Professional Documents

Culture Documents

Sharda Engineers & Constructions: Liquid Penetrant Test Inspection Report

Uploaded by

Amol KhatateOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sharda Engineers & Constructions: Liquid Penetrant Test Inspection Report

Uploaded by

Amol KhatateCopyright:

Available Formats

SHARDA ENGINEERS & CONSTRUCTIONS

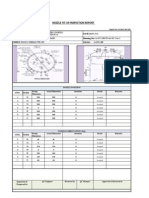

Report No.: 02 Client:RIL Project: Retail outlet phase || BC 2718 Code of Ref. for examination: ASME Sec. V, Ed. 2010 Procedure No.:LPT-O1 REVO Dated 20/6.2012 Material type: is 2062 Surface condition: Grinding PENETRANT Make: ORION Brand: 115/115 PR Batch No.: P/006/2012/JP Expiry date: Apr-14 Application: SPRAYING Dwell time: 10 MIN Lighting equipment used: NO Date:26/08/2012

LIQUID PENETRANT TEST INSPECTION REPORT

Drg. No.: ZO-F10-F2-02 DHT.1 OF 4 REV 11 Acc. Std.: ASME Sec. VIII Div.1, Ed.2010 Material thick.:6mm Part Temp.: Ambient Method: Solvent Removable/visible Removal technique: Solvent Removal

Doc. No.: QAP-01 REV-00 DATED 04/08/2012

DEVELOPER CLEANER Make: ORION Make: Brand: 115/115PR Brand: Batch No.: D/006/2012 Batch No.: Expiry date: MAY 2014 Expiry date: Application: SPRAYING Application: Developing time: 10 MIN Drying time: Date & time of inspection: 26/08/2012 Welder No. 2 2 2 2 2 2 2 2 2 Stage of Insp. Back chip DPT Back chip DPT Back chip DPT Back chip DPT Back chip DPT Back chip DPT Back chip DPT Back chip DPT Back chip DPT

ORION 115P/115D R/005/2012/JP Apr-14 SPRAYING 10 MIN

Sr. No. Nozzle Mark Nozzle size & Sch 80 NB IS 1239 MCLASS 1 N1 150# SORF 80 NB IS 1239 MCLASS 2 N2 150# SORF 100 NB IS 1239 MCLASS 3 N3 150# SORF 100 NB IS 1239 MCLASS 4 N4 150# SORF 80 NB IS 1239 MCLASS 5 N5 150# SORF 80 NB IS 1239 MCLASS 6 N6 150# SORF 80 NB IS 1239 MCLASS 7 N7 150# SORF 100 NB IS 1239 MCLASS 8 N8 150# SORF 600 NB IS 1239 MCLASS 9 M 150# SORF Post Cleaning : Done For Sharda Engineers & Consturctions EIC

Observation Satisfactory Satisfactory Satisfactory Satisfactory Satisfactory Satisfactory Satisfactory Satisfactory Satisfactory

Result (Acc. / Rej. / Repair) Acceptable Acceptable Acceptable Acceptable Acceptable Acceptable Acceptable Acceptable Acceptable

For RIL EIC

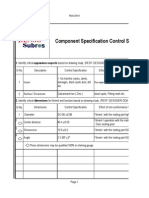

SHARDA ENGINEERS & CONSTRUCTIONS

Report No.: 03 Date:27/08/2012

LIQUID PENETRANT TEST INSPECTION REPORT

Client:RIL Project: Retail outlet phase || BC 2718 Code of Ref. for examination: ASME Sec. V, Ed. 2010 Procedure No.:LPT-O1 REVO Dated 20/6.2012 Drg. No.: ZO-F10-F2-02 DHT.1 OF 4 REV 11 Acc. Std.: ASME Sec. VIII Div.1, Ed.2010 Material thick.:6mm Part Temp.: Ambient Method: Solvent Removable/visible Removal technique: Solvent Removal

Doc. No.: QAP-01 REV-00 DATED 04/08/2012

Material type: is 2062 Surface condition: Grinding PENETRANT Make: ORION Brand: 115/115 PR Batch No.: P/006/2012/JP Expiry date: Apr-14 Application: SPRAYING Dwell time: 10 MIN Lighting equipment used: NO Sr. No. 1 2 3 4 5 6 7 8 9 Nozzle Mark N1 N2 N3 N4 N5 N6 N7 N8 M

