Professional Documents

Culture Documents

Sebda2050508 SM PC220-5

Uploaded by

César AugustoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sebda2050508 SM PC220-5

Uploaded by

César AugustoCopyright:

Available Formats

SEBMA2050508

(SEBM02050508)

KOMRt bU

PC200,2OoLC-5

PC200,2ooLC-5

MIGHTY

PC220,22OLC-5

MACHINE MODEL

PC2004

PC2004 MIGHTY

PC2OOLC-5

PC2OOLC-5 MIGHTY

PC220-5

PC22OLC-5

SERIAL NO.

45001 and up

A70001 and up

58019 and up

45001 and up

A70001 and up

58019 and up

35001 and up

35001 and up

A70001 and up

0 Open Serial Numbers references (i.e. 45001 and up) apply to all machine Serial Numbers listed above.

Closed Serial Numbers references (i.e. 4500145003) apply only to those machine Serial Numbers.

l This shop manual may contain attachments and optional equipment that are not available in your area.

Please consult your local Komatsu distributor for those items you may require. Material and specification

are subject to change without notice.

l PC200, 2OOLG5, MIGHTY mount the S6D95L engine;

PC220, 22OLG5 mount the SA6D95L engine.

For details of the engine, see the 95 Series Engine Shop Manual.

FEB 92

00-l

@

CONTENTS

No. of page

10 STRUCTURE AND FUNCTION . . . . . . . . . . . . . . . . lo-1

20 TESTING AND ADJUSTING . . . . . . . . . . . . . . . . . . ~~-1

30 DISASSEMBLY AND ASSEMBLY . . . . . . : . . . . . 3o_1

40 MAINTENANCE STANDARD . . . . . . . . . . . . . . . . . 4o_1

Not to be reproduced in whole or in part without the prior written permission of

KOMAl!BU, Tokyo, Japan.

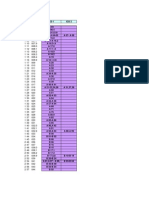

The affected pages are indicated by the use of

the following marks. It is requested that necessary

actions be taken to these pages according to the

table below.

Mark Indication Action required

0 Page to be newly added Add

0 Page to be replaced Replace

(

) Page to be deleted Discard

Pages having no marks are those previously revised

or made additions.

