Professional Documents

Culture Documents

Alumina Based Ceramic Fiber

Uploaded by

Melih AltıntaşOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alumina Based Ceramic Fiber

Uploaded by

Melih AltıntaşCopyright:

Available Formats

Muhammad Muddaser Sharif 07-NTU-087

A small-dimension filament or thread composed of a ceramic material, usually alumina, used in lightweight units for electrical, thermal, and sound insulation, filtration at high temperatures, packing, and reinforcing other ceramic materials.

1st alumina based ceramic fiber was produced in early 1970s for thermal insulations It was produced to overcome the relatively lower creep temperature (900 C) of silica based fibers A pure -alumina fiber was first produced by Du Pont in 1979

Excellent Thermal Shock Resistance 99% Pure Alumina Trace Level of Silica (0.09 wt%) Dimensional Stability in Hydrogen Low Thermal Conductivity No Outgassing

1.

2. 3. 4.

Precursors of alumina are viscous aqueous solutions of basic aluminum salts Spinning of the precursor produces a gel fiber This gel fiber is then dried and heat treated. Decomposition of the precursor induces the precipitation of aluminium hydroxides, such as boehmite AlO(OH)

5. This produces the outgassing of a large volume of residual compounds 6. The compounds associated volume change and porosity at this step has to be carefully controlled. 7. Above 400C and up to around 1000 C the fibre is composed of grains, in the range of 10 to 100nm

8. Above 1100C, stable a-alumina nucleates and a rapid growth of micron-sized grains occurs together with the coalescence of pores 9. The fibres become extremely brittle owing to large grain boundaries emerging at the fibres surfaces and ca 10. The use of alumina fibres above 1100 C therefore requires the control of the nucleation and growth of a-alumina and porosity can not be used in this form.

11. The solution to this problem is achieved by adding either silica precursors or seeds for aalumina formation to the fiber precursors and has led to two classes of alumina-based fibers.

You might also like

- Selenium cells: The construction, care and use of selenium cells with special reference to the Fritts cellFrom EverandSelenium cells: The construction, care and use of selenium cells with special reference to the Fritts cellNo ratings yet

- 15T001 High Performance Fibres: B.Tech. Textiletechnology 2018 Semester 7 Elective Department of Textile TechnologyDocument15 pages15T001 High Performance Fibres: B.Tech. Textiletechnology 2018 Semester 7 Elective Department of Textile TechnologyPravin KumarNo ratings yet

- A Novel Method For Preparing Ultra-Fine Alumina-Borate Oxide Fibres Via An Electrospinning TechniqueDocument5 pagesA Novel Method For Preparing Ultra-Fine Alumina-Borate Oxide Fibres Via An Electrospinning TechniqueAsif Fareed QaisraniNo ratings yet

- Ceramic FibersDocument24 pagesCeramic FibersWasi BangashNo ratings yet

- Ceramic FibresDocument18 pagesCeramic Fibressuhaib_abdurahmanNo ratings yet

- AluminaDocument5 pagesAluminaehsannasiri100% (1)

- Aluminium Voor ConstructeursDocument145 pagesAluminium Voor ConstructeursweltklangNo ratings yet

- Ceramic Fiber 23Document28 pagesCeramic Fiber 23Kowsik RajendranNo ratings yet

- IMC Rockwool - A Leading Philippine Fire Safe Insulation CompanyDocument8 pagesIMC Rockwool - A Leading Philippine Fire Safe Insulation CompanyCiroNo ratings yet

- Development of New High-Purity Alumina: This Paper Is Translated From R&D Report, "SUMITOMO KAGAKU", Vol. 2007-IDocument10 pagesDevelopment of New High-Purity Alumina: This Paper Is Translated From R&D Report, "SUMITOMO KAGAKU", Vol. 2007-ILawrence LauNo ratings yet

- Ali Hamid AcrylicDocument21 pagesAli Hamid AcrylicnatinaelNo ratings yet

- Inorganic FibresDocument17 pagesInorganic Fibresmahe_ftNo ratings yet

- 1700 C Rapid Cycle Furnace Design: FabricationDocument12 pages1700 C Rapid Cycle Furnace Design: FabricationpetarlNo ratings yet

