Professional Documents

Culture Documents

PC Interactive Catalog

Uploaded by

TÙng TÙngCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PC Interactive Catalog

Uploaded by

TÙng TÙngCopyright:

Available Formats

AMERCOAT

A PPG brand

Protective Coatings Product Catalog

Epoxy Coatings and Linings

Section 3 Product Description

AMERCOAT

One Multi-Purpose Single Component Epoxy

Amercoat 78HB Amine-Cured Coal Tar Epoxy

Amercoat 90HS Epoxy Phenolic Tank Lining

Amercoat 133 Solvent Free Cycloaliphatic Amine Tank Lining

Amercoat 240 Universal Amine Epoxy Coating

Amercoat 240LT Low Temperature Cure Amine Epoxy

Amercoat 242HB Solvent Free Glass Flake Reinforced Lining

Amercoat 253 Novolac Epoxy Tank Lining

Amercoat 333 Solvent Free Cycloaliphatic Amine Tank Lining

Amercoat 351 Solvent Free Modified Phenolic Amine Tank Lining

Amercoat 370 Fast Dry Multi-Purpose Epoxy Coating

Amercoat 385/385PA Multi-Purpose Polyamide Epoxy Coating

Amercoat 399 Fast Dry, High Solids Epoxy Coating

AMERTHANE

490 Elastomeric Polyurea Hybrid

NOVAGUARD 840 Solvent Free Amine Cured Novolac Phenolic Epoxy Coating

NOVAGUARD 890 Solvent Free Amine Cured Novolac Phenolic Epoxy Coating

www.ppgpmc.com/northamercia

PSX

Engineered Siloxane Topcoats

Section 1 Product Description

PSX ONE High Solids, Single Pack Acrylic Polysiloxane

PSX 700 Engineered Siloxane

PSX 700A Clear Coat Engineered Siloxane Clear Coat

AMERLOCK

Epoxy

Section 2 Product Description

Amerlock 2 Fast Dry, Surface Tolerant, High Solids Epoxy Coating

Amerlock 2 Aluminum Fast Dry Aluminum Epoxy Mastic Coating

Amerlock 2 VOC Low VOC, Fast Dry, High Solids Epoxy Coating

Amerlock 2/400 GFK High Solids Glass Flake Epoxy Coating

Amerlock 400 High Solids Epoxy Coating

Amerlock 400 Aluminum Aluminum Epoxy Mastic Coating

Amerlock 400 VOC Low VOC, High Solids Epoxy Coating

Amerlock 400BF Epoxy Masonry Block Filler

Amerlock Sealer Penetrating Epoxy Primer Sealer

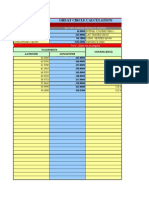

Protective Coatings Product Catalog Index

2013 PPG Industries

Zinc Rich Primers

Section 5 Product Description

Amercoat 68HS Zinc Rich Epoxy Primer

Amercoat 68HS VOC Low VOC, Zinc Rich Epoxy Primer

Amercoat 68MCZ Moisture Cure Urethane Zinc Primer

DIMETCOTE

9 Inorganic Zinc Silicate Primer

Dimetcote 9 VOC Low VOC, Inorganic Zinc Silicate Primer

Dimetcote 9H Inorganic Zinc Silicate Primer

Dimetcote 21-5 Water Based Inorganic Zinc Silicate Primer

Dimetcote 302H Reinforced Inorganic Zinc Primer

Primers

Section 4 Product Description

Amercoat 185H Universal Phenolic Alkyd Primer

Amercoat 5105 Alkyd Primer

Amercoat 5108 Alkyd Shop Primer

DSP-3 Water Based Inorganic Zinc Silicate Pre-Construction Primer

SIGMACOVER 280US Polyamide Cured Epoxy Primer

SIGMAGUARD 260 High Build Amine Adduct Cured Novolac Phenolic Epoxy Holding

Primer

SIGMAWELD 199US Moisture Curing, Reduced Zinc (Ethyl) Silicate Pre-Construction Primer

Index (continued)

Epoxy Coatings and Linings (contd)

Section 3 Product Description

PHENGUARD 930 High Build Amine Adduct Cured Novolac Phenolic Epoxy Primer

PHENGUARD 935 High Build Amine Adduct Cured Novolac Phenolic Epoxy Coating

PHENGUARD 940 High Build Amine Adduct Cured Novolac Phenolic Epoxy Finish

SIGMAGUARD CSF 650 Solvent Free Amine Cured Epoxy Coating

SIGMAGUARD 720 Reinforced High Solids Polyamine Adduct Cured Epoxy Coating

Topcoats

Section 6 Product Description

Amercoat 220P Int./Ext. Gloss DTM Industrial Enamel

Amercoat 229T Gloss Epoxy Acrylic Topcoat

Amercoat 450H Gloss Acrylic Aliphatic Polyurethane Topcoat

Amercoat 450HSG Semi-Gloss Acrylic Aliphatic Polyurethane Topcoat

Amercoat 5420 Gloss Alkyd Enamel

www.ppgpmc.com/northamercia

2013 PPG Industries

Fire Proofing Coatings

Section 8 Product Description

PITT-CHAR XP

Thick Film Intumescent Coating for Hydrocarbon Fires

STEELGUARD FM550 Thin Film Intumescent Coating for Cellulosic Fires

Specialty Products & Additives

Section 9 Product Description

AMERASE Graffiti Cleaner

Amercoat 114A

Epoxy Filler Compound

Amercoat 851 Flow Control Additive

Amercoat 861 Epoxy Accelerator

Amercoat 866M Urethane Accelerator

Amercoat 880 Glassflake Additive

Amercoat 884 Thixotropic Fumed Silica Additive

Amercoat 965 Acrylic Modified Cement

Prep 88 Water Based Alkaline Cleaner

TIDEGUARD 171A Sprayable Epoxy Cladding

Topcoats (contd)

Section 6 Product Description

AMERSHIELD Polyester-Acrylic Aliphatic Polyurethane Topcoat

Amershield VOC

Low VOC, Polyester-Acrylic Aliphatic Polyurethane

2013 PPG Industries

www.ppgpmc.com/northamercia

Index (continued)

Amercoat, Amerlock, Amershield, Amerthane, Dimetcote, PSX and TideGuard are trademarks or registered

trademarks of PPG Industries Ohio, Inc. Pitt-Char XP is a registered trademark of PPG Architectural Finishes, Inc.

NOVAGUARD, PHENGUARD, SIGMACOVER, SIGMAGUARD, SIGMAWELD, STEELGUARD are trademarks of

PPG Coatings Nederland B.V. Hi-Temp is a registered trademark of Hi-Temp Coatings Technology Company, Inc.

High Heat Coatings

Section 7 Product Description

Amercoat 741 High Temperature Self Cure, Inorganic Topcoat

Amercoat 872 High Temperature Silicone Zinc Primer

Amercoat 873 High Temperature Silicone Topcoat

Amercoat 874HS High Temperature Silicone Acrylic Topcoat

Amercoat 878 High Temperature Silicone Aluminum

Amercoat 3279 High Temperature Modified Silicone Aluminum

Hi-Temp

500VHA Hot Applied Silicone Acrylic

Hi-Temp 500VS Silicone Acrylic Topcoat

Hi-Temp 1000VS Silicone Topcoat for Hi-Temp 1027

Hi-Temp 1027

High Build, Ambient Temperature Cure Primer

PSX 892HS High Temperature Polysiloxane

October 2012

Revision of April 2012

DESCRIPTION High Solids, Single Pack Acrylic Polysiloxane

PRINCIPAL CHARACTERISTICS High gloss topcoat

High solids, low VOC

Ease of application, brush, roll, or spray

Isocyanate free

Excellent gloss retention

Meets SSPC Paint 36 Level 3 requirements

COLOR AND GLOSS Standard Color Offering, Safety Colors, Custom Colors

Gloss

* Certain colors, especially red, orange, and yellow may require additional coats for adequate hiding, especially if

applied over primers with a significant color contrast.

BASIC DATA

Volume solids 75% 3%

VOC 1.75 lbs/gal (210 g/L)

Recommended

Dry film thickness (per coat) 2 3 mils (50 75 microns)

Theoretical Spread Rate @ 1 mil dft 1203 ft

2

/ gallon

@ 2 mils dft 602 ft

2

/ gallon

@ 3 mils dft 401 ft

2

/ gallon

Components 1

Shelf Life 1 year from date of manufacture

SURFACE PREPARATION Coating performance is proportional to the degree of surface preparation. Refer to

the application instructions for specific primers and intermediate coats for application

and curing procedures. Ensure epoxies are free from amine blush prior to overcoating.

All previous coats must dry and free of contaminants. Adhere to all minimum and

maximum topcoat times for specific primers and intermediate coats. Aged epoxy

coatings may require abrading prior to applying PSX ONE. A test patch over unknown

coatings is recommended.

ENVIRONMENTAL CONDITIONS

Ambient temperatures 40F to 120F (5C to 49C)

Material temperatures 50F to 90F (10C to 32C)

Relative humidity 20 90%

Surface temperature 40F to 120F (5C to 49C)

Surface temperature must be at least 5F above dew point temperature.