Mark Page

Ti me of

revi si on

. oo- 1

. oo- 2

l oo- 2- l

. oo- 2- 2

l 00- 2- 3

l 00- 2- 4

l oo- 3

l oo- 4

l oo- 5

. 00- 6

. oo- 7

l 00- 8

l oo- 9

l 00- 10

. 00- 11

. 00- 12

l 00- 13

. 00- 14

l 00- 15

l 00- 16

0 00- 17

0 00- 18

0 00- 19

0 00- 20

0 00- 21

0 00- 22

0 00- 23

0 00- 24

LIST OF REVISED PAGES

Mark Page

Ti me of

revi si on

lo- 1

l o- 2

. I O- 3

0 l o- 3- 1

I O- 4

I O- 4- 1

I O- 4- 2

l I O- 5

l I O- 6

l o- 7

l o- 8

l o- 9

I O- I O

I O- 11

I O- 12

l I O- 13

0 I O- 14

10- 15

l l o- 16

. 10- 17

l I O- 18

I O- 19

0 10- 19- I

10- 20

10- 20- l

10- 20- 2

I O- 21

I O- 22

Mark Page

Ti me of

revi si on

I O- 23

I O- 24

I O- 25

l o- 26

l o- 27

l o- 28

10- 29

I O- 30

I O- 31

I O- 32

I O- 33

10- 34

10- 35

l o- 36

l I O- 37

. I O- 38

I O- 39

. I O- 40

I O- 41

I O- 42

I O- 43

10- 44

I O- 45

l 10- 45- I

10- 45- Z

1 o- 45- 3

10- 45- 4

10- 45- 5

Mark Page

Ti me of

revi si on

10- 45- 6

0 10- 45- 7

0 10- 45- 8

0 10- 45- g

0 1 O- 45- 10

0 1 o- 45- 11

0 1 O- 45- 12

I O- 46

10- 47

l o- 48

10- 49

10- 49- I

10- 50

1 o- 51

I O- 52

1 o- 53

1 o- 54

1 O- 56

10- 57

I O- 58

I O- 59

I O- 60

I O- 61

I O- 62

I O- 65

l I O- 66

I O- 67

I O- 68

Mark Page

Ti meof

revi si on

1 O- 69

. 10- 69- I

1 O- 69- 2

1 O- 69- 3

1 O- 69- 4

I O- 70

I O- 71

I O- 72

. I O- 73

. I O- 74

I O- 75

I O- 76

l I O- 77

1 o- 77- 1

l 1 O- 77- 2

. 1 o- 77- 3

10- 77- 4

. I O- 78

l I O- 79

I O- 80

l o- 81

I O- 82

l o- 83

. l o- 84

1 O- 85

l 1 O- 86

I O- 87

l 10- 88

Mark Page

Ti me of

revi si on

1 O- 89

l 1 O- 89- 1

1 O- 89- 2

l 1 O- 89- 3

1 O- 89- 4

1 O- 89- 5

. 1 O- 89- 6

0 1 O- 89- 8

1 O-90

l 1 o- 91

l 1 o-92

1 o-93

1 o-94

1 o-95

1 O- 96

1 o-97

1 O- 97- 1

1 o-97-2

l 1 o-97-3

1 O- 98

. 1 o-99

0 1 o-99-1

. 1 o-99-2

10-100

. 10-101

. 10- 102

. 10- 103

l I O- 104

I O- 105

I O- 106

0 I O- 107

I O- 109

10- 110

10- 111

I O- 112

10- 113

. 10- 114

. 10- 115

l o- 116

I O- 117

Vl ark Page

Ti me of

revi si on

0 I O- 118

10- 118- 1

10- 118- 2

l I O- 119

l 10- 120

0 10- 121

10- 122

l o- 123

l o- 124

10- 124- I

10- 124- 2

10- 124- 3

10- 124- 4

I O- 125

I O- 126

l I O- 127

. I O- 128

I O- 129

I O- 130

I O- 131

I O- 132

20- 1

20- 2

20- 3

20- 4

20- 5

. 20- 6

. 20- 7

20. 8

20- 9

20- 10

20- 11

20- 12

20- 13

20- 14

20- 15

20- 16

20- 18

Vl ark Page

Ti me of

Mark Page

Ti me of

revi si on revi si on

20- 19

0 20- 20

0 20- 21

0 20- 22

20- 23

0 20- 24

l 20- 25

20- 26

20- 27

l 20- 28

a 20- 28- I

20- 28- 2

20- 28- 3

20- 29

20- 30

20- 31

20- 32

20- 33

20- 33- I

20- 34

20- 35

20- 36

20- 37

20- 38

20- 39

20- 40

20- 41

20- 42

20- 43

20- 44

20- 45

20- 46

20- 47

20- 47- I

. 20- 47- 2

0 20- 48

0 20- 49

l 20- 49- l

. 20- 49- 2

20- 50

20- 51

20- 52

20- 53

20- 54

20- 55

20- 56

20- 57

20- 58

20- 59

20- 60

20- 61

20- 62

20- 63

20- 64

20- 65

20- 66

20- 67

l 20- 68

l 20- 69

l 20- 70

. 20- 71

0 20- 72

l 20- 73

. 20- 74

. 20- 75

. 20- 76

20- 77

0 20- 78

20- 79

20- 90

20- 91

20- 92

20- 93

20- 94

20- 95

20- 96

20- 97

20- 97- l

. 20- 98

. 20- 99

Mark Page

Ti me of

revi si on

0 20- 100

0 20- 101

20- 102

. 20- 103

20- 104

. 20- 104- I

20- 105

0 20- 106

20- 107

0 20- 107- l

20- 107- 2

20- 108

20- 109

20- 110

20- 111

20- 113

. 20- 114

20- 115

. 20- 116

0 20- 117

0 20- 117- l

0 20- 117- 2

0 20- 117- 3

0 20- 117- 4

20- 118

. 20- 119

. 20- 120

20- 121

20- 122

20- 123

20- 124

20- 126

20- 127

l 20- 128

20- 129

0 20- 129- l

20- 129- 2

0 20- 130

20- 131

20- 132

Mark Page

Ti me of

revi si on

20- 133

. 10- 133- I

20- 133- 2

20- 133- 3

20- 133- 4

0 20- 134

20- 135

. 20- 135- I

20- 135- 2

0 20- 136

20- 137

0 20- 137- l

20- 137- 2

l 20- 137- 3

20- 137- 4

20- 138

20- 139

l 20- 140

. 20- 141

. 20- 142

. 20- 142- I

. 20- 143

. 20- 144

. 20- 145

. 20- 146

. 20- 147

20- 148

20- 149

. 20- 150

. 20- 151

0 20- 152

. 20- 153

0 20- 154

20- 155

20- 156

20- 157

20- 158

20- 159

20- 160

20- 161

Mark Page

Ti me of

revi si on

Mark Page

Ti me of

Page

Ti me of

revi si on

Mark

revi si on

20- 162

20- 163

20- 164

20- 165

20- 166

20- 167

20- 169

. 20- 170

0 20- 171

l 20- 172

20- 173

20- 174

20- 175

20- 176

20- 177

20- 178

20- 179

20- 180

20- 181

20- 182

20- 183

20- 184

20- 185

20- 186

20- 187

20- 188

20- 189

20- 190

20- 192

20- 193

20- 194

20- 195

20- 196

20- 198

20- 199

20- 200

20- 201

20- 202

20- 203

20- 204

20- 205

20- 206

20- 207

20- 208

20- 209

20- 210

20- 211

20- 213

20- 214

20- 215

20- 216

20- 217

. 20- 218

20- 219

20- 220

20- 221

20- 222

20- 223

20- 224

20- 225

20- 226

20- 227

20- 228

20- 229

0 20- 230

20- 231

20- 232

20- 233

20- 234

20- 235

20- 236

20- 237

20- 238

20- 239

20- 240

20- 241

20- 242

20- 243

20- 244

0 20- 245

. 20- 246

. 30- 1

0 30. 2

30. 4

30. 5

30. 6

l 30. 7

30- 7- I

0 30- 7- 2

. 30- 8

. 30- 9

a 30- 10

( 30- 10- I )

0 30- 11

30- 12

30- 13

30- 14

30- 15

30- 16

30- 17

30- 18

30- 19

30- 20

30- 21

30- 22

30- 23

30- 24

30- 25

30- 26

30- 27

30- 28

30- 29

30- 30

30- 31

30- 32

30- 33

30- 34

30- 35

Mark Page

Ti me of

revi si on

30- 36

30- 37

30- 38

30- 39

30- 40

30- 41

. 30- 42

0 30- 42- I

0 30- 42- 2

0 30- 43

30- 43- 1

30. 43- 2

30- 43- 3

30- 43- 4

30- 43. 5

30- 43. 6

30- 43. 7

30- 43. 8

30. 43- 9

30- 43- 10

30- 43- 11

30- 43- 12

30- 43- 13

30- 43- 14

30- 44

30- 45

30- 45- I

30- 45- 2

30- 45- 3

30- 45- 4

30- 45- 5

30- 45- 6

30- 45- 7

30- 45- 8

30- 46

30- 47

30- 48

30- 49

30- 50

30- 51

00$3

i

Mark Page

Ti me of

revi si on

Mark Page

Ti me of

Mark Page

Ti me of

Mark Page

Ti me of

revi si on revi si on revi si on

30- 52

30- 53

30- 54

30- 55

30- 56

30- 57

30- 58

30- 59

30- 60

30- 61

30- 62

30- 63

30- 64

30- 65

30- 65- I

30- 65- 2

30- 65- 3

30- 65- 4

30- 65- 5

30- 65- 6

30- 65- 7

30- 65- 8

30- 65- g

30- 65- 10

30- 65- 11

30- 65- 12

30- 65- 13

30- 65- 14

30- 65- 15

30- 65- 16

30- 65- 17

30- 65- 18

30- 66

30- 67

30- 68

30- 69

30- 70

30- 71

30- 72

30- 73

30- 74

30- 75

. 30- 76

. 30- 77

0 30- 77- l

0 30- 77- 2

0 30- 77- 3

0 30- 77- 4

30- 78

30- 79

30- 80

30- 81

30- 82

30- 83

30- 83- l

30- 83- 2

30- 84

30- 85

30- 85- I

30- 85- 2

30- 86

30- 87

30- 88

30- 89

30- 90

30- 91

30- 92

30- 93

30- 94

30- 95

30- 95- l

30- 95- 2

30- 96

30- 97

30- 98

30- 99

30- 100

30- 101

30- 102

30- 103

30- 104

30- 105

30- 106

30- 107

40- 1

0 40. 2

40- 3

40- 4

40- 5

40- 6

40- 7

40- 8

40. 9

40- 10

40- 11

40- 12

40- 13

40- 13- 2

40- 14

0 40- 15

40- 16

40- 17

40- 18

40- 19

40- 20

40- 21

0 40- 21- 2

40- 21- 3

40- 21- 4

40- 21- 5

40- 21- 6

40- 21- 7

40- 21- 8

( 40- 21- 9)

0 40- 21- 10

0 40- 21- 11

0 40- 21- 12

0 40- 21- 13

0 40- 21- 14

0 40- 21- 15

0 40- 21- 16

0 40- 21- 17

40- 22

40- 23

40- 24

. 40- 25

. 40- 26

40- 27

. 40- 27- I

. 40- 27- 2

0 40- 28

40- 29

40- 30

40- 31

Mar. k Page

Ti me of

revi si on

oii-4

A

IMPORTANT SAFETY NOTICE

Proper service and repair is extremely important for the safe operation of your machine.

The service and repair techniques recommended by Komatsu and described in this

manual are both effective and safe methods of operation. Some of these operations re-

quire the use of tools specially designed by Komatsu for the purpose.

A

YY

To prevent injury to workers, the symbols and

$

are used to mark safety pre-

cautions in this manual. The cautions accompanying these symbols should always be

followed carefully. If any dangerous situation arises or may possibly arise, first consider

safety, and take the necessary actions to deal with the situation.

A SAFETY

GENERAL PRECAUTIONS

Mistakes in operation are extremely dangerous.

Read the Operation and Maintenance Manual

carefully BEFORE operating the machine.

1. Before carrying out any greasing or repairs,

read all the precautions given on the

decals which are fixed to the machine.

2.When carrying out any operation, always

wear safety shoes and helmet. Do not wear

loose work clothes, or clothes with buttons

missing.

l Always wear safety glasses when hitting

parts with a hammer.

. Always wear safety glasses when

grinding parts with a grinder, etc.

3. If welding repairs are needed, always have a

trained, experienced welder carry out the

work. When carrying out welding work,

always wear welding gloves, apron, glasses,

cap and other clothes suited for welding

work.

4.When carrying out any operation with two

or more workers, always agree on the op-

erating procedure before starting. Always

inform your fellow workers before starting

any step of the operation. Before starting

work, hang UNDER REPAIR signs on the

controls in the operators compartment.

5. Keep all tools in good condition and learn

the correct way to use them.

6. Decide a place in the repair workshop to

keep tools and removed parts. Always keep

the tools and parts in their correct places.

Always keep the work area clean and make

sure that there is no dirt or oil on the floor.

Smoke only in the areas provided for

smoking. Never smoke while working.

PREPARATIONS FOR WORK

7. Before adding oil or making any repairs,

park the machine on hard, level ground, and

block the wheels or tracks to prevent the

machine from moving.

8. Before starting work, lower blade, ripper,

bucket or any other work equipment to the

ground. If this is not possible, insert the

safety pin or use blocks to prevent the work

equipment from falling. In addition, be sure

to lock all the control levers and hang

warning signs on them.

9. When disassembling or assembling, sup-

port the machine with blocks, jacks or

stands before starting work.

10. Remove all mud and oil from the steps or

other places used to get on and off the

machine. Always use the handrails, ladders

or steps when getting on or off the

machine. Never jump on or off the machine.

If it is impossible to use the handrails,

ladders or steps, use a stand to provide safe

footing.

00-3

PRECAUTIONS DURING WORK

19. Be sure to assemble all parts again in their

original places.

11. When removing the oil filler cap, drain plug

or hydraulic pressure measuring plugs,

loosen them slowly to prevent the oil from

spurting out.

Before disconnecting or removing compo-

nents of the oil, water or air circuits, first

remove the pressure completely from the

circuit.

Replace any damaged parts with new parts.

. When installing hoses and wires, be

sure that they will not be damaged by

contact with other parts when the ma-

chine is being operated.

20. When installing high pressure hoses, make

sure that they are not twisted. Damaged

tubes are dangerous, so be extremely care-

ful when installing tubes for high pressure

circuits. Also, check that connecting parts

are correctly installed.

