Professional Documents

Culture Documents

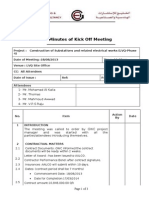

Zamil Steel Erection Manual

Uploaded by

mahmod awad83%(12)83% found this document useful (12 votes)

5K views60 pagesThis document provides an overview and instructions for erecting pre-engineered steel buildings. It discusses the importance of understanding the engineering documents, including anchor bolt plans, cross sections, framing plans, and sheeting layouts. It outlines the steps for erecting the building, including preparing the site, unloading materials, erecting the framing, sheeting walls and roofs, and installing trims. Safety precautions, quality control measures, and maintenance procedures are also covered. The document provides detailed information on the equipment, tools, and safety gear needed for the erection process.

Original Description:

Zamil Steel erection Manua

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides an overview and instructions for erecting pre-engineered steel buildings. It discusses the importance of understanding the engineering documents, including anchor bolt plans, cross sections, framing plans, and sheeting layouts. It outlines the steps for erecting the building, including preparing the site, unloading materials, erecting the framing, sheeting walls and roofs, and installing trims. Safety precautions, quality control measures, and maintenance procedures are also covered. The document provides detailed information on the equipment, tools, and safety gear needed for the erection process.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

83%(12)83% found this document useful (12 votes)

5K views60 pagesZamil Steel Erection Manual

Uploaded by

mahmod awadThis document provides an overview and instructions for erecting pre-engineered steel buildings. It discusses the importance of understanding the engineering documents, including anchor bolt plans, cross sections, framing plans, and sheeting layouts. It outlines the steps for erecting the building, including preparing the site, unloading materials, erecting the framing, sheeting walls and roofs, and installing trims. Safety precautions, quality control measures, and maintenance procedures are also covered. The document provides detailed information on the equipment, tools, and safety gear needed for the erection process.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 60

Contents

1. Understanding the Engineering Documents ............................. 4

1.1 Anchor Bolt Setting Plan

1.2 Cross Section

1.3 Roof Framing Plan

1.4 Roof Sheeting Layout

1.5 Sidewall & Endwall Sheeting & Framing

1.6 Other Drawings

1.7 Bill of Materials (BOM)

2. Preparation for Erection ....................................................................... 11

2.1 Introduction

2.2 Pre-Erection Checks

2.3 Receiving Materials at Site

2.4 Unloading Containers (for Overseas Shipments)

3. Erection of the Framing ........................................................................ 14

3.1 Preparation of the First Bay

3.2 Main Frames

3.3 Mezzanine Floors

3.4 Crane Beams

4. Sheeting & Trimming .............................................................................. 19

4.1 Sheeting Preparation

4.2 Sheeting the Walls

4.3 Sheeting the Roof

4.4 Miscellaneous Trimming

4.5 Fascia

5. Care & Handling of Sheeting ............................................................. 25

5.1 Handling & Installation of Sheeting

5.1.1 Unloading

5.1.2 Storage

5.1.3 Handling

5.1.4 Cutting & Fixing

5.1.5 Completion & Inspection

5.1.6 Paint Repair

5.2 Water Test Procedures for Roong

5.3 General Tips

6. Maintenance Procedure ....................................................................... 29

6.1 Maintenance for Longer Life

6.2 Safety Notes

6.3 Exterior Maintenance Procedure

6.4 Maintenance of Accessories

6.5 Record of Maintenance

7. Safety Precautions ................................................................................... 32

8. Quality Control .......................................................................................... 33

9. Basic Erection Equipment .................................................................... 34

9.1 Main Erection Equipment ............................................................... 35

Mobile Crane

Forklift

Telescopic Handler

Scissor Lift

Lifting Beam

Slings

9.2 Electrical Equipment & Tools ......................................................... 37

Generator

Screw Gun

Nibbler

Grinder

Hammer Drill

Hole Cutter

Impact Wrench

Electric Shear

Heavy Duty Drill with Reamer

Reciprocating Saw

Drill 10 mm

Powder Actuated Tool

Pop Rivet Puller

9.3 Measuring & Surveying Equipment ........................................... 42

Plumb Bo

Theodolite

Automatic Level

Spirit Level

Measuring Tape & Square

9.4 Safety Equipment .............................................................................. 43

Welding Hood

Goggles

Gloves

Safety Harness & Fall Arrest

Safety Boots

Hard Hat

First Aid Box

Cones & Ribbons

Portable Fire Extinguisher

Ear Protection

9.5 Other Equipment ............................................................................... 44

Welding Machine

Oxy - Acetylene Cutting Outt

10. Attachments ................................................................................................. 45

Glossary ........................................................................................................... 55

Commonly Used Abbreviations ............................................................. 58

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

Guy Wires

Clamps, Shackles & Clips

Ratchet Puller

Light Duty Scaffolding

Ladders

Aviation Snips (Left & Right Cut)

Vise Grips

Torque Wrench (With Sockets)

Ratchet Spanne (With 19 mm Sockets)

Staple Applicator

Utility Knife

Hacksaw

Mastic Gun

Spud Wrench

Drift Pin

Miscellaneous Tools

Tool Belt & Bolt Bag

Chalk Line

Introduction

The primary goal of Zamil Steel is the satisfaction of

our customers. We design, detail and fabricate our

buildings using sound principles of engineering,

and fabricate every component with the utmost

attention to quality and detail. When work at the

factory is nished, only one nal operation remains,

erection. The importance of following a specic

method of erection cannot be underestimated,

and the purpose of this manual is to facilitate and

ensure Quality Erection, thereby creating the nest

possible steel structure.

For purpose discussed here, erection refers to the

assembling of the various component parts that

make up the pre-engineered steel building. The

erection process entails much more than merely

installing the fabricated steel for the building. It

actually begins with the foundation and building

anchorage and continues to cleaning the job site

upon completion.

The methods and procedures suggested by this

Erection Guide represent basic, safe erection

practices. They can, and should, be modified

when necessary to adapt to special conditions or

circumstances.

Before beginning erection work, familiarize

yourself with the building details and the sequence

of erection. This will enable you to plan your work

efciently and avoid unnecessary delays during

construction.

Zamil Steels policy of continuous product

improvement may necessitate changes in

materials, design specications, and procedures

without prior notice.

Important notice: Zamil Steel recommends that

the erection work, be caried out by a Zamil Steel

certied builder. However, Zamil Steel accepts no

responsibility for erection quality, leakage, defects

or collapse due to negligence or failure to follow

proper erection procedures.