General air quality Area should be sheltered from airborne particulates and pollutants. Avoid combustion

gases or other sources of carbon dioxide that may promote ambering of light colors.

Ensure good ventilation during application and curing. Provide shelter to prevent wind

from affecting spray patterns.

INSTRUCTIONS FOR USE

Mixing Agitate with a power mixer for 1-2 minutes until completely dispersed.

Airless spray 30:1 pump or larger, 0.013 - 0.017 fluid tip

Air spray Thin up to 20%, standard conventional equipment, 0.070 fluid orifice. A moisture and oil

trap in the main line is essential.

Brush & roll Use a high quality natural bristle brush and / or solvent resistant, 1/4" or 3/8" nap roller.

Ensure brush / roller is well loaded to avoid air entrainment. Multiple coats may be

necessary to achieve adequate film build. Amercoat 851 flow control additive can be

used to for enhanced flow and leveling with brush and roll application.

PSX

ONE

page 1/3

Thinner Amercoat 911

Cleaning solvent Amercoat 12 Cleaner or Amercoat 911 thinner

Primers Amercoat One, Amercoat 5105, Amercoat 185H, Amercoat 370, Amercoat 385,

Amercoat 399, Amerlock 2/400, Amercoat 235, Amercoat 240, Pittguard Epoxies,

Amerlock Sealer, Amercoat 68HS, Amercoat 237M

Safety precautions For paint and recommended thinners see safety sheet 1430, 1431 and relevant material

safety data sheets

This is a solvent borne paint and care should be taken to avoid inhalation of spray mist

or vapor as well as contact between the wet paint and exposed skin or eyes.

DRY/CURE TIMES PSX ONE @ 2 mils dft

AVAILABILITY

Packaging Available in 1-gallon and 5-gallon units

Product codes PXONE23 Pearl Gray base

PXONE3 White base

PXONE9 Black base

PXONET1 Deep tint base*

PXONET2 Light tint base*

PXONET3 Neutral tint base*

PXONET4 Red tint base*

PXONET5 High Hiding Yellow tint*

* Tintable with UCD PS Line colorants only.

Worldwide statement While it is always the aim of PPG Protective & Marine Coatings to supply the same product

on a worldwide basis, slight modification of the product is sometimes necessary to comply

with local or national rules/circumstances. Under these circumstances an alternative product

data sheet is used.

WARRANTY STATEMENT

PPG warrants (i) its title to the product, (ii) that the quality of the product conforms to PPGs specifications for such product in

effect at the time of manufacture and (iii) that the product shall be delivered free of the rightful claim of any third person for

infringement of any U.S. patent covering the product.

THESE ARE THE ONLY WARRANTIES THAT PPG MAKES AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES,

UNDER STATUTE ORARISING OTHERWISE IN LAW, FROMA COURSE OF DEALING OR USAGE OF TRADE, INCLUDING

WITHOUT LIMITATION, ANY OTHER WARRANTY OF FITNESS FORA PARTICULAR PURPOSE OR USE, ARE DISCLAIMED

BY PPG.

Any claim under this warranty must be made by Buyer to PPG in writing within five (5) days of Buyers discovery of the claimed

defect, but in no event later than the expiration of the applicable shelf life of the product, or one year from the date of the delivery

of the product to the Buyer, whichever is earlier. Buyers failure to notify PPG of such non-conformance as required herein

shall bar Buyer from recovery under this warranty.

PSX ONE

page 2/3

50F 70F 90F

Dry to touch 3 hours 2 hours 1 hour

Dry through 16 hours 9 hours 5 hours

Dry to recoat 5 hours 2 hours 1 hour

Maximum recoat 30 days

page 3/3

PSX ONE

LIMITATION OF LIABILITY

IN NO EVENT WILL PPG BE LIABLE UNDER ANY THEORY OF RECOVERY (WHETHER BASED ON NEGLIGENCE OF

ANY KIND, STRICT LIABILITY OR TORT) FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IN ANY WAY RELATED TO, ARISING FROM, OR RESULTING FROMANY USE MADE OF THE PRODUCT.

The information in this sheet is intended for guidance only and is based upon laboratory tests that PPG believes to be reliable.

PPG may modify the information contained herein at any time as a result of practical experience and continuous product

development. All recommendations or suggestions relating to the use of the PPG product, whether in technical documentation,

or in response to a specific inquiry, or otherwise, are based on data, which to the best of PPGs knowledge, is reliable. The

product and related information is designed for users having the requisite knowledge and industrial skills in the industry and it

is the end-users responsibility to determine the suitability of the product for its own particular use and it shall be deemed that

Buyer has done so, as its sole discretion and risk.

PPG has no control over either the quality or condition of the substrate, or the many factors affecting the use and application of

the product. Therefore, PPG does not accept any liability arising from any loss, injury or damage resulting from such use or

the contents of this information (unless there are written agreements stating otherwise). Variations in the application environment,

changes in procedures of use, or extrapolation of data may cause unsatisfactory results.

This sheet supersedes all previous versions and it is the Buyers responsibility to ensure that this information is current prior to

using the product.

Current sheets for all PPG Protective & Marine Coatings Products are maintained at www.ppgpmc.com. The English text of

this sheet shall prevail over any translation thereof.

PSX and Amercoat are registered trademarks of PPG Industries Ohio, Inc.

March 2013

Revision of October 2012

DESCRIPTION Engineered Siloxane

PRINCIPAL CHARACTERISTICS Unique, high gloss epoxy siloxane

Virtually HAPs free, ultra-low VOC

High durability in challenging environments

Abrasion resistant

Resists dirt pickup, easily cleaned

Can be applied directly to zinc primers as a 2-coat system

Can be applied direct-to-steel in ISO 12944 C1-C3 environments

COLOR AND GLOSS Gloss

Standard and Custom Colors available

Yellow, red, and orange colors will fade faster than other colors due to the replacement of lead-based pigments

with lead free pigments in these colors.

BASIC DATA

Volume solids 90% 3%

VOC* 0.7 lbs/gal (84 g/L)

* The mixed and applied coating cure reaction will produce VOC of mixed alcohols. For 100 g/l VOC

requirements, a VOC - exempt thinner such as 97-939 may be used as needed.

Recommended

Dry film thickness* 3 - 7 mils per coat (75-175 microns)

* When applying more than one coat, it is recommended that the total dry film thickness not exceed 10 mils.

Theoretical Spread Rate 1444 ft

2

/gal @ 1 mils dft

289 ft

2

/gal @ 5 mils dft

Components 2

Dry Temperature Resistance* Continuous 200F Intermittent 250F (<5% of the time, max 24 hours)

* Color will drift at elevated temperatures.

Shelf Life 2 years from date of manufacture when stored indoors in the original unopened

container. Store product in dry conditions at temperatures of 40-100F

SURFACE PREPARATION Coating performance is proportional to the degree of surface preparation.

Steel Abrasive blast to SSPC SP-6 or higher with an angular 1.0-3.0 mil surface profile.

Or see instructions for specific primer

Apply PSX 700 as soon as possible to prevent the blasted surface from rusting.

Keep moisture, oil, grease, or other organic matter off surface before coating.

For touch up and repair, power tool cleaning in accordance with SSPC SP-11 is

acceptable.

Concrete See specific primer

Non-Ferrous Metals and Abrasive blast in accordance with SSPC SP-16 guidelines to achieve a uniform and

Stainless Steel dense 1.5-4.0 mil anchor profile. Size and hardness of abrasive should be adjusted

as necessary based on the hardness of the substrate. Aluminum may be treated

with a surface treatment compliant with Mil-DTL-5541 or equivalent (non-immersion

applications only).

Galvanized Steel Remove oil or soap film with detergent or emulsion cleaner. Lightly abrasive blast

with a fine abrasive in accordance with SSPC SP-16 guidelines to achieve a profile of

1.5-3.0 mils. When light abrasive blasting is not possible, galvanizing can be treated

with a suitable zinc phosphate conversion coating. Galvanizing that has at least 12

months of exterior weathering and has a rough surface with white rust present may

be over-coated after power washing and cleaning to remove white rust and other

contaminants. The surface must have a measurable profile.

PSX

700

page 1/4

A test patch is recommended to confirm adhesion. Not recommended over chromate

sealed galvanizing without blasting to thoroughly remove chromates. Adhesion

problems may occur.

Aged Coatings Contact your PPG representative. A test patch of PSX 700 over in-tact clean

coating and observation for film defects and adhesion over a period of time may be

required, dependent upon the type of coating.

PSX 700 is compatible over Amercoat 450-series.

ENVIRONMENTAL CONDITIONS

Ambient temperatures 32F to 100F (0C to 32C) (FD cure should be used below 40F)

Material temperatures 32F to 100F (0C to 32C)

Relative humidity 40% minimum

Work area can be artificially humidified by atomized water spray and/or ponding water under the coated

structures.

Surface temperature 32F to 120F (0C to 49C)

Surface temperature must be at least 5F above dew point temperature.

Note: PSX 700 should be allowed to reach a Dry-to-Touch condition before force curing

above 140F

General air quality Area should be sheltered from airborne particulates and pollutants. Ensure good

ventilation during application and curing. Provide shelter to prevent wind from affecting

spray patterns.

