Professional Documents

Culture Documents

50037-QA-PLN-002 Rev.0

Uploaded by

seehariCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

50037-QA-PLN-002 Rev.0

Uploaded by

seehariCopyright:

Available Formats

INSPECTION AND TEST PLAN

Rev. 0

RESIDUAL OFFSHORE CONSTRUCTION WORK AT PARADIP CONTRACT NO. PLCC/PHCPL/SPM/0825

Page 2 of 13

RECORD OF AMMENDMENTS SHEET

Version

A B 0

Purpose

Issued for Inter Disciplinary Check (IDC) Issued for Client Review Issued for approval for construction

List of updated/modified sections if any

IDC comments are incorporated

Intec comments on section 6.1-6.10 have been incorporated and closed out Section 10.5 Test pressure changed from 20 bar for 4 hours to 225 psig for 3 hours Section 9 Added and Mooring Hawser Section 9 Added section 9.2, 9.3, and 9.4

50037-QA-PLN-002

25-11-2008

INSPECTION AND TEST PLAN

Rev. 0

RESIDUAL OFFSHORE CONSTRUCTION WORK AT PARADIP CONTRACT NO. PLCC/PHCPL/SPM/0825

Page 3 of 13

TABLE OF CONTENTS

1.0 2.0 3.0 4.0

INTRODUCTION ........................................................................................................................4 REFERENCES ...........................................................................................................................5 TERMS AND DEFINITIONS ......................................................................................................6 INSPECTION AND TEST PLAN................................................................................................7

50037-QA-PLN-002

25-11-2008

INSPECTION AND TEST PLAN

Rev. 0 1.0 INTRODUCTION 1.1 General

RESIDUAL OFFSHORE CONSTRUCTION WORK AT PARADIP CONTRACT NO. PLCC/PHCPL/SPM/0825

Page 4 of 13

Indian Oil Corporation Ltd (IOCL) is setting up a crude oil receiving facility having Single Point Mooring terminal about 20 Kms off the coast of Paradip port in the east coast of India. This facility will enable to unload the crude oil from the VLCCs to meet the crude oil requirement of its refineries located in the eastern part of India. Global Industries Asia Pacific Pte Ltd (GIAP) has been contracted by Indian Oil Corporation Ltd to perform the Residual Offshore works at Paradip, Group I project, which involves the below scope of work. 1.2

Scope of Work Pre-installation and Anchor clearance Survey. Towing of the CALM Buoy (11.5m dia., approx 250 T, SBM-IMODCO Turn Table Type) from Paradip Port jetty to SPM location (approx 20 km). Locating and marking the ends of all the six anchor chains. Each chain is studless apprx 345 m long, weighing 70 T and secured to anchor piles positioned at a radius 316m from the CALM Buoy location, equally spaced at 60 deg. Cross Tensioning of the anchor chains upto 300 T. Positioning the CALM Buoy at the PLEM centre and affixing the chains to the Buoy. Leak test of the Floating Hose String at the jetty before transportation to the CALM Buoy location. Transportation, Assembly and Hydro testing of the Submarine Hose Strings. Affixing the 20 dia Submarine Hoses and Associated Systems. Affixing the 24 dia Floating hoses. Installation of the Hydraulic Umbilical from HPU to the PLEM Actuators. Installation of the Mooring Hawser and associated Mooring Systems. Leak Testing of the CALM Buoy System. Commissioning support. Post Installation Survey.

1.3 Document Purpose The purpose of Inspection and Test Plan is to define the type and level of inspection requirements, which are to be performed during the installation, mechanical completion and pre commissioning phases of the project. It also identifies the reference documents to be allowed/ acceptance criteria and verifying documents which are needed to provide the documentary evidence of the successful completion of the inspection activity and compliance with specified test requirements. This Inspection and test plan also specifies the mutually agreed type and level of inspection, such as witnessing, hold, review and monitoring by all relevant parties before the commencement of quality control activities in the project.

50037-QA-PLN-002 25-11-2008

INSPECTION AND TEST PLAN

Rev. 0 2.0 REFERENCES The below are the key reference documents for this project. All external codes and standards of latest versions are available for project reference in Global intranet and accessible for all employees. Sl. No 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 2.10 Document No. 50037-QA-PLN-001 50037-PM-PLN-001 50037-SI-PRD-001 50037-SI-PRD-002 50037-SI-PRD-003 50037-SU-PRD-001 50037-SU-DOC-001 50037-SU-PRD-002 50037-SU-DOC-002 50037-ME-DOC-001 Project Quality Plan Project Execution Plan CALM Buoy Installation Procedure Anchor Handling and Mooring Procedure Pre-commissioning Procedure Pre-installation Survey Procedure Pre-installation Survey report As-Built Survey Procedure As-Built Survey Report Marine Spread Specifications & Certification Dossier Description

