Professional Documents

Culture Documents

Micrometer Calibration Using Slip Gauges

Uploaded by

MachineryengOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Micrometer Calibration Using Slip Gauges

Uploaded by

MachineryengCopyright:

Available Formats

1

Metrology Laboratory

Department of Mechanical Engineering

Experiment No. 1B

MICROMETER CALIBRATION

Aim:

- To study various types of micrometers.

- To calibrate the given micrometers, using slip gauge as standard.

- To study use of combination set.

Apparatus:

- Set of Micrometers

- Set of Slip gauges

- Combination set

Theory:

A micrometer is a device used widely in mechanical engineering and machining for

precision measurement, along with other metrological instruments such as dial calipers

and vernier calipers. Micrometer screw-gauge is used for measuring accurately the

diameter of a thin wire or the thickness of a sheet of metal. It consists of a U-shaped

frame, fitted with a screwed spindle which is attached to a thimble, as shown in Fig. 1.

Fig. 1 Screw gauge

2

Micrometers use the principle of a screw to amplify small distances that are too small to

measure directly into large rotations of the screw that are big enough to read from a scale.

The accuracy of a micrometer derives from the accuracy of the threadform that is at its

heart. The basic operating principles of a micrometer are as follows:

The amount of rotation of an accurately made screw can be directly and precisely

correlated to a certain amount of axial movement (and vice versa), through the constant

known as the screw's pitch (for single start screw thread). A screw's pitch is the distance

it moves forward or backward axially with one complete turn. The screw has a known

pitch such as 0.5 mm. Hence in this case, for one revolution of the screw the spindle

moves axially by 0.5 mm. This movement of the spindle is shown on an engraved linear

millimeter scale on the sleeve. On the thimble there is a circular scale which is divided

into 50 or 100 equal parts.

When the anvil and spindle end are brought in contact, the edge of the circular scale

should be at the zero of the sleeve (linear scale) and the zero of the circular scale should

be opposite to the datum line of the sleeve. If the zero is not coinciding with the datum

line, there will be a positive or negative zero error as shown in Fig. 2.

Fig. 2 Zero error in case of screw gauge

The least count of the micrometer screw can be calculated using the formula given below:

Least count =Pitch/ Number of divisions on the circular scale =0.5 mm/50 =0.01 mm

As an example, to determine the diameter of a wire, the wire is to be placed

between the anvil and spindle end, and the thimble is rotated till the wire is firmly

held between the anvil and the spindle. The ratchet is provided to avoid excessive

pressure on the wire. It prevents the spindle from further movement. The diameter

of the wire could be determined from the reading as shown in Figure 3.

3

Fig. 3 Linear and circular scales of screw gauge

Reading =Linear scale reading +(coinciding cicular scale * Least count)

=2.5 mm+(46*0.01) =2.96 mm (for Figure 3)

Accuracy of the measured reading is the degree of veracity while precision is the degree

of reproducibility. The analogy may be used to explain the difference between accuracy

and precision is the target comparison. In this analogy, repeated measurements are

compared to arrows that are shot at a target as shown in Figure 4. Accuracy describes the

closeness of arrows to the bullseye at the target center. Arrows that strike closer to the

bullseye are considered more accurate. The closer a system's measurements to the

accepted value, the more accurate the system is considered to be.

Low Accuracy

High Precision

High Accuracy

Low Precision

High Accuracy

High Precision

Fig. 4 Difference between accuracy and precision

Gauge block or slip gauge is a precision ground and lapped length measuring standard. It

is used as a reference for the setting of measuring equipment used in machine shops, such

as micrometers, sine bars, and dial indicators (when used in calibration or inspection

role).

These gauges consists of a set of steel blocks, each of which has one pair of opposite

faces lapped flat and parallel accurately to a few millionths of an inch. They are used to

check the accuracy of workshop and similar gauges, which in use arc subjected to

Linear scale Circular scale

4

wearing action; slip gauges should never be used as ordinary measuring gauges, but as

reference or master standards. They arc generally employed in connection with

comparator instruments when workshop gauges have to be checked.