Understanding

the Engineering

Documents

1

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

1.1 Anchor Bolt Setting Plan

1.2 Cross-Section

1.3 Roof Framing Plan

1.4 Roof Sheeting Layout

1.5 Sidewall & End wall

Sheeting & Framing

1.6 Other Drawings

1.7 Bill of Materials (BOM)

4

1. Understanding the Engineering Documents

Prior to beginning the erection work, it is essential

to have a clear understanding of the Engineering

Documents, especially the Erection Drawings and

Bill of Materials.

Erection Drawings to be used at site should be

labeled Issued for Construction and represent

the latest project revision. Approval Drawings

should never be used at the erection site.

1.1 Anchor Bolt Setting Plan

This drawing shows the layout of all anchor bolts, it

is normally presented on one sheet, but for relatively

large buildings, this layout may be represented on

two or more sheets. Erection drawings are not

made to scale, so do not attempt to scale any

dimensions. All dimensions appear in millimeters

unless otherwise noted on the drawings.

The Anchor Bolt layout also includes an anchor bolt

schedule, in table form, showing the, quantities

and sizes of the anchor bolts required.

The key plan species out-to-out the dimensions,

bay spacing dimensions, bolt setting details and

critical dimensions for the span. Critical distances

on the drawing should be respected at all times.

The details specify whether grout is required under

the columns. The grout thickness will be shown on

the drawings, as well as the bolt projection.

Adherence to anchor bolt setting tolerance is

important; deviation shall not exceed 6mm.

5

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

CROSS SECTION

CROSS SECTION

1.2 Cross-Section

The cross-section drawing indicates columns

and rafter references, connection details, bolt

schedules, ange brace schedules and other

information as applicable, such as strut tubes and

ange brace details.

When reviewed in conjunction with the Bill of

Materials it is possible to determine the weight

of individual members, or a combination of

assembled members. This data is essential during

the planning of erection, and needed in order

to determine the capacity of the erection crane to

be used.

The cross section drawing may be typical

throughout in standard buildings but for more

complex jobs, there may be several cross sections,

identied by grid numbers.

6

ROOF FRAMING PLAN

ROOF FRAMING PLAN

1. Understanding the Engineering Documents

1.3 Roof Framing Plan

The roof framing plan illustrates the purlins, bracing

and related miscellaneous details. Part numbers

are indicated on this drawing for purlins, bracing,

sag rods (where applicable), strut tubes etc.

The drawings should be studied very carefully,

otherwise it is possible to overlook critical details

such as nested purlins, strut purlins, strut clips,

and purlins/girts at expanstion joints.

7

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

ROOF SHEETING LAYOUT

ROOF SHEETING PLAN

1.4 Roof Sheeting Layout

The roof sheeting plan displays all the panels

including their length and part numbers. It also

shows the sky light distribution and downspout

positions.

Standard details of panel lap, fasteners, trims and

insulation are also included. It is very important to

note the starting dimension of the sheeting from

the steel line.

8

SIDWALL SHEETING

SIDWALLFRAMINGANDSHEETINGELEVATION

1.5 Sidewall & Endwall Sheeting & Framing

Depending upon the drawing and erection

requirements, sidewall framing and sheeting may

be represented on one drawing or more.

The framing elevation shows the position and

part numbers of girts, eave struts, bracing and

sag rods.

The sheeting elevations show the panel positions

with length and part numbers. Wall lights eave

trims, gutters and downspouts are also shown

along with part numbers. Related standard details

are included which indicate the number, size and

position of fasteners. Additional trimming details

are also included in the drawing. For side walls, it

is important to check the starting dimension of the

sheeting from the steel line.

End-walls are detailed in a similar manner.

1. Understanding the Engineering Documents

9

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

1.6 Other Drawings

Other drawings may include crane beam layouts

and details; Mezzanine layouts and details;

and accessories such as Sliding Doors, Roll-up

doors, Staircase Cage Ladders, Personnel doors,

Windows, Louvers and Ventilators.

1.7 Bill of Materials (BOM)

The BOM supplied with the Erection Drawings is

the Customer BOM.

The BOM begins with a cover sheet indicating the

job number, building number and phase, customer

name, location, and building size. The cover sheet

also shows the number of phases in the building,

any revisions, and special notes.

The second page indicates the various sub-areas of

the phases. On the next page, the detailed BOM

list of the items included in each phase begins.

The sub total of weight and the total number

of items is shown at the end of each sub-area.

The last page indicates the total BOM quantity and

weight.

The BOM is a reference to the items shown on the

Erection Drawings and can be used to verify that all

items have been received at the site. It is also used

to identify frame weights for crane capacities.

The BOM has 9 columns indicating

1 - Line number

2 - Part number

3 - Quantity

4 - Revision number

5 - Description of part

6 - Colour

7 - Length of item

8 - Weight of item

9 - Total weight of line item

10

Preparation

for Erection

2

2.1 Introduction

2.2 Pre-Erection Checks

2.3 Receiving Materials at Site

2.4 Unloading Containers

(for Overseas Shipments)

11

2.1 Introduction

Erection of Pre-Engineered steel buildings is a

straightforward operation, provided some basic

principles are followed and common sense used.

The light weight of built-up and cold formed

members used in pre-engineered steel buildings

require less crane capacity but will need more

temporary bracing during the erection stages. Due

to the synergic design, temporary bracing should

be left in place until the braced bay components

are completely erected, aligned and tightened.

A clear understanding of the sequence of erection

is necessary together with careful planning.

The erection drawings and bills of material

provided by Zamil Steel should be studied before

commencement. Familiarize yourself with the

various components and their weights, evaluate

the site conditions, and decide where to start,

bearing in mind the stability of the building

during erection thence a braced bay must be

erected rst.

The major components comprise of, rigid frame

columns and rafters, eave struts, purlins, girts,

ange braces, end-wall columns and bracing

systems which may be cables, rods, angles

or portals.

2.2 Pre-Erection Checks

Make sure that the building foot print, in addition

to 10m wide strip around it, is clear of obstructions,

level and compacted. Check the anchor bolt

settings for compliance with the details provided

on the Anchor Bolt Setting Plan. The allowable

tolerances are given in the General Notes on

the drawing.

Check the foundation levels. In buildings that

require grout, shim packs are placed in the

centre of the bolt pattern. Buildings without

crane systems generally do not require grout, but

variances inconcrete levels may necessitate the

use of shims if the concrete is outside the stated

tolerances. Due to design requirements on certain

buildings, double nuts may be used.

A comprehensive survey report should be made

and documented. A site take-over report from

the client will assure site accessibility and level for

cranes and trucks to maneuver freely.

The following dimentions must

be controlled:

A - Steel Line to outer bolt row

B - Diagonal distance between bolt groups

C - Distance from axis center line to bolt row

C - Distance between bolts

D - Distance between frame axis

E - Destance between Steel Lines Levels of

foundations Anchor Bolt protrusion

Anchor bolts in concrete foundations

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

12

2.3 Receiving Materials at Site

Receiving and unloading of materials should take

place as near as possible to the place of erection.