12.The water and oil in the circuits are hot

when the engine is stopped, so be careful

not to get burned.

Wait for the oil and water to cool before car-

rying out any work on the oil or water

circuits.

21

13. Before starting work, remove the leads from

the battery. Always remove the lead from

the negative (-1 terminal first.

14. When raising heavy components, use a

When assembling or installing parts, always

use the specified tightening torques. When

installing protective parts such as guards, or

parts which vibrate violently or rotate at

high speed, be particularly careful to check

that they are installed correctly.

hoist or crane.

Check that the wire rope, chains and hooks

are free from damage.

Always use lifting equipment which has

ample capacity.

Install the lifting equipment at the correct

places. Use a hoist or crane and operate

slowly to prevent the component from hit-

ting any other part. Do not work with any

part still raised by the hoist or crane.

15. When removing covers which are under in-

ternal pressure or under pressure from a

spring, always leave two bolts in position on

opposite sides. Slowly release the pressure,

then slowly loosen the bolts to remove.

16. When removing components, be careful not

to break or damage the wiring. Damaged

wiring may cause electrical fires.

17. When removing piping, stop the fuel or oil

from spilling out. If any fuel or oil drips on to

the floor, wipe it up immediately. Fuel or oil

on the floor can cause you to slip, or can

even start fires.

18.As a general rule, do not use gasoline to

wash parts. In particular, use .only the mini-

mum of gasoline when washing electrical

parts.

22. When aligning two holes, never insert your

fingers or hand. Be careful not to get your

fingers caught in a hole.

23. When measuring hydraulic pressure, check

that the measuring tool is correctly assem-

bled before taking any measurements.

24.Take care when removing or installing the

tracks of track-type machines.

When removing the track, the track sepa-

rates suddenly, so never let anyone stand at

either end of the track.

00-4

FOREWORD

This shop manual has been prepared as an aid to improve the quality of repairs by giving the

serviceman an accurate understanding of the product and by showing him the correct way to perform

repairs and make judgements. Make sure you understand the contents of this manual and use it to full

effect at every opportunity.

This shop manual mainly contains the necessary technical information for operations performed in

a service workshop.

For ease of understanding, the manual is divided into chapters for each main group of

components; these chapters are further divided into the following sections.

STRUCTURE AND FUNCTION

This section explains the structure and function of each component. It serves not only to give

an understanding of the structure, but also serves as reference material for troubleshooting.

TESTING AND ADJUSTING

This section explains checks to be made before and after performing repairs, as well as

adjustments to be made at completion of the checks and repairs.

Troubleshooting charts correlating Problems to Causes are also included in this section.

DISASSEMBLY AND ASSEMBLY

This section explains the order to be followed when removing, installing, disassembling or

assembling each component, as well as precautions to be taken for these operations.

MAINTENANCE STANDARD

This section gives the judgement standards when inspecting disassembled parts.

NOTICE

The specifications contained in this shop manual are subject to change at any

time and without any advance notice. Contact your KOMATSU distributor for the

latest information.

I I

00-5

HOW TO READ THE SHOP MANUAL

HOW TO READ THE SHOP MANUAL

VOLUMES

Shop manuals are issued as a guide to carry-

ing out repairs. They are divided as follows:

Chassis volume: issued for every machine

model

Engine volume: Issued for each engine series

Electrical volume :

Attachments volume :

Each issued as

one volume to

cover all models

These various volumes are designed to avoid

duplicating the same information. Therefore to

deal with all repairs for any model, it is neces-

sary that chassis, engine, electrical and attach-

ment volumes are ready.

DISTRIBUTION AND UPDATING

Any additions, amendments or other

changes will be sent to KOMATSU distributers.

Get the most up-to-date information before

you start any work.

FILING METHOD

1. See the page number on the bottom of the

page. File the pages in correct order.

2. Following examples shows how to read the

page number.

Example 1 (Chassis volume):

10-3

TT

3.

Item number (IO. Structure

and Function)

Consecutive page number for

each item.

Example 2 (Engine volume):

12-410

t

Unit number (I. Engine)

Item number (2. Testing and

Adjusting)

Group No. (4. Fuel system)

Consecutive page No. (Page

10 of Group 4)

Additional pages: Additional pages are in-

dicated by a hyphen i-1 and number after the

page number. File as in the example.

Example:

1 o-4 12-203

REVISED EDITION MARK (a@)@ .... )

When a manual is revised, an edition mark is

recorded on the bottom outside corner of the

pages.

REVISIONS

Revised pages are shown at the LIST OF

REVISED PAGES on the between the title page

and SAFETY page.

SYMBOLS

So that the shop manual can be of ample

practical use, important places for safety and

quality are marked with the following symbols.

Symbol Item

*

el

kg

Q

Safety

Caution

Weight

Tighten-

ig torque

Coat

Xl. water

Drain

Remarks

Special safety precautions are

necessary when performing the

work.

Extra special safety precautions

are necessary when performing

the work because it is under

internal pressure.

Special technical precautions or

other precautions for

preserving standards are

necessary when performing the

work.

Weight of parts or systems.

Caution necessary when

selecting hoisting wire, or when

working posture is important,

etc.

Places that require special

attention for the tightening

torque during assembly.

Places to be coated with

adhesives and lubricants etc.

Places where oil, water or fuel

must be added, and the

capacity.

Places where oil or water must

be drained, and quantity to be

drained.

1 o-5 12-204

00-6

HOISTING INSTRUCTIONS

HOISTING INSTRUCTIONS

A

Heavy parts (25 kg or more) must be

lifted with a hoist etc. In the Disassembly

and Assembly section, every part weigh-

ing 25 kg or more is indicated clearly with

the symbol &

1. If a part cannot be smoothly removed from

the machine by hoisting, the following

checks should be made:

. Check for removal of all bolts fastening

the part to the relative parts.

. Check for existence of another part

causing interference with the part to be

removed.

2. Wire ropes

I) Use adequate ropes depending on the

weight of parts to be hoisted, referring to

the table below:

Wire ropes

(Standard Z or S twist ropes

without galvanizing)

Rope diameter (mm) Allowable load (tons)

10 1 .o

11.2 1.4

12.5 1.6

14 2.2

16 2.8

18 3.6

20 4.4

22.4 5.6

30 10.0

40 18.0

50 28.0

60 40.0

The allowable load value is estimated to

be one-sixth or one-seventh of the

breaking strength of the rope used.

2) Sling wire ropes from the middle portion

of the hook.

Slinging near the edge of the hook may

cause the rope to slip off the hook during

hoisting, and a serious accident can result.

Hooks have maximum strength at the

middle portion.

100% 88% 79% 71% 41%

FSO064

3) Do not sling a heavy load with one rope

alone, but sling with two or more ropes

symmetrically wound on to the load.

A

Slinging with one rope may cause

turning of the load during hoisting,

untwisting of the rope, or slipping of

the rope from its original winding

position on the load, which can result

in a dangerous accident.

4) Do not sling a heavy load with ropes

forming a wide hanging angle from the

hook.

When hoisting a load with two or more

ropes, the force subjected to each rope

will increase with the hanging angles. The

table below shows the variation of

allowable load (kg) when hoisting is made

with two ropes, each of which is allowed

to sling up to 1000 kg vertically, at various

hanging angles.

When two ropes sling a load vertically, up

to 2000 kg of total weight can be

suspended. This weight becomes 1000 kg

when two ropes make a 120 hanging

angle. On the other hand, two ropes are

subjected to an excessive force as large as

4000 kg if they sling a 2000 kg load at a

lifting angle of 150.

60 90

Lifting angle : a

120 15o

FSO065

00-7

STANDARD TIGHTENING TORQUE

mm

STANDARD TIGHTENING TORQUE

1 STANDARD TIGHTENING TORQUE OF BOLTS AND NUTS

The following charts give the standard tightening torques of bolts and nuts. Exceptions are given in

sections of Disassembly and Assembly.

Thread diameter Width

of bolt across flat

(mm) (mm) 0

?

0

z

kgm

Nm

6 10 1.35kO.15 13.2* 1.4

8 13 3.2kO.3 31.4+-2.9

10 17 6.7 +0.7 65.7k6.8

12 19 11.5fl.O 112k9.8

14 22 18.Ok2.0 177*19

16 24 28.5*3 279&29

18 27 39+-4 383t39

20 30 56a6 549t58

22 32 76+8 745 & 78

24 36 94.5*10 927?98

27 41 135*15 1320t140

30 46 175*20 172Ok 190

33 50 225*25 221 O-+240

36 55 280?30 2750a 290

39 60 335*35 328Ok 340

This torque table does not apply to the bolts with which nylon packings or other non-

ferrous metal washers are to be used, or which require tightening to otherwise specified

torque.