DEVELOPER CLEANER Make: ORION Make: Brand: 115/115PR Brand: Batch No. D/006/2012 Batch No.: Expiry date: MAY 2014 Expiry date: Application: SPRAYING Application: Developing time: 10 MIN Drying time: Date & time of inspection: 27/08/2012 Stage of Insp. Final weld joint Final weld joint Final weld joint Final weld joint Final weld joint Final weld joint Final weld joint Final weld joint Final weld joint

ORION 115P/115D R/005/2012/JP Apr-14 SPRAYING 10 MIN

Welder No. Nozzle size & Sch 80 NB IS 1239 MCLASS 2 150# SORF 80 NB IS 1239 MCLASS 2 150# SORF 100 NB IS 1239 MCLASS 2 150# SORF 100 NB IS 1239 MCLASS 2 150# SORF 80 NB IS 1239 MCLASS 2 150# SORF 80 NB IS 1239 MCLASS 2 150# SORF 80 NB IS 1239 MCLASS 150# SORF 2 100 NB IS 1239 MCLASS 2 150# SORF 600 NB IS 1239 MCLASS 150# SORF 2

Observation Result (Acc. / Rej. / Repair) Satisfactory Satisfactory Satisfactory Satisfactory Satisfactory Satisfactory Satisfactory Satisfactory Satisfactory Acceptable Acceptable Acceptable Acceptable Acceptable Acceptable Acceptable Acceptable Acceptable

Post Cleaning : Done For Sharda Engineers & Consturctions EIC For RIL EIC

You might also like

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- QC-F-09 LPT-290-610Document2 pagesQC-F-09 LPT-290-610Narendra BabuNo ratings yet

- DS-50-0804.02-6000-004 Rev D2 Non Slam Check Valve PDFDocument2 pagesDS-50-0804.02-6000-004 Rev D2 Non Slam Check Valve PDFjhon smithNo ratings yet

- WRZK 4 Run@31-July 2011Document5 pagesWRZK 4 Run@31-July 2011Adel FawziNo ratings yet

- (732-Itp-40 (V-6905) 42000-SNG-69-42000P-MS-5733-504-0000-06Document10 pages(732-Itp-40 (V-6905) 42000-SNG-69-42000P-MS-5733-504-0000-06sathi11189No ratings yet

- SVL OngcDocument75 pagesSVL Ongcdbircs1981No ratings yet

- 16 JRTP 02 ITP - Rev01Document13 pages16 JRTP 02 ITP - Rev01khsaeed100% (1)

- End of Stage Report - 2613597 - TG12 C133 FrontDocument8 pagesEnd of Stage Report - 2613597 - TG12 C133 FrontAmit BateNo ratings yet

- Ppap For Neel MetalDocument40 pagesPpap For Neel MetalshuklahouseNo ratings yet

- Dry TR TestDocument9 pagesDry TR Testamjaad100% (1)

- Test Certificate 01Document1 pageTest Certificate 01Anoop RaghuNo ratings yet

- Penetrant Test Report: PT DegremontDocument14 pagesPenetrant Test Report: PT DegremontMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Revise Insp Report - 1 PDFDocument4 pagesRevise Insp Report - 1 PDFShankar RajNo ratings yet

- Sample Approval Report: Item Description VendorDocument2 pagesSample Approval Report: Item Description VendorDeepak C. RajwarNo ratings yet

- Technical Bid Evaluation SummaryDocument6 pagesTechnical Bid Evaluation SummaryhalipzramlyzNo ratings yet

- PT02Document1 pagePT02اسران احمدNo ratings yet

- Itp For SSDP Project Rev CDocument9 pagesItp For SSDP Project Rev CRachel FloresNo ratings yet

- R0607-Cm-Itr-08-606 321a PDFDocument13 pagesR0607-Cm-Itr-08-606 321a PDFShelton S S SheltonNo ratings yet

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- Mu-00-S08 Urs For Cooling Water Circulation PumpsDocument13 pagesMu-00-S08 Urs For Cooling Water Circulation Pumpsdhanu_lagwankarNo ratings yet