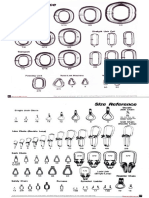

The slip gauges are supplied in sets, the number in each set varying according to the purpose in

view. The most widely employed set consists of 81 gauges of differing thickness made up as

fallows:

Nine pieces with range of 0.1 001 to 0.1009 in. in steps of 0.0001 in.

Forty-nine pieces with a range of 0.101 to 0.149 in. in steps of 0.001 in.

Nineteen pieces with a range of 0.05 to 0.95 in. in steps of 0.05 in.

Four pieces of parallel width, 1 in, 2 in, 3 in, and 4 in. respectively.

Metric unit sets of 103 pieces are made up as follows:

Forty-nine pieces with a range of 1.01 to 1.09 mm. in steps of 0.01 mm.

Forty-nine pieces with a range of 0.50 to 24.50 mm. In steps of 0.50 mm.

Four pieces of25, 50, 75, and 100 mm respectively.

One extra piece of 1.005 mm.

Smaller sets of 76, 56, 48, and 31 pieces are also supplied in the metric sizes, and sets of 49, 41,

35 and 28 in English sizes.

Before using these gauges they should be wiped with a piece of soft linen cloth. If the presence of

any grease is suspected, or in the case of new gauges having a protective coating, the surface

should be wiped over with a piece of soft linen moistened with benzole or petrol. The removal of

any grease including that from the fingers is important since; otherwise, dirt may be picked up

more easily. In a dustless atmosphere however, a trace of grease on the surface assists in

obtaining a satisfactory wringing action.

Fingering of slip gauges should be avoided as much as possible since it tends to promote

tarnishing and thermal expansion effects. A change of only in temperature causes a length change

of about 1 /1, 00, 000 in. per inch thickness of gauge.

It is important for fine precision measurements to use slip gauges in a room thermo-statistically

controlled at 20

0

C and to allow, the work and the gauges sufficient time to attain this temperature

if taken into heat-regulated room. Gauges after use should be wiped off carefully at once and

returned to their storage case, closing the lid of the latter as soon as possible.

Wringing is the process of sliding two blocks together so that their faces lightly bond.

When combined with a very light film of oil, this action excludes any air from the gap

between the two blocks. The alignment of the ultra-smooth surfaces in this manner

permits molecular attraction to occur between the blocks, and forms a very strong bond

between the blocks along with no discernible alteration to the stacks overall dimensions.

5

The recommended procedure for wringing a pair of slip gauges together is as

follows and shown in the Fig. 5.

First clean the surfaces as desired previously, and then place one gauge centrally

across the other gauge at right angles to form a symmetrical cross. Finally rotate

the upper gauge over the lower one to its final coincident position. This method

results in appreciably less rubbing action than the upper gauge is slid lengthwise

over the lower one.

Fig. 5 Wringing of slip gauges

Procedure:

For calibration of micrometers

1. Check the range of measurement of the micrometer.

2. Note down zero error of the micrometer, if any.

3. Select a number of slip gauge combinations.

4. Measure each slip gauge combination with the micrometer and note down micrometer

reading (M) and slip gauge combination length (G) in tabular form.

5. Plot a calibration chart for the micrometer taking M on the X-axis and (M-G) on the

Y-axis.

6. Repeat the steps l-5 for other micrometers.

Precautions:

! While making slip gauge combination, do the wringing correctly, so that no foreign

particles are entrapped.

! While taking micrometer reading, care should be taken to clamp the spindle in position,

before taking it away from the block, as due to friction the Spindle will rotate and give a

wrong reading.

! Turn the spindle always in the clockwise direction to avoid backlash error.

6

Observations & Result:

Micrometer

Details

Sl. No. of

reading

Slip Gauge

reading (G)

Micrometer

Reading (M)

Error

(M-G)

Range:

No.:

Make:

Zero error:

1

2

3

Discussion:

Sources of measurement errors

Questions:

1. Discuss functions and principle of ratchet drive in case of a micrometer.

2. Why does zero error occur in a micrometer?

3. Differentiate among terms accuracy, precision, sensitivity, & readability.

4. When is an instrument required to be calibrated?

5. What is the use of calibration chart?

6. What do you mean by Protector Slip Gauge?

7. What is wringing? How is it done?

8. Sketch the type of anvil required for measuring the thickness of a paper, chip

thickness?