Sr Nm (newton meter): 1 Nm & 0.1 kgm

2.TlGHTENlNG TORQUE OF SPLIT FLANGE BOLTS

Use these torques for split flange bolts.

Threaorj gianeter

(mm)

10

12

16

Width

across flats

(mm)

14

17

22

Tightening torque

kgm

Nm

6.7kO.7 65.7k6.8

11.5*1 1 12+9.8

28.5*3 279*29

00-8

STANDARD TIGHTENING TORQUE

Sealing surface

3.TlGHTENlNG TORQUE FOR NUTS OF FLARED

Use these torques for nut part of flared.

Thread diameter Width across flats

of nut part of nut part

(mm) (mm)

T

kgm

14 19 2.5i0.5

18 24 5k2

22 27 822

24 32 14+3

30 36 18*3

33 41 20+5

36 46 25+5

42 55 30-+5

Tightening torque

COATING MATERIALS

Nm

24.5 24.9

49* 19.6

78.5 k 19.6

137.3229.4

176.5229.4

196.1 -t49

245.2 *49

294.2249

The recommended coating materials prescribed in Komatsu Shop Manuals are listed below.

Nomenclature Komatsu code Applications

LT-IA

LT-1B

Used to apply rubber pads, rubber gaskets, and cork plugs.

Used to apply resin, rubber, metallic and

non-metallic parts when a fast, strong seal is needed.

LT-2

LT-3

Preventing bolts, nuts and plugs from loosening and leaking oil.

Provides an airtight, electrically insulating seal.

Used for aluminum surfaces.

LT-4

Used to coat plugs (plate shaped, bowl shaped) and holes, and

mating portion of shaft.

Sealant gasket

LG-1

LG-3

LG-4

LG-5

Used with gaskets and packings to increase sealing effect.

Heat-resistant gasket for precombustion chambers

and exhaust piping.

Used b itself on mounting surfaces on the final drive and transmission

cases. Thickness after tightening: Y 0.07 - 0.08 mm)

Used by itself to seal grease fittings, tapered screw fittings and tapered

screw fittings in hydraulic circuits of less than 50 mm in diameter.

Antifriction compound

(Lubricant including

molybdenum disulfide)

Grease

(Lithium grease)

LG-6

LG-7

LM-P

G2-LI

Silicon base type used in combination with LG-1 and LG-4.

Has a shorter curing time than LG-6, and is easier

to peel off.

Applied to bearings and taper shafts to facilitate press-fitting and to

prevent sticking, burning or rusting.

Applied to bearings, sliding parts and oil seals for lubrication, rust

prevention and facilitation of assembling work.

Vaseline

I

-

Used for protecting battery electrode terminals from corrosion.

l LT-2 is also called LOCTITE in the shop manuals.

00-9

ELECTRIC WIRE CODE

ELECTRIC WIRE CODE

In the wiring diagrams, various colors and symbols are employed to indicate the thickness of wires.

This wire code table will help you understand WIRING DIAGRAMS.

Example: 5WB indicates a cable having a nominal number 5 and white coating with black stripe.

CLASSIFICATION BY THICKNESS

Nominal

Copper wire

Cable O.D. Current rating

number Number / Dia. of strands/ Cross section (mm) I (A)

Applicable circuit

0.85

2

strands (mm) (mm?

11 0.32 0.88

26 0.32 2.09

2.4 12 Starting, lighting, signal etc.

3.1 20 Lighting, signal etc.

5 65 I-~ 0.32

I

5.23 1 4.6

I

37

I

Charging and signal

15

I

84

I

0.45

I

13.36 7.0

I

59 1 Starting (Glow plug)

40

60

85

127

0.80

0.80

42.73

63.84

11.4

13.6

135

178

Starting

Starting

100 217 0.80 109.1 17.6

I

230 Starting

CLASSIFICATION BY COLOR AND CODE

Lighting Instrument Signal Other

L R Y G

Red Yellow Green Blue

GW LW RW YR

Red &White Yellow & Red Green & White Blue &White

GR LR

Auxi_ Color White&Black - Black &Yellow

liary _

Code WL BR

Green & Red Blue & Red

LY GY

Green &Yellow

(GB)

I I I

Color White 81 Blue - Black & Red Blue &Yellow

(LB)

Red & Green Yellow & Blue (Green &Black) (Blue &Black)

(GL)

(Green & Blue)

-

-

00- l 0

CONVERSION TABLE

CONVERSION TABLE

Method of using the Conversion Table

The Conversion Table in this section is provided to enable simple conversion of figures. For details of the

method of using the Conversion Table, see the example given below.

Example

l Method of using the Conversion Table to convert from millimeters to inches

1. Convert 55 mm into inches.

(1)

(2)

(3)

Locate the number 50 in the vertical column at the left side, take this as @, then draw a horizontal

line from @.

Locate the number 5 in the row across the top, take this as @J, then draw a perpendicular line

down from @.

Take the point where the two lines cross as 0. This point 0 gives the value when converting

from millimeters to inches. Therefore, 55 mm = 2.165 inches.

2. Convert 550 mm into inches.

(1) The number 550 does not appear in the table, so divide by IO (move the decimal point one place

to the left) to convert it to 55 mm.

(2) Carry out the came procedure as above to convert 55 mm to 2.165 inches.

(3) The original value (550 mm) was divided by 10, so multiply 2.165 inches by 10 (move the decimal

point one place to the right) to return to the original value. This gives 550 mm = 21.65 inches.

Millimeters to inches

@

I

@--

0 1 2 3 4 5; 6

I

0 0.039 0.079 0.118 0.157 0.197 / 0.236

10 0.394 0.433 0.472 0.512 0.551 0.591 I 0.630

20 0.787 0.827 0.866 0.906 0.945 0.984 I 1.024

30 1.181 1.220 1.260 1.299 1.339 1.378 j 1.417

40 1.575 1.614 1.654 1.693 1.732 1.772 I 1.811

0 /

50 1.969 2.008 2.047 2.087 2.126 -----

-----_

12.165 2.205 -----__---_.---____________------..

60 2.362 2.402 2.441 2.480 2.520 2.559 2.598

70 2.756 2.795 2.835 2.874 2.913 2.953 2.992

80 3.150 3.189 3.228 3.268 3.307 3.346 3.386

90 3.543 3.583 3.622 3.661 3.701 3.740 3.780

1 mm = 0.03937 in

7 8 9

0.276 0.315 0.354

0.669 0.709 0.748

1.063 1.102 1.142

1.457 1.496 1.536

1.850 1.890 1.929

2.244 2.283 2.323

2.638 2.677 2.717

3.032 3.071 3.110

3.425 3.465 3.504

3.819 3.858 3.898

00-l 1

CONVERSI ONTABLE

Millimeters to Inches

1 mm =O. O3937i n

1 3 4

0.039 0. 079 0. 118 0. 157 0. 197

0. 433 0. 472 0. 512 0. 551 0. 591

0. 827 0. 866 0. 906 0. 945 0. 984

1. 220 1. 260 1. 299 1. 339 1. 378

1. 614 1. 654 1. 693 1. 732 1. 772

50 1. 969 2. 008

60 2. 362 2. 402

70 2. 756 2. 795

80 3. 150 3. 189

90 3. 543 3. 583

2. 047

2. 441

2. 835

3. 228

3. 622

2. 087 2. 126 2. 165

2. 480 2. 520 2. 559

2. 874 2. 913 2. 953

3. 268 3. 307 3. 346

3. 661 3. 701 3. 740

l-

Ki l ogram 0 1 2 3 4 5

2. 20

24. 25

46. 30

68. 34

90. 39

4. 41 6. 61 8. 82

26. 46 28. 66 30. 86

48. 50 50. 71 51. 91

70. 55 72. 75 74. 96

92. 59 94. 80 97. 00

11. 02

33. 07

55. 12

77. 16

99. 21

112. 44

134. 48

156. 53

178. 57

200. 62

114. 64

136. 69

158. 73

180. 78

202. 83

116. 85

138. 89

160. 94

182. 98

205. 03

I

119. 05

141. 10

163. 14

185. 19

207. 24

121. 25 123. 46 125. 66

143. 30 145. 51 147. 71

165. 35 167. 55 169. 76

187. 39 189. 60 191. 80

209. 44 211. 64 213. 85

/

6 8 9

0. 236 0. 276 0. 315 0. 354

0. 630 0. 669 0. 709 0. 748

1. 024 1. 063 1. 102 1. 142

1. 417 1. 457 1. 496 1. 536

1. 811 1. 850 1. 890 1. 929

2. 205 2. 244 2. 283 2. 323

2. 598 2. 638 2. 677 2. 717

2. 992 3. 032 3. 071 3. 110

3. 386 3. 425 3. 465 3. 504

3. 780 3. 819 3. 858 3. 898

0

0

10

20

30

40

0.394

0. 787

1. 181

1. 575

Kilogram to Pound 1 kg =2. 2046 l b

I

I :