INSTRUCTIONS FOR USE

Mixing ratio by volume 4 parts base to 1 part hardener

Only mix full kits. Pre-mix base component with a pneumatic air mixing at moderate

speeds to homogenize the container. Pour in the hardener component and power

agitate until thoroughly mixed.

Pot life

Airless spray Standard airless spray equipment, 30:1 pump or larger, 0.015 0.017 fluid tip

recommended

Air spray Thin up to 10%, standard conventional equipment, 0.070 fluid orifice. A moisture and oil

trap in the main line is recommended. Separate regulators for air and fluid pressure are

recommended. Use an agitated pressure pot.

Brush & roll Use a well loaded, high quality natural bristle brush. Maintain a wet edge.

Use a high quality, well loaded, solvent resistant, low nap (1/4-3/8) roller. Amercoat 851

flow control additive may be used to enhance flow and leveling of brush strokes and

roller stipple.

Be aware that multiple coats may be required to achieve uniform and sufficient film

thickness to provide proper hiding when applying by brush or roller.

Thinner Amercoat 911, Amercoat 101 (recommended for > 90F)

Cleaning solvent Amercoat 12 Cleaner or Amercoat 911 thinner

Primers Dimetcote 9-series, Dimetcote 21-5, Dimetcote 302H, Amercoat 68HS, Amerlock 2/400,

Amercoat 370, Amercoat 385, Amercoat 240, Amercoat 235

A mist coat / full coat application technique is required when applying over inorganic

zincs to prevent application bubbling. Thin the mist coat up to 15% with Amercoat 911 or

Amercoat 101. Ensure dry spray is removed from the surface.

Limitations for use For Industrial or Professional Use Only

Safety precautions For paint and recommended thinners see safety sheet 1430, 1431 and relevant material

safety data sheets

This is a solvent borne paint and care should be taken to avoid inhalation of spray mist

or vapor as well as contact between the wet paint and exposed skin or eyes.

PSX 700

page 2/4

Temperature 50F 70F 90F

PSX 700 & PSX 700FD 6.5 hours 4 hours 1.5 hours

page 3/4

PSX 700

DRY/CURE TIMES* PSX 700 @ 4 mils dft and 40% relative humidity

* Surface must be power washed as needed to remove all surface contaminants. Surface must be clean and

dry. Use Prep 88 for very dirty surfaces. When re-coating between the dry through time and 7 days, solvent

wipe the surface with Amercoat 911 or Amercoat 12 prior to application of the second coat.

PSX 700FD @ 4 mils dft and 40% relative humidity

* Surface must be power washed as needed to remove all surface contaminants. Surface must be clean and

dry. Use Prep 88 for very dirty surfaces. When re-coating between the dry through time and 7 days, solvent

wipe the surface with Amercoat 911 or Amercoat 12 prior to application of the second coat.

PRODUCT QUALIFICATIONS SSPC Paint 36 Level 3 Performance

NFPA Class A Flame Spread

USDA Incidental Food Contact

AWWA D102-08 Outside Coating System

AVAILABILITY

Packaging Available in 1 gallon and 5 gallon kits

Product codes PX700-23 Pearl Gray Base

PX700-3 White Base

PX700-9 Black Base

PX700-T1 Deep Tint Base*

PX700-T2 Light Tint Base*

PX700-T3 Neutral Tint Base*

PX700-T4 Red Tint Base*

PX700-T5 High Hiding Yellow Tint Base*

PX700-71 Safety Red Base

PX700-81 Safety Yellow Base

PX700-B Hardener component

PX700FD-B Fast Dry hardener component

* Product must be tinted with special PSX tints only. Tintable with UCD PS Line colorants only.

Worldwide statement While it is always the aim of PPG Protective & Marine Coatings to supply the same product

on a worldwide basis, slight modification of the product is sometimes necessary to comply

with local or national rules/circumstances. Under these circumstances an alternative product

data sheet is used.

32F 50F 70F 90F

Dry to touch 9 hours 4.5 hours 2 hours 1 hour

Dry through 24 hours 8.5 hours 4.5 hours 3 hours

Dry to overcoat* 20 hours 7 hours 3 hours 2 hours

Maximum overcoat unlimited*

40F 50F 70F 90F

Dry to touch 9 hours 6 hours 3 hours 1.5 hours

Dry through 24 hours 11 hours 6 hours 4 hours

Dry to overcoat* 20 hours 9 hours 4.5 hours 3 hours

Maximum overcoat unlimited*

page 4/4

WARRANTY STATEMENT

PPG warrants (i) its title to the product, (ii) that the quality of the product conforms to PPGs specifications for such product in

effect at the time of manufacture and (iii) that the product shall be delivered free of the rightful claim of any third person for

infringement of any U.S. patent covering the product.

THESE ARE THE ONLY WARRANTIES THAT PPG MAKES AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES,

UNDER STATUTE ORARISING OTHERWISE IN LAW, FROMA COURSE OF DEALING OR USAGE OF TRADE, INCLUDING

WITHOUT LIMITATION, ANY OTHER WARRANTY OF FITNESS FORA PARTICULAR PURPOSE OR USE, ARE DISCLAIMED

BY PPG.

Any claim under this warranty must be made by Buyer to PPG in writing within five (5) days of Buyers discovery of the claimed

defect, but in no event later than the expiration of the applicable shelf life of the product, or one year from the date of the delivery

of the product to the Buyer, whichever is earlier. Buyers failure to notify PPG of such non-conformance as required herein

shall bar Buyer from recovery under this warranty.

LIMITATION OF LIABILITY

IN NO EVENT WILL PPG BE LIABLE UNDER ANY THEORY OF RECOVERY (WHETHER BASED ON NEGLIGENCE OF

ANY KIND, STRICT LIABILITY OR TORT) FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IN ANY WAY RELATED TO, ARISING FROM, OR RESULTING FROMANY USE MADE OF THE PRODUCT.

The information in this sheet is intended for guidance only and is based upon laboratory tests that PPG believes to be reliable.

PPG may modify the information contained herein at any time as a result of practical experience and continuous product

development. All recommendations or suggestions relating to the use of the PPG product, whether in technical documentation,

or in response to a specific inquiry, or otherwise, are based on data, which to the best of PPGs knowledge, is reliable. The

product and related information is designed for users having the requisite knowledge and industrial skills in the industry and it

is the end-users responsibility to determine the suitability of the product for its own particular use and it shall be deemed that

Buyer has done so, as its sole discretion and risk.

PPG has no control over either the quality or condition of the substrate, or the many factors affecting the use and application of

the product. Therefore, PPG does not accept any liability arising from any loss, injury or damage resulting from such use or

the contents of this information (unless there are written agreements stating otherwise). Variations in the application environment,

changes in procedures of use, or extrapolation of data may cause unsatisfactory results.

This sheet supersedes all previous versions and it is the Buyers responsibility to ensure that this information is current prior to

using the product.

Current sheets for all PPG Protective & Marine Coatings Products are maintained at www.ppgpmc.com. The English text of

this sheet shall prevail over any translation thereof.

PSX 700

PSX and Amercoat are registered trademarks of PPG Industries Ohio, Inc.

October 2012

Revision of September 2012

DESCRIPTION Engineered Siloxane Clear Coat

PRINCIPAL CHARACTERISTICS Unique, high gloss epoxy siloxane

Low HAPs, ultra-low VOC

High durability in challenging environments

Abrasion resistant

Resists dirt pickup, easily cleaned

Isocyanate free

COLOR AND GLOSS Clear

Gloss

BASIC DATA

Volume solids 80% 3%

VOC 0.9 lbs/gal (108 g/L) based on (EPA Method 24)

* The mixed and applied coating cure reaction will produce VOC of mixed alcohols.

Recommended

Dry film thickness* (per coat) 2 3 mils (50 75 microns)

Theoretical Spread Rate @ 1 mil dft 1283 ft

2

/ gallon

@ 3 mils dft 428 ft

2

/ gallon

Components 2

Shelf Life 2 years from date of manufacture when stored indoors in the original unopened container.

Store product in dry conditions at temperatures of 40-100F.

SURFACE PREPARATION Coating performance is proportional to the degree of surface preparation. See specific

primer for surface preparation details.

Aged Coatings Contact your PPG representative. A test patch of PSX 700A Clear Coat over in-tact

clean coating and observation for film defects and adhesion over a period of time

may be required, dependent upon the type of coating. PSX 700A Clear Coat should

be applied over a UV-resistant coating in applications exposed to direct sunlight.

PSX 700A Clear Coat is compatible over Amercoat 450-series.

ENVIRONMENTAL CONDITIONS

Ambient temperatures 32F to 120F (0C to 49C)

Surface temperature must be at least 5F above the dew point temperature.

Material temperatures 32F to 100F (0C to 32C)

Relative humidity 50% minimum

Work area can be artificially humidified by atomized water spray and/or ponding water under the coated

structures. After the film is dry-to-touch, a fine mist may be applied over the coating to expedite curing in low

humidity environments.

Surface temperature 32F to 120F (0C to 49C)

Surface temperature must be at least 5F above the dew point temperature.

General air quality Area should be sheltered from airborne particulates and pollutants. Ensure good ventilation

during application and curing. Provide shelter to prevent wind from affecting spray patterns.