RESIDUAL OFFSHORE CONSTRUCTION WORK AT PARADIP CONTRACT NO. PLCC/PHCPL/SPM/0825

Page 5 of 13

50037-QA-PLN-002

25-11-2008

INSPECTION AND TEST PLAN

Rev. 0

RESIDUAL OFFSHORE CONSTRUCTION WORK AT PARADIP CONTRACT NO. PLCC/PHCPL/SPM/0825

Page 6 of 13

3.0 TERMS AND DEFINITIONS The key terms/ acronyms etc. are defined in the following table or within individual project documents. Terms and definitions shall be as per ISO 9000:2000. AFC Contractor Company CALM FIM ITP MWS NCR PLEM PQP : : : : : : : : : Approved for Construction by Company Global Industries Asia Pacific Pte. Ltd (GIAP) India Oil Corporation Limited (IOCL) Catenary Anchor Leg Mooring Buoy Free Issued Material Inspection and Test Plan Marine Warranty Surveyor Non Conformance Report Pipeline End Manifold Project Quality Plan is a document specifying which procedures and associated resources shall be applied by whom and when to a specific project product, process or contract. Quality Assurance, Part of quality management, focused on providing confidence that quality requirements will be fulfilled. Quality Control, Part of quality management focused on fulfilling quality requirements. Quality Management System Remote Operated Vehicle Single Buoy Mooring : Personnel nominated by the Company to review, witness and/or approve project activities wherever applicable.

QA QC QMS ROV SBM 3rd Party

: : : :

50037-QA-PLN-002

25-11-2008

INSPECTION AND TEST PLAN

Rev. 0 4.0 INSPECTION AND TEST PLAN

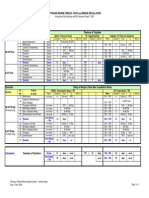

REF. NO. 1 1.1 1.2 1.3 1.3 1.4 ACTIVITY DESCRIPTION INSTALLATION PROCEDURES CALM Buoy Installation Anchor Handling and Mooring Pre-commissioning Singapore Singapore Singapore Singapore Singapore 50037-SI-PRD-001: CALM Buoy Installation Procedure 50037-SI-PRD-002: Anchor Handling and Mooring Procedure 50037-SI-PRD-003: Pre-Commissioning Procedure 50037-SU-PRD-001: PreInstallation Survey Procedure 50037-SU-PRD-002: As-Built Survey Procedure 50037-SU-PRD-003: Derrick Barge Survey and Positioning Procedures AFC AFC AFC AFC AFC P/R P/R P/R P/R P/R R/A R/A R/A R/A R/A R/A R/A R/A R/A R/A LOCATION REFERENCE PROCEDURE/ ACCEPTANCE CRITERIA VERIFYING DOCUMENTS SURVEILLANCES BY

GIAP IOCL 3rd PARTY

RESIDUAL OFFSHORE CONSTRUCTION WORK AT PARADIP.

CONTRACT NO. PLCC/PHCPL/SPM/0825

Page 7 of 13

Pre-installation Survey As-Built Survey

1.5 2

Derrick Barge Survey and Positioning

Singapore

AFC

P/R

R/A

R/A

RECEIPT OF COMPANY FREE ISSUED MATERIALS (FIM)

2.1

Inspect & Receive Companys FIM.

Paradip port

FIM Delivery Notes Shipping documents Materials certificates OSD Check & Visual inspections

NA: NOT APPLICABLE P: PERFORM

Materials Receiving Report

P/H

R/A

R/A

50037-QA-PLN-002

LEGEND :

A: APPROVE H: HOLD

R: REVIEW W: WITNESS

25-11-2008

INSPECTION AND TEST PLAN

Rev. 0

RESIDUAL OFFSHORE CONSTRUCTION WORK AT PARADIP.

CONTRACT NO. PLCC/PHCPL/SPM/0825

REFERENCE PROCEDURE/ ACCEPTANCE CRITERIA VERIFYING DOCUMENTS

Page 8 of 13

SURVEILLANCES BY

GIAP IOCL 3rd PARTY

REF. NO. 3 3.1 3.2 3.3 3.4

ACTIVITY DESCRIPTION

LOCATION

FABRICATION OF INSTALLATION AIDS (CHAIN TENSIONER & SPREADER BAR) Welding Procedures & Welder Qualification records Visual & dimensions Inspection NDT Load Testing of Chain Tensioner & Spreader Bar Fabrication Documentation MOBILIZATION & TOWING Ensure the following are secured, lashed, seafastened and preserved properly as per drawings Diving Spread Installation Aids Free Issued Materials Ensure "Tow Approval" issued by Marine Warranty Surveyor

LEGEND : 50037-ME-DOC-001: Marine

Batam Batam Batam Batam

AWS D1.1 AWS D1.1 & 50037-DWG-005 AWS D1.1 , WPS, WQT, ASNT 50037-DWG-005 : Chain Tensioner

Approved documents As-Built Drawing NDT Reports 3rd Party - Load Test/ Functional Test Report

R W R W

NA NA NA NA

NA NA NA NA

3.5 4

Batam

WPS, Welder Certs, Electrode Certs, Materials Mill certs, NDT reports, As- As-Built Dossier built drawings, etc

NA

NA

Spread Specifications & Certification Dossier Batam

Load-out Drawings & Sea

MPI Report for deck

4.1

welds

Rigging gears

P/W

NA

NA

Fastening Drawings

certificates

4.2

Paradip port

IOCL appointed MWSs approval

Tow Approval Certificate by MWS

R: REVIEW W: WITNESS

P/W

50037-QA-PLN-002

A: APPROVE H: HOLD

NA: NOT APPLICABLE P: PERFORM

25-11-2008

INSPECTION AND TEST PLAN

Rev. 0

RESIDUAL OFFSHORE CONSTRUCTION WORK AT PARADIP.