The lay-down area should be clean and leveled. A

suitable forklift or telescopic handler is ideal for

unloading, but a mobile crane is equally suitable. In

either case, care needs to be exercised in handling

the various components and bundles, to minimize

damage to paint. Protect cold-formed members

such as purlins, girts, and channels from weather,

by storing the bundles with an inclination to permit

water drainage in case of rain or condensation. It is

advisable to lightly cover with a tarpaulin. Bundles

of sheets should be stored in the same way,

keeping the bundles clear of the ground. Check

materials against the Packing List and immediately

report shortage or excess material to Zamil Steel

representative.

2.4 Unloading Containers

(for Overseas Shipments)

Good Preparation will make container unloading

a straight forward operation. If possible select a

rm, level, asphalt, concrete or compacted area.

Unloading will be considerably easier if a small step

is made so that the inside base of the container is

level with the external ground.

Unload the container from the trailer using a mobile

crane and four leg slings or chains of the correct

capacity. Set the container on the ground, and

level it, open the doors before nal positioning.

Sliding tracks are provided in the container for

withdrawing the skid. Pull out the tracks, lay them

on the leveled ground, and align them with the

inside tracks. Secure the tracks by nails or steel pins,

the tracks must be continuous from the container

to end of the runway, (Length of Container).

Attach chains to the front of the skid in the

container, and then attach to the pulling vehicle.

Take up the strain on the chains, and steadily pull

the skid from the container. When the materials

are clear of the container, remove the skids from

the container oor.

Unloading from trailer

Unloading to lay-down area

Stacking on wooden planks

Unloading containers

13

Erection of

the Framing

3

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

3.1 Preparation of the First Bay

3.2 Main Frames

3.3 Mezzanine Floors

3.4 Crane Beams

14

Step 2

Step 3

3.1 Preparation of the First Bay

Prepare all materials for the rst bay erection with

permanent bracing, (braced bay). Identify the rafter

sections required by part number, assemble the

rafter sections as near as possible to their intened

positions. The splice connections are made with

high strength bolts; the sizes are shown on the

drawing cross section, identied as S1, S2, and S3

etc. Tighten the splice bolts and check for correct

torque value using a calibrated torque wrench, or

by turn of nut method. Attach eave strut clips using

high strength bolts. Fix ange braces to the rafter

using machine bolts, the ange brace positions

and part numbers are shown on the drawing cross

section. Flange braces are tted on one side of

the rafter only. For uniformity it is preferable to

maintain the same side throughout the building.

Attach temporary guy wires to the rafter, manila or

nylon ropes are not recommended for temporary

guying, they can stretch and break. They are also

unsuitable for aligning purpoes.

Prepare the mobile crane and Forklift for erection.

3.2 Main Frames

Erect the rst four columns at the braced bay.

Verify the part number and orientation, and

position over the anchor bolts. Adjust the columns

for plumb by tightening or loosening the anchor

bolt nuts (Step 1).

Fix the wall girts to the columns for additional

stability. Girts are attached to the columns by mild

steel (MS) bolts.

Position the crane for lifting the assembled rafter

sections. Make sure that the ridge connection

is torque-tightened (Step 2). Check that slings,

chain and shackles are in good condition and of

adequate capacity for the weight to be lifted. The

chains or slings should be long enough to provide

sufcient spread, at an angle of not less than

45 degrees. The spread of the slings is normally

calculated by dividing the member length by

four, which will give the distance of the lifting

point from each end. This formula may require

some minor adjustment depending on the weight

3. Erection of the Framing

3.1 First frame of braced bay 3.2 Second frame of braced bay 3 1 First frame of braced bay 3 2 Second frame of braced bay 3.3 Roof purlins

Step 1

15

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

Step 4

Step 5

distribution and conguration of the rafter. Refer

to image 3.1.

Flange clamps are a safe lifting device which also

minimizes damage to paint. When using clamps,

install temporary bolts in the purlins holes, or use

G clamps to prevent the clamps from sliding. If

clamps are not available, conventional slings may

be used, in which case timber or other protection

should be used on the anges to prevent slipping

and damage.

Commence lifting the rafter (Step 3). Previously

attached hand ropes will help to guide the rafter

to its position. Carefully lower the rafter to the

column cap plates, and position it using spud

wrenches. Spud wrenches are an invaluable tool

for aligning members and holding in position

whilst bolting up.

Install the high strength bolts, nuts and washers

in the knee connection. The bolt is normally

placed from the top, with the nut and washer on

the underside. Hand-tighten the bolts. Ratchet

pullers are attached to the guy wires, which are

then connected to suitable stable objects, such as

anchor bolts. The rafter is now aligned by means

of the guy wires and ratchet pullers. Once all guy

wires are in place it is safe to release the crane

(Step 4).

Erect the second rafter and hold in place with the

crane, at the same time position the purlins and

bolt-up using mild steel bolts (Step 5). Connect

the previously attached ange braces to the purlins

with mild steel bolts (Step 6). The eave strut should

also be installed at this stage, but unlike the purlins

the eave strut requires high strength bolts. Refer

to image 3.2.

3.4 Roof bracing 3.5 Erect next bay 3.6 Erect remaining bays

Step 6

16

3. Erection of the Framing

Complete the purlin installation and then install

the diagonal bracing. Before tightening the

diagonal bracing, ensure that the lip of the hillside

washer is correctly seated in the web slot. Adjust

the tension of the bracing; at the same time adjust

the rafter alignment. The bracing shall be just

tight enough to eliminate visual sagging. In case

of portal bracing, it must also be erected before

proueding in the other bay. For high endwalls use

temporary bracing during erection. Refer to image

3.3 on the previous page.

The completed braced bay should now be aligned.

A theodolite should be used for plumbing, if

available, or for buildings of low eave height, a

spirit level or plumb-bob may sufce (Step 7).

A tolerance of 1:300 is allowable in low rise

buildings. Refer to image 3.4.

After completing the rst bay alignment the high

strength bolts at the knee connection shall be fully

tightened. Time spent on correct alignment of the

rst bay will reap benets as work proceeds with

the remaining bays.

The remaining bays are erected following the

same procedure (Step 8). All components shall

be installed as work progresses, including crane

beams. Refer to image 3.5.

Multi-span frames provide a degree of exibility in

erection in that partial spans may be erected if site

conditions dictate. Refer to image 3.6.

When the main frames are all completed, the

end-wall framing is erected. Pre-assembly of

columns and girts on the ground saves time and

is more efcient. End-wall posts are connected

to the purlins by post spanners using high

strength bolts.