INSTRUCTIONS FOR USE

Mixing ratio by volume 5 parts base : 1 part hardener

Only mix full kits. Pre-mix base component with a pneumatic air mixing at moderate

speeds to homogenize the container. Pour in the hardener component and power

agitate until thoroughly mixed.

PSX

700A Clear Coat

page 1/3

Pot life*

Airless spray Standard airless spray equipment,

30:1 pump or larger, 0.015 0.017" fluid tip recommended

Air spray Thin up to 10%, standard conventional equipment, 0.070 fluid orifice. A moisture and oil

trap in the main line is recommended. Separate regulators for air and fluid pressure are

recommended. Use an agitated pressure pot.

Brush & roll Use a well loaded, high quality natural bristle brush. Maintain a wet edge.

Use a high quality, well loaded, solvent resistant, low nap (1/4"- 3/8") roller. Amercoat 851

flow control additive may be used to enhance flow and leveling of brush strokes and

roller stipple.

Be aware that multiple coats may be required to achieve uniform and sufficient film

thickness to provide proper hiding when applying by brush or roller.

Thinner Amercoat 911, Amercoat 101 (recommended for > 90F)

Cleaning solvent Amercoat 12 Cleaner or Amercoat 911 thinner

Primers* Amerlock 2/400, Amercoat 370, Amercoat 385, Amercoat 240, Amercoat 235,

Amerlock Sealer, Pitt-guard Epoxies

* Epoxies should be topcoated with a UV-resistant coating such as PSX polysiloxanes, Amercoat 450H-series,

or Pitthane polyurethane for applications with direct sunlight exposure.

Safety precautions For paint and recommended thinners see safety sheet 1430, 1431 and relevant material

safety data sheets

This is a solvent borne paint and care should be taken to avoid inhalation of spray mist

or vapor as well as contact between the wet paint and exposed skin or eyes.

DRY/CURE TIMES* PSX 700A Clear Coat @ 4 mils dft and 40% relative humidity

* Surface must be power washed as needed to remove all surface contaminants. Surface must be clean and

dry. When re-coating within 72 hours, solvent wipe the surface with Amercoat 911 thinner prior to application of

the second coat.

PRODUCT QUALIFICATIONS NFPA Class A Flame Spread

USDA Incidental Food Contact

AVAILABILITY

Packaging Available in 1-gallon kits

Product codes PX700A0 Base component

PX700A0B Hardener component

Worldwide statement While it is always the aim of PPG Protective & Marine Coatings to supply the same product

on a worldwide basis, slight modification of the product is sometimes necessary to comply

with local or national rules/circumstances. Under these circumstances an alternative product

data sheet is used.

PSX 700A Clear Coat

Temperature 50F 70F 90F

PSX 700A Clear Coat 6.5 hours 4 hours 1.5 hours

page 2/3

32F 50F 70F 90F

Dry to touch 4.5 hours 2.5 hours 1.5 hours 1 hour

Dry through 24 hours 7 hours 4 hours 3 hours

Dry to overcoat* 20 hours 6 hours 3 hours 2 hours

Maximum overcoat 30 days

page 3/3

PSX 700A Clear Coat

WARRANTY STATEMENT

PPG warrants (i) its title to the product, (ii) that the quality of the product conforms to PPGs specifications for such product in

effect at the time of manufacture and (iii) that the product shall be delivered free of the rightful claim of any third person for

infringement of any U.S. patent covering the product.

THESE ARE THE ONLY WARRANTIES THAT PPG MAKES AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES,

UNDER STATUTE ORARISING OTHERWISE IN LAW, FROMA COURSE OF DEALING OR USAGE OF TRADE, INCLUDING

WITHOUT LIMITATION, ANY OTHER WARRANTY OF FITNESS FORA PARTICULAR PURPOSE OR USE, ARE DISCLAIMED

BY PPG.

Any claim under this warranty must be made by Buyer to PPG in writing within five (5) days of Buyers discovery of the claimed

defect, but in no event later than the expiration of the applicable shelf life of the product, or one year from the date of the delivery

of the product to the Buyer, whichever is earlier. Buyers failure to notify PPG of such non-conformance as required herein

shall bar Buyer from recovery under this warranty.

LIMITATION OF LIABILITY

IN NO EVENT WILL PPG BE LIABLE UNDER ANY THEORY OF RECOVERY (WHETHER BASED ON NEGLIGENCE OF

ANY KIND, STRICT LIABILITY OR TORT) FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IN ANY WAY RELATED TO, ARISING FROM, OR RESULTING FROMANY USE MADE OF THE PRODUCT.

The information in this sheet is intended for guidance only and is based upon laboratory tests that PPG believes to be reliable.

PPG may modify the information contained herein at any time as a result of practical experience and continuous product

development. All recommendations or suggestions relating to the use of the PPG product, whether in technical documentation,

or in response to a specific inquiry, or otherwise, are based on data, which to the best of PPGs knowledge, is reliable. The

product and related information is designed for users having the requisite knowledge and industrial skills in the industry and it

is the end-users responsibility to determine the suitability of the product for its own particular use and it shall be deemed that

Buyer has done so, as its sole discretion and risk.

PPG has no control over either the quality or condition of the substrate, or the many factors affecting the use and application of

the product. Therefore, PPG does not accept any liability arising from any loss, injury or damage resulting from such use or

the contents of this information (unless there are written agreements stating otherwise). Variations in the application environment,

changes in procedures of use, or extrapolation of data may cause unsatisfactory results.

This sheet supersedes all previous versions and it is the Buyers responsibility to ensure that this information is current prior to

using the product.

Current sheets for all PPG Protective & Marine Coatings Products are maintained at www.ppgpmc.com. The English text of

this sheet shall prevail over any translation thereof.

PSX and Amercoat are registered trademarks of PPG Industries Ohio, Inc.

April 2013

Revision of January 2013

DESCRIPTION Fast Dry, Surface Tolerant, High Solids Epoxy Coating

PRINCIPAL CHARACTERISTICS Fast dry

Low VOC

High performance general maintenance coating for new or old steel

Self priming over most existing coatings

Compatible with prepared damp surfaces

Compatible with adherent rust remaining on prepared surfaces

Dry temperature resistance up to 450F on insulated or uninsulated surfaces when

mixed with Amercoat 880 glass flake additive

Suitable for use in many industries including off-shore, water/wastewater, power,

steel fabrication and public use facilities.

COLOR AND GLOSS* Semi-gloss

Standard primer colors, custom colors, and aluminum

* Epoxy coatings will chalk and fade with exposure to sunlight. Light colors are prone to ambering to some

extent. Note that product tinted to custom colors are not recommended for immersion service. Only use factory

grind batches for immersion.

BASIC DATA

Volume solids 85% 3%

VOC 1.5 lbs/gal (180 g/L) EPA Method 24

(Use Amerlock 2 VOC when <100 g/L formulation is required)

1.4 lbs/gal (163 g/L) Directive 1999/13/EC, SED

Recommended

Dry film thickness (per coat) 4 8 mils (100 200 microns)

Theoretical Spread Rate @ 1 mils dft 1331 ft

2

/gal

@ 5 mils dft 266 ft

2

/gal

Components 2

Dry Temperature Resistance* Continuous 200F Intermittent 350F (<5% of the time, max 24 hours)

* Color will drift at elevated temperatures.

Shelf Life 3 years from date of manufacture

* when stored in original sealed containers in dry conditions between 40-100F

SURFACE PREPARATION Coating performance is, in general, proportional to the degree of surface preparation.

Abrasive blasting is usually the most effective and economical method.When this is

impossible or impractical, Amerlock 2 can be applied over mechanically cleaned

surfaces. All surfaces must be clean, dry and free of all contaminants, including salt

deposits. Contact PPG for maximum allowable salt containment levels.

Mild Steel Remove all loose rust, dirt, grease or other contaminants by one of the following

depending on the degree of cleanliness required: SSPC-SP2, 3, 6, 7 or 10 (ISO

8501-1 St-2, St-3, Sa 1, Sa 2.5). These minimum surface preparation standards

apply to steel that has been previously abrasive blasted. The choice of surface

preparation will depend on the system selected and end-use service conditions.

For more severe service and immersion, clean to SSPC-SP10 (ISO8501-1 Sa 2.5).

Blast to achieve an anchor profile of 1.0-5.0 mils (25-125 microns) as indicted by a

Keane-Tator Surface profile Comparator or Testex Tape. Previously blasted steel

may be ultra-high pressure water jetted to SSPC SP WJ-2(L) / NACE WJ-2(L).

The wet surface can be dried by blowing with dry compressed air giving special at-

tention to horizontal surfaces and recesses.

Concrete Prepare / clean surface in accordance with SSPC SP-13 guidelines. Abrade surface

per ASTM D-4259 to remove all efflorescence and laitance, to expose sub-surface

voids, and to provide a surface roughness equivalent of 60 grit sandpaper or

coarser. Test for moisture by conducting a plastic sheet test in accordance with

ASTM D4263. Fill voids as necessary with Amercoat 114A epoxy filler. For slabs on

grade, test for moisture in accordance with ASTM F1869 (calcium chloride test).

