Professional Documents

Culture Documents

Wade04.book Page 1 Thursday, April 15, 2004 12:20 PM: Chapter 1 - 1

Uploaded by

siamak001Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wade04.book Page 1 Thursday, April 15, 2004 12:20 PM: Chapter 1 - 1

Uploaded by

siamak001Copyright:

Available Formats

CHAPTER 1 1

INTRODUCTION

The term process control implies that there is a process for which there is a desired behavior

and that there is some controlling function that acts to elicit that desired behavior. This broad

concept can embrace everything from societal processes governed by some regulatory control

authority to automated manufacturing processes. In practically all cases, however, a common

thread is that some measure of the actual process behavior is compared with the desired pro-

cess behavior. This feedback action then generates a control policy that acts to minimize or

eliminate the deviation between desired and actual behavior.

We are concerned in this book with a particular segment of automated process controlthat

which is applied to chemical, refining, pulp and paper, power generation, and similar types of

processes. Even within this limited scope of applications, we will limit the discussion prima-

rily to processes that are operated continuously for long periods of time and within a narrow

region of the operating variables. In other words, we exclude such important operating modes

as batch processing, start-ups, and grade changes. Many of the control techniques to be pre-

sented here, however, can be adapted to these other modes of operation.

For the processes we focus on in this book, the processs behavior is often characterized by

measured values of such process variables as temperatures, flow rates, pressures, and the like.

The desired behavior, then, is stated to be the set points of those process variables. Until fairly

recent times, most applications of industrial process control used simple feedback controllers

that regulated the flows, temperatures, and pressures. These controllers required a form of

adjustment called tuning to match their controlling action to the unique requirements of indi-

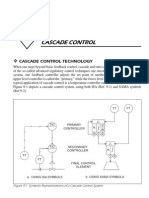

vidual processes. Occasionally, more advanced forms of control, such as ratio and cascade,

could be found; even more rarely one might find a feedforward control loop. As long as most

of the control systems were implemented with analog hardware, applications were limited to

simple regulatory control. This was due to the cost of additional components, the additional

interconnections more advanced control required, the burden of maintenance, and the vulnera-

bility to failure of many devices in the control loop. With the advent of digital control systems,

however, more sophisticated loops became feasible. Advanced regulatory controlwhich

includes the previously mentioned ratio, cascade, and feedforward control as well as additional

forms such as constraint (selector) control and decouplingcould readily be implemented

simply by configuring software function blocks.

With this additional capability, however, a need developed for a systematic approach toward

using it. This is called control strategy design. In order to design a technically successful and

1

Wade04.book Page 1 Thursday, April 15, 2004 12:20 PM

BASIC AND ADVANCED REGULATORY CONTROL: SYSTEM DESIGN AND APPLICATION

2 CHAPTER 1

economically viable control strategy, the control system engineer must be well grounded in the

techniques of feedback control as well as the tools of advanced regulatory control. The requi-

site knowledge includes both how to implement and how to tune. Even before that, however,

the control system engineer must be adept at recognizing when to use (and conversely, when

not to use) certain control methods as well as in projecting the expected benefits.

Using advanced regulatory control provides many benefits. One of the most important is sim-

ply closer control of the process. It will become very clear later in this book that with basic

regulatory (i.e., feedback) control, there must be a deviation from set point before control

action can occur. We will call this the feedback penalty. The objective of advanced regula-

tory control is for the control action to be taken by incurring only a minimal feedback penalty.

The reduction in feedback penalty may be stated in a variety of ways, such as a reduction of

the maximum deviation from set point, as a reduction of the standard deviation, or simply as a

reduction in the amount of off-spec product produced. This reduction in feedback penalty can

provide several forms of economic benefit, such as improvement in product quality, energy

savings, increased throughput, or longer equipment life.

Process control is but one part of an overall control hierarchy. It extends downward to safety

controls and other directly connected process devices and upward to encompass optimization

and even higher levels of business management, such as scheduling, inventory, and asset man-

agement (see Figure 1-1). Indeed, corporate profitability may be enhanced more significantly

as a result of these higher-level activities than from improved process control per se. However,

since each layer of the hierarchy depends upon the proper functioning of the layers beneath it,

one of the primary benefits of advanced regulatory control is that it enables the higher levels,

such as optimization and enterprise management and control.