The complete frame should be checked for plumb

and alignment. Adjustments can be made by

tightening or loosening bracing, or by ratchet

puller, to pull a misaligned frame into plumb.

After completion of all checking, bolt tightening

can commence. Air or electric impact wrenches

may be used and checked with a torque wrench,

or they can be tightened manually using the

Turn of Nut Method (preferred).

The Turn of Nut Method is achieved by bringing all

the bolts in the pattern to a snug tight position,

using a normal spud wrench. Match mark the

nuts against the connection plate, and then apply

a further one third turn to all the nuts.

Prior to sheeting, framed opening members for

sliding doors shall be installed; this includes door

jambs, brackets and header.

PLUMBING THE BRACED BAY

Step 8

Step 7

17

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

3.3 Mezzanine Floors

When mezzanine oors are provided, they are

erected with the main frames, generally prior

to sheeting.

The mezzanine beams are first installed by

connecting to the columns with clips and high

strength bolts as indicated on the drawing details.

The joists are then placed between the beams and

connected as shown on erection drawings. An

edge angle is then screwed at the perimeter of the

mezzanine area, prior to laying and screwing the

decking panels.

The decking panels are attached by self drilling

fasteners without washers. Openings for stairs

and penetrations are framed before xing the

concrete reinforcement.

It is important to advise the concreting crew about

placement of concrete, particularly if a pump is to

be used. The concrete should be evenly spread;

concentrated piles of wet concrete could cause

deformation in joists or decking, which could

lead to collapse. It is, sometimes advisable to use

temporary shoring at mid spans inorder to assure

straightness of nished concrete.

3.4 Crane Beams

Special care should be taken in buildings with

crane runways, the column supporting runway

beams should be erected on shims provided, or

double nuts in addition to grouting under the

base plates.

Alignment of crane beams i s very important, the

centerlines of the crane beam webs should matche

with the centerlines of the crane wheels, and the

maximum allowabletolerance is 10mm.

Alignment is achieved by setting each end of the

beam to the correct dimension as shown on the

drawing, and stretching a line from end to end,

alternately, a theodolite can be used if available.

The crane beam brackets have slotted holes to

assist in ease of alignment, if the building has been

carefully plumbed, adjustment will be minimal.

During alignment install the T brackets and shim

plates, and install the angle braces from column

to beam. Once nal alignment is conrmed, fully

tighten all high strength bolts.

3.5 Important

No loads should be supported from the purlins

unless the building has been designed for those

additional loads. In such cases, the loads can be

supported from the purlins after the roof sheets

have been installed and fully screwed.

The following sketches show correct and incorrect

methods of support from rafters and purlins.

Rafters

Purlins

18

Sheeting &

Trimming

4

4.1 Sheeting Preparation

4.2 Sheeting the Walls

4.3 Sheeting the Roof

4.4 Miscellaneous Trimming

4.5 Fascia

19

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

4.1 Sheeting Preparation

Touch-up any damaged paint on the main frame

prior to sheeting.

The base angle is xed to the concrete slab by

means of masonry nails. Power actuated tools are

preferred for xing. The xings for the base angle

are provided by the erection contractor, to ensure

compatibility of nails and xing tools.

The base angle should be set at the wall grit line

(steel line) which is 200mm from the column

ange in the case of by-pass girts.

There is a tendency for wall girts to sag under their

own dead load, especially in bays over 7.5 meters.

Girts are temporarily supported in a horizontal line

with vertical timber props from oor to girt, girt

to girt, and girt to eave strut. The props remain in

place until the wall panels are screwed. They can

then be removed and relocated to the next bay.

The girts will remain straight and horizontal once

the panels are installed. In bays over 8.5 meters

sag rods are provided and once adjusted there is

no requirement for temporary timber props.

Before commencing with sheeting check the

details on the drawings. A starting position will be

given in relation to the steel line. Mark the starting

position, and then mark out the gauge cover

width of the sheets along the concrete notch. This

will provide a check against creep or bunching

of the panels. An important point in order for the

corner trims to t as detailed. Insulation is more

convenient to handle if unrolled on the ground

and pre-cut to the required lengths. A full length

piece is used from eave to oor, with an allowance

at top and bottom for folding over.

Tools Preparation on roof

20

A chalk line is essential for marking the girt position

and thus maintaining a straight screw line. All

screws are self drilling and require an electric

screw-gun with a speed of 2000 to 2500 RPM.

Depth sensitive or torque regulated screw-guns

should be used to control the screw tightness. The

EPDM washer should be compressed 1 mm wider

than the steel washer when correctly tightened.

4.2 Sheeting the Walls

The rst drop of insulation is xed using double

face tape on the eave strut and the base angle;

this is used to hold the insulation in place. The

insulation must be kept vertical, and pulled taught.

Remove the bres from the allowance at top and

bottom and fold the white facing before placing

the wall panel. Place the panel in the pre-marked

position, plumb it and screw.

The second drop of insulation is xed to the

double faced tape and then the side tabs are

stapled to the rst drop at 300mm centres,

folded and stapled again in-between the previous

staples, thus providing a closed joint and vapour

barrier. Then, the second panel is installed in the

same manner and so on.

End-wall panels are pre-cut in the factory. The

panels are stepped, the steps being covered by

the gable trim. (Field cutting may be necessary on

steep slopes).

The preferred procedure is to complete all wall

sheeting before starting the roof, as the eave trim

covers the top of the wall panel and ts under

the roof panel. Outside foam closures are placed

between the wall panel and the eave trim to

provide a dust free junction.

If there is no wall insulation, foam closures are used

between the panel and eave strut / base angle.

Chalk Line

Wall Insulation

Multi-level Man-basket

4. Sheeting & Trimming

21

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

4.3 Sheeting the Roof

Prepare the roof panels by segregating them by

their length shown on the roof sheeting plan. The

sequence of roong is from eave to ridge on both

slopes nishing with the ridge panel.

To commence, it is advisable to temporarily x

one run of panels accross the building to walk

on. The insulation can then be unrolled beside the

walkway.

Double faced tape is applied to the eave struts, or

an intermediate purlin if the roll does not cover

the full width of the building. The insulation is

lifted into place and is retained in place by the

double faced tape. Before placing the roof panel,

the insulation end should be folded over to be

concealed at the eave. It is necessary to scrape

away the bres on the folded portion. The inside

foam closure is placed on the fold at the eave strut,

and the panel is then positioned.

Adjust the line of the panel for squareness to avoid

saw-toothing at the eave line. Use a nylon line

projected from the eave strut by 65mm to give the

correct distance and line.

Screw the panel and move progressively panel by

panel up to the ridge. After completing several

runs of panel, the temporary walkway can be

lifted, insulated, and sheeted.