CONTRACT NO. PLCC/PHCPL/SPM/0825

REFERENCE PROCEDURE/ ACCEPTANCE CRITERIA

50037-SU-PRD-003: Derrick

Page 9 of 13

VERIFYING DOCUMENTS SURVEILLANCES BY

GIAP IOCL 3rd PARTY

REF. NO. 5

ACTIVITY DESCRIPTION SURVEY Pre Installation Survey

LOCATION

5.1

(Locating Anchor Chains & Report any significant seabed debris for resolution) Post Installation As Built Survey.

CALM Terminal Site

Barge Survey and Positioning Procedures 50037-SU-PRD-001: PreInstallation Survey Procedure

50037-SU-DOC-001: Pre- Installation Survey Report

P/W

W/A

W/A

5.2

(SPM position, positions and angles of anchor chains, positions of Under buoy house , floating hoses, coordinates of PLEM, etc)

50037-SU-PRD-002: As-Built Survey 50037-SU-DOC-002: CALM Terminal As-Built Survey Procedure Site Reports

P/W

W/A

W/A

6 6.1

TENSIONING OF ANCHOR CHAINS & INSTALLATION OF SPM Check the calibration status of load cell(s) CALM Terminal Site CALM Terminal Site CALM Terminal Site CALM Terminal Site

A: APPROVE H: HOLD

50037-SI-PRD-001: CALM Buoy Installation Procedure 50037-SI-PRD-001: CALM Buoy Installation Procedure 50037-SI-PRD-001: CALM Buoy Installation Procedure 50037-SI-PRD-001: CALM Buoy Installation Procedure

NA: NOT APPLICABLE P: PERFORM

Calibration Certificate

6.2

Ensure that chain is pulled through the chain hawse/chaser Check that tension load is ~ 150T or Cross tensioning to be ~ 300T for anchors chains tensioning Check that each chains are marked with indelible florescent colour visible in water

LEGEND :

Visual Check Anchor Chains Tensioning Report Visual check

R: REVIEW W: WITNESS

6.3

P/W

W/A

W/A

6.4

P/W

50037-QA-PLN-002

25-11-2008

INSPECTION AND TEST PLAN

Rev. 0

RESIDUAL OFFSHORE CONSTRUCTION WORK AT PARADIP.

CONTRACT NO. PLCC/PHCPL/SPM/0825

REFERENCE PROCEDURE/ ACCEPTANCE CRITERIA 50037-SI-PRD-001: CALM Buoy Installation Procedure 50037-DI-MAN-001 Diving Procedures Manual 50037-SI-PRD-001: CALM Buoy Installation Procedure 50037-DI-MAN-001 Diving Procedures Manual 50037-SI-PRD-001: CALM Buoy Installation Procedure 50037-SI-PRD-001: CALM Buoy Installation Procedure 50037-SI-PRD-001: CALM Buoy Installation Procedure 50037-SI-PRD-001: CALM Buoy Installation Procedure 50037-DI-MAN-001 Diving Procedures Manual VERIFYING DOCUMENTS Visual check

Page 10 of 13

SURVEILLANCES BY

GIAP IOCL 3rd PARTY

REF. NO.

ACTIVITY DESCRIPTION Check the ends of all six chains are fixed to submerged marker buoy

LOCATION CALM Terminal Site

6.5

P/W

6.6

Check that each chains are straight line from anchor piles to SPM

CALM Terminal Site

Visual check

P/W

6.7

Check the chain numbers are marked to indentify with respect to PLEM ~ CALM Buoy Check the chains are locked off on a reference link by the Chain Stopper Check 2 links remain above the chain stopper after excess chains are cut off.

CALM Terminal Site CALM Terminal Site CALM Terminal Site

Visual Check

P/W

6.8

Visual Check

P/W

6.9

Visual Check

Fugro Survey Report

P/W

6.10

Ensure the anchor chains have been installed and connected per procedures / drawings.

CALM Terminal Site

for Anchor Chains Installation Report Diver Survey Report

P/W

W/A

W/A

50037-QA-PLN-002

LEGEND :

A: APPROVE H: HOLD

NA: NOT APPLICABLE P: PERFORM

R: REVIEW W: WITNESS

25-11-2008

INSPECTION AND TEST PLAN

Rev. 0

RESIDUAL OFFSHORE CONSTRUCTION WORK AT PARADIP.