You might also like

- Experiment Measurement of Lengths, Heights, Diameters, Vernier CaliperDocument11 pagesExperiment Measurement of Lengths, Heights, Diameters, Vernier Caliperv sharvan kumar asst.prof(mech)No ratings yet

- Mechanical Measurement LaboratoryDocument24 pagesMechanical Measurement LaboratoryMahendra SinghNo ratings yet

- Micrometer Screw GaugeDocument13 pagesMicrometer Screw GaugeLugafloNo ratings yet

- Micrometer CalibrationDocument2 pagesMicrometer Calibrationpammy313No ratings yet

- Calibrating a Vernier Caliper for Precise MeasurementsDocument6 pagesCalibrating a Vernier Caliper for Precise MeasurementsPrateek Nyati100% (1)

- Expt 1 - Calibration of Vernier CaliperDocument5 pagesExpt 1 - Calibration of Vernier Calipersathyadally100% (1)

- Calibration Procedure For Calibration of External MicrometerDocument11 pagesCalibration Procedure For Calibration of External MicrometerDiganta Hatibaruah100% (1)

- Cp-005-Calibration of Internal MicrometerDocument5 pagesCp-005-Calibration of Internal MicrometerSUNILNo ratings yet

- Calibration Laboratory Depth Micro Meter: Revision Record SheetDocument8 pagesCalibration Laboratory Depth Micro Meter: Revision Record SheetManivasagan VasuNo ratings yet

- Calibration PDFDocument20 pagesCalibration PDFHakim HakimNo ratings yet

- Calibrate Outside MicrometersDocument2 pagesCalibrate Outside MicrometerserharsinghNo ratings yet

- Instrument Calibration ProcedureDocument16 pagesInstrument Calibration ProcedureMohammad Nurayzat JohariNo ratings yet

- Calibration Frequency TableDocument7 pagesCalibration Frequency Tablefajar_92No ratings yet

- Dial Indicator Calibration Procedure TS-0051Document3 pagesDial Indicator Calibration Procedure TS-0051alexrferreiraNo ratings yet

- Free Digital Multimeter Calibration ProcedureDocument12 pagesFree Digital Multimeter Calibration ProcedurejoaoNo ratings yet

- Procedure For Caliper Calibration (Rev.1)Document10 pagesProcedure For Caliper Calibration (Rev.1)syisyi87No ratings yet

- Measure Uncertainity in Torque WrenchDocument11 pagesMeasure Uncertainity in Torque WrenchAnonymous uXdS9Y7100% (2)

- Outside Micrometer CalibrationDocument2 pagesOutside Micrometer CalibrationJJNo ratings yet

- Instrument Calibration ProcedureDocument7 pagesInstrument Calibration Procedurejosejose19No ratings yet

- Calibrate Dial Gages for Linear MeasurementDocument13 pagesCalibrate Dial Gages for Linear MeasurementSUNIL100% (1)

- Calibrating External MicrometersDocument5 pagesCalibrating External MicrometersSUNIL100% (1)

- Pi Tape Calibration ProcedureDocument11 pagesPi Tape Calibration ProcedureAaron QuinnNo ratings yet

- Copyrighted Material Licensed for Limited UseDocument13 pagesCopyrighted Material Licensed for Limited UseSarvesh Mishra50% (2)

- Vernier CaliperDocument2 pagesVernier CaliperMechtek LabNo ratings yet

- Calibration of EquipmentDocument27 pagesCalibration of Equipmentzilangamba_s4535No ratings yet

- Outside Micrometer Calibration Procedure: 1.0 Standards and EquipmentDocument2 pagesOutside Micrometer Calibration Procedure: 1.0 Standards and EquipmentCoop StElzearNo ratings yet

- SOP For Inhouse CalibrationDocument7 pagesSOP For Inhouse Calibrationvasudeva yasas80% (5)

- Guide to Using Callipers and Micrometers EffectivelyDocument100 pagesGuide to Using Callipers and Micrometers Effectivelymcbalzan100% (3)

- Monitoring Variations in Tests and CalibrationsDocument5 pagesMonitoring Variations in Tests and CalibrationsV VijayNo ratings yet