The maximum allowable moisture transmission is 3 lbs / 1,000 ft

2

/24 hours. Refer to

Information Sheet 1496ACUS for further details regarding moisture measurements.

AMERLOCK

2

page 1/4

Galvanized Steel Remove oil or soap film with detergent or emulsion cleaner. Lightly abrasive blast

with a fine abrasive in accordance with SSPC SP-16 guidelines to achieve a profile of

1.5-3.0 mils. When light abrasive blasting is not possible, galvanizing can be treated

with a suitable zinc phosphate conversion coating. Galvanizing that has at least 12

months of exterior weathering and has a rough surface with white rust present may

be over-coated after power washing and cleaning to remove white rust and other

contaminants. The surface must have a measurable profile. A test patch is recom-

mended to confirm adhesion. Not recommended over chromate sealed galvanizing

without blasting to thoroughly remove chromates. Adhesion problems may occur.

Non-Ferrous Metals and Abrasive blast in accordance with SSPC SP-16 guidelines to achieve a uniform and

Stainless Steel dense 1.5-4.0 mil anchor profile. Size and hardness of abrasive should be adjusted

as necessary based on the hardness of the substrate. Aluminum may be treated

with a surface treatment compliant with Mil-DTL-5541 or equivalent (non-immersion

applications only).

Aged coatings All surfaces must be clean, dry, tightly bonded and free of all loose paint, corrosion

products or chalky residue. Abrade surface, or clean with Prep 88. Amerlock 2 is

compatible over most types of properly applied and tightly adhering coatings, however,

a test patch is recommended to confirm compatibility.

Repair Prepare damaged areas to original surface preparation specifications, feathering

edges of intact coating. Thoroughly remove dust or abrasive residue before touch-up.

ENVIRONMENTAL CONDITIONS

Ambient temperatures* 20F to 122F (-6C to 50C)

* Amerlock 400 hardener can be used with the Amerlock 2/400 base component for applications that require a

long pot life. The A component is the same for Amerlock 400 and Amerlock 2. The B components are inter-

changeable.

Material temperatures 40F to 90F (5C to 32C)

Relative humidity 0 to 100%, surface must be free of visible moisture. For immersion service and for

optimum performance, surface temperature must be at least 5F above the dew point

temperature.

Surface temperature 20F to 122 F (-6C to 50C)

* Amerlock 2 may be applied to surfaces as hot as 250F (121C) for non-immersion service. When applying

Amerlock 2 to surfaces between 122F and 250F, Amerlock 2 must be thinned at 1/2 pint per gallon with only

Amercoat 101 thinner. Multiple thin passes may be required to achieve film build and to avoid solvent blistering.

General air quality Area should be sheltered from airborne particulates and pollutants. Avoid combustion

gases or other sources of carbon dioxide that may promote amine blush. Ensure good

ventilation during application and curing. Provide shelter to prevent wind from affecting

spray patterns. Refer to Information Bulletin #1489 for further information on prevention,

detection, and mitigation of amine blush.

INSTRUCTIONS FOR USE

Mixing ratio by volume 1 part base to 1 part hardener

Pre-mix pigmented components with a pneumatic air mixer at moderate speeds to

homogenize the container. Add hardener to base and agitate with a power mixer for 1-2

minutes until completely dispersed.

Pot life

Induction time None required

Airless spray 45:1 pump or larger, 0.017-0.019 fluid tip

Can be sprayed with plural component application equipment.

Air spray Thin up to 20%, standard conventional equipment, 0.070 fluid orifice

Brush & roll Use a high quality natural bristle brush and / or solvent resistant, 3/8 nap roller. Ensure

brush / roller is well loaded to avoid air entrainment. Multiple coats may be necessary to

achieve adequate film build.

Thinner Amercoat 65 (xylene), Amercoat 101 (recommended for > 90F), Amercoat T10,

Amercoat 8 (to extend pot life 10-20%)

AMERLOCK 2

page 2/4

32F 50F 70F 90F

2 4 hours 2 hours 1 hour 0.5 hour

2AL 3 hours 1.5 hours 0.75 hour 0.5 hour

page 3/4

AMERLOCK 2

Cleaning solvent Amercoat 12 Cleaner or Amercoat 65 thinner (xylene)

Primers Direct to substrate; Dimetcote series primers, Amercoat 68HS, Amercoat 68MCZ

Topcoats Amercoat 450 Series Polyurethanes, Amershield, PSX 700, PSX One, Amercoat 220

Series Acrylics, Pitthane Polyurethanes

Safety precautions For paint and recommended thinners see safety sheet 1430, 1431 and relevant material

safety data sheets

This is a solvent borne paint and care should be taken to avoid inhalation of spray mist

or vapor as well as contact between the wet paint and exposed skin or eyes.

DRY/CURE TIMES Amerlock 2 @ 5 mils dft

Amerlock 2 Aluminum @ 5 mils dft

* Dry times are dependent on air and surface temperatures as well as film thickness, ventilation, and relative

humidity. Maximum recoating time is highly dependent upon actual surface temperatures not simply air

temperatures. Surface temperatures should be monitored, especially with sun-exposed or otherwise heated

surfaces. Higher surface temperatures shorten the maximum recoat window. An extended recoatable window

may be allowable in some circumstances. Please contact your PPG PMC representative for more details.

Surface must be clean and dry. Any contamination must be identified and removed. A detergent wash with

Prep 88 or equivalent is required prior to application of topcoats after 30 days of exposure. However, particular

attention must be paid to surfaces exposed to sunlight where chalking may be present. In those situations, a

further degree of cleaning may be required. PPG Technical Service can advise on suitable cleaning methods.

If maximum recoat/topcoat time is exceeded, then roughen surface.

PRODUCT QUALIFICATIONS Compliant with USDA Incidental Food Contact Requirements

NFPA Class A for Flame Spread and Smoke Development

Qualified for ANSI/NSF Standard 61 (potable water) for tanks, pipes, valves, and fittings.

For NSF application instructions, please visit our website at:

www.ppgamercoatus.ppgpmc.com/NSF/

AWWA C210-98

AWWA C550-98

AWWA D102-06 ICS #1, #2, #3, #5

LEEDs compliant for Anti-corrosive Paint category

Nuclear Service Level 2 (ANSI N 5.12, ANSI N 101.2)

NORSOK M501 Rev. 5, System 7 Subsea surfaces

32F 50F 70F 90F

Dry to touch 24 hours 8 hours 2 hours 1 hour

Dry through 38 hours 14 hours 5 hours 3 hours

Dry to recoat/topcoat 24 hours 12 hours 6 hours 3 hours

Max recoat, self 90 days 60 days 30 days 14 days

Max topcoat,

urethanes, PSX

30 days 21 days 7 days 4 days

Cure to immersion

factory colors only

21 days 7 days 4 days 3 days

Cure to immersion -

potable water

Refer to: www.ppgamercoatus.ppgpmc.com/NSF/

for specific application and curing requirements

32F 50F 70F 90F

Dry to touch 30 hours 11 hours 3.5 hours 2 hours

Dry through 48 hours 17 hours 7 hours 3.5 hours

Dry to recoat 30 hours 12 hours 6 hours 3 hours

Max recoat, self 90 days 60 days 30 days 14 days

Max topcoat,

urethanes, PSX

30 days 21 days 7 days 4 days

Cure to immersion 21 days 7 days 4 days 3 days

page 4/4

AVAILABILITY

Packaging Available in 2-gallon and 5-gallon kits

2-gallon kits have 1 full gallon of base and 1 full gallon of hardener

5 gallon kits have 2.5 gallons of base and 2.5 gallons of hardener

Inventory (made to order, etc..) Global availability

Product codes AK2-1 Buff

AK2-3 White

AK2-9 Black

AK2-23 Pearl Gray

AK2-72 Oxide Red

AK2-81 Safety Yellow

AK2-T1 Deep Tint base*

AK2-T2 Light Tint base*

AK2-T3 Neutral Tint base*

AK2-T4 Red Tint base*

AK2-T5 High Hiding Yellow Tint base*

AK2-B Hardener component

AK2-01A Amerlock 2AL Aluminum Base

AK2-01B Amerlock 2AL Aluminum Hardener

* Tintable using UCD V-Line colorants only.

Worldwide statement While it is always the aim of PPG Protective & Marine Coatings to supply the same product

on a worldwide basis, slight modification of the product is sometimes necessary to comply

with local or national rules/circumstances. Under these circumstances an alternative product

data sheet is used.

WARRANTY STATEMENT

PPG warrants (i) its title to the product, (ii) that the quality of the product conforms to PPGs specifications for such product in

effect at the time of manufacture and (iii) that the product shall be delivered free of the rightful claim of any third person for

infringement of any U.S. patent covering the product.

THESE ARE THE ONLY WARRANTIES THAT PPG MAKES ANDALL OTHER EXPRESS OR IMPLIED WARRANTIES, UNDER

STATUTE ORARISING OTHERWISE IN LAW, FROMACOURSE OF DEALING OR USAGE OF TRADE, INCLUDING WITHOUT

LIMITATION, ANY OTHER WARRANTY OF FITNESS FORA PARTICULAR PURPOSE OR USE, ARE DISCLAIMED BY PPG.