Panel end-laps require bead mastic. The bead

mastic should be carefully unrolled from the release

paper, and placed over the panel corrugations. Do

not stretch the bead, otherwise it may break when

the panel is placed over it Ensure that the panel

end-laps are as per drawing details.

Make sure that the panel ribs are kept in a straight

line from eave to ridge. Use a chalk line tomark

the purlin location and maintain a straight line

of screws, thus avoiding mis-drilling and possible

leakage. End-laps have additional screws as

detailed on the drawing.

Proceed with the next run of insulation, stepling

the side tabs together, before placing the next run

of panels. When both slopes of the roof panel

have been xed, the ridge panel or ridge cap

is laid, connecting both slopes. If a ridge cap is

used then outside foam closures are used to ll

the panel prole, if a ridge panel is used as with

TypeS panel, it nests without foam closures. Bead mastic

Double face tapes

Sheeting the roof

Direction of sheeting installation

Sheeting the roof

22

4.4 Miscellaneous Trimming

Upon completion of the roong, gable trims are

installed. Outside foam closures are used against

the end-wall panel. The stitch screws securing the

gable trim also keep the foam closures in place.

Eave gutters are spliced using two runs of owable

mastic and pop-rivets at 25 mm centres. The

gutter is then hung by means of gutter straps

which are screwed through the roof panel with

suitable screws.

Down spout connections are cut with aviation

snips in locations shown on the roof plan. The

down spouts are assembled in straight sections

and a shoe, the complete unit is then attached to

the gutter by pop rivets and to the wall panel by

straps and rivets.

Personnel doors are supplied in knock-down

form and are generally eld-located. The frame

is assembled and installed. The wall panels are

carefully cut using an electric nibbler, nal cutting

and tting of head trim should be done with

aviation snips. The galvanized threshold support

is tted and screwed to the concrete before

the frame is connected to the girt by clips, and

anchored to the oor with expansion bolts. Check

that the frame is plumb and square before nal

xing. Head trim, jamb trims and the door leaf are

now tted.

4. Sheeting & Trimming

As work proceeds, it is important to keep the roof

area clean, a soft brush should always be readily

available to sweep off drill swarf, metal lings

or grinding dust, which will cause light surface

corrosion if not removed.

Stitch screws are xed at panel side-laps at 500mm

centres, or as detailed.

Note: Roof panels are generally xed in

the valley of the panels, unless

noted otherwise.

Fixing Trims Fixing Eave Trim

23

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

Where interior liner panel is detailed, a base angle

is xed to the oor as for the external panels.

It shall be positioned 200 mm away from the

exterior base angle. The liner panels are pre cut

to length, but may require cutting vertically at

columns, depending on the bay width. Closure

trims are tted at columns, and a head trim along

the top of the panel. Trims are xed with 4.8 x 20

stitch screws, the panels with 5.5 x 25 self drilling

screws. Sliding doors leafs are assembled on

the oor. The framing members are connected

by mild steel bolts and clips. The sheeting is xed

before hanging the door. The trolley trucks are

located in the top member of the door leafs. The

adjusting nuts on the trolley trucks should be

set equally, nal adjustments can be made after

hanging the doors.

Once the doors are hung and positioned over

the bottom door guide, the stoppers, the landles

and the door hood are installed. Note that there

are two types of hood trim. One ts behind the

sheeting in the door opening, and the other ts in

front of the sheeting on each side of the opening.

Complete details are on the drawing. Bottom

running doors are also available.

4.5 Fascia

Fascia posts are bolted to brackets. Fascia girts are

then attached to the posts. The girts consist of C

and Z sections, which must be correctly aligned

and levelled before commencing sheeting the

fascia. Use temporary props if necessary. Prepare

the sheeting by installing the sill trim on the

bottom girt.

Check the starting dimension from the corner of

the framing. Set up the rst panel. Clamp it with

vice grips when adjusted to its correct position.

Mark the girt line with a chalk line and then screw

the panel to the girt.

Continue installing panels on each elevation

until sheeting is completed. The back-up panels

are installed next; they are attached to the top

girt, and overlap the valley gutter at the base.

The external corner trims are installed using 4.8

x 20 stitch screws. The Cap ashing can now be

installed using 4.8 x 20 stitch screws. Make sure

that the ashing slopes into the building as shown

on the drawing. The overlapping joints of the

ashing should be sealed with owable mastic.

The soft panel edge trim is tted to the wall

panel, make sure that it is level with the sill trim,

and is levelled around the building. Starting the

soft in the correct place is important, if the soft

panel and wall/fascia sheets are the same type,

the ribs should be aligned. Align the ribs, and x

the panels as shown in the detail. Corner panels

should be mitred equally.

24

Care &

Handling

of Sheeting

5

5.1 Handling & Installation

of Sheeting

5.1.1 Unloading

5.1.2 Storage

5.1.3 Handling

5.1.4 Cutting & Fixing

5.1.5 Completion &

Inspection

5.1.6 Paint Repair

5.2 Water Test Procedures

for Roong

5.3 General Tips

25

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

5.1 Handling & Installation of Sheeting

It is important to use correct sized drill bits and

screws for secure fastening of panels. During

xing, the panel should be correctly aligned and

temporarily clamped to ensure the holes are

drilled correctly.

Drilling of holes produces very hot metal chips

(swarf), which should be brushed off the panel.

This should be done immediately, if possible, and

the work area should be swept with a soft broom

at the end of each day work.

Care should be taken in walking on roof panels.

Workers on the roof should use soft footwear.

Metal studs or heel tips will cause damage to the

painted panels.

It is important to walk in the correct place on roof

panels. Always step in the valley of the panel,

which is in contact with the purlin. Standing on

the high corrugations may result in deformation

of the panel.

For achieving a quality job, use a screwgun with a

depth locator or torque adjuster, this will ensure

correct xing of fasteners.

When drilling use a rubber or leather thimble

on the drill bit to prevent the chuck of the drill

damaging the panel paint when the drill goes

through the material.

5.1.1 Unloading

Sheets are packed in bundles, and may be unloaded

by a suitable forklift truck or crane. Care must be

taken not to break the back of the sheets when

unloading. If chains or cable slings are used for

unloading, good protection must be provided for

the corners of the bundle.

Note: Long panels may be difcult to handle by

lifting the bundle from beneath.

Step in the valleys of the panel

Stand away from high corrugations

Brushing metal chips

26

5.1.2 Storage

Packs of sheets should be stored in a safe area

of the site. They should be stored clear of the

ground and elevated at one end to allow for water

drainage should they become wet. Preferably, the

bundles should be loosely covered with a tarpaulin;

this will afford additional protection but allow

air circulation.

5.1.3 Handling

Care should be taken when handling sheets.