I

6 7 8 9

13. 23

35. 27

57. 32

79. 37

101. 41

15. 43

37. 48

59. 53

81. 57

103. 62

17. 64 19.84

39. 68 41. 89

61. 73 63.93

83. 78 85.98

105. 82 108. 03

127. 87 130. 07

149. 91 152. 12

171. 96 174. 17

194. 01 196. 21

216. 05 218. 26

10 22. 05

20 44. 09

30 66. 14

40 88. 18

50 110. 23

60 132. 28

70 154. 32

80 176. 37

90 198. 42

00- 12

CONVERSI ONTABLE

Liter to U.S. Gallon

1 g =0. 2642 U. S. Gal

t

I

I

I

1 2 3 4 5 6 7 8 9 0

10 2. 642

20 5. 283

30 7. 925

40 10. 567

50 13. 209

60 15. 850

70 18. 492

80 21. 134

90 23. 775

0. 264

2. 906

5. 548

8. 189

10. 831

0. 528

3. 170

5. 812

8. 454

11. 095

13. 473 13. 737

16. 115 16. 379

18. 756 19. 020

21. 398 21. 662

24. 040 24. 304

0.793 1. 057 1. 321 1. 585 1. 849 2. 113 2. 37E

3. 434 3. 698 3. 963 4. 227 4. 491 4. 755 5. 015

6. 076 6. 340 6. 604 6. 869 7. 133 7. 397 7. 661

8. 718 8. 982 9. 246 9. 510 9. 774 10. 039 10. 30:

11. 359 11. 624 11. 888 12. 152 12. 416 12. 680 12. 944

14. 001 14. 265 14. 529 14. 795 15. 058 15. 322 15. 586

16. 643 16. 907 17. 171 17. 435 17. 700 17. 964 18. 228

19. 285 i 9. 549 19. 813 20. 077 20. 341 20. 605 20. 870

21. 926 22. 190 22. 455 22. 719 22. 983 23. 247 23. 511

24. 568 24. 832 25. 096 25. 361 25. 625 25. 889 26. 153

l- L

Liter to U.K. Gallon

1 P=O. 21997 U. K. Gal

c

1 2 3 4 5 6 7 8 9 0

10 2. 200

20 4. 399

30 6. 599

40 8. 799

0. 220 0. 440 0. 660 0. 880 1. 100 1. 320 1. 540 1. 760 1. 980

2. 420 2. 640 2. 860 3. 080 3. 300 3. 520 3. 740 3. 950 4. 179

4. 619 4. 839 5. 059 5. 279 5. 499 5. 719 5. 939 6. 159 6.379

6. 819 7. 039 7. 259 7. 479 7. 969 7. 919 8. 139 8. 359 8.579

9. 019 9. 239 9. 459 9. 679 9. 899 10. 119 10. 339 10. 559 10. 778

50 10. 998 11. 281 11. 438

60 13. 198 13. 418 13. 638

70 15. 398 15. 618 15. 838

80 17. 598 17. 818 18. 037

90 19. 797 20. 017 20. 237

11. 658 11. 878 12. 098 12. 318 12. 528 12. 758 12. 978

13. 858 14. 078 14. 298 14. 518 14. 738 14. 958 15. 178

16. 058 16. 278 16. 498 16. 718 16. 938 17. 158 17. 378

18. 257 18. 477 18. 697 18. 917 19. 137 19. 357 19. 577

20. 457 20. 677 20. 897 21. 117 21. 337 21. 557 21. 777

L

00- 13

CONVERSION TABLE

kgm to ft.lb

1 kg. m=7. 233f t. l b

0 1 2 3 4 5 6 7 8 9

7. 2 14. 5 21. 7 28. 9 36. 2 43. 4 50. 6 57. 9 65. 1

10 72. 3 79. 6 86. 8 94. 0 101. 3 108. 5 115. 7 123. 0 130. 2 137. 4

20 144. 7 151. 9 159. 1 166. 4 173. 6 180. 8 188. 1 195. 3 202. 5 209. 8

30 217. 0 224. 2 231. 5 1 238. 7 245. 9 253. 2 260. 4 267. 6 274. 9 282. 1

40 289. 3 396. 6 303. 8 311. 0 318. 3 325. 5 332. 7 340. 0 347. 2 354. 4

50 361. 7 368. 9 376. 1 383. 4 390. 6 397. 8 405. 1 412. 3 419. 5 426. 8

60 434. 0 441. 2 448. 5 455. 7 462. 9 470. 2 477. 4 484. 6 491. 8 499. 1

70 506. 3 513. 5 520. 8 528. 0 535. 2 542. 5 549. 7 556. 9 564. 2 571. 4

80 578. 6 585. 9 593. 1 600. 3 607. 6 614. 8 622. 0 629. 3 636. 5 643. 7

90 651. 0 658. 2 665. 4 672. 7 679. 9 687. 1 694. 4 701. 6 708. 8 716. 1

100 723. 3 730. 5 737. 8 745. 0 752. 2 759. 5 766. 7 773. 9 781. 2 788. 4

110 795. 6 802. 9 810. 1 817. 3 824. 6 831. 8 839. 0 846. 3 853. 5 860. 7

120 868. 0 875. 2 882. 4 889. 7 896. 9 904. 1 911. 4 918. 6 925. 8 933. 1

130 940. 3 947. 5 954. 8 962. 0 969. 2 976. 5 983. 7 990. 9 998. 2 1005. 4

140 1012. 6 1019. 9 1027. 1 1034. 3 1041. 5 1048. 8 1056. 0 1063. 2 1070. 5 1077. 7

150 1084. 9 1092. 2 1099. 4 1106. 6 1113. 9 1121. 1 1128. 3 1135. 6 1142. 8 1150. 0

160 1157. 3 1164. 5 1171. 7 1179. 0 1186. 2 1193. 4 1200. 7 1207. 9 1215. 1 1222. 4

170 1129. 6 1236. 8 1244. 1 1251. 3 1258. 5 1265. 8 1273. 0 1280. 1 1287. 5 1294. 7

180 1301. 9 1309. 2 1316. 4 1323. 6 1330. 9 1338. 1 1345. 3 1352. 6 1359. 8 1367. 0

190 1374. 3 1381. 5 1388. 7 1396. 0 1403. 2 1410. 4 1417. 7 1424. 9 1432. 1 1439. 4