Any claim under this warranty must be made by Buyer to PPG in writing within five (5) days of Buyers discovery of the claimed

defect, but in no event later than the expiration of the applicable shelf life of the product, or one year from the date of the delivery

of the product to the Buyer, whichever is earlier. Buyers failure to notify PPG of such non-conformance as required herein

shall bar Buyer from recovery under this warranty.

LIMITATION OF LIABILITY

IN NO EVENT WILL PPG BE LIABLE UNDER ANY THEORY OF RECOVERY (WHETHER BASED ON NEGLIGENCE OF

ANY KIND, STRICT LIABILITY OR TORT) FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IN ANY WAY RELATED TO, ARISING FROM, OR RESULTING FROMANY USE MADE OF THE PRODUCT.

The information in this sheet is intended for guidance only and is based upon laboratory tests that PPG believes to be reliable.

PPG may modify the information contained herein at any time as a result of practical experience and continuous product

development. All recommendations or suggestions relating to the use of the PPG product, whether in technical documentation,

or in response to a specific inquiry, or otherwise, are based on data, which to the best of PPGs knowledge, is reliable. The

product and related information is designed for users having the requisite knowledge and industrial skills in the industry and it

is the end-users responsibility to determine the suitability of the product for its own particular use and it shall be deemed that

Buyer has done so, as its sole discretion and risk.

PPG has no control over either the quality or condition of the substrate, or the many factors affecting the use and application of

the product. Therefore, PPG does not accept any liability arising from any loss, injury or damage resulting from such use or

the contents of this information (unless there are written agreements stating otherwise). Variations in the application environment,

changes in procedures of use, or extrapolation of data may cause unsatisfactory results.

This sheet supersedes all previous versions and it is the Buyers responsibility to ensure that this information is current prior to

using the product.

Current sheets for all PPG Protective & Marine Coatings Products are maintained at www.ppgpmc.com. The English text of

this sheet shall prevail over any translation thereof.

AMERLOCK 2

Amercoat and Amerlock are registered trademarks of PPG Industries Ohio, Inc.

November 2012

Revision of November 2012

DESCRIPTION Fast Dry Aluminum Epoxy Mastic Coating

PRINCIPAL CHARACTERISTICS Fast dry, Low Temperature Curing

Low VOC

High performance general maintenance coating for new or old steel

Self priming over most existing coatings

Formulated with lamellar aluminum flake for enhanced corrosion protection

Compatible with adherent rust remaining on prepared surface

COLOR AND GLOSS* Dull Metallic

Aluminum

BASIC DATA

Volume solids 88% 3%

VOC 1.0 lbs/gal (120 g/L)

Recommended

Dry film thickness (per coat) 4 8 mils (100 200 microns)

Theoretical Spread Rate @ 1 mils dft 1411 ft

2

/gal

@ 6 mils dft 235 ft

2

/gal

Components 2

Shelf Life 3 years from date of manufacture

SURFACE PREPARATION Coating performance is, in general, proportional to the degree of surface preparation.

Steel Remove weld spatter, protrusions, and laminations in steel. Remove all surface

contaminants, oil and grease in accordance with SSPC SP-1.

Abrasive blast with an angular abrasive to an SSPC SP-10 cleanliness or higher for

immersion service. Achieve a surface profile of 2.0-4.0 mils. For atmospheric service,

abrasive blast to SSPC SP-6 standards.

The product may be applied over an SSPC WJ-2(L) where a previous blast profile

can be exposed.

For maintenance and repair in atmospheric service, the product can be applied

over surfaces prepared in accordance with SSPC SP-2 or SSPC SP-3 (hand and

power tool cleaning).

Amercoat 114A may be used as a pit filler for severely pitted steel and surface dis-

continuities.

Check with PPG technical service for the maximum allowable soluble salt level for

water immersion service. This will vary based on the water chemistry and service

temperatures.

Non-ferrous metals Lightly abrasive blast in accordance with SSPC SP-16 to achieve a uniform and

dense 1.5-4.0 mil anchor profile.

Aged Coatings and Repairs Ensure the coating system is sound and well adhered. Do not apply over acrylic

coatings or coatings that exhibit poor solvent resistance. Atest patch is recommended.

Sweep blast or otherwise thoroughly abrade the existing coating in accordance with

SSPC SP-7. Alternately, Prep 88 may be used to prepare some existing coatings.

Please refer to Prep 88 data sheet for details. Feather the edges of tightly adhered,

in-tact coatings at the perimeter of repair areas. Power tool clean the existing steel

in accordance with SSPC SP-3 (atmospheric service) or SSPC SP-11 (immersion

service).

AMERLOCK

2AL

page 1/3

ENVIRONMENTAL CONDITIONS

Ambient temperatures 20F to 122F (-6C to 50C)

Material temperatures 40F to 90F (5C to 32C)

Relative humidity 0 to 90%, For immersion service and for optimum performance, surface temperature

must be at least 5F above the dew point temperature.

Surface temperature 20F to 122 F (-6C to 50C)

* The surface should be inspected to ensure there is no ice present on the substrate in cold weather conditions.

General air quality Area should be sheltered from airborne particulates and pollutants. Avoid combustion

gases or other sources of carbon dioxide that may promote amine blush. Ensure good

ventilation during application and curing. Provide shelter to prevent wind from affecting

spray patterns. Refer to Information Bulletin #1489 for further information on prevention,

detection, and mitigation of amine blush.

INSTRUCTIONS FOR USE

Mixing ratio by volume 1 part base to 1 part hardener

Pre-mix pigmented components with a pneumatic air mixer at moderate speeds to

homogenize the container. Add hardener to base and agitate with a power mixer for 1-2

minutes until completely dispersed.

Pot life

Induction time None required

Airless spray 45:1 pump or larger, 0.019-0.021 fluid tip

Can be sprayed with plural component application equipment.

Air spray Thin up to 20%, standard conventional equipment, 0.070" fluid orifice

Brush & roll Use a high quality natural bristle brush and / or solvent resistant, 3/8" nap roller. Ensure

brush / roller is well loaded to avoid air entrainment. Multiple coats may be necessary to

achieve adequate film build.

Thinner Amercoat 65 (xylene), Amercoat 101 (recommended for > 90F)

Cleaning solvent Amercoat 12 Cleaner or Amercoat 65 thinner (xylene)

Primers Direct to substrate; Dimetcote series primers, Amercoat 68HS

Topcoats Amercoat 450 Series Polyurethanes, Amershield, PSX 700, PSX One, Amercoat 220

Series Acrylics

Safety precautions For paint and recommended thinners see safety sheet 1430, 1431 and relevant material

safety data sheets

This is a solvent borne paint and care should be taken to avoid inhalation of spray mist

or vapor as well as contact between the wet paint and exposed skin or eyes.

DRY/CURE TIMES* Amerlock 2AL @ 5 mils dft

* Dry times are dependent on air and surface temperatures as well as film thickness, ventilation, and relative

humidity. Maximum recoating time is highly dependent upon actual surface temperatures not simply air

temperatures. Surface temperatures should be monitored, especially with sun-exposed or otherwise heated

surfaces. Higher surface temperatures shorten the maximum recoat window.

Surface must be clean and dry. Any contamination must be identified and removed. A detergent wash with

Prep 88 or equivalent is required prior to application of topcoats after 30 days of exposure. However, particular

attention must be paid to surfaces exposed to sunlight where chalking may be present. In those situations, a

further degree of cleaning may be required. PPG Technical Service can advise on suitable cleaning methods.

If maximum recoat/topcoat time is exceeded, then roughen surface.

AMERLOCK 2AL

page 2/3

32F 50F 70F 90F

2AL 3 hours 1.5 hours 0.75 hour 0.5 hour

32F 50F 70F 90F

Dry to touch 30 hours 11 hours 3.5 hours 2 hours

Dry through 48 hours 17 hours 7 hours 3.5 hours

Dry to recoat 30 hours 12 hours 6 hours 3 hours

Max recoat, self 90 days 60 days 30 days 14 days

Max topcoat,

urethanes, PSX

30 days 21 days 7 days 4 days

Cure to immersion 21 days 7 days 4 days 3 days

page 3/3

AMERLOCK 2AL

AVAILABILITY

Packaging Available in 2-gallon and 5-gallon kits

2-gallon kits have 1 full gallon of base and 1 full gallon of hardener

5 gallon kits have 2.5 gallons of base and 2.5 gallons of hardener

Inventory (made to order, etc..) Global availability

Product codes AK2-01A Amerlock 2 Aluminum base

AK2-01B Amerlock 2 Aluminum hardener

Worldwide statement While it is always the aim of PPG Protective & Marine Coatings to supply the same product

on a worldwide basis, slight modification of the product is sometimes necessary to comply

with local or national rules/circumstances. Under these circumstances an alternative product

data sheet is used.

WARRANTY STATEMENT

PPG warrants (i) its title to the product, (ii) that the quality of the product conforms to PPGs specifications for such product in

effect at the time of manufacture and (iii) that the product shall be delivered free of the rightful claim of any third person for

infringement of any U.S. patent covering the product.