- Alumina Hydrate Purity PDFDocument10 pagesAlumina Hydrate Purity PDFNurfarhana JelenNo ratings yet

- ŠamotDocument1 pageŠamotDinko BrezakNo ratings yet

- Aluminum Manufacturing ReportDocument30 pagesAluminum Manufacturing ReportmalynNo ratings yet

- Insulation CalculationDocument8 pagesInsulation CalculationRafay SiddiquiNo ratings yet

- CHEMISTRY SPM FORM 4 Short Notes Chapter 9 MANUFACTURED SUBSTANCES IN INDUSTRYDocument6 pagesCHEMISTRY SPM FORM 4 Short Notes Chapter 9 MANUFACTURED SUBSTANCES IN INDUSTRYJay Bee100% (9)

- Alumina Material Review: Properties and ApplicationsDocument6 pagesAlumina Material Review: Properties and ApplicationsJoão CovelloNo ratings yet

- Solid Insulators-Wps OfficeDocument24 pagesSolid Insulators-Wps OfficeMarco LacsamanaNo ratings yet

- Author's Accepted Manuscript: Ceramics InternationalDocument41 pagesAuthor's Accepted Manuscript: Ceramics InternationalHaroldNo ratings yet

- Glass Wool (Soumendra Roy)Document11 pagesGlass Wool (Soumendra Roy)Soumendra RoyNo ratings yet

- Australian Aluminium: Teacher Guide Some Links May Not Work On The Web Version Please See in Class For Details MRGDocument12 pagesAustralian Aluminium: Teacher Guide Some Links May Not Work On The Web Version Please See in Class For Details MRGYusman LatungguNo ratings yet

- How Aluminium Is ProducedDocument3 pagesHow Aluminium Is ProducedHtet Arkar KyawNo ratings yet

- Electric Power Cables1 PDFDocument21 pagesElectric Power Cables1 PDFDipankar MondalNo ratings yet

- Polymeric Composite Materials-5.1Document8 pagesPolymeric Composite Materials-5.1HALİM BOZTEPENo ratings yet

- Fibre Wrapping (Carbon, Aramid, Glass)Document1 pageFibre Wrapping (Carbon, Aramid, Glass)Dikshant HasbeNo ratings yet

- Mineral FibrelDocument19 pagesMineral FibrelnitishkohliNo ratings yet

- Inorganic Fibers Lecture Class NoteDocument23 pagesInorganic Fibers Lecture Class NoteGemeda GebinoNo ratings yet

- Pipe Insulation Material Selection GuideDocument4 pagesPipe Insulation Material Selection GuidebinoykrishnaNo ratings yet

- High Purity AluminaDocument13 pagesHigh Purity AluminaNilay JoshiNo ratings yet

- Glass Fibers ProductionDocument6 pagesGlass Fibers ProductionVivekananda SubramaniNo ratings yet

- Yy Yy Yyyyyy Y Y Yyyy Yy Yyy!"Y Yy Yyyy Y Yy Yy#Y$Y Yy Y Y Yy%Y Y & Yy Yy Y' ('Y YDocument4 pagesYy Yy Yyyyyy Y Y Yyyy Yy Yyy!"Y Yy Yyyy Y Yy Yy#Y$Y Yy Y Y Yy%Y Y & Yy Yy Y' ('Y YSENTHIL KUMARNo ratings yet

- How Aluminium Alloys Are ProducedDocument4 pagesHow Aluminium Alloys Are Producedمحمد نجارNo ratings yet

- Aluminium (Al) - Forms Casting BasedDocument13 pagesAluminium (Al) - Forms Casting BasedSansar PanchalNo ratings yet

- Mehran University of Engineering and Technology: Topic: Acrylic Synthetic FiberDocument9 pagesMehran University of Engineering and Technology: Topic: Acrylic Synthetic FiberGhulamullah KhaskheliNo ratings yet