00- 14

CONVERSI ONTABLE

kg/cm* to lb/in*

1 kg/ cm' = 14. 22331b/ i n2

0 1 2 3 4 5 6 7 8 9

14. 2 28. 4 42. 7 56. 9 71. 1 85. 3 99. 6 113. 8 128. 0

10 142. 2 156. 5 170. 7 184. 9 199. 1 213. 4 227. 6 241. 8 256. 0 270. 2

20 284. 5 298. 7 312. 9 327. 1 341. 4 355. 6 369. 8 384. 0 398. 3 412. 5

30 426. 7 440. 9 455. 1 469. 4 483. 6 497. 8 512. 0 526. 3 540. 5 554. 7

40 568. 9 583. 2 597. 4 611. 6 625. 8 640. 1 654. 3 668. 5 682. 7 696. 9

50 711. 2 725. 4 739. 6 753. 8 768. 1 782. 3 796. 5 810. 7 825. 0 839. 2

60 853. 4 867. 6 881. 8 896. 1 910. 3 924. 5 938. 7 953. 0 967. 2 981. 4

70 995. 6 1010 1024 1038 1053 1067 1081 1095 1109 1124

80 1138 1152 1166 1181 1195 1209 1223 1237 1252 1266

90 1280 1294 1309 1323 1337 1351 1365 1380 1394 1408

100 1422 1437 1451 1465 1479 1493 1508 1522 1536 1550

110 1565 1579 1593 1607 1621 1636 1650 1664 1678 1693

120 1707 1721 1735 1749 1764 1778 1792 1806 1821 1835

130 1849 2863 1877 1892 1906 1920 1934 1949 1963 1977

140 1991 2005 2020 2034 2048 2062 2077 2091 2105 2119

150 2134 2148 2162 2176 2190 2205 2219 2233 2247 2262

160 2276 2290 2304 2318 2333 2347 2361 2375 2389 2404

170 2418 2432 2446 2460 2475 2489 2503 2518 2532 2546

180 2560 2574 2589 2603 2617 2631 2646 2660 2674 2688

190 2702 2717 2731 2745 2759 2773 2788 2802 2816 2830

200 2845 2859 2873 2887 2901 2916 2930 2944 2958 2973

210 2987 3001 3015 3030 3044 3058 3072 3086 3101 3115

220 3129 3143 3158 3172 3186 3200 3124 3229 3243 3257

230 3271 3286 3300 3314 3328 3343 3357 3371 3385 3399

240 3414 3428 3442 3456 3470 3485 3499 3513 3527 3542

00- l 5

CONVERSION TABLE

Temperature

Fahrenheit-Centigrade Conversion. -A simple way to convert a Fahrenheit temperture reading into a Centigrade

temperature reading or vice versa is to enter the accompanying table in the center or boldface column of figures.

These figures refer to the temperature in either Fahrenheit or Centigrade degrees.

If it is desired to convert from Fahrenheit to Centigrade degrees,consider the center column as a table of Fahrenheit

temperatures and read the corresponding Centigrade temperature in the column at the left.

If it isdesired to convert from Centigrade to Fahrenheit degrees, consider the center column as a table of Centigrade

values, and read the corresponding Fahrenheit temperature on the right.

OC OF OC OF OC OF OC "F

40. 4 - 40 - 40. 0 - 11. 7 11 51. 8 7. 8 46 114. 8 27. 2 81 117. 8

- 37. 2 - 35 - 31. 0 - 11. 1 12 53. 6 8. 3 47 116. 6 27. 8 a2 179. 6

- 34. 4 - 30 - 22. 0 - 10. 6 13 55. 4 8. 9 48 I l a. 4 28. 3 83 181. 4

- 31. 7 - 25 - 13. 0 - 10. 0 14 57. 2 9. 4 49 120. 2 28. 9 84 183. 2

- 28. 9 - 20 - 4. 0 - 9. 4 15 59. 0 10. 0 50 122. 0 29. 4 85 185. 0

- 28. 3 - 19 - 2. 2 - 8. 9 16 60. 8 10. 6 51 123. 8 30. 0 a6 186. 8

- 27. 8 - 18 - 0. 4 - 8. 3 17 62.6 11. 1 52 125. 6 30. 6 87 188. 6

- 27. 2 - 17 1. 4 -7.8 18 64. 4 11. 7 53 127. 4 31. 1 88 190. 4

- 26. 7 - 16 3. 2 - 7. 2 19 66. 2 12. 2 54 129. 2 31. 7 89 192. 2

- 26. 1 - 15 5. 0 - 6. 7 20 68. 0 12. 8 55 131. 0 32. 2 90 194. 0

- 25. 6 - 14 6. 8 - 6. 1 21 69. 8 13. 3 56 132. 8 32. 8 91 195. 8

- 25. 0 - 13 8. 6 - 5. 6 22 71. 6 13. 9 57 134. 6 33. 3 92 197. 6

- 24. 4 - 12 10. 4 - 5. 0 23 73. 4 14. 4 58 136. 4 33. 9 93 199. 4

- 23. 9 - 11 12. 2 - 4. 4 24 75. 2 15. 0 59 138. 2 34. 4 94 201. 2

- 23. 3 - 10 14. 0 - 3. 9 25 77. 0 15. 6 60 140. 0 35. 0 95 203. 0

- 22. 8 - 9 15. 8 - 3. 3 26 78. 8 16. 1 61 141. 8 35. 6 96 204. 8

- 22. 2 - 8 17. 6 - 2. 8 27 80. 6 16. 7 62 143. 6 36. 1 97 206. 6

- 21. 7 -7 19.4 - 2. 2 28 82. 4 17. 2 63 145. 4 36. 7 98 208. 4

- 21. 1 - 6 21. 2 - 1. 7 29 84. 2 17. 8 64 147. 2 37. 2 99 210. 2

- 20. 6 - 5 23. 0 - 1. 1 30 86. 0 18. 3 65 149. 0 37. 8 100 212. 0

- 20. 0 - 4 24. 8 - 0. 6 31 87. 8 18. 9 66 150. 8 40. 6 105 221. 0

- 19. 4 - 3 26. 6 0 32 89. 6 19. 4 67 152. 6 43. 3 110 230. 0

- 18. 9 - 2 28. 4 0. 6 33 91. 4 20. 0 68 154. 4 46. 1 115 239. 0

- 18. 3 - 1 30. 2 1. 1 34 93. 2 20. 6 69 156. 2 48. 9 120 248. 0

- 17. 8 0 32. 0 1. 7 35 95. 0 21. 1 70 158. 0 51. 7 125 257. 0

- 17. 2 1 33. 8 2. 2 36 96. 8 21. 7 71 159. 8 54. 4 130 266. 0

- 16. 7 2 35. 6 2. 8 37 98. 6 22. 2 72 161. 6 57. 2 135 275. 0

- 16. 1 3 37. 4 3. 3 38 100. 4 22. 8 73 163. 4 60. 0 140 284. 0

- 15. 6 4 39. 2 3. 9 39 102. 2 23. 3 74 165. 2 62. 7 145 293. 0

- 15. 0 5 41. 0 4. 4 40 104. 0 23. 9 75 167. 0 65. 6 150 302. 0

- 14. 4 6 42. 8 5. 0 41 105. 8 24. 4 76 168. 8 68. 3 155 311. 0

- 13. 9 7 44. 6 5. 6 42 107. 6 25. 0 77 170. 6 71. 1 160 320. 0

- 13. 3 a 46. 4 6. 1 43 109. 4 25. 6 78 172. 4 73. 9 165 329. 0

- 12. 8 9 48. 2 6. 7 44 111. 2 26. 1 79 174. 2 76. 7 170 338. 0

- 12. 2 10 50. 0 7. 2 45 113. 0 26. 7 80 176. 0 79. 4 175 34z. o

00- 16

WEIGHT TABLE

A

This weight table is a guide for use when transporting or handling components.

PC200,2OOLC-5

Machine Model

Serial Numbers

Engine assembly

l Engine

l Damper

l Hydraulic pump

Radiator and oil cooler assembly

Hydraulic tank assembly

(without hydraulic oil)

Fuel tank (without fuel)

Revolving frame

Operators cab

Operators seat

Counterweight

Swing machinery

Control valve assembly

Swing motor assembly

Travel motor assembly

Center swivel joint

Track frame assembly

l Track frame

l Swing circle assembly

l Idler

l Idler cushion

0 Carrier roller

l Track roller

l Final drive

PC200-5

45001 and up

647

432

20

195

91

Unit: kg

PC2OOLC-5

45001andup

647

432

20

195

91

194 194

98 98

1,555 1,555

238 238

31.7 31.7

3,300 3,300

258 258

171 171

50 50

137x2 137x2

43 43

4,391 4,604

2,362 2,390

270 270

140x2 140x2

135x2 135x2

21 x4 21 x4

37x14 37x18

322x2 322x2

Unit: kg

Machine Model PC200-5 I PC2OOLC-5

Serial Numbers

I

45001 and up

I

45001 and up

Track shoe assembly

l Triple-grouser shoe (500 mm)

I 1

I

2,360

I

-

l Triple-grouser shoe (600 mm)

I

2,620

I

2,850

l Flat shoe (610 mm)

2,870 3,120

3,130 3,400

3,380 3,680

3,280

-

l Triple-grouser shoe (700 mm)

l Triple-grouser shoe (800 mm)

l Triple-grouser shoe (900 mm)

l Swamp shoe (860 mm)