- Ultrasonic Test Report: Tested by Industrial Engineering Services.19/1-D, Tolarbagh, MirpurDocument4 pagesUltrasonic Test Report: Tested by Industrial Engineering Services.19/1-D, Tolarbagh, MirpurAmit HasanNo ratings yet

- 049-Itp For Lighting and Small Power (Building) PDFDocument15 pages049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- INSPECTION AND TEST PLAN (ITP) FOR TEST TANK PDM T-1001 A Rev B PDFDocument7 pagesINSPECTION AND TEST PLAN (ITP) FOR TEST TANK PDM T-1001 A Rev B PDFgst ajah100% (4)

- Ppap Spacer TubeDocument37 pagesPpap Spacer TubeSeenivasagam SeenuNo ratings yet

- Inspection Test PlanDocument2 pagesInspection Test PlanAneesh JoseNo ratings yet

- Gate Valve DSDocument5 pagesGate Valve DSkhaireddin100% (1)

- Nozzle Fit-Up Inspection Report: Inspected & Prepared byDocument9 pagesNozzle Fit-Up Inspection Report: Inspected & Prepared byDaison PaulNo ratings yet

- S-900-1670-581 - 1 - (Inspection and Test Plan For Rotating Machinery (Pumps and Air Compressors) )Document10 pagesS-900-1670-581 - 1 - (Inspection and Test Plan For Rotating Machinery (Pumps and Air Compressors) )Alif Rahmat Febrianto100% (3)

- D04Document7 pagesD04Ahmed SoomroNo ratings yet

- Repair Procedure ANNEXUREDocument16 pagesRepair Procedure ANNEXUREShaikh AdilNo ratings yet

- Yanbu: Export Refinery ProjectDocument5 pagesYanbu: Export Refinery ProjectJanakiraman MalligaNo ratings yet

- Turbo Docs P-01267 - Repair MHI ST Rotor Unit 5-1Document34 pagesTurbo Docs P-01267 - Repair MHI ST Rotor Unit 5-1yuliantoNo ratings yet

- LPG EQUIPMENT-ST-HR SegregationDocument34 pagesLPG EQUIPMENT-ST-HR SegregationShubhamNo ratings yet

- Oil Pantriting ProcedureDocument5 pagesOil Pantriting ProcedureSERT-QA/QC- BUZNo ratings yet

- Siemens: 1200 MW DGEN Mega Power ProjectDocument4 pagesSiemens: 1200 MW DGEN Mega Power ProjectJuzer MadarwalaNo ratings yet

- 5501 F FS For Gas Turbine0582642418Document55 pages5501 F FS For Gas Turbine0582642418pramodtryNo ratings yet

- CSCS Rods & BracketsDocument66 pagesCSCS Rods & BracketsshuklahouseNo ratings yet

- AC7102.1D Nadcap Audit Criteria For BrazingDocument11 pagesAC7102.1D Nadcap Audit Criteria For BrazingrsjfidderNo ratings yet

- Company Profile Piling PipeDocument52 pagesCompany Profile Piling PipeMargaretta WijayantiNo ratings yet

- P445 - Technical Proposal Rev.0Document37 pagesP445 - Technical Proposal Rev.0ArtG.EnziNo ratings yet

- TBE Inlet Separator V 2100 FLNG2Document6 pagesTBE Inlet Separator V 2100 FLNG2halipzramlyzNo ratings yet

- Sa-Dar-Cv-W O74-004Document6 pagesSa-Dar-Cv-W O74-004Divakar PanigrahiNo ratings yet

- 5086F Functional Specification For Rotary PumpDocument61 pages5086F Functional Specification For Rotary PumpANRSrinivasanNo ratings yet

- VTR (Vacume Test) Qaqc07Document5 pagesVTR (Vacume Test) Qaqc07AliDadKhanNo ratings yet

- Pipe CodeDocument113 pagesPipe CodeVikas Kumar PathakNo ratings yet

- Hydrostatic Test Procedure: Salalah Ammonia ProjectDocument6 pagesHydrostatic Test Procedure: Salalah Ammonia ProjectAbdelkhak KhallaNo ratings yet

- PSVsDocument8 pagesPSVsMichael HaiseNo ratings yet

- Fit-Up Dimensional Inspection: No. Drawing Dim. Actual Dim. Tolerance Remarks Location Deviation ResultDocument4 pagesFit-Up Dimensional Inspection: No. Drawing Dim. Actual Dim. Tolerance Remarks Location Deviation ResultVanvien LeNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerJebranNo ratings yet