CONTRACT NO. PLCC/PHCPL/SPM/0825

REFERENCE PROCEDURE/ ACCEPTANCE CRITERIA

50037-SI-PRD-001: CALM Buoy

Page 11 of 13

VERIFYING DOCUMENTS SURVEILLANCES BY

GIAP IOCL 3rd PARTY

REF. NO.

ACTIVITY DESCRIPTION

LOCATION

6.11

Verify the CALM Buoy system has been CALM Terminal installed in specified positions and coordinates Site INSTALLATION OF UNDER BUOY HOSES Ensure the hose identifications with respect to CALM Terminal SPM / PLEM inlets/ manifolds Site Bolts types/ spec are correct for the flanges and hoses Ensure the tightening of flange bolts to the required torque values Ensure the configuration of Under buoy houses installation is as per AFC drawings INSTALLATION OF FLOATING HOSES Ensure the hose identifications with respect to CALM Terminal SPM / PLEM inlets/ manifolds Site Bolts types/ spec are correct for the flanges and hoses CALM Terminal Site CALM Terminal Site CALM Terminal Site CALM Terminal Site

Installation Procedure

Fugro Survey Report for CALM Buoy Installation

P/W

W/A

W/A

7 7.1

50037-SI-PRD-002: CALM Buoy Installation Procedure 50037-SI-PRD-002: CALM Buoy Installation Procedure 50037-SI-PRD-002: CALM Buoy Installation Procedure 50037-SI-PRD-002: CALM Buoy Installation Procedure

AFC SBM Assembly Drawings AFC SBM Assembly Drawings Bolt Tensioning/ Tightening Reports Fugro Under Buoy Hoses Configuration Survey Report

7.2

7.3

P/W

R/A

R/A

7.4 8 8.1 8.2

P/W

R/A

R/A

50037-SI-PRD-001: CALM Buoy Installation Procedure 50037-SI-PRD-001: CALM Buoy Installation Procedure

AFC SBM Assembly Drawings AFC SBM Assembly Drawings

P P

W W

W W

50037-QA-PLN-002

LEGEND :

A: APPROVE H: HOLD

NA: NOT APPLICABLE P: PERFORM

R: REVIEW W: WITNESS

25-11-2008

INSPECTION AND TEST PLAN

Rev. 0

RESIDUAL OFFSHORE CONSTRUCTION WORK AT PARADIP.

CONTRACT NO. PLCC/PHCPL/SPM/0825

REFERENCE PROCEDURE/ ACCEPTANCE CRITERIA 50037-SI-PRD-001: CALM Buoy Installation Procedure 50037-SI-PRD-001: CALM Buoy Installation Procedure VERIFYING DOCUMENTS Bolt Tensioning/ Tightening Reports Fugro - Floating Hoses Configuration Survey Report Fugro - Umbilical Hoses Configuration Survey Report AFC Mooring Hawser drawing AFC Mooring Hawser drawing AFC Mooring Hawser drawing

Page 12 of 13

SURVEILLANCES BY

GIAP IOCL 3rd PARTY

REF. NO. 8.3

ACTIVITY DESCRIPTION Ensure the tightening of flange bolts to the required torque values Ensure the configuration of Floating houses installation is as per AFC drawings

LOCATION CALM Terminal Site CALM Terminal Site

P/W

R/A

R/A

8.4 9 9.1

P/W

R/A

R/A

INSTALLATION OF UMBILICAL and MOORING HAWSER Ensure umbilical identification with respect to PLEM ~ HPU inlets/outlets. Ensure mooring hawser has been preassembled as per AFC drawings Check all shackles and chain support buoys have split pins or other retaining pin to prevent from backing loose. Ensure mooring hawser has been securely installed to the mooring arm structure CALM Terminal S50037-SI-PRD-001: CALM Buoy Site Installation Procedure 50037-SI-PRD-001: CALM Buoy CALM Terminal Installation Procedure Site Drawing No. MR.00.002.7700 50037-SI-PRD-001: CALM Buoy CALM Terminal Installation Procedure Site Drawing No. MR.00.002.7700 50037-SI-PRD-001: CALM Buoy CALM Terminal Installation Procedure Site Drawing No. MR.00.002.7700 50037-SI-PRD-003: PreCommissioning Procedure 50037-SI-PRD-003: PreCommissioning Procedure

NA: NOT APPLICABLE P: PERFORM R: REVIEW W: WITNESS

P/W

9.2

A/W

9.3

A/W

9.4 10 10.1 10.2

A/W

LEAK TESTS (HOSES & CALM BUOY SYSTEM) Ensure pressure gauges are calibrated and CALM Terminal used within specific test range Site Check the bleed-off air prior to pressurising CALM Terminal Site

A: APPROVE H: HOLD

AFC AFC

P P

R R

R R

50037-QA-PLN-002

LEGEND :

25-11-2008

INSPECTION AND TEST PLAN

Rev. 0

RESIDUAL OFFSHORE CONSTRUCTION WORK AT PARADIP.