SYMBOLS

Chapter 2 discusses the graphical symbols used in control system documentation. Listed

below are the mathematical symbols that are used generally throughout the book. Some sym-

bols used in this book are used only for the discussion of a particular topic; these symbols are

therefore defined in that discussion and are not listed here. Chapter 15 uses a unique set of

symbols that are defined at the beginning of that chapter. The following are the symbols found

throughout this book:

b bias value (manual reset) on proportional-only controller output

e error (deviation between set point and process variable)

E when capitalized, refers to (Laplace) transform of error

K steady-state gain of first-order lag

K

C

controller gain (noninteractive and interactive control algorithms)

K

D

derivative gain (independent gains control algorithm)

K

I

integral gain (independent gains control algorithm)

K

P

proportional gain (independent gains control algorithm)

K

p

process gain (change in process variable / change in controller output)

m manipulated variable, controller output

Wade04.book Page 2 Thursday, April 15, 2004 12:20 PM

BASIC AND ADVANCED REGULATORY CONTROL: SYSTEM DESIGN AND APPLICATION

CHAPTER 1 3

M when capitalized, refers to (Laplace) transform of manipulated variable

PB proportional band

PI control algorithm with proportional and integral modes

PID control algorithm with proportional, integral, and derivative modes

PV process variable (see also symbol x)

SP set point (see also symbol x

SP

)

T

D

derivative time (noninteractive and interactive control algorithms)

T

I

integral time (minutes/repeat) (noninteractive and interactive control

algorithms)

x process variable (see also symbol PV)

x

SP

set point (see also symbol SP)

u disturbance variable

derivative gain when a derivative filter is used with noninteractive or

interactive control algorithm)

dead time

first-order lag-time constant

Figure 1-1. Overall Process Control and Information System Hierarchy

OPTMZATON

PROCESS

SAFETY CONTROLS

BASC REGULATORY CONTROL

(Feedback)

ADVANCED REGULATORY CONTROL

(Cascade, Ratio, Feedforward, Override,

Decoupling, Dead-Time Compensation)

ENTERPRSE LEVEL CONTROLS

(Accounting, Scheduling,

Asset Management, etc.)

Wade04.book Page 3 Thursday, April 15, 2004 12:20 PM

You might also like

- Marlin Ch13Document44 pagesMarlin Ch13Ashwin Kumar SabatNo ratings yet

- 5.2.1 Manufactura Integrada Por ComputadoraDocument10 pages5.2.1 Manufactura Integrada Por ComputadoraMartín MirelesNo ratings yet

- Ench 617 Notes I (2021)Document20 pagesEnch 617 Notes I (2021)Mohan kumar0% (1)

- Keep Advanced Control Systems OnlineDocument29 pagesKeep Advanced Control Systems OnlineBisto MasiloNo ratings yet

- Loop Checking A Technicians GuideDocument24 pagesLoop Checking A Technicians GuideJ Mohamed UvaisNo ratings yet

- Process Control: A Practical Approach: © 2011 John Wiley & Sons Ltd. ISBN: 978-0-470-97587-9Document2 pagesProcess Control: A Practical Approach: © 2011 John Wiley & Sons Ltd. ISBN: 978-0-470-97587-9Trường Đỗ ThếNo ratings yet

- Process Engineers: Take Control!: Rocess OntrolDocument11 pagesProcess Engineers: Take Control!: Rocess OntrolJennifer PiragautaNo ratings yet

- Industrial Automation and Control Technology Management: Level-VDocument22 pagesIndustrial Automation and Control Technology Management: Level-Vfrezer mesfinNo ratings yet

- 5 6325398082863237450Document68 pages5 6325398082863237450DishaNo ratings yet

- FUNCTIONS OF TECHNOLOGY MANAGEMENT - ControllingDocument44 pagesFUNCTIONS OF TECHNOLOGY MANAGEMENT - ControllingRuzel AmpoanNo ratings yet

- A Introduction To Advanced Process ControlDocument5 pagesA Introduction To Advanced Process Controlsandeep lal100% (1)

- 6 Steps To Designing A Flexible Control System With ISADocument4 pages6 Steps To Designing A Flexible Control System With ISAEduardo BlancoNo ratings yet

- Industry Automation and Drive Technologies Training ManualDocument36 pagesIndustry Automation and Drive Technologies Training ManualPop-Coman SimionNo ratings yet

- PL-05 Chapter04 Rev3Document38 pagesPL-05 Chapter04 Rev3kevin ArandiaNo ratings yet

- Chapter Overview: 2: Modeling BasicsDocument84 pagesChapter Overview: 2: Modeling BasicsGigiNo ratings yet

- Overview of Undergraduate Control PDFDocument48 pagesOverview of Undergraduate Control PDFboban_mikicNo ratings yet

- Improve manufacturing performance through loop checkingDocument8 pagesImprove manufacturing performance through loop checkingOhaneje Uzoma67% (3)