- CMM Verification Version 2Document111 pagesCMM Verification Version 2Sandrock_01sr2No ratings yet

- Thread Gauge Acceptance CriteriaDocument7 pagesThread Gauge Acceptance CriteriaNilesh Sargara100% (2)

- CP-003 Calibration of Vernier CaliperDocument6 pagesCP-003 Calibration of Vernier CaliperSUNILNo ratings yet

- Calibration Procedure.Document7 pagesCalibration Procedure.Mohammed Kamal71% (7)

- PosiTector 6000 Manual PDFDocument39 pagesPosiTector 6000 Manual PDFPepe PedroNo ratings yet

- Calibrate Vernier Calipers ProcedureDocument2 pagesCalibrate Vernier Calipers Proceduregiamillia100% (2)

- Calibration of Measuring InstrumentDocument5 pagesCalibration of Measuring InstrumentNaman ShuklaNo ratings yet

- Roundness - GD&TDocument23 pagesRoundness - GD&TKishor kumar Bhatia100% (3)

- Calibration MethodDocument4 pagesCalibration MethodevanNo ratings yet

- Sample Calibration ProceduresDocument37 pagesSample Calibration ProceduresGabriel Dediu100% (1)

- Calibration of Pressure GaugeDocument16 pagesCalibration of Pressure GaugeRITIKA SHUKLANo ratings yet

- Norma ISO 13385Document24 pagesNorma ISO 13385jorge_t_71100% (3)

- Calibration of Micrometer Vernier CaliperDocument5 pagesCalibration of Micrometer Vernier CalipermanaimekalaiNo ratings yet

- Lab ManualDocument19 pagesLab ManualAjij Mujawar100% (1)

- ComparatorsDocument42 pagesComparatorsNaman Dave100% (2)

- Calipers (New Standard ISO-ASME)Document8 pagesCalipers (New Standard ISO-ASME)Hernando Sanchez100% (4)

- Is 13875 1 1993Document17 pagesIs 13875 1 1993KOSAKA LABNo ratings yet

- 048-012 Thread Plug GaugeDocument5 pages048-012 Thread Plug GaugeRavichandran DNo ratings yet

- Instrument Calibration ProcedureDocument10 pagesInstrument Calibration ProcedureMohammad Nurayzat JohariNo ratings yet

- DKD Calibration of Torque DKD K 09301 EQS 8010 Datasheet SCHATZ enDocument2 pagesDKD Calibration of Torque DKD K 09301 EQS 8010 Datasheet SCHATZ enMohamedSafeerNo ratings yet

- Calibration Procedure For Calibration of External Micrometer PDFDocument8 pagesCalibration Procedure For Calibration of External Micrometer PDFscopeldelimaNo ratings yet

- MMM Lab ManualDocument13 pagesMMM Lab ManualSangam PatilNo ratings yet

- Outside Micrometer Calibration Record SheetDocument1 pageOutside Micrometer Calibration Record SheetSeleccion Tecnico Industrial0% (1)

- FUNDAMENTALS OF TORQUE CALIBRATIONDocument137 pagesFUNDAMENTALS OF TORQUE CALIBRATIONMiguel Alfonso Ruiz MendezNo ratings yet

- Calibration of Dial GaugeDocument21 pagesCalibration of Dial GaugeAnthony Burns82% (11)

- Nacla Z540 3Document12 pagesNacla Z540 3Somsak Navayon100% (1)

- Murali - Metrology & Measurements Lab ManualDocument30 pagesMurali - Metrology & Measurements Lab ManualsubhashNo ratings yet

- Introduction of Micrometer Screw GaugeDocument8 pagesIntroduction of Micrometer Screw Gaugesamar karemoreNo ratings yet

- Section 5 Basic MeasurementsDocument62 pagesSection 5 Basic Measurementsrolando maisoNo ratings yet

- Micrometer Screw GaugeDocument11 pagesMicrometer Screw GaugeAshwin kumarNo ratings yet

- Measurements Lab Manual, Mechanical Engineering, MG UniversityDocument29 pagesMeasurements Lab Manual, Mechanical Engineering, MG Universitypramodkb_cusat100% (1)