CONTRACT NO. PLCC/PHCPL/SPM/0825

REFERENCE PROCEDURE/ ACCEPTANCE CRITERIA 50037-SI-PRD-003: PreCommissioning Procedure 50037-SI-PRD-003: PreCommissioning Procedure @ 225 psig for 3 hours VERIFYING DOCUMENTS AFC Floating and Under Buoy Hoses Leak Test Report CALM Buoy System Leak Test Report Company approved installation & survey records, & reports AFC

Page 13 of 13

SURVEILLANCES BY

GIAP IOCL 3rd PARTY

REF. NO. 10.3 10.4 10.5 11 11.1

ACTIVITY DESCRIPTION Check the bleed-off air prior to pressurising Leak test for Floating and Under buoy hoses. Leak Test of CALM Buoy System. (PLEM Valve ~ Blind of Floating Hoses) AS BUILT DOCUMENTATION Ensure that all as-built documentations/ records are reviewed and approved/signed by relevant parties onboard. Submission of As built for Company approval.

LOCATION CALM Terminal Site Paradip port CALM Terminal Site

P P/W P/W

R W/A W/A

R W/A W/A

Singapore

50037-AB-DOC-001: As-Built Documents 50037-AB-DOC-001: As-Built Documents

P/R

R/A

R/A

11.2

Singapore

P/R

R/A

R/A

50037-QA-PLN-002

LEGEND :

A: APPROVE H: HOLD

NA: NOT APPLICABLE P: PERFORM

R: REVIEW W: WITNESS

25-11-2008

You might also like

- PDOC-476-CTRU-06 Rotating Equipment Installation ProcedureDocument7 pagesPDOC-476-CTRU-06 Rotating Equipment Installation Procedure1339979No ratings yet

- 23792turret Buoy BookDocument32 pages23792turret Buoy BookTeck Tiong Huan100% (1)

- Offshore Mooring Risk AnalysisDocument109 pagesOffshore Mooring Risk Analysisbubbly_blu2No ratings yet

- 05) Offshore Marine Spread Duration (Topsides & Bridges)Document1 page05) Offshore Marine Spread Duration (Topsides & Bridges)YusufNo ratings yet

- MS002-UZ-PRO-0B1-50220 - B01 Welding Qualification Plan For Riser FabDocument19 pagesMS002-UZ-PRO-0B1-50220 - B01 Welding Qualification Plan For Riser FabPuspita LerianaNo ratings yet

- Re F RefDocument67 pagesRe F Refprab100% (1)

- Rockwater Spool Load-Out ProcedureDocument75 pagesRockwater Spool Load-Out ProcedurePhani Kumar G SNo ratings yet

- Spool and Riser Flooding & HydrotestDocument30 pagesSpool and Riser Flooding & HydrotestPhani Kumar G SNo ratings yet

- Pigging Head and Spool InstallationDocument38 pagesPigging Head and Spool InstallationWilliam O OkolotuNo ratings yet

- Thesis On SPM Pipe LayingDocument64 pagesThesis On SPM Pipe Layingydmisra100% (6)

- Load - Out Plan/Procedur E: Rev. Statu S Date Revision Memo Issuer Checker ApproverDocument18 pagesLoad - Out Plan/Procedur E: Rev. Statu S Date Revision Memo Issuer Checker ApproverLai Quoc100% (1)

- Turret Bouy Tech DescriptionDocument36 pagesTurret Bouy Tech Descriptiondbekos100% (1)

- Offshore Pipeline Installation OverviewDocument99 pagesOffshore Pipeline Installation OverviewMuhammad Geovani100% (3)

- C 84514 BK KK0 PRO GN 00 0014 Subsea Pre Commissioning Procedure - Rev.0BDocument65 pagesC 84514 BK KK0 PRO GN 00 0014 Subsea Pre Commissioning Procedure - Rev.0BFAR_A_DAY100% (3)

- QMP-MOA-013 (Rev.1) Preparation of Method Statements (CSC)Document10 pagesQMP-MOA-013 (Rev.1) Preparation of Method Statements (CSC)Vasilica BarbarasaNo ratings yet

- 0028-4 GL Guidelines For Transport and Install of Steel JacketsDocument38 pages0028-4 GL Guidelines For Transport and Install of Steel Jacketsdamnaged100% (1)

- Shore ApproachDocument5 pagesShore Approachvpandya1981No ratings yet

- Method Statement For Pipeline Cleaning: Kurdistan Crude Oil PipelineDocument38 pagesMethod Statement For Pipeline Cleaning: Kurdistan Crude Oil Pipelineanon_894950656No ratings yet

- Our Activities: Technology Creating ValueDocument12 pagesOur Activities: Technology Creating Valuenazwan14No ratings yet

- Quality Control Plan (QCP) Piping Prefabrication and ErectionDocument54 pagesQuality Control Plan (QCP) Piping Prefabrication and ErectionismariadiNo ratings yet