- 1 Process Dynamics and Control No1Document32 pages1 Process Dynamics and Control No1Ayushi100% (1)

- Editorial Choosing Advanced ControlDocument9 pagesEditorial Choosing Advanced ControlMohd HamedNo ratings yet

- Understand Advanced Process Control: Back To BasicsDocument4 pagesUnderstand Advanced Process Control: Back To BasicsJohn AnthoniNo ratings yet

- AnswersDocument5 pagesAnswersShaik RoshanNo ratings yet

- Sistema de Control 2Document98 pagesSistema de Control 2Esteban CastellanoNo ratings yet

- Basic TheoryDocument5 pagesBasic TheoryzakiNo ratings yet

- Basic Control Concepts Unit2Document10 pagesBasic Control Concepts Unit2Noyon NoyonNo ratings yet

- ControlDocument43 pagesControlaramNo ratings yet

- Computer SystemDocument4 pagesComputer SystemJorge GutierrezNo ratings yet

- Introduction to Process Control Dynamics and SystemsDocument16 pagesIntroduction to Process Control Dynamics and SystemsByron MawoyoNo ratings yet

- PROCESS CONTROL STRATEGIESDocument11 pagesPROCESS CONTROL STRATEGIESRapee Puaksungnoen100% (1)

- DdadaedDocument2 pagesDdadaedShuraihilqadhi KasuleNo ratings yet

- Fundamentals of Process Control Theory ThirdEd - Murrill - Unit2Document10 pagesFundamentals of Process Control Theory ThirdEd - Murrill - Unit2Ganesh GanyNo ratings yet

- Increasing Customer Value of Industrial Control Performance Monitoring-Honeywell's ExperienceDocument21 pagesIncreasing Customer Value of Industrial Control Performance Monitoring-Honeywell's ExperienceJake Berryman TannebergerNo ratings yet

- Automatic Control SystemsDocument3 pagesAutomatic Control SystemsIffatNo ratings yet

- Chapter - 6: Instrumentation & Process Control in The ProcessDocument10 pagesChapter - 6: Instrumentation & Process Control in The ProcessgauriNo ratings yet

- Design Aspects of Control SystemDocument3 pagesDesign Aspects of Control Systemmekeilah romaNo ratings yet

- College of Engineering Education Matina, Davao CityDocument8 pagesCollege of Engineering Education Matina, Davao CityGrazel MDNo ratings yet

- Plantwide Control-A Review and A New Design Procedure: Challenge ProcessDocument32 pagesPlantwide Control-A Review and A New Design Procedure: Challenge Processhamidrezaee008No ratings yet

- HP - 09.10 - Practical Process Control System MetricsDocument3 pagesHP - 09.10 - Practical Process Control System MetricsUzma Abdul RaufNo ratings yet

- Bid Management ProcessDocument0 pagesBid Management Processcoyote41No ratings yet

- Experiment 12 Instrumentation and Control LabDocument17 pagesExperiment 12 Instrumentation and Control LabAyesha KhurramNo ratings yet

- Ha - Case Study - G13 - Batch3Document49 pagesHa - Case Study - G13 - Batch3Sanika TalathiNo ratings yet

- Relevance of Actions and Measurements in Control PerformancesDocument7 pagesRelevance of Actions and Measurements in Control PerformancesLucas DuarteNo ratings yet

- Engineering Manufacturing Control Systems Using PROSA and Delegate MASDocument29 pagesEngineering Manufacturing Control Systems Using PROSA and Delegate MASkhairrajNo ratings yet

- Online Quality Management SystemDocument9 pagesOnline Quality Management Systemselinasimpson361No ratings yet

- Process Control Fundamentals: Revision Date: January 2020Document202 pagesProcess Control Fundamentals: Revision Date: January 2020DidiNo ratings yet

- A Unified Framework For Pull Control Mechanisms in Multi-Stage Manufacturing SystemsDocument31 pagesA Unified Framework For Pull Control Mechanisms in Multi-Stage Manufacturing SystemsqrminstituteplNo ratings yet

- MM UNIT 3b 2021Document78 pagesMM UNIT 3b 2021Mr. S. Paul JoshuaNo ratings yet

- Automation in Manufacturing: February 1997Document9 pagesAutomation in Manufacturing: February 1997anujNo ratings yet

- Fundamentals of Automatic Control SystemsDocument11 pagesFundamentals of Automatic Control SystemsLouie CamposNo ratings yet

- Chemical Enginineering Fourth YearDocument68 pagesChemical Enginineering Fourth YearHabib NuredinNo ratings yet