- Seal Design GuideDocument119 pagesSeal Design GuideaytepeNo ratings yet

- SOP Number Insert Number: Standard Operating ProcedureDocument2 pagesSOP Number Insert Number: Standard Operating ProcedureLawNo ratings yet

- Manual Best Management PortsDocument156 pagesManual Best Management PortsAchraf DouiriNo ratings yet

- Lip Seal Installation PDFDocument11 pagesLip Seal Installation PDFMachineryengNo ratings yet

- ESA Best Available Techniques Issue 1Document4 pagesESA Best Available Techniques Issue 1vprochockyNo ratings yet

- HA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FDocument25 pagesHA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FMachineryeng0% (1)

- SOP Templates 03Document1 pageSOP Templates 03MachineryengNo ratings yet

- Steam TurbinesDocument8 pagesSteam Turbinesspalaniyandi100% (1)

- JC Gasket CranfoilDocument2 pagesJC Gasket CranfoilMachineryengNo ratings yet

- Seal Design For High Pressure Offshore-Morton & EvansDocument10 pagesSeal Design For High Pressure Offshore-Morton & EvansMachineryengNo ratings yet

- Hsg253 The Safe Isolation of Plant and EquipmentDocument81 pagesHsg253 The Safe Isolation of Plant and EquipmentRichard HollidayNo ratings yet

- Pit Ot Tube Pump TechnologyDocument12 pagesPit Ot Tube Pump TechnologymariasofiarossiNo ratings yet

- Api 617 CameronDocument31 pagesApi 617 CameronMachineryengNo ratings yet

- Compressor MountingDocument41 pagesCompressor MountingjmacarroNo ratings yet

- Creating A World That Doesnt BreakdownDocument23 pagesCreating A World That Doesnt BreakdownmersiumNo ratings yet

- Norsok ST 2001Document131 pagesNorsok ST 2001mamounsdNo ratings yet

- Compressor Performance Test Procedure Shaybah Rev.2 BorsigDocument23 pagesCompressor Performance Test Procedure Shaybah Rev.2 BorsigMachineryengNo ratings yet

- BORSIG ZM Compression - Innovative Solutions for Process Gas CompressionDocument16 pagesBORSIG ZM Compression - Innovative Solutions for Process Gas CompressionMachineryengNo ratings yet

- Borsig BZM - 2016 - EngDocument84 pagesBorsig BZM - 2016 - EngMachineryengNo ratings yet

- Compressor Turbo-Air API a4-IRDocument12 pagesCompressor Turbo-Air API a4-IRMachineryengNo ratings yet

- UtilityDocument8 pagesUtilityAmit JainNo ratings yet

- Lifts and Hoists Maintenance Tasks PDFDocument19 pagesLifts and Hoists Maintenance Tasks PDFMachineryengNo ratings yet

- BORSIG Valve PresentationDocument18 pagesBORSIG Valve PresentationMachineryengNo ratings yet

- HA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FDocument25 pagesHA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FMachineryeng0% (1)

- Lifiting Chain Size Referance PDFDocument1 pageLifiting Chain Size Referance PDFMachineryengNo ratings yet

- Perf Improv To Aches Rev 0Document16 pagesPerf Improv To Aches Rev 0Poncho RmzNo ratings yet

- Burgmann Quick Guide To Identifying Mechanical Seal FailuresDocument1 pageBurgmann Quick Guide To Identifying Mechanical Seal FailuresakabbaraNo ratings yet

- SVS.435 Steam Turbine Control UpgradesDocument4 pagesSVS.435 Steam Turbine Control UpgradesMachineryengNo ratings yet

- Selection of Material Nace - H2S - Technical Paper PDFDocument21 pagesSelection of Material Nace - H2S - Technical Paper PDFajaysharma_1009No ratings yet

- Improved Thermal Piping Analysis For Reciprocating Compressor Piping SystemsDocument7 pagesImproved Thermal Piping Analysis For Reciprocating Compressor Piping SystemsJimmy Alexander AvilaNo ratings yet

- Dahal, Purna Prasad - Paper - Nonlinear Pushover Analysis of Steel Frame StructureDocument5 pagesDahal, Purna Prasad - Paper - Nonlinear Pushover Analysis of Steel Frame StructureMihaiNo ratings yet