- Methanol Bunkering Barge Supplier Conssolidated Checklist PackDocument20 pagesMethanol Bunkering Barge Supplier Conssolidated Checklist PackMehtab Alam ShaikhNo ratings yet

- Technical Procedure For Mattress InstallationDocument15 pagesTechnical Procedure For Mattress Installationflawlessy2kNo ratings yet

- Seabed PreparationDocument16 pagesSeabed PreparationPhani Kumar G SNo ratings yet

- FLEXIBLE FLOWLINE RELOCATION & TIE-IN PROCEDURE Rev A - 12022-AMC-TIN-PRO-0016 - IssuedDocument92 pagesFLEXIBLE FLOWLINE RELOCATION & TIE-IN PROCEDURE Rev A - 12022-AMC-TIN-PRO-0016 - IssuedWilliam O OkolotuNo ratings yet

- 50037-ME-DOC-001 - Marine Spread Specifications and Certifications DossierDocument9 pages50037-ME-DOC-001 - Marine Spread Specifications and Certifications DossierseehariNo ratings yet

- Chapter 5 - Conclusion & RecommendationDocument4 pagesChapter 5 - Conclusion & RecommendationMohamad Shukri0% (1)

- Zawtika Project ITP for Electrical, Instrumentation and Telecom InspectionDocument13 pagesZawtika Project ITP for Electrical, Instrumentation and Telecom Inspectionsfd640No ratings yet

- Offshore Pipeline Installation ProcedureDocument31 pagesOffshore Pipeline Installation Procedurecbsd24100% (1)

- ITP For CW and ACW Piping WorkDocument8 pagesITP For CW and ACW Piping WorkPhong DoNo ratings yet

- 2005-4100-0R-0011 - Rev0 - ITP For Jacket and Deck Installation (JRM Scope) - Approved PrintedDocument24 pages2005-4100-0R-0011 - Rev0 - ITP For Jacket and Deck Installation (JRM Scope) - Approved PrintedhavutaNo ratings yet

- ITP-Interpipe - Cryogenic SolutionsDocument47 pagesITP-Interpipe - Cryogenic SolutionsLiauw Cooperation0% (1)

- Pipeline Shore Approach Installation Techniques and Soil Liquefaction RisksDocument12 pagesPipeline Shore Approach Installation Techniques and Soil Liquefaction RisksafifahrashidNo ratings yet

- Standard PracticeDocument14 pagesStandard PracticeRomi Abdul RahmanNo ratings yet

- Main Inspection Test Plan SampleDocument2 pagesMain Inspection Test Plan SampleMuhd AfiqNo ratings yet

- Berthing Load Test On Wharf - r3Document15 pagesBerthing Load Test On Wharf - r3surya ilhamNo ratings yet

- Method Statement For AMD2 Brownfield Early Works Rev 0 PDFDocument51 pagesMethod Statement For AMD2 Brownfield Early Works Rev 0 PDFph0inixNo ratings yet

- Shell Pipeline River Dredging ProcedureDocument12 pagesShell Pipeline River Dredging ProcedureDaniel DamboNo ratings yet

- A1G5F1 - OW-310690-201-MT - Excavation and Backfilling Rev C1Document20 pagesA1G5F1 - OW-310690-201-MT - Excavation and Backfilling Rev C1khabiranNo ratings yet

- SA04C2-MS-MET-AAG-0009 Method Statement of Pneumatic Test For SS and GRE PipesDocument11 pagesSA04C2-MS-MET-AAG-0009 Method Statement of Pneumatic Test For SS and GRE PipesABAID ULLAHNo ratings yet

- Fabrication and InstallationDocument6 pagesFabrication and Installations33d_2010No ratings yet

- Tepng Onshore Const Itt Project Quality PlanDocument45 pagesTepng Onshore Const Itt Project Quality PlanTrustEmmaNo ratings yet

- Method Statement For Pipe Cold Bending For Installation of PipelinesDocument16 pagesMethod Statement For Pipe Cold Bending For Installation of Pipelinesmansih457No ratings yet

- Project Execution Plan PDFDocument14 pagesProject Execution Plan PDFAnonymous nbWDHCv100% (1)

- Test package flow logDocument2 pagesTest package flow logsyedahmad39No ratings yet

- Site Inspection Test PlanDocument24 pagesSite Inspection Test Planprabu palaniswamyNo ratings yet

- FPSO Umbilical-Flexible Riser Installation ProcedureDocument96 pagesFPSO Umbilical-Flexible Riser Installation ProcedureMinh Hong Pham100% (1)

- Standard Inspection & Test Plan (ITP) FOR Tank PadDocument5 pagesStandard Inspection & Test Plan (ITP) FOR Tank PaddendyNo ratings yet

- TP-01Hydrostatic Test Cover SheetDocument4 pagesTP-01Hydrostatic Test Cover SheetAnonymous GaMb5H52100% (1)