Erectors should use clean gloves to avoid dirty

marks, oil or grease stains on sheets. When

handling individual panels from the stack, each

panel should be lifted clear, not dragged along,

which cause scratches.

5.1.4 Cutting & Fixing

Only proper tools should be used for cutting

proled sheets. An electric nibbler should be

used for cutting across the ribs, an electric shear

for cutting longitudinally, and aviation snips for

small detail work. Never use a grinding desk for

cutting sheets

5. Care and Handling of Sheeting

Storage

Storage and handling

Handling individual panels

27

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

5.1.5 Completion & Inspection

On completion, the sheeted area should be

inspected. Any ferrous objects such as pop-rivet

stalks, bolts, nails, screws etc. left on the roong

should be removed.

Any accidental scratches or minor damage should

be touched-up with the appropriate paint. The

area should be left clean.

5.1.6 Paint Repair

For minor scratches, a small brush can be used

to apply touch-up paint of matching color to the

damaged area.

If damage has affected the galvanized coating,

then the damaged area should be coated with

special primer followed by a special polyurethane

nish coat.

5.2 Water Test Procedures for Roong

There is really no better way of water testing a

roof than actual rainfall, as to simulate even fall or

wind blown rain is impossible.

If medium to heavy rain has fallen after completion

of roong, and no leakage is visible then the roof

should be considered tested and satisfactory.

If the roong has been completed during a dry

season, and testing is required, then the following

test can be carried out:

A 25 to 30mm diameter hose will be required with

sufcient mains pressure, or a tank and electric

pump. Two tests can be done.

1. The hose should be positioned on the ridge,

or highest point of the roof. The water should

then cascade down each slope, down each

valley between panel ribs. The hose should not

be deliberately directed at the panel end-laps

and side-laps.

2. The second and longer test can be carried out

if desired by attaching a rotary garden sprinkler

to the hose and allow the whole roof to be

systematically watered. This is the nearest

method of stimulating rainfall as the sprinkler

system causes the water to bounce, thus nding

any weakness in lap conditions.

5.3 General Tips

1. Erection shall start from a braced bay and

the bracing shall be xed before proceeding

to the other bays.

2. Purlins and girts shall be immediately xed

to each erected bay to maintain the building

stability during erection

3. Always check the starting position of roof

panels.

4. Panels should be plumbed and held in place

by Vice Grips before screwing.

5. The panel gauge should be marked on the

sheeting notch.

6. A line should be used to maintain a straight

sheeting line at the eave.

7. A chalk line should be used to ensure the

screws are installed in a straight line, and

avoid mis-drilling.

8. Roof sheets should be undamaged.

9. Bead mastic must be carefully placed over the

corrugations at end laps.

10. Insulation should be neatly folded at the

base angle and eave. It can never be neatly

cut off afterwards.

11. Pre-drilling is required when using stainless

steelfastner.

28

Maintenance

Procedure

6

6.1 Maintenance for Longer Life

6.2 Safety Notes

6.3 Exterior Maintenance

Procedure

6.4 Maintenance of Accessories

6.5 Record of Maintenance

29

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

6.1 Maintenance for Longer Life

Now that your Zamil Steel Building is complete,

we recommend that you follow our simple

maintenance recommendations. By doing so

you will substantially enhance the life of your

investment.

The frequency of maintenance is dependent

upon the environmental zone in which the

building is located. The table below contains

the recommended maintenance frequencies for

different building locations.

Building Location

Maintenance

Frequency

Within 5 km of the sea Every 3 months

High pollution industrial area Every 3 months

Medium pollution industrial area Every 4 months

Areas of high humidity Every 4 months

Low pollution industrial area Every 6 months

Dry desert regions Every 6 months

6.2 Safety Notes

Lxercise exIreme cauIion when working on

roofs.

Use proessional mainIenance sIa or

maintenance works.

Lnsure IhaI access ladders reach aI leasI one

meter above the step off poing.

Secure ladders Io Ihe building and ensure IhaI

they are on a rm base.

Do noI sIep on skylighIs.

When walking on Ihe roo, sIep in Ihe valleys,

of the panel, not on the ribs.

Whenever possible, walk on Ihe purlin line, i.e,

screws line.

ProIecI areas o roo, subjecI Io requenI access,

by temporary or permanent walkways.

When mainIaining overhead crane runways,

immobilize the crane before commencement of

work.

6.3 Exterior Maintenance Procedure

PrevenIive mainIenance shall commence

immediately after a project is erected or

modied.

Debris and small iIems such as screws, pop

rivets, drill bits or any ferrous object shall be

removed by sweeping with a soft nylon brush.

Large items such as sheet metal cut-offs shall be

removed by hand to avoid damaging the surface

of the roof panels. Such debris shall be removed

after any trade (e.g., electricians, plumbers, air

conditioning technicians, steel erectors, etc.)

has worked on the roof.

Sand and dusI reIain salI and moisIure, which

will eventually breakdown the paint and zinc

layers, resulting in corrosion of the base metal.

Sand and dust shall be removed by washing

with clean potable water and a soft nylon brush,

working from the highest point to the lowest,

followed by a nal rinse using a hose and clean

potable water.

The mosI vulnerable areas o Ihe building are

gutters, roof sheets, sheltered areas under eaves

or canopies and upper portions of walls or roof

extensions.

lor buildings locaIed in high polluIion indusIrial

areas, or close to marine environments, water

alone may not be sufcient to remove saline

deposits that have become encrusted on the

panels.

In such cases, a mild detergent shall be added

to the initial washing water. Panels shall be

washed with the mild detergent solution and

a soft nylon brush. A nal rinse with clean

potable water should follow. Oil, grease, tar,

wax or similar substances can be removed with

mineral spirits followed by a detergent solution

and a clean potable water rinse.

Do noI use causIic or abrasive cleaners, Ihey

may damage the paint and zinc layers.

Ground level shall be mainIained aI leasI

150mm below the base of the wall panel.

accoumulations of wind blown sand shall be

removed. Plants and shrubs surrounding the

building shall not touch the wall panel; They

may scratch the painted panels.

30

Lave guIIers and valley guIIers shall be

thoroughly cleaned with a mild detergent

solution and a soft nylon brush, followed by

a rinse of clean potable water. Downspouts

shall be clear of blockage and the downspout

discharge shall have adequate drainage area.