- The Law of AttractionDocument3 pagesThe Law of AttractionjeffNo ratings yet

- Different Sieving Methods For Varying ApplicationsDocument19 pagesDifferent Sieving Methods For Varying ApplicationsAbeer AbdullahNo ratings yet

- Astronomy Assessment Solar System-Sun Moon EarthDocument3 pagesAstronomy Assessment Solar System-Sun Moon Earthapi-132786865No ratings yet

- SteelDesign PlateGirder Fu NewDocument32 pagesSteelDesign PlateGirder Fu NewFhatony Silvershadows BondanNo ratings yet

- Industrial RoboticsDocument77 pagesIndustrial RoboticsIslam Fouad100% (4)

- Government Polytechnic College Muttom: Laboratory Manual Survey Practical-IiDocument38 pagesGovernment Polytechnic College Muttom: Laboratory Manual Survey Practical-IiSanjithRNairNo ratings yet

- Accessing and manipulating matrix elementsDocument3 pagesAccessing and manipulating matrix elementsJay PatelNo ratings yet

- Hyperladder 1kb Product ManualDocument1 pageHyperladder 1kb Product Manualhandika ramadhaniNo ratings yet

- Capacities (CP)Document40 pagesCapacities (CP)georgekc77No ratings yet

- Radial and Standard Bond Log Interpretation PrinciplesDocument24 pagesRadial and Standard Bond Log Interpretation Principlesroybert arcia100% (1)

- Derivation of Gradient Divergence Curl in Spherical CoordinatesDocument9 pagesDerivation of Gradient Divergence Curl in Spherical CoordinatesCarlos TeixeiraNo ratings yet

- Crystal Structure SymmetryDocument45 pagesCrystal Structure SymmetryBasharat AhmadNo ratings yet

- Xtensions: Discovering Advanced Algebra Solutions ManualDocument52 pagesXtensions: Discovering Advanced Algebra Solutions ManualjordybeltNo ratings yet

- AN4699-Overview of Sensor Signal PathsDocument17 pagesAN4699-Overview of Sensor Signal Pathsnestor265No ratings yet

- Use of Nanotechnology in Cement-Based Materials PDFDocument5 pagesUse of Nanotechnology in Cement-Based Materials PDFHarini S BNo ratings yet

- Projectile MotionDocument40 pagesProjectile MotionJoshua VicenteNo ratings yet

- 2007 Steel Joists & Joist GirdersDocument161 pages2007 Steel Joists & Joist GirdersAnonymous PjmE9RJcghNo ratings yet

- Office of The Dy - Executive Engineer Pri Sub Division-TandurDocument3 pagesOffice of The Dy - Executive Engineer Pri Sub Division-TandurkalyanreddysNo ratings yet

- Synthesis of Sulfanilamide from Aniline in Four StepsDocument2 pagesSynthesis of Sulfanilamide from Aniline in Four StepsArindam DasNo ratings yet

- JH - Beam DesignDocument14 pagesJH - Beam DesignJonathanNo ratings yet

- RTD Incotest PresentationDocument27 pagesRTD Incotest PresentationAsadAliNo ratings yet

- ZGP Refraction IndexDocument6 pagesZGP Refraction Indexourapteryx514No ratings yet

- Worksheet - Lab Equip Answer Key UttislDocument2 pagesWorksheet - Lab Equip Answer Key Uttislyuefen tohNo ratings yet

- Answer 2Document4 pagesAnswer 2廖宥丞No ratings yet

- DPP 5TH May 2020Document14 pagesDPP 5TH May 2020Nishit PNo ratings yet

- Recent Topics of Japanese Design Codes For Steel and Composite BridgesDocument6 pagesRecent Topics of Japanese Design Codes For Steel and Composite BridgesHuan VoNo ratings yet

- Adaptive Approximate Bayesian Computation For Complex ModelsDocument20 pagesAdaptive Approximate Bayesian Computation For Complex ModelsCarlos HenriqueNo ratings yet

- Ducted Fan ThesisVTOhanian2011Document203 pagesDucted Fan ThesisVTOhanian2011pest619No ratings yet