- Project Execution Plan For Offshore Maintenance Coating OperationDocument13 pagesProject Execution Plan For Offshore Maintenance Coating OperationMitchellgrany100% (3)

- Flexible Jumper Design PremiseDocument12 pagesFlexible Jumper Design PremiseAgus BudionoNo ratings yet

- Attachment 6 - Piping Test Package (Manifold 206) - A4A0Z9Document44 pagesAttachment 6 - Piping Test Package (Manifold 206) - A4A0Z9Ali Hajirassouliha100% (1)

- Gangway Tower Preservation Procedure On SiteDocument4 pagesGangway Tower Preservation Procedure On SiteSalim Mohd RazNo ratings yet

- LOCG-GEN-Guideline-006 Rev 0 - Lift-Off Transportation + Inshore Mating of TopsidesDocument26 pagesLOCG-GEN-Guideline-006 Rev 0 - Lift-Off Transportation + Inshore Mating of TopsidesTomkel VoonNo ratings yet

- Pipeline Trench Excavating Procedure B-CON-PRO-210-39157: Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282Document12 pagesPipeline Trench Excavating Procedure B-CON-PRO-210-39157: Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282ZaidiNo ratings yet

- Section C-3a - Cathodic Protection Installation Method StatementDocument18 pagesSection C-3a - Cathodic Protection Installation Method StatementOkeymanNo ratings yet

- Procedure For Flushing and Hydrotesting (On-Plot)Document11 pagesProcedure For Flushing and Hydrotesting (On-Plot)Vijay Allimuthu Avathipalayam100% (3)

- Mabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkDocument38 pagesMabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkJabel Oil Services Technical DPTNo ratings yet

- MS For MV Cable Pulling ProcedureDocument10 pagesMS For MV Cable Pulling Procedurekbldam100% (2)

- Ms For MV Cable Pulling ProcedureDocument11 pagesMs For MV Cable Pulling ProcedureFaris Abandeh100% (1)

- Itp - Rev eDocument36 pagesItp - Rev ezaki_saddarNo ratings yet

- Andreas Dracoulis - Haynes and BooneDocument15 pagesAndreas Dracoulis - Haynes and BooneJoão Mendonça SantosNo ratings yet

- TOTAL FIBONACCI TRADING TRADE SETUPSDocument12 pagesTOTAL FIBONACCI TRADING TRADE SETUPSChandler BingNo ratings yet

- Numbering SystemDocument8 pagesNumbering SystemseehariNo ratings yet

- Snagit 13 - CaptureDocument71 pagesSnagit 13 - CaptureseehariNo ratings yet

- Harmonic Analysis: Chapter TenDocument40 pagesHarmonic Analysis: Chapter TenKishore Chandrasekhar PatnaikNo ratings yet

- Operations Department Procedure Manual: by byDocument29 pagesOperations Department Procedure Manual: by byseehariNo ratings yet

- KPMG Law - Legal Guideline For Offshore Project Contracts PDFDocument24 pagesKPMG Law - Legal Guideline For Offshore Project Contracts PDFseehari100% (1)

- PJT-PDP-TLM-733 Project Document & Drawing NumberingDocument19 pagesPJT-PDP-TLM-733 Project Document & Drawing NumberingseehariNo ratings yet

- Pre-Comm Sow Sogtrev0Document10 pagesPre-Comm Sow Sogtrev0seehariNo ratings yet

- Charter Party PDFDocument149 pagesCharter Party PDFseehariNo ratings yet

- 20jan15raymondflood FourierDocument40 pages20jan15raymondflood FourierseehariNo ratings yet

- Trading The MACDDocument24 pagesTrading The MACDemirav283% (6)

- Proposed Project Execution Baseline Schedule Rev BDocument1 pageProposed Project Execution Baseline Schedule Rev BseehariNo ratings yet

- Google book search project to digitize public domain textsDocument232 pagesGoogle book search project to digitize public domain textsseehariNo ratings yet

- 48'' Pipeline Shore Approach Reportpdf PDFDocument22 pages48'' Pipeline Shore Approach Reportpdf PDFvpandya1981100% (2)

- Diagramma Della Verita by GalilieoDocument11 pagesDiagramma Della Verita by Galilieopremnaryans50% (2)

- Intro To Ortho ProjectionDocument22 pagesIntro To Ortho ProjectionseehariNo ratings yet

- Volume Average ExponentialDocument9 pagesVolume Average ExponentialrentacuraNo ratings yet

- Trading The MACDDocument24 pagesTrading The MACDemirav283% (6)

- 2nd Internal Question Papers For Electrical and ElectronicsDocument1 page2nd Internal Question Papers For Electrical and ElectronicsseehariNo ratings yet

- Creating A Frame Title BlockDocument2 pagesCreating A Frame Title BlockseehariNo ratings yet

- TEPZZ 7Z - A T: European Patent ApplicationDocument39 pagesTEPZZ 7Z - A T: European Patent ApplicationseehariNo ratings yet