- White Paper Lambda Tuning As A Promising Controller Tuning Method For Refinery Pss en 67720Document10 pagesWhite Paper Lambda Tuning As A Promising Controller Tuning Method For Refinery Pss en 67720Anish ShahNo ratings yet

- Process Control Lab AssignmentDocument3 pagesProcess Control Lab AssignmentJessica De GuzmanNo ratings yet

- What Is A Validation Master PlanDocument8 pagesWhat Is A Validation Master PlanNate RomanNo ratings yet

- Steve Doty, Pe, CemDocument2 pagesSteve Doty, Pe, CemzulfikartukuboyaNo ratings yet

- Yokogawa PID Tuning Guide - CsTunerDocument28 pagesYokogawa PID Tuning Guide - CsTunerZohaib Alam100% (2)

- 27.ijaest Vol No 8 Issue No 2 DC Motor Control Using Fuzzy Logic Controller 291 296Document6 pages27.ijaest Vol No 8 Issue No 2 DC Motor Control Using Fuzzy Logic Controller 291 296Vikas PatelNo ratings yet

- Semi-Markov Models: Control of Restorable Systems with Latent FailuresFrom EverandSemi-Markov Models: Control of Restorable Systems with Latent FailuresNo ratings yet

- Nature-Inspired Optimization Algorithms for Fuzzy Controlled Servo SystemsFrom EverandNature-Inspired Optimization Algorithms for Fuzzy Controlled Servo SystemsNo ratings yet

- Carriage of Goods by SeaDocument499 pagesCarriage of Goods by Seasiamak00195% (21)

- Derivation of Equations For Installed Valve Characteristics: AppendixDocument5 pagesDerivation of Equations For Installed Valve Characteristics: Appendixsiamak001No ratings yet

- Basic and Advanced Regulatory Control - System Design and Application (2nd Edition)Document4 pagesBasic and Advanced Regulatory Control - System Design and Application (2nd Edition)siamak001No ratings yet

- Preface: Wade04.book Page Xiii Thursday, April 15, 2004 12:20 PMDocument3 pagesPreface: Wade04.book Page Xiii Thursday, April 15, 2004 12:20 PMMowaten MasryNo ratings yet

- 1815 16 PDFDocument17 pages1815 16 PDFsiamak001No ratings yet

- 1815 10 PDFDocument11 pages1815 10 PDFsiamak001No ratings yet

- 1815 Appa PDFDocument5 pages1815 Appa PDFsiamak001No ratings yet

- 365 Index Term LinksDocument23 pages365 Index Term Linkssiamak001No ratings yet

- Dead-Time Compensation and Model-Based Control: Wade04.book Page 291 Thursday, April 15, 2004 12:20 PMDocument20 pagesDead-Time Compensation and Model-Based Control: Wade04.book Page 291 Thursday, April 15, 2004 12:20 PMsiamak001No ratings yet

- 1815 09Document14 pages1815 09Guadalupe EMNo ratings yet

- Basic and Advanced Regulatory Control:: System Design and ApplicationDocument4 pagesBasic and Advanced Regulatory Control:: System Design and Applicationsiamak001No ratings yet

- 1815 13 PDFDocument24 pages1815 13 PDFsiamak001No ratings yet

- 1815 12 PDFDocument21 pages1815 12 PDFUmar IftikharNo ratings yet

- Multivariable Model Predictive Control: Real-World ProblemsDocument24 pagesMultivariable Model Predictive Control: Real-World Problemssiamak001No ratings yet

- 1815 11 PDFDocument32 pages1815 11 PDFsiamak001No ratings yet

- Advanced Regulatory ControlDocument22 pagesAdvanced Regulatory ControlRuan Henrique ColomboNo ratings yet

- 1815 06Document54 pages1815 06farshidianNo ratings yet

- 1815 08 PDFDocument4 pages1815 08 PDFsiamak001No ratings yet

- Guide For Scientific Paper WritingDocument7 pagesGuide For Scientific Paper WritingReza TeflissiNo ratings yet

- Modifications To Standard Pid Control: 1 de M K e Edt T T DTDocument40 pagesModifications To Standard Pid Control: 1 de M K e Edt T T DTsiamak001No ratings yet

- 1815 07 PDFDocument9 pages1815 07 PDFsiamak001No ratings yet

- Grow your career at BATDocument2 pagesGrow your career at BATsiamak001No ratings yet