Minor damage Io sheeIing or Irims shall be

repaired as follows:

- Lightly abrade the affected area

- If base metal is exposed, apply one coat of

zinc chromate primer

- Apply one coat of matching touch-up paint

LquipmenI, which is locaIed Ihrough or adjacenI

to roof or wall panels may cause moisture

build up on or near the panel. The following

conditions shall be avoided:

- Water run-off from air conditioning units

- Open water storage tanks adjacent to panels

- Steam outlets

- Acid storage

- Copper pipes fastened to steel panels

6.4 Maintenance of Accessories

8uildings wiIh Cranes

- Every 6 months check that all bracing is tight

- Check that all high strenght bolts in the crane

beams and the main frame connections are

tight

Personnel Doors

- Lubricate hinges and lockset

- Remove dirt and girt from the threshould

- Ensure that the door cannor swing back and

strike the wall panels, as this will sprain the

hinges and damage the panel

Sliding Door

- Regularly clean the bottom guide to recove

sand and stones

Pollup Doors

- Clean and lubricate the chain and reduction

drive gears

Power VenIs

- Clean fan blades to remove build-up of dust

and dirt

6.5 Record of Maintenance

A Periodic Maintenance Log Book shall be kept.

All maintenance dates shall be recorded and

signed by the maintenance staff.

31

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

7

Safety

Precautions

For safety reasons there are precautions that need

to be taken during erection.

Make daily check on all lifting equipment.

Make daily checks on all lifting slings,

check forfraying and kinking.

Check that all access equipment is in

good condition, including scaffolding and

ladders.

Check weather conditions, strong winds

are dangerous during erection and

sheeting.

Check for overhead electric lines before

moving in with a crane.

Check that all erectors have the correct

personal safety equipment, hard hats,

boots, safety harness etc.

Check electric cables for hand tools,

discard frayed or split cables.

Ensure that there are sufcient guy wires

on site for temporary bracing.

Ensure that erection always starts at a

braced bay.

Ensure that permanent bracing and ange

stays are installed as work proceeds.

Ensure that high strength bolts are used

where indicated.

Ensure that high strength bolts are

correctly tightened.

Maintain a clean and tidy site, thus

avoiding material loss or accidents.

Tie down sheeting once the bundle is

opened.

Sweep roof sheeting at the end of each

day work, drill swarf will corrode the

panels if not removed.

When walking on the roof, step in the

valley of the panels, not the ribs.

If when waking on the roof step on the

purlinlines

Use the correct tools for the job, wrong

tools will damage materials and produce

poor quality.

Do not step on the skylights while working

on the roof

Finally, acquire contractors all Risk

Insurance;

7.1

7.2

7.3

7.4

7.5

7.6

7.7

7.8

7.9

7.10

7.11

7.12

7.13

7.14

7.15

7.16

7.17

7.18

7.19

7.20

32

8

Quality

Control

Erection Quality Plan

The safety and Quality of Erection should be

ensured by engaging experienced and qualied

Engineers, Supervisors and Technicians on the job.

The Quality Control should be effective at various

stages of erection starting from receipt inspection

till the nal handing over. To ensure this, Standard

Inspection and Testing Program (ITP) / Quality

plan (or) a project specic Inspection and Testing

Program - ITP / Quality Plan shall be followed.

The Quality Plan as a minimum should contain

the following:

a. ITP - Inspection and Testing Program

(Attachment I, 2 pages)

b. Erection Inspection Check list - EICL

(Attachment II, 3 pages)

c. Method Statement

d. Procedures and Inspection Forms referred in

the ITP

e. Bolt Tightening Procedure

(Attachment III, 3 pages)

f. Paint Touch up Procedure

g. Site Organization chart including a dedicated

qualied person for QC and Safety

Erection shall not start without:

The submission o Ihe QualiIy Plan

ldenIiying a dedicaIed QualiIy and

Safety Person

ConducIing a PrelnspecIion MeeIing PlM

See the Sample Quality Plan as attached.

33

Z

a

m

i

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

S

t

e

e

l

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

Basic Erection

Equipment

9

9.1 Main Erection Equipment

9.2 Electrical Equipment

& Tools

9.3 Measuring & Surveying

Equipment

9.4 Safety Equipment

9.5 Other Equipment

34

9. Basic Erection Equipment

9.1 Main Erection Equipment

Mobile Crane

Mobile Cranes are ideal for erecting pre-engineered steel buildings.

The required capacity of the crane varies. The capacity must be

calculated considering the heaviest member (or assemblies of

members), the building conguration and the site conditions.

Forklift

Forklift are ideal for unloading tralers, for meterial handling on site,

and in certain cases, for the erection of the main frames. Buildings

up to 6m eave height can be erected by rough terrain forklifts with

a 3-stage mast and a capacity of at least 3 MT. By attaching a man

platform, forklifts can be used for xing wall sheeting, eave gutters,

trims, etc.

Telescopic Handler

Telescopic handlers are even more versatile than forklifts. They can

be used for many different operations of a construction site. Having

a wide range of accessories, they can be used for building erection

and other general construction work.

With a man platform attachment, telescopic handlers are suitable

for xing wall sheeting and other external building accessories.

Scissor Lift

Scissor lifts are suitable for use on level, paved areas for xing roof

liner panels. They are also very useful for other purposes such as

electromechanical works.

Lifting Beam

A purpose-made lifting beam (spreader bar) of 6 or 12 m long is

required for lifting long span rafters and frame assemblies.

35

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

Slings

Purpose-made slings, used alone or in combination with lifting

beams, are used for lifting building components or assemblies.

One, two or four leg slings are available, with hooks or eyes, and

for different load capacities. They are available as a chain, wire or

polyester. The sizes and types of slings required shall be determined

by the weights of the components and assemblies to be lifted.

Guy Wires

Guy wires are steel wire ropes of 8 to 10 mm in diameter and

different lengths (length depends on building height). They are

used to provide temporary bracing for the building normally

used in combination with ratchet pullers. As a rule of thumb, the

minimum length guy wire should be at least 1.5 times the building

height. The guy wire should be attached to the rarter before it

is lifted into place and then tied-off to a xed object to provide

temporary bracing during erection. The degree of bracing depends

on the size of the building and local weather conditions. Guy

wires are also used to achieve correct alignment of the building.

Important Note: Nylon ropes shall not be used for temporary

bracing.

Clamps

Clamps are used for attaching guy wires to rafters or holding

components (such as sheeting) in place prior to xing.

Shackles

Shackles are used for connecting slings and / or guy wires. Note:

Shackles shall have the safe working load (S.W.L) clearly stamped

on them.

Clips

Clips are used for making eyes in guy wires or for adjusting their

lengths.

36

Ratchet Puller

Ratchet & Tirfor pullers are used for tensioning the guy wires that

are used in temporary bracing and aligment of the building. Various

capacities of ratchet pullers are avialable.Normally one ton capacity

pullers are adequate for bracing and aligning most pre-engineered

buildings. Heavy duty pullers, Tirfors, are available when extra

capacity is required.

Light Duty Scaffolding

Access towers are mobile work platforms, useful for sheeting walls

and installing wall accessories and trims.