2,900

-

Boom assembly

Arm assembly 628

Bucket assembly

I

646

I

646

Boom cylinder assembly

I

187x2

I

187x2

Arm cylinder assembly

I

251

I

251

Bucket cylinder assembly

Link (large) assembly

I

153

I

153

I

80

I

80

Link (small) assembly

I

22 x 2

I

22 x 2

Boom pin

Arm pin

Bucket pin

Link pin

43+10x2 43+10x2

+25+10+20 +25+10+20

10x2 10x2

20 x 2 20 x 2

18x2 18x 2

PC200,2OOLC-5 MIGHTY

Machine Model

Serial Numbers

Engine assembly

l Engine

l Damper

l Hydraulic pump

Radiator and oil cooler assembly

Hydraulic tank assembly

(without hydraulic oil)

Fuel tank (without fuel)

PC200-5 MIGHTY PC2OOLC-5 MIGHTY

58019 and up 58019 and up

647 647

432 432

20 20

195 195

105 105

194 194

I

98

I

98

Revolving frame 1,923 1,923

Operators cab 238 238

Operators seat 31.7 31.7

Counterweight

Swing machinery

Control valve assembly

Swing motor assembly

Travel motor assembly

Center swivel joint

I

4,300

I

4,300

I

258

I

258

I

171

I

171

I

50

I

50

I

137 x 2

I

137x2

I

43

I

43

Track frame assembly 4, 391

l Track frame 2,362

l Swing circle assembly 270

l Idler 140x2

l Idler cushion 135x2

l Carrier roller 21 x4

l Track roller 37x 14

l Final drive 322 x 2

4,604

2,390

270

140x2

135x2

21 x4

37x18

322 x 2

Unit: kg

Machine Model 1 PC200-5 MIGHTY 1 PC2OOLC-5 MIGHTY

Serial Numbers

I

58019 and up

I

58019 and up

Track shoe assembly

l Triple-grouser shoe (500 mm)

l Triple-grouser shoe (600 mm)

l Rubber shoe (600 mm)

2,360

-

2,620 2,850

2,940

Boom assembly 1,362 1,362

Arm assembly 875 875

Bucket assembly

Boom cylinder assembly

Arm cylinder assembly

Bucket cylinder assembly

Link (large) assembly

Link (small) assembly

710 710

187x2 187x2

251 251

182 182

80 80

I

30 x 2

I

30 x 2

Boom pin

43+10x2 43+10x2

+25+ IO+20 +25+10+20

Arm pin

10x2

Bucket pin 20 x 2 20 x 2

Link pin 18x2 18 x 2

0k20

PC220,22OLC-5

Unit: kg

Machine Model PC220-5 PC22OLC-5

Serial Numbers 35001 and up 35001 and up

Engine assy 647 647

l Engine 432 432

l Damper 20 20

l Hydraulic pump 195 195

Radiator and oil cooler assembly 101

Hydraulic tank assembly

(without hydraulic oil)

Fuel tank assembly (without fuel) 98 98

Revolving frame 1,840 1,840

Operators cab 238 238

Operators seat 31.7 31.7

Counterweight 4,300 4,300

Swing machinery

I

258

I

258

Control valve assembly

Swing motor assembly

Travel motor assembly

Center swivel joint

50 50

137x2 137x2

Track frame assembly

l Track frame

0 Swing circle

l Idler

l Idler cushion

0 Carrier roller

l Track roller

l Final drive

4,920 5,565

2,824 3,275

270 270

140x2 140x2

135x2 135x2

21 x4 21 x4

37x16 37x20

322x2

I

322x2

Unit: kg

Machine Model PC220-5 PC22OLC-5

Serial Numbers

I

35001 and up

I

35001 and up

Track shoe assembly

l Triple-grouser shoe (500 mm)

l Triple-grouser shoe (600 mm)

l Triple-grouser shoe (700 mm)

l Triple-grouser shoe (800 mm)

2,460

-

2,730 2,960

3,000 3,250

3,260 3,540

Boom assembly

Arm assembly

Bucket assembly

Boom cylinder assembly

718 718

774 774

214x2 214x2

Arm cylinder assembly

I

297 297

Bucket cylinder assembly

Link (large) assembly

Link (small) assembly

182 182 ::

g

80 80 z

22 x 2 22 x 2

Boom pin

51+10x2 51+10x2

+30+10+32 +30-I-10+32

Arm pin

I

10x2

I

10x2

Bucket pin 20 x 2 20 x 2

Link pin 18x 2 18x2

0022

LIST OF LUBRICANT AND WATER

PC200,2OOLC-5 Serial No: 45001 - 58018

PC220,22OLC-5 Serial No: 35001 - 36613

KIND OF

I

. _... -._.

RESERVOIR

FLUID

14 32

- 1l - l n

I ..~ -- I AMBIENT TEMPERATURE

CAPACITY ( Q )

50 68 86 F

10 20 30C

Specified Refill

Engine oil pan

Swing machinery case

Final drive case (each)

Damper case

Engine oil

Track roller (1 piece)

Idler (1 piece)

18.5 17.5

11.3 10

,:..:: . . ,: :.. ., . . ., . . . : 7.6 7.6

I 1.0

: :

..:. :

I

230

: .:.i:::.:~.:~:.:.:::jl:~~~:~::~...::~.,~ :, :, :I : :: ::: .A: . . . . . -&

170

j- ,: . .: . . ;.:,,, , 5w_4: _;,:y+ ::,;;_:: :; j :.

I , I I I

0.19 - 0.21 0.19 - 0.21

Gear oil 0.23 0.25 _ 0.23 _ 0.25

0.07 - 0.08 0.07 - 0.08

Fuel tank Diesel fuel

:: 3% ;:::.

310

-

. . . .

.;.. :... ,:.,

,S, ,,.,, . . . . ..j.. i > : ASTM D975 No. 2. : ~,, :,,,

I I I I

z

Cooling system Water Add antifreeze 19.7

-

0 _

2 x ASTM D975 No. 1

NOTE:

(I) When fuel sulphur content is less than 0.5%, (2)

change oil in the oil pan every periodic main-

tenance hours described in this manual.

Change oil according to the following table if

fuel sulphur content is above 0.5%.

I (3)

Fuel sulphur content

I

Change interval of oil in

engine oil pan

When starting the engine in an atmospheric

temperature of lower than OC, be sure to

use engine oil of SAEI OW, SAEI OW-30 and

SAE15W-40 even though an atmospheric

temperature goes up to 10C more or less in

the day time.

Use API classification CD as engine oil and if

API classification CC, reduce the engine oil

change interval to half.

ASTM: American Society of Testing and Material

SAE: Society of Automotive Engineers

Specified capacity: Total amount of oil including oil for components and oil in piping

Refill capacity: Amount of oil needed to refill system during normal inspection and maintenance.

o623

PC200,2OOLC-5 Serial No: 58019 and up

PC200,22OLC-5 MIGHTY

PC220,22OLC-5 Serial No: 36614 and up

RESERVOIR

Engine oil pan

Swing machinery cast

Final drive case (each:

Damper case

Hydraulic system

Carrier roller (1 piece)

Track roller (1 piece)

Idler (1 piece)

Fuel tank

Cooling system

KIND OF

FLUID

AMBIENT TEMPERATURE

CAPACITY ( Q )

14 32 50 68 86 F

-10 0 IO 20 3oc

I-r

Specified Refill

Water

., ., . . . . . .

1 I I I

Add antifreeze

19.7

[20.2]

% ASTM D975 No. 1

NOTE:

(I) When fuel sulphur content is less than 0.5%,

change oil in the oil pan every periodic main-

tenance hours described in this manual.

Change oil according to the following table if

fuel sulphur content is above 0.5%.

Fuel sulphur content

Change interval of oil in

engine oil pan

ASTM: American Society of Testing and Material

SAE: Society of Automotive Engineers

(2)

(3)

18.5

9.3

7.6

t

t

I.1 9 - 0.21

8.23 - 0.25

.07 - 0.08

-

-

:

[ 1: PC200, 2OOLC-5 MIGHTY s

0

When starting the engine in an atmospheric

temperature of lower than 0C. be sure to

use engine oil of SAEI OW. SAEI OW-30 and

SAEl5W-40 even though an atmospheric

temperature goes up to 10C more or less in

the day time.

Use API classification CD as engine oil and if

API classification CC, reduce the engine oil

change interval to half.

Specified capacity: Total amount of oil including oil for components and oil in piping

Refill capacity: Amount of oil needed to refill system during normal inspection and maintenance.