THESE ARE THE ONLY WARRANTIES THAT PPG MAKES AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES,

UNDER STATUTE ORARISING OTHERWISE IN LAW, FROMA COURSE OF DEALING OR USAGE OF TRADE, INCLUDING

WITHOUT LIMITATION, ANY OTHER WARRANTY OF FITNESS FORA PARTICULAR PURPOSE OR USE, ARE DISCLAIMED

BY PPG.

Any claim under this warranty must be made by Buyer to PPG in writing within five (5) days of Buyers discovery of the claimed

defect, but in no event later than the expiration of the applicable shelf life of the product, or one year from the date of the delivery

of the product to the Buyer, whichever is earlier. Buyers failure to notify PPG of such non-conformance as required herein

shall bar Buyer from recovery under this warranty.

LIMITATION OF LIABILITY

IN NO EVENT WILL PPG BE LIABLE UNDER ANY THEORY OF RECOVERY (WHETHER BASED ON NEGLIGENCE OF

ANY KIND, STRICT LIABILITY OR TORT) FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IN ANY WAY RELATED TO, ARISING FROM, OR RESULTING FROMANY USE MADE OF THE PRODUCT.

The information in this sheet is intended for guidance only and is based upon laboratory tests that PPG believes to be reliable.

PPG may modify the information contained herein at any time as a result of practical experience and continuous product

development. All recommendations or suggestions relating to the use of the PPG product, whether in technical documentation,

or in response to a specific inquiry, or otherwise, are based on data, which to the best of PPGs knowledge, is reliable. The

product and related information is designed for users having the requisite knowledge and industrial skills in the industry and it

is the end-users responsibility to determine the suitability of the product for its own particular use and it shall be deemed that

Buyer has done so, as its sole discretion and risk.

PPG has no control over either the quality or condition of the substrate, or the many factors affecting the use and application of

the product. Therefore, PPG does not accept any liability arising from any loss, injury or damage resulting from such use or

the contents of this information (unless there are written agreements stating otherwise). Variations in the application environment,

changes in procedures of use, or extrapolation of data may cause unsatisfactory results.

This sheet supersedes all previous versions and it is the Buyers responsibility to ensure that this information is current prior to

using the product.

Current sheets for all PPG Protective & Marine Coatings Products are maintained at www.ppgpmc.com. The English text of

this sheet shall prevail over any translation thereof.

Amercoat and Amerlock are registered trademarks of PPG Industries Ohio, Inc.

November 2012

Revision of October 2012

DESCRIPTION Low VOC, Fast Dry, High Solids Epoxy Coating

PRINCIPAL CHARACTERISTICS Fast dry, dry to recoat in 3 hours at 70F (21C)

VOC compliant for <100 g/L specifications

High performance general maintenance coating for new or old steel

Self priming over most existing coatings

Compatible with prepared damp surfaces

Compatible with adherent rust remaining on prepared surfaces

Dry temperature resistance up to 450F on insulated or uninsulated surfaces when

mixed with Amercoat 880 glass flake additive

COLOR AND GLOSS* Standard primer colors and custom colors

Semi-gloss

* Epoxy coatings will chalk and fade with exposure to sunlight. Light colors are prone to ambering to some

extent. Note that product tinted to custom colors are not recommended for immersion service. Only use factory

grind batches for immersion.

BASIC DATA

Volume solids 83% 3%

VOC 0.7 lbs/gal (84 g/L)

Recommended

Dry film thickness (per coat) 4 8 mils per coat (100 200 microns)

Theoretical Spread Rate @ 1 mil dft 1331 ft

2

/ gallon

@ 5 mils dft 266 ft

2

/ gallon

Components 2

Dry Temperature Resistance* Continuous 200F Intermittent 350F (<5% of the time, max 24 hours)

* Color will drift at elevated temperatures.

Shelf Life 3 years from date of manufacture

SURFACE PREPARATION Coating performance is, in general, proportional to the degree of surface preparation.

Steel Remove weld spatter, protrusions, and laminations in steel. Grind welds smooth in

accordance with NACE RP-0178. Remove all surface contaminants, oil and grease

in accordance with SSPC SP-1. Abrasive blast with an angular abrasive to a SSPC

SP-10 cleanliness or higher for immersion service. Achieve a surface profile of 2.0-

4.0 mils. For atmospheric service, abrasive blast to SSPC SP-6 standards.

The product may be applied over a SSPC SP WJ-2(L) where a previous blast pro-

file can be exposed.

For maintenance and repair in atmospheric service, the product can be applied

over surfaces prepared in accordance with SSPC SP-2 or SSPC SP-3 (hand and

power tool cleaning).

Amercoat 114A may be used as a pit filler for severely pitted steel and surface dis-

continuities. Check with PPG technical service for the maximum allowable soluble

salt level for water immersion service. This will vary based on the water chemistry

and service temperatures.

Concrete Prepare / clean surface in accordance with SSPC SP-13 guidelines. Abrade surface

per ASTM D-4259 to remove all efflorescence and laitance, to expose sub-surface

voids, and to provide a surface roughness equivalent of 60 grit sandpaper or

coarser. Test for moisture by conducting a plastic sheet test in accordance with

ASTM D4263. Fill voids as necessary with Amercoat 114A epoxy filler. For slabs on

grade, test for moisture in accordance with ASTM F1869 (calcium chloride test).

The maximum allowable moisture transmission is 3 lbs / 1,000 ft

2

/24 hours. Refer to

Information Sheet 1496ACUS for further details regarding moisture measurements.

AMERLOCK

2VOC

page 1/4

Galvanized Steel Remove oil or soap film with detergent or emulsion cleaner. Lightly abrasive blast

with a fine abrasive in accordance with SSPC SP-16 guidelines to achieve a profile of

1.5-3.0 mils. When light abrasive blasting is not possible, galvanizing can be treated

with a suitable zinc phosphate conversion coating. Galvanizing that has at least 12

months of exterior weathering and has a rough surface with white rust present may

be over-coated after power washing and cleaning to remove white rust and other

contaminants. The surface must have a measurable profile. A test patch is recom-

mended to confirm adhesion. Not recommended over chromate sealed galvanizing

without blasting to thoroughly remove chromates. Adhesion problems may occur.

Non-Ferrous Metals and Abrasive blast in accordance with SSPC SP-16 guidelines to achieve a uniform and

Stainless Steel dense 1.5-4.0 mil anchor profile. Size and hardness of abrasive should be adjusted

as necessary based on the hardness of the substrate. Aluminum may be treated

with a surface treatment compliant with Mil-DTL-5541 or equivalent (non-immersion

applications only).

Aged Coatings and Repairs All surfaces must be clean, dry, tightly bonded and free of all loose paint, corrosion

products or chalky residue. Abrade surface, or clean with Prep 88. Amerlock 2VOC

is compatible over most types of properly applied and tightly adhering coatings, how-

ever, a test patch is recommended to confirm compatibility.

Repair Ensure the coating system is sound and well adhered. Do not apply over acrylic

coatings or coatings that exhibit poor solvent resistance. A test patch is

recommended. Sweep blast or otherwise thoroughly abrade the existing coating in

accordance with SSPC SP-7. Alternately, Prep 88 may be used to prepare some

existing coatings. Please refer to Prep 88 data sheet for details. Feather the edges

of tightly adhered, in-tact coatings at the perimeter of repair areas. Power tool clean

the existing steel in accordance with SSPC SP-3 (atmospheric service) or SSPC

SP-11 (immersion service).

ENVIRONMENTAL CONDITIONS

Ambient temperatures 20F to 122F (-6C to 50C)

Material temperatures 40F to 90F (5C to 32C)

Relative humidity 0-100%, surface must be free of visible moisture. For immersion service and for opti-

mum performance, surface temperature must be at least 5F above the dew point tem-

perature.

Surface temperature 20F to 122F (-6C to 50C)

General air quality Area should be sheltered from airborne particulates and pollutants. Avoid combustion

gases or other sources of carbon dioxide that may promote amine blush and ambering

of light colors. Ensure good ventilation during application and curing. Provide shelter to

prevent wind from affecting spray patterns.

INSTRUCTIONS FOR USE

Mixing ratio by volume 1 parts base to 1 part hardener

Pre-mix pigmented components with a pneumatic air mixer at moderate speeds to

homogenize the container. Add hardener to base and agitate with a power mixer for 1-2

minutes until completely dispersed.

Pot life

Induction time None required

Airless spray 45:1 pump or larger, 0.017-0.019 fluid tip

Can be sprayed with plural component application equipment.

Air spray Thin up to 20%, standard conventional equipment, 0.070" fluid orifice

Brush & roll Use a high quality natural bristle brush and / or solvent resistant, 3/8" nap roller. Ensure

brush / roller is well loaded to avoid air entrainment. Multiple coats may be necessary to

achieve adequate film build.

AMERLOCK 2VOC

50F 70F 90F

2VOC 2 hours 1 hour 0.5 0.75 hour

page 2/4

page 3/4

AMERLOCK 2VOC

Thinner PPG 97-739 and tert-butyl acetate are VOC exempt thinners which can be used

without limit to maintain < 100 g/L.

The following thinners may be used up to 2.5 oz. per gallon to maintain a VOC of

< 100 g/L.