- Nanopartikel AluminaDocument10 pagesNanopartikel AluminaNovitasari0% (1)

- Inorganic Fibers Properties and UsesDocument9 pagesInorganic Fibers Properties and UsesHarsh RajNo ratings yet

- Industry & The Environment: AluminiumDocument33 pagesIndustry & The Environment: AluminiumJaleel ForbesNo ratings yet

- Aluminium SmeltingDocument41 pagesAluminium SmeltingVanamali Krish100% (1)

- Alumina BubblesDocument2 pagesAlumina BubblesJayant ParimalNo ratings yet

- Cables and Conductors - 1Document7 pagesCables and Conductors - 1Mopha BrandyNo ratings yet

- Tutorial Insulation of Electrical CablesDocument8 pagesTutorial Insulation of Electrical CablesLedred1No ratings yet

- Axim Refractory Materials BrochureDocument1 pageAxim Refractory Materials BrochurejoravicaNo ratings yet

- Kaowool Rope and Textiles: North America: +1 (0) 706 796 4200 / Asia: +65 (0) 6595 0000Document1 pageKaowool Rope and Textiles: North America: +1 (0) 706 796 4200 / Asia: +65 (0) 6595 0000ppicNo ratings yet

- Introduction to Nylon Fibre: Properties & UsesDocument3 pagesIntroduction to Nylon Fibre: Properties & UsesDebasish GhoshNo ratings yet

- Materials For Laptop BodyDocument6 pagesMaterials For Laptop BodySuparna KhasnabisNo ratings yet

- Hall-Héroult Process: Main Articles: andDocument1 pageHall-Héroult Process: Main Articles: andA-ReaderNo ratings yet

- Alloy foil and Ceramic Powder analysis (38Document4 pagesAlloy foil and Ceramic Powder analysis (38Elango SureshNo ratings yet

- Introduction To CompositesDocument16 pagesIntroduction To CompositesalfajNo ratings yet

- Native Specimens: Alfian Pangestu 2712100041 The Making AluminiumDocument2 pagesNative Specimens: Alfian Pangestu 2712100041 The Making AluminiumAli YafiNo ratings yet

- Aluminum - Production and Transformation: From BauxiteDocument5 pagesAluminum - Production and Transformation: From Bauxitelamia97No ratings yet

- RefractoryDocument85 pagesRefractoryMOHD AZAMNo ratings yet

- Glass Fibre: Historical BackgroundDocument11 pagesGlass Fibre: Historical Backgroundapi-19731065100% (1)

- BMS Presentation - Lightweight Properties and Uses of AluminiumDocument17 pagesBMS Presentation - Lightweight Properties and Uses of AluminiumHarshit AroraNo ratings yet

- Refractories in Cement ManufacturingDocument24 pagesRefractories in Cement ManufacturingNael91% (23)

- Aalco Metals LTD - Aluminium Alloy Introduction To Aluminium and Its Alloys - 9 PDFDocument3 pagesAalco Metals LTD - Aluminium Alloy Introduction To Aluminium and Its Alloys - 9 PDFsourabh yadavNo ratings yet

- MWDocument11 pagesMWjitendraNo ratings yet

- Types of Glass FibresDocument37 pagesTypes of Glass FibresAayush GoelNo ratings yet

- Food Labelling For Dummies Screen v9 041013Document16 pagesFood Labelling For Dummies Screen v9 041013Melih AltıntaşNo ratings yet

- Guide To Raising Healthy BeefDocument4 pagesGuide To Raising Healthy BeefMelih AltıntaşNo ratings yet

- 2011 Tire Startup Paged SDocument8 pages2011 Tire Startup Paged SMohamed AbdullaNo ratings yet

- 2014 Exhibitor List: Company Booth NumberDocument2 pages2014 Exhibitor List: Company Booth NumberMelih AltıntaşNo ratings yet

- 2011 Tire Startup Paged SDocument8 pages2011 Tire Startup Paged SMohamed AbdullaNo ratings yet