- 1815 04 PDFDocument21 pages1815 04 PDFsiamak001No ratings yet

- 1815 03 PDFDocument29 pages1815 03 PDFsiamak001No ratings yet

- Children's Film in The Digital Age - Essays On Audience, Adaptation and Consumer Culture (PDFDrive)Document211 pagesChildren's Film in The Digital Age - Essays On Audience, Adaptation and Consumer Culture (PDFDrive)Basia KowalskaNo ratings yet

- Ms Word McqsDocument12 pagesMs Word McqsUraiBa AnsaRi0% (1)

- Vspa 50Document5 pagesVspa 50elfo111No ratings yet

- DS 1Document23 pagesDS 1aayush bhatiaNo ratings yet

- Introduction to SONET and DWDM Digital Transmission StandardsDocument35 pagesIntroduction to SONET and DWDM Digital Transmission StandardsOmar Ayoub100% (1)

- Types of EvidenceDocument13 pagesTypes of EvidenceSteven Jan Sab-itNo ratings yet

- Frequently Asked Questions (Faq) FOR New Unifi Mobile Prepaid #BebasDocument1 pageFrequently Asked Questions (Faq) FOR New Unifi Mobile Prepaid #BebasNgHanSeongNo ratings yet

- SBC For Toll PlazaDocument6 pagesSBC For Toll PlazaruchitaNo ratings yet

- Cognitive TheoryDocument18 pagesCognitive TheoryshaelynNo ratings yet

- DLTSoul DrinkersDocument7 pagesDLTSoul DrinkersIgnacio Burón García100% (1)

- Hemera Creality CR10s Pro Upgrade Guide (Edition 1)Document24 pagesHemera Creality CR10s Pro Upgrade Guide (Edition 1)gumushNo ratings yet

- Positive Role The Indian Youth Can Play in PoliticsDocument2 pagesPositive Role The Indian Youth Can Play in PoliticsArul ChamariaNo ratings yet

- Stakeholder RegisterDocument7 pagesStakeholder Registerrouzbehk6515No ratings yet

- From Self Disorders To The Schizophrenic Self: Riccardo Piero Dalle LucheDocument31 pagesFrom Self Disorders To The Schizophrenic Self: Riccardo Piero Dalle LucheMichel de NostredameNo ratings yet

- Radiation Safety Officers Handbook A PDFDocument100 pagesRadiation Safety Officers Handbook A PDFAlejandro Zubiate100% (1)

- Johnson RPM Chart Evinrude E-Tec RPM Chart Mercury 4-Stroke RPM ChartDocument2 pagesJohnson RPM Chart Evinrude E-Tec RPM Chart Mercury 4-Stroke RPM ChartUlf NymanNo ratings yet

- Free Study PDF Download from pebexam BlogDocument22 pagesFree Study PDF Download from pebexam Blogk_jaiswalNo ratings yet

- ADocument3 pagesAcristinandreeamNo ratings yet

- Beck Thinking and Depression Idiosyncratic Content and Cognitive DistortionsDocument10 pagesBeck Thinking and Depression Idiosyncratic Content and Cognitive DistortionsFrancisco GaravagliaNo ratings yet

- Investment Banking Interview Strengths and Weaknesses PDFDocument15 pagesInvestment Banking Interview Strengths and Weaknesses PDFkamrulNo ratings yet

- Apu White SmokeDocument3 pagesApu White SmokeGoutam SahaNo ratings yet

- Nervous System Reaction PaperDocument3 pagesNervous System Reaction PaperJohn Ruel Sanchez IINo ratings yet

- Holt MCD Earth Science Chapter 30Document34 pagesHolt MCD Earth Science Chapter 30ADEDAMOPE ODUESONo ratings yet

- Spiros Styliaras: Devops EngineerDocument2 pagesSpiros Styliaras: Devops EngineerΣπύρος ΣτυλιαράςNo ratings yet

- TW Ycm01265958803Document62 pagesTW Ycm0126595880313239563No ratings yet

- Niche PartitioningDocument3 pagesNiche PartitioningKhang LqNo ratings yet

- Midterm Exam: Cecor2 - Hydraulics and Geotechnical EngineeringDocument2 pagesMidterm Exam: Cecor2 - Hydraulics and Geotechnical EngineeringEjay EmpleoNo ratings yet

- Significant Ships 1993Document101 pagesSignificant Ships 1993Joe TahirNo ratings yet

- TCXD 46-1984 / Lightning Protection For Buildings - Standard For Design and ConstructionDocument30 pagesTCXD 46-1984 / Lightning Protection For Buildings - Standard For Design and ConstructiontrungjindoNo ratings yet

- SAP MM Purchase Info Record GuideDocument3 pagesSAP MM Purchase Info Record GuidevikneshNo ratings yet