Amercoat 65 (xylene), Amercoat 101 (recommended for > 90F),

Amercoat 8 (to extend pot life 10-20%)

Cleaning solvent Amercoat 12 Cleaner or Amercoat 65 thinner (xylene)

Primers Direct to substrate; Dimetcote- Series Primers, Amercoat 68HS, Amercoat 68MCZ

Topcoats Amercoat 450-Series Polyurethanes, Amershield VOC, PSX 700, PSX One

Safety precautions For paint and recommended thinners see safety sheet 1430, 1431 and relevant material

safety data sheets

This is a solvent borne paint and care should be taken to avoid inhalation of spray mist

or vapor as well as contact between the wet paint and exposed skin or eyes.

DRY/CURE TIMES Amerlock 2VOC @ 5 mils dft

* Dry times are dependent on air and surface temperatures as well as film thickness, ventilation, and relative

humidity. Maximum recoating time is highly dependent upon actual surface temperatures not simply air

temperatures. Surface temperatures should be monitored, especially with sun-exposed or otherwise heated

surfaces. Higher surface temperatures shorten the maximum recoat window.surfaces. Higher surface tem-

peratures shorten the maximum recoat window.

Surface must be clean and dry. Any contamination must be identified and removed. A detergent wash with

Prep 88 or equivalent is required prior to application of topcoats after 30 days of exposure. However, particular

attention must be paid to surfaces exposed to sunlight where chalking may be present. In those situations, a

further degree of cleaning may be required. PPG Technical Service can advise on suitable cleaning methods.

If maximum recoat/topcoat time is exceeded, then roughen surface.

PRODUCT QUALIFICATIONS Compliant with USDA Incidental Food Contact Requirements

AWWA D102-06 ICS #1, #2, #3, #5

LEEDs compliant for Anti-corrosive Paint category

AVAILABILITY

Packaging Available in 2-gallon and 5-gallon kits

2-gallon kits have 1 full gallon of base and 1 full gallon of hardener

5 gallon kits have 2.5 gallons of base and 2.5 gallons of hardener

32F 50F 70F 90F

Dry to touch 24 hours 8 hours 2 hours 1 hour

Dry through 38 hours 13 hours 4.5 hours 2 hours

Dry to recoat/

topcoat

24 hours 6 hours 3 hours 1.5 hours

Max recoat, self 90 days 60 days 30 days 14 days

Max topcoat,

urethanes, PSX

30 days 14 days 7 days 4 days

Cure to immersion

factory colors only

21 days 7 days 3 days 2 days

page 4/4

Product codes AK2V-1 Buff base component

AK2V-3 White base component

AK2V-9 Black base component

AK2V-23 Pearl Gray base component

AK2V-72 Oxide Red base component

AK2V-81 Safety Yellow base component

AK2V-T1 Deep Tint base component*

AK2V-T2 Light Tint base component*

AK2V-T3 Neutral Tint base component*

AK2V-T5 High Hiding Yellow base component*

AK2V-B Hardener component

* Tintable using UCD V-Line colorants only.

Worldwide statement While it is always the aim of PPG Protective & Marine Coatings to supply the same product

on a worldwide basis, slight modification of the product is sometimes necessary to comply

with local or national rules/circumstances. Under these circumstances an alternative product

data sheet is used.

WARRANTY STATEMENT

PPG warrants (i) its title to the product, (ii) that the quality of the product conforms to PPGs specifications for such product in

effect at the time of manufacture and (iii) that the product shall be delivered free of the rightful claim of any third person for

infringement of any U.S. patent covering the product.

THESE ARE THE ONLY WARRANTIES THAT PPG MAKES AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES,

UNDER STATUTE ORARISING OTHERWISE IN LAW, FROMA COURSE OF DEALING OR USAGE OF TRADE, INCLUDING

WITHOUT LIMITATION, ANY OTHER WARRANTY OF FITNESS FORA PARTICULAR PURPOSE OR USE, ARE DISCLAIMED

BY PPG.

Any claim under this warranty must be made by Buyer to PPG in writing within five (5) days of Buyers discovery of the claimed

defect, but in no event later than the expiration of the applicable shelf life of the product, or one year from the date of the delivery

of the product to the Buyer, whichever is earlier. Buyers failure to notify PPG of such non-conformance as required herein

shall bar Buyer from recovery under this warranty.

LIMITATION OF LIABILITY

IN NO EVENT WILL PPG BE LIABLE UNDER ANY THEORY OF RECOVERY (WHETHER BASED ON NEGLIGENCE OF

ANY KIND, STRICT LIABILITY OR TORT) FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IN ANY WAY RELATED TO, ARISING FROM, OR RESULTING FROMANY USE MADE OF THE PRODUCT.

The information in this sheet is intended for guidance only and is based upon laboratory tests that PPG believes to be reliable.

PPG may modify the information contained herein at any time as a result of practical experience and continuous product

development. All recommendations or suggestions relating to the use of the PPG product, whether in technical documentation,

or in response to a specific inquiry, or otherwise, are based on data, which to the best of PPGs knowledge, is reliable. The

product and related information is designed for users having the requisite knowledge and industrial skills in the industry and it

is the end-users responsibility to determine the suitability of the product for its own particular use and it shall be deemed that

Buyer has done so, as its sole discretion and risk.

PPG has no control over either the quality or condition of the substrate, or the many factors affecting the use and application of

the product. Therefore, PPG does not accept any liability arising from any loss, injury or damage resulting from such use or

the contents of this information (unless there are written agreements stating otherwise). Variations in the application environment,

changes in procedures of use, or extrapolation of data may cause unsatisfactory results.

This sheet supersedes all previous versions and it is the Buyers responsibility to ensure that this information is current prior to

using the product.

Current sheets for all PPG Protective & Marine Coatings Products are maintained at www.ppgpmc.com. The English text of

this sheet shall prevail over any translation thereof.

AMERLOCK 2VOC

Amercoat and Amerlock are registered trademarks of PPG Industries Ohio, Inc.

October 2012

Revision of September 2012

DESCRIPTION High solids glass flake epoxy coating

PRINCIPAL CHARACTERISTICS High build, up to 20 mils in one coat

Compatible with adherent rust remaining on prepared surfaces

Continuous dry temperature resistance of 425F on insulated or uninsulated

surfaces

Resistant to well defined cathodic protections

Decreased film permeability due to glass flake pigmentation

COLOR AND GLOSS Flat

Standard primer colors and custom colors

* Epoxy coatings will characteristically chalk and fade upon exposure to sunlight. Light colors are prone to

ambering to some extent. Only use factory colors for immersion service.

BASIC DATA

Volume solids 87% 3%

VOC 1.4 lbs/gal (172 g/L)

Recommended

Dry film thickness (per coat)* 8 20 mils (200 500 microns)

* For high temperature applications above 250F, limit total film thickness to 10 mils dft with spot readings to 12

mils.

Theoretical Spread Rate @ 1 mils dft 1347 ft

2

/gallon

@ 8 mils dft 168 ft

2

/gallon

@ 20 mils dft 67 ft

2

/gallon

Components 2

Shelf Life 3 years from date of manufacture

SURFACE PREPARATION Coating performance is, in general, proportional to the degree of surface preparation.

Steel Remove weld spatter, protrusions, and laminations in steel. Grind welds smooth in

accordance with NACE RP-0178. Remove all surface contaminants, oil and grease

in accordance with SSPC SP-1.

Abrasive blast with an angular abrasive to an SSPC SP-10 cleanliness or higher for

immersion service. Achieve a surface profile of 2.0-4.0 mils. For atmospheric service,

abrasive blast to SSPC SP-6 standards.

The product may be applied over an SSPC SP-12 WJ-2(L) where a previous blast

profile can be exposed.

For maintenance and repair in atmospheric service, the product can be applied

over surfaces prepared in accordance with SSPC SP-2 or SSPC SP-3 (hand and

power tool cleaning).

Amercoat 114A may be used as a pit filler for severely pitted steel and surface

discontinuities.

Check with PPG technical service for the maximum allowable soluble salt level for

water immersion service. This will vary based on the water chemistry and service

temperatures.

Concrete Remove all surface contaminants such as oil, grease, and embedded chemicals.

Abrade the surface per ASTM D 4259 to remove all chalk and surface glaze or

laitance. Mechanical surface preparation should expose sub-surface voids and

provide a surface profile equivalent to 60 grit sandpaper or coarser. Surface should

be free from moisture in accordance with ASTM D4263. Refer to Information Sheet

#1496ACUS for further details regarding moisture measurements. Slabs on grade

should have a maximum moisture content of 3 lbs/1,000 ft

2

/24 hours when

measured by calcium chloride test.

AMERLOCK

2/400GF

page 1/4

Non-ferrous metals Lightly abrasive blast in accordance with SSPC SP-16 to achieve a uniform and

dense 1.5-4.0 mil anchor profile.

Stainless Steel Abrasive blast with a hard angular abrasive to achieve a uniform and dense anchor

profile of 1.5-4.0 mils.

Aged Coatings and Repairs Ensure the coating system is sound and well adhered. Do not apply over acrylic

coatings or coatings that exhibit poor solvent resistance. Atest patch is recommended.

Sweep blast or otherwise thoroughly abrade the existing coating in accordance with

SSPC SP-7. Alternately, Prep 88 may be used to prepare some existing coatings.