Ladders

Extension ladders are used to access roofs. mezzanines, catwalks,

etc. Step ladders are free standing ladders used for minor xing and

trimmings.

9.2. Electrical Equipment & Tools

Generator

When a main electrical supply is not available, generators are

required for the power tools 5 KVA generators are suitable for most

electric hand tools.

Screw Gun

Electric screw guns are necessary for installing self drilling fastners

in roofs. In order to avoid over-tightening of the screws, screw guns

should have either torque or depth controls. The recommened

speed is 0 to 2000 RPM (revolutions per minute).

9. Basic Erection Equipment

37

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

Nibbler

Electric nibblers are required to cut openings in proled sheets.

Cutting with nibblers guaranees controlled maneuverability

and excellent cutting quality, preventing meterial distrotion and

eliminating the risk of corrosion at the cut edges.

Grinder

In pre-engineered building erection, grinders are used for cutting

mild steel angles such as base and gable angles.

Note: Sheeting shall not be cut with angle grinders. Angle grinders

produce rough and unsightly cuts, which will very quickly corrode.

Hammer Drill

Hammer drills are mainly used for the installation of expansion

bolts.

Hole Cutter

In pre-engineered buildings, all holes are prepunched. Should

circumstance dictate changes, then the hole cutter is the ideal tool

for making the required site modications.

Impact Wrench

The impact wrench is used for tightening high strength nuts and

bolts of the main frames. Both pneumatic and electric models are

available. Pneumatic models are heavy duty wrenches and are

suibable for the large diameter bolts. An air compressor is required

when using a pneumatic model.

38

Electric Shear

Electrical shears produce a clean cut in at sheet. They are not

suitable for cutting over corrugations of panels.

Heavy Duty Drill with Reamer

A heavy duty slow speed drill with a tapered reamer is used for

enlarging holes in steel members, if needed. The recommended

speed of the drill is 0 to 500 RPM (revolutions per minute).

Reciprocating Saw

A reciprocating saw is ideal for cutting insulated roof and wall

sandwich panels (Zamil Steel Tempcon panels).

Drill 10 mm

A 10 mm drill, with a speed of 0 to 2400 RPM (reolutions per

minute), is required for pre-drilling holes for pop rivets and any

other bolts that require eld drilled holes.

Powder Actuated Tool

Powder actuated tools are used for xing base angles to oor slabs

or tie beams. They can also be used to x steel decking panels to

mazzanine joists.

Pop Rivet Puller

Pop rivet pullers are used for xing pop rivets in trims and gutter

joints.

9. Basic Erection Equipment

39

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

Aviation Snips

(Left & Right Cut) Aviation snips are used for cutting trims and

small openings in sheet panels. This method of cutting produces a

very clean cut, which will not rust. They provide a ne control for

intricate cuts.

Vice Grips

Vice grips have many uses as a third hand and are essential to

clamp sheets and trims while xing the screws or rivets.

Torque Wrench

(With Sockets) Zamil Steel recommends that high strength bolts

are tightened by the turn-of-nut method (see Chapter 3 of Zamil

Steel Erection Guide). If the torque requires checking, a torque

wrench (with different sockets sizes) should be used on which the

torque value is preset perior to checking.

Ratchet Spanner

(With 19 mm Socket) For quick tightening of purlin and girt bolts

and other machine bolts.

Staple Applicator

They are used for stapling tabs on berglass insulation.

Utility Knife

Utility Knives are used for cutting berglass insulation

Hacksaw

Hacksaws are used for cutting light gauge metal.

40

Mastic Gun

Mastic guns are required for the application of the owable mastic,

which is commonly used for sealing gutter joints and overlapping

ashing.

Spud Wrench

Spud wrenches are used during erection to align holes in two steel

members and to tighten the bolts. Various sizes of spud wrenches

are required that would suit the bolt sizes.

Drift Pin

Drift pins are used to align holes in two steel members. They can be

hammered if additional force is needed.

Miscellaneous Tools

Hammers Wood saws Screwdrivers Comination spanner sets

Sweeping brooms

Tool Belt & Bolt Bag

A tool belt & bolt bag provides a safe and convenient way of

carrying tools and bolts.

Chalk Line

Chalk lines are used for marking staight lines on the panel along the

position of purlins and girts. The marked line identies the position

of the screws.

9. Basic Erection Equipment

41

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

9.3. Measuring & Surveying Equipment

Plumb Bob

Plumb bobs are used for plumbing vertical members up to a height

of 6 m.

Theodolite

Theodolites are used in setting out the building foundations and

anchor bolts. They are also used for checking the vertical alignment

of columns and the alignment of crane beams.

Automatic Level

Automatic levels are used to check the elevation of anchor bolts,

the nished oor level and the base plates of columns.

Spirit Level

Spirit levels are used for leveling individual components and for

plumbing.

Measuring Tape & Square

Measuring tapes are used for miscellaneous checking, setting out

and general easuring. A right angle square is used for setting out

90* angles.

42

9.4. Safety equipment

Welding Hood

Welding hoods shall be used during welding.

Goggles

Goggles shall be used whilst cutting or grinding.

Gloves

Gloves shall be worn when handling steel components. Clean

gloves should be worn while handling sheets.

Safety Harness & Fall Arrest

Safety harnesses shall be worn when working over 2 meters above

the ground levels.

Safety Boots

Protective footwear shall be worn at all times while on working site

to avoid toe, sole or ankle injuries.

Hard Hat

Personal head protection shall be used be on site at all times.

9. Basic Erection Equipment

43

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

First Aid Box

First aid boxes should be on site at all times under a qualied

rst aid person. All contents shall be maintained and expiry dates

checked periodically.

Cones and Ribbons

Cone and warning ribbons are used to indicate danger areas on

sites.

Portable Fire Extinguisher

Fire extinguishers shall be installed on vehicles and in areas where

welding or burning works are executed.

Ear Protection

Ear protection shall be used where noise is higher than 85 dB.

9.5. Other Equipment

Welding Machine

Electric welding machines are used for light duty welding such as

tack welding of light guage steel members.

Oxy-acetylene Cutting Outt

Oxy-acetylene is used for cutting steel members.

44

Attachments

10

10.1 Inspection and Testing

Program (ITP-Standard Jobs)

10.2 Erection Inspection List

(EICL)

10.3 Tightening and Inspection

of High Strength Bolts

10.4 Anchor Bolt

Installation Guide

45

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

Attachment I

46

10. Attachments

Attachment I

47

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M

a

n

u

a

l

Attachment II

48

10. Attachments

Attachment II

49

Z

a

m

i

l

S

t

e

e

l

P

r

e

-

E

n

g

i

n

e

e

r

e

d

B

u

i

l

d

i

n

g

s

I

E

r

e

c

t

i

o

n

M