systems - MCS - 20130530161524 PDFDocument124 pagesNew Guide To Installlation of PV Systems - MCS - 20130530161524 PDFRodel D Dosano100% (1)

- EEE 465 Breakdown MechanismsDocument16 pagesEEE 465 Breakdown MechanismsMd IbtidaNo ratings yet

- RME Reviewer 2Document60 pagesRME Reviewer 2Rodel PelimianoNo ratings yet

- Iec60079-11 (Ed5.0) en DDocument11 pagesIec60079-11 (Ed5.0) en DHuu Nguyen50% (2)

- 01A Design Criteria For TowersDocument3 pages01A Design Criteria For TowersNisarg TrivediNo ratings yet

- HVE MCQ PDFDocument71 pagesHVE MCQ PDFVivek Raut86% (7)

- Is 996.2009 PDFDocument25 pagesIs 996.2009 PDFSunny ShahNo ratings yet

- Rittal Technical System Catalog RiLine and Maxi-PLS 5 2622Document19 pagesRittal Technical System Catalog RiLine and Maxi-PLS 5 2622Arsalan MalikNo ratings yet

- Miniature MV Series SwitchDocument6 pagesMiniature MV Series SwitchChrist Rodney MAKANANo ratings yet

- Micom P120/P121/P122/P123: P12x/EN T/Eb6Document628 pagesMicom P120/P121/P122/P123: P12x/EN T/Eb6RK KNo ratings yet

- Mil C 24643aDocument114 pagesMil C 24643aFranklin SolanoNo ratings yet

- Engineering Material: Electrical PropertiesDocument35 pagesEngineering Material: Electrical PropertiesKentChonNo ratings yet

- Tan Delta Test On 6KV HT MotorDocument6 pagesTan Delta Test On 6KV HT MotorSellappan MuthusamyNo ratings yet

- Technical SpecificationDocument7 pagesTechnical Specificationshivam dwivediNo ratings yet

- 1SDA054046R1 t4h 250 pr221ds Ls I in 160 3p F FDocument2 pages1SDA054046R1 t4h 250 pr221ds Ls I in 160 3p F FAlexNo ratings yet

- Voltage SagDocument77 pagesVoltage SagDedi Nugroho50% (2)

- Manual Aire Acondicionado SurreyDocument16 pagesManual Aire Acondicionado SurreyPedroNo ratings yet

- A Mechanism of Motor Failure: Purdue E-PubsDocument6 pagesA Mechanism of Motor Failure: Purdue E-PubsS-Mohyedin MousaviNo ratings yet

- Diesel Generating Set Manual - ENGDocument65 pagesDiesel Generating Set Manual - ENGEquipo TransporteNo ratings yet

- Uppcl ReportDocument44 pagesUppcl ReportManish Raj100% (1)

- Iec60245-2 (Ed2.2) en DDocument7 pagesIec60245-2 (Ed2.2) en DĐặng Chí HảiNo ratings yet