- Data Sheet FOR HSD STORAGE TANK 5000 KL (01-T-002) : Client ReviewDocument6 pagesData Sheet FOR HSD STORAGE TANK 5000 KL (01-T-002) : Client ReviewWardhana Zolli100% (1)

- 5903f - Inert Gas GeneratorDocument18 pages5903f - Inert Gas GeneratorAvinash PatilNo ratings yet

- Ongc 2004a Rev 7Document78 pagesOngc 2004a Rev 7dzardoniNo ratings yet

- Nema Frame Motors (17-Samss-503) Pages (1-3) : Saudi Aramco Pre-Commissioning FormDocument13 pagesNema Frame Motors (17-Samss-503) Pages (1-3) : Saudi Aramco Pre-Commissioning FormHaleem Ur Rashid Bangash100% (1)

- Laporan Hasil Inspkesi-00Document23 pagesLaporan Hasil Inspkesi-00adisutardiNo ratings yet

- Thickness LogDocument136 pagesThickness Logdandiar1No ratings yet

- W13018-YT01-GDF-457110 Rev 5-APVDocument8 pagesW13018-YT01-GDF-457110 Rev 5-APVJosé santanaNo ratings yet

- A05-004 - Inspection Test Plan - Shell & Tube Heat Exchangers - 5-210D-HA-01 A B C DDocument14 pagesA05-004 - Inspection Test Plan - Shell & Tube Heat Exchangers - 5-210D-HA-01 A B C Dbingmin100% (4)

- Inspection & Test PlanDocument1 pageInspection & Test PlanMelissa MurrayNo ratings yet

- 3604 1Document17 pages3604 1Tiffany WilsonNo ratings yet

- LF-D 025 PMS DeckDocument12 pagesLF-D 025 PMS Deckalsitor100% (1)

- Z0 F50 A4 5346 00Document1 pageZ0 F50 A4 5346 00Amol KhatateNo ratings yet

- Reception Card CompressedDocument6 pagesReception Card CompressedAmol KhatateNo ratings yet

- Z0 Z00 C2 4285 00Document1 pageZ0 Z00 C2 4285 00Amol KhatateNo ratings yet

- Standard Cement Consumption For WorkDocument2 pagesStandard Cement Consumption For WorkAmol KhatateNo ratings yet

- Grater BombayDocument13 pagesGrater BombayAmol KhatateNo ratings yet

- MBF Star Lease Guide 2018Document8 pagesMBF Star Lease Guide 2018Amol KhatateNo ratings yet

- HrushiDocument1 pageHrushiAmol KhatateNo ratings yet

- Cost AnalysisDocument3 pagesCost AnalysisAmol KhatateNo ratings yet

- Trunky Project Minral Water PlantDocument29 pagesTrunky Project Minral Water PlantAmjad PervazNo ratings yet

- I Do NOT Release These Programs So That YouDocument3 pagesI Do NOT Release These Programs So That YouPhearun PayNo ratings yet

- CE 316 CH 7 9-3-12Document28 pagesCE 316 CH 7 9-3-12Neatha ChimNo ratings yet

- DSR PuneDocument22 pagesDSR PunedigvijayjagatapNo ratings yet

- Mansh SKWJW Anmfi SJSJWDocument4 pagesMansh SKWJW Anmfi SJSJWAmol KhatateNo ratings yet

- Supplier Pre-Qualification Survey Rev 1-5-06-11Document19 pagesSupplier Pre-Qualification Survey Rev 1-5-06-11Amol KhatateNo ratings yet

- My Poetry Amol by ChanceDocument1 pageMy Poetry Amol by ChanceAmol KhatateNo ratings yet

- Drikinf Water PlantDocument7 pagesDrikinf Water PlantAmol KhatateNo ratings yet

- Drikinf Water PlantDocument7 pagesDrikinf Water PlantAmol KhatateNo ratings yet

- Transaction Details: Customer Care Account Services Postpay Bill PaymentDocument2 pagesTransaction Details: Customer Care Account Services Postpay Bill PaymentAmol KhatateNo ratings yet