- Al Gharasi Profile 2008Document9 pagesAl Gharasi Profile 2008Melih AltıntaşNo ratings yet

- MPNP Application Kit 2Document54 pagesMPNP Application Kit 2Timoy Cajes0% (1)

- Beekeeping BasicsDocument102 pagesBeekeeping Basicsibd1ibuc100% (1)

- ECyclingUSA Tire Recycling Businesses 26 Feb 2013Document18 pagesECyclingUSA Tire Recycling Businesses 26 Feb 2013Melih AltıntaşNo ratings yet

- York U at A Glance 2014Document2 pagesYork U at A Glance 2014Melih AltıntaşNo ratings yet

- Dolch Words - Pre Primer ListDocument40 pagesDolch Words - Pre Primer Listbjw19000100% (2)

- 100 Ways To Say It PDFDocument55 pages100 Ways To Say It PDFVikas NarangNo ratings yet

- Doing Business in Japan: 2013 Country Commercial Guide For U.S. CompaniesDocument138 pagesDoing Business in Japan: 2013 Country Commercial Guide For U.S. CompaniesMelih AltıntaşNo ratings yet

- Global Advanced WordlistDocument198 pagesGlobal Advanced WordlistMelih Altıntaş100% (1)

- Turkey Textiles (Panel)Document73 pagesTurkey Textiles (Panel)Melih AltıntaşNo ratings yet

- 52 RefractoriespittsburghDocument29 pages52 RefractoriespittsburghDefriNo ratings yet

- Up Words SentencesDocument587 pagesUp Words SentencespriyaspvNo ratings yet

- 125 Useful English PhrasesDocument11 pages125 Useful English PhrasesMohan PereraNo ratings yet

- Turkish Plastic Sector 2010Document8 pagesTurkish Plastic Sector 2010Melih AltıntaşNo ratings yet

- The Representative MaterialsDocument1 pageThe Representative MaterialsMelih AltıntaşNo ratings yet

- Top 5 Us Export and Import Commodities: FollowonheadonmasterpageaDocument6 pagesTop 5 Us Export and Import Commodities: FollowonheadonmasterpageaMelih AltıntaşNo ratings yet

- 30 - Aaqr 12 04 Oa 0094 - 1145 1150 PDFDocument6 pages30 - Aaqr 12 04 Oa 0094 - 1145 1150 PDFMelih AltıntaşNo ratings yet

- 100 Ways To Say It PDFDocument55 pages100 Ways To Say It PDFVikas NarangNo ratings yet

- U.S. Manufacturing and The Importance of International Trade: It's Not What You ThinkDocument24 pagesU.S. Manufacturing and The Importance of International Trade: It's Not What You ThinkMelih AltıntaşNo ratings yet

- Brochure Export Guarantee Program PDFDocument2 pagesBrochure Export Guarantee Program PDFMelih AltıntaşNo ratings yet

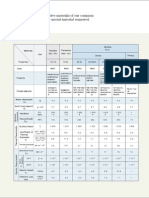

- 8510-1042 Ceramic Material Properties PDFDocument1 page8510-1042 Ceramic Material Properties PDFMelih AltıntaşNo ratings yet

- Global Trade Magazine Free The Free Trade Zone Rare Bird Trading March April 2012Document7 pagesGlobal Trade Magazine Free The Free Trade Zone Rare Bird Trading March April 2012Melih AltıntaşNo ratings yet

- 12 06 2013 PDFDocument1 page12 06 2013 PDFMelih AltıntaşNo ratings yet

- MSM CS Keramik en KL DefDocument2 pagesMSM CS Keramik en KL DefMelih AltıntaşNo ratings yet

- Aradur 2963Document39 pagesAradur 2963saku_asmaNo ratings yet

- Refractorymaterials 150313053315 Conversion Gate01Document19 pagesRefractorymaterials 150313053315 Conversion Gate01tesfayregs gebretsadikNo ratings yet

- Pre-Cleaner Max3: Conveyor ComponentsDocument2 pagesPre-Cleaner Max3: Conveyor ComponentsAttila GanglNo ratings yet