- Alt Fuel PropertiesDocument3 pagesAlt Fuel PropertiesseehariNo ratings yet

- Pasavento Instructions For Zup Pattern IndicatorDocument13 pagesPasavento Instructions For Zup Pattern IndicatormleefxNo ratings yet

- MCS R6Y DrawingDocument4 pagesMCS R6Y DrawingseehariNo ratings yet

- Motion Um002 en PDocument280 pagesMotion Um002 en PseehariNo ratings yet

- M.tech - Credit SystemDocument16 pagesM.tech - Credit SystemRamesh BammankattiNo ratings yet

- .B.E.-B.Tech - VTUDocument8 pages.B.E.-B.Tech - VTUyamaha640No ratings yet

- HBG 25 Gantry Robot PrintDocument1 pageHBG 25 Gantry Robot PrintseehariNo ratings yet

- MCS R6S Belt Z DrawingDocument4 pagesMCS R6S Belt Z DrawingseehariNo ratings yet

- Techint Group Brochure 2013Document100 pagesTechint Group Brochure 2013MD AFROZ RAZANo ratings yet

- Chapter 1 Engineering ManagementDocument4 pagesChapter 1 Engineering ManagementGeorge Russell80% (5)

- GadDocument1 pageGadFakhruddin DhilawalaNo ratings yet

- Elcometer Wet-Film Gage 115 Spec SheetDocument2 pagesElcometer Wet-Film Gage 115 Spec SheetMary CasillasNo ratings yet

- 123 Rule For TRS MMD DG ShippingDocument2 pages123 Rule For TRS MMD DG ShippingGurjit SinghNo ratings yet

- RUDDER PLATING DIAGRAMDocument1 pageRUDDER PLATING DIAGRAMMuhammad Ilham AlfiansyahNo ratings yet

- Solving Problems Involving Kinds of Propotion StudentDocument18 pagesSolving Problems Involving Kinds of Propotion StudentJohn Daniel BerdosNo ratings yet

- Hanoi 2023 Peoples Picks AwardsDocument113 pagesHanoi 2023 Peoples Picks AwardsNguyen Anh VuNo ratings yet

- Comp7 - Answer Key - Dec. Exam - 1st SetDocument2 pagesComp7 - Answer Key - Dec. Exam - 1st SetHazel Joy LusellaNo ratings yet

- X Wing - Quick.referenceDocument6 pagesX Wing - Quick.referenceatilaT0RNo ratings yet

- Finger Print Based Voting System For Rigging Free Governing SystemDocument2 pagesFinger Print Based Voting System For Rigging Free Governing SystemArvind TilotiaNo ratings yet

- Adept Conveyor Technologies Product ManualDocument32 pagesAdept Conveyor Technologies Product ManualBagus Eko BudiyudhantoNo ratings yet

- Sports AcousticsDocument43 pagesSports Acousticssiddhant raoNo ratings yet

- Tivax STB-T12 Owners ManualDocument32 pagesTivax STB-T12 Owners ManualJesseNo ratings yet

- 74HCT259D 8-Bit Addressable Latch DATA SHEETDocument11 pages74HCT259D 8-Bit Addressable Latch DATA SHEETMarc BengtssonNo ratings yet

- Galaxy NanoporeDocument11 pagesGalaxy NanoporeDeborah ShirleenNo ratings yet

- Djoko The Indonesian Mineral Mining Sector Prospects and ChallengesDocument42 pagesDjoko The Indonesian Mineral Mining Sector Prospects and ChallengesUmesh ShanmugamNo ratings yet

- RDT Steering System Pressure ChartDocument118 pagesRDT Steering System Pressure ChartAnonymous 340A7vnwV1100% (2)

- Wiper & Washer Circuit PDFDocument1 pageWiper & Washer Circuit PDFluis eduardo corzo enriquezNo ratings yet

- Ahmed 2022Document20 pagesAhmed 2022Mariela Estefanía Marín LópezNo ratings yet

- WozairDocument4 pagesWozairRajakumar Bajji SubburamanNo ratings yet

- Estudio CarmenaDocument11 pagesEstudio CarmenaAlfredo BalcázarNo ratings yet

- Soal Big A Tukpd 2011-2012 RevisiDocument5 pagesSoal Big A Tukpd 2011-2012 RevisiTriana WatiNo ratings yet

- Complete The Table With The Missing WordsDocument2 pagesComplete The Table With The Missing WordssoniaNo ratings yet

- Yara Crop Nutrition For HorticultureDocument8 pagesYara Crop Nutrition For HorticultureadjieNo ratings yet

- 2008 Company Performance 2008 Company Performance & 2009 Business Outlook & 2009 Business OutlookDocument30 pages2008 Company Performance 2008 Company Performance & 2009 Business Outlook & 2009 Business OutlookKakasNo ratings yet

- Sap MRP ConfigDocument23 pagesSap MRP Configsharadapurv100% (1)

- Greek MathemaDocument6 pagesGreek MathemaSebastian GhermanNo ratings yet

- Operator Identities 2Document3 pagesOperator Identities 2jasmonNo ratings yet