- Tank Fab BroDocument8 pagesTank Fab BroJagadish KatamNo ratings yet

- UCSP Report (Group 6)Document23 pagesUCSP Report (Group 6)cee's the dayNo ratings yet

- New Media and Communication Research: Current Epistemological ApproachesDocument19 pagesNew Media and Communication Research: Current Epistemological ApproachesammarNo ratings yet

- AC - BaudrillardDocument14 pagesAC - BaudrillardYajat BhargavNo ratings yet

- Tahiti Vacation GuideDocument84 pagesTahiti Vacation GuideAlex D.No ratings yet

- Coca Cola: Corporate Social ResponsibilityDocument14 pagesCoca Cola: Corporate Social ResponsibilitySumbal JameelNo ratings yet

- English Practice 32: Section I-PhoneticsDocument7 pagesEnglish Practice 32: Section I-PhoneticsCorcatterNo ratings yet

- Urban Legend BOOK 6Document5 pagesUrban Legend BOOK 6Louise MarcassaNo ratings yet

- The Last Walk - An Article On Krishnamurti by Asit ChandmalDocument12 pagesThe Last Walk - An Article On Krishnamurti by Asit ChandmalK Circle100% (4)

- Astm D 1114Document26 pagesAstm D 1114Christian Rodrigo Gonzalez CockbaineNo ratings yet

- Previous Studies.: The Heb Sed Festival Sequence and Pbrooklyn 47.218.50Document8 pagesPrevious Studies.: The Heb Sed Festival Sequence and Pbrooklyn 47.218.50Mohammed MohieNo ratings yet

- Marx - Historical MaterialismDocument10 pagesMarx - Historical MaterialismAakash Kumar YadavNo ratings yet

- LASCH, Christopher - The Minimal Self Psychic Survival in Troubled TimesDocument254 pagesLASCH, Christopher - The Minimal Self Psychic Survival in Troubled Timestibacanetti100% (1)

- Kiwanis International Policies and ProceduresDocument180 pagesKiwanis International Policies and ProceduresChristianKhrizMoMoralesNo ratings yet

- 05 20 15Document36 pages05 20 15grapevineNo ratings yet

- Vdoc - Pub - Nephilim Crown 5g ApocalypseDocument167 pagesVdoc - Pub - Nephilim Crown 5g ApocalypseRachet DanielNo ratings yet

- Publishable Research-Bernadeth P. D GuzmanDocument19 pagesPublishable Research-Bernadeth P. D GuzmanGAD MinSCATNo ratings yet

- Transfusion Resource Handbook 2018 PDFDocument30 pagesTransfusion Resource Handbook 2018 PDFPratama PuteraNo ratings yet

- Tom ZuidemaDocument2 pagesTom ZuidemawalterdescargaNo ratings yet

- Roseberry - La Falta de Brazos CoffeDocument32 pagesRoseberry - La Falta de Brazos Coffebolontiku9No ratings yet

- Piping Engineering Design Criteria Rev02Document15 pagesPiping Engineering Design Criteria Rev02swatkoolNo ratings yet

- Castes Races and Tribes of MahaDocument6 pagesCastes Races and Tribes of MahaRohan PaulNo ratings yet

- National Honor Society EssayDocument4 pagesNational Honor Society Essayapi-650343119No ratings yet

- AR Bio 10-10Document1 pageAR Bio 10-10Asante RiverwindNo ratings yet

- Bài Tập Động Từ Trái Nghĩa Có Đáp ÁnDocument8 pagesBài Tập Động Từ Trái Nghĩa Có Đáp ÁnNguyễn Ngọc Kỳ ThưNo ratings yet

- CVDocument3 pagesCVapi-489460252No ratings yet

- Report On The International Status of Open Source Software 2010Document154 pagesReport On The International Status of Open Source Software 2010LinuxMalaysia MalaysiaNo ratings yet

- Chapter 02 PDFDocument29 pagesChapter 02 PDFLucía AlbarracinNo ratings yet

- 2018 Politics II InfopackDocument58 pages2018 Politics II InfopackRevathi VaisnaveeNo ratings yet

- ENCS 282 - CoursepackDocument222 pagesENCS 282 - CoursepackFrank100% (1)

- American 2011 Annual Report Folklore SocietyDocument34 pagesAmerican 2011 Annual Report Folklore SocietyprembiswasNo ratings yet