- CatalogDocument46 pagesCataloglangtu2011No ratings yet

- Glaze Chemistry Primer: Hamilton Williams, JRDocument22 pagesGlaze Chemistry Primer: Hamilton Williams, JRThongMaVan100% (1)

- Traditional Ceramic MaterialsDocument2 pagesTraditional Ceramic MaterialsFarooq ShahNo ratings yet

- Catalogue Bleaching EarthDocument3 pagesCatalogue Bleaching EarthGiuliano Castellani CiodaroNo ratings yet

- Basf AdsorbentsDocument8 pagesBasf AdsorbentsNasir KhanNo ratings yet

- ReviewDocument119 pagesReviewlhphong021191No ratings yet

- Oxo Act02 C3uu cm01 XxaannDocument3 pagesOxo Act02 C3uu cm01 Xxaannpreeti.2405100% (1)

- Project Report PDFDocument33 pagesProject Report PDFGAUTAM KUMAR BHATTACHARYANo ratings yet

- Allied Mineral Refractory Castable - Refractory Cement - Allied Mineral PDFDocument2 pagesAllied Mineral Refractory Castable - Refractory Cement - Allied Mineral PDFLeo CrisuNo ratings yet

- Using Pindan Sand-Clay in Pavement Structural LayersDocument15 pagesUsing Pindan Sand-Clay in Pavement Structural Layersganguly147147No ratings yet

- Introduction To MukandDocument25 pagesIntroduction To MukandNiraj ThakurNo ratings yet

- Introduction To Materials: Prof. H. K. KhairaDocument75 pagesIntroduction To Materials: Prof. H. K. KhairaDhanush NairNo ratings yet

- Ceramics PPT CEMDocument37 pagesCeramics PPT CEMskhanveNo ratings yet

- 12 Chemistry Exemplar Chapter 1Document403 pages12 Chemistry Exemplar Chapter 1chiragNo ratings yet

- Mineral Processing and Extractive Metallurgy Review: An International JournalDocument31 pagesMineral Processing and Extractive Metallurgy Review: An International JournalAswin KrishnaNo ratings yet

- Metallurgical SlagDocument27 pagesMetallurgical SlagADITYA RAHMANNo ratings yet

- Company OSDocument36 pagesCompany OSNabeel Mhmd100% (1)

- Aluminum - Aluminium and Its AlloysDocument226 pagesAluminum - Aluminium and Its Alloysminhduc_leNo ratings yet

- Comparison of Commercial AntacidsDocument22 pagesComparison of Commercial AntacidsRitesh Kumar78% (18)

- Surface Modification Options Boost Implant OsseointegrationDocument5 pagesSurface Modification Options Boost Implant OsseointegrationananthNo ratings yet

- Chemistry Notes for Class 12 Chapter 6 Isolation of Elements (39Document14 pagesChemistry Notes for Class 12 Chapter 6 Isolation of Elements (39kunal bansalNo ratings yet

- Walter Product Innovations 16 2 UsDocument270 pagesWalter Product Innovations 16 2 Ust1nz mdsNo ratings yet

- Magnelis Brochure enDocument8 pagesMagnelis Brochure enorkunituNo ratings yet

- Utilization of aluminum hydroxide to lower stomach acid and phosphate levelsDocument5 pagesUtilization of aluminum hydroxide to lower stomach acid and phosphate levelsputrik agustinaNo ratings yet

- Composite of AC Al2O3Document16 pagesComposite of AC Al2O3Meidita KsNo ratings yet

- Metals - Form 4 Chemistry Topical QuestionsDocument13 pagesMetals - Form 4 Chemistry Topical QuestionsEmmanuel KipyegonNo ratings yet

- Cement Its Chemistry and PropertiesDocument13 pagesCement Its Chemistry and PropertiesMuhammad MurtazaNo ratings yet

- Additives Reference Guide 2013Document80 pagesAdditives Reference Guide 2013Victor MelloNo ratings yet