0024

10 STRUCTURE AND FUNCTION

Engine related parts and

engine mount ......................... lo- 2

Radiator, oil cooler and after-cooler ..... IO- 3

Fuel tank and piping ...................... IO- 4

Power train .............................. IO- 4-2

Final drive ................................. IO- 5

Swing circle ............................... IO- 7

Swing machinery ......................... IO- 8

Track frame and recoil spring ............ IO- 9

Idler ........................................ IO-I 0

Track roller, carrier roller ................. 1 O-l 1

Track shoe ................................. 1 O-l 2

Hydraulic piping ........................... IO-15

Hydraulic circuit diagram ................. IO-I 6

Hydraulic tank ............................. IO-20

OLSS (Open center Load Sensing

System) .............................. 10-20-I

Hydraulic pump ........................... lo-21

Control valve .............................. lo-40

Swing motor .............................. 1 O-50

Center swivel joint ........................ IO-54

Travel motor .............................. IO-56

Valve control .............................. IO-65

PPC valve .................................. 1 O-66

Accumulator ............................... IO-72

Safety lock valve .......................... 1 O-73

Solenoid valve assembly .................. 1 O-74

Shuttle valve ............................ 1 O-77-4

Boom holding valve ...................... 1 O-78

Hydraulic cylinder ......................... IO-82

Electrical wiring diagram ................. IO-84

Electrical circuit diagram ................. 1 O-86

Engine control system .................. 1 O-89-6

Governor motor linkage .................. IO-90

PEMC system ............................. 1 O-98

EMACC ................................... 1 O-l 25

10- l

8

Section A - A

Section B - B

I

205FO5005

Section C-C Section D - D Section E-E

1. Drive plate 7. Damper assembly

2. Torsion spring 8. Air cleaner

3. Stopper pin 9. Muffler

4. Friction plate l 10. Intake connector

5. Cone spring 11. Front engine mount

6. Friction washer 12. Rear engine mount

Out l i ne

l The damper assembly is a wet type.

Oil capacity: 1.80 Q

1 o-2

Gc

RADIATOR OIL COOLER AND AFTER-COOLER

PC200,2OOLC-5

PC220,22OLC-5

* The after-cooler attached only PC220,22OLC-5

ZI,

4 5 6 7 8 9

3

2

View Z

1. Fan shroud

2. Fan

3. Radiator outlet hose

4. Radiator inlet hose

5. Radiator

6. Radiator cap

7. Oil cooler

8. After -cooler

9. Oil cooler inlet hose

IO. Oil cooler outlet hose

1 1. Net

12. After-cooler inlet

13. After-cooler outlet

14. Sub-tank

205FO5006

SPECIFICATIONS

Radiator

PC200-5 Serial No: 45001 - 51419

PC220-5 Serial No: 35001 - 35928

CG-2

PC200-5 Serial No: 51420 and up

PC220-5 Serial No:,35929 and up

cwx-4

Oil cooler: SF-2

After-cooler: 6 rows

PC200,2OOLC-5 MIGHTY

View 2

7. Oil cooler 1. Fan shroud

2. Fan

3. Radiator outlet hose

4. Radiator inlet hose

5. Radiator

6. Radiator cap

8 7 8

205FO5604

SPECIFICATIONS

8. Oil cooler inlet hose

9. Oil cooler outlet hose

10. Net

11. Sub-tank

Radiator: CWX-4

Oil cooler: SF-3

FUEL TANK AND PIPING

Section A-A

205FO5007

1. Drain valve

2. Fuel tank

3. Filler cap (with lock device)

4. Sight gauge

5. Fuel level sensor

1 o-4

DIAGRAM OF FUEL SYSTEM (with automatic air bleeding mechanism)

1. Fuel tank

2. Gauze filter

3. Priming pump

4. Feed pump

5. Fuel filter

6. Air bleed plug

7. Fuel injection pump

8. Fuel injection nozzle

9. Over-flow valve

6206F120- 1

Automatic bleeding of the fuel system

An overflow valve has been added to the

fuel injection pump to bleed any air that

has entered the fuel supply system during

replacement of the fuel filter, etc.

When cranking is carried out by the starting

motor, the feed pump starts to send fuel

under pressure. Because of this, the fuel

containing air is drained from the overflow

valve in the injection pump, and returns to

the fuel tank.

POWER TRAIN

1. Idler 7. Hydraulic pump

2. Center swivel joint 8. Swing brake solenoid valve

3. Control valve assembly 9. Travel speed solenoid valve

4. Final drive IO. Swing motor

5. Travel motor 1 1. Swing machinery

6. Engine 12. Swing circle

205FO5008

FINAL DRIVE

PC200,2OOLC-5 Serial No: 45001 - 58018

PC220,22OLC-5 Serial No: 35001 - 36613

1. Oil level plug

2. Drain plug

3. No. 1 sun (I 8 teeth) gear

4. No. 2 sun (I 2 teeth) gear

5. No. 2 planetary carrier

6. Cover

7. No. 1 planetary carrier

8. Sprocket

9. Floating seal

10. Travel motor

ll.Hub

12. No.1 planet gear (31 teeth)

13. Ring gear (81 teeth)

14. No. 2 planet (34 teeth) gear

SPECIFICATIONS

Reduction ratio:

81 +I2

-

(

x 81 i-18

+1 =

12

)(

18

1

-41.625

14 13 12 11

205FO5009

PC200,2OOLC-5 Serial No: 58019 and up

PC200,2OOLC-5 MIGHTY

PC220,22OLC-5 Serial No: 36614 and up

- 10

1. Oil level plug

2. Drain plug

3. No. 1 sun (I 8 teeth) gear

4. No. 2 sun (I 2 teeth) gear

5. No. 2 planetary carrier

6. Cover

7. No. 1 planetary carrier

8. Sprocket

9. Floating seal

10. Travel motor

ll.Hub

12. No.1 planet gear (31 teeth)

13. Ring gear (81 teeth)

14. No. 2 planet (34 teeth) gear

SPECIFICATIONS

Reduction ratio:

t

81 +I2

)i

81

-

+ 18 +1 =

12 18

)

-41.625

Section A - A

205FO5806

SWING CIRCLE

b

Section B - B

/

1. Swing circle outer race

2. Ball bearing

3. Swing circle inner race (I 10 teeth)

a. Inner race soft zone S

b. Outer race soft zone S

Section A- A

i

SPECIFICATIONS

110

Reduction ratio: - = 7.333

15

Grease volume: 21 Q (G2-LI)

205FO5010

10- 7

SWING MACHINERY

1. Swing pinion (I 5 teeth)

2. Cover

3. Cage

4. Planetary carrier

5. Ring gear (63 teeth)

6. Bearing holder

7. Drive gear (15 teeth)

8. Swing motor

9. Bearing holder

10. Breather

1 1. Oil level gauge

12. Cover

13. Driven gear (76 teeth)

14. Planetary gear (24 teeth)

15. Sun (I 5 teeth) gear

16. Drain plug

SPECIFICATIONS

Reduction ratio: gx(63 A15) =

6

26.347

Section B - B

Section C - C

Section A - A

205FO5011

TRACK FRAME AND RECOIL SPRING

1

\

_.--A _

1. Idler

Depending on the model, the dimensions and

2. Track frame

number of track rollers is different, but the

3. Carrier roller

basic structure is the same. (The diagram

4. Final drive

shows PC2001

5. Track roller

Sr Number of track rollers

6. Track

PC200: 7 (each side)

7. Center guard

PC200LC: 9 (each side)

8. Recoil spring

PC220: 8 (each side)

9. Front guard

PC22OLC: 10 (each side)

9 8 7 6 5

205FO5012

1 o-9

IDLER

205FO5013

1. Lubricating plug

2. support

3. Idler

4. Floating seal

5. Idler shaft

6. Bushing

10- 10

TRACK ROLLER

205F2452

CARRIER ROLLER

1. Lubricating plug

2. Collar

3. Floating seal

4. Track roller

5. Bushing

6. Shaft

1. Shaft

2. Collar

3. Floating seal

4. Carrier roller

5. Ring

6. Cover

7. Lubricating plug

205FO5014

10- l 1

TRACK SHOE

1 2 3 4 5 6 7 8

1. Link

2. Shoe

3. Regular pin

4. Regular bushing

5. Regular dust seal

6. Master bushing

7. Master dust seal

8. Master pin

9. Shoe nut

10. Shoe bolt

205FO5015

Standard shoe specifications

PC200 600 mm triple-shoe

Link pitch: 190 mm

Number of shoe: 90

PC220 600 mm triple-shoe

Link pitch: 190 mm

Number of shoe: 94

PC2OOLC 700 mm triple-shoe

Link pitch: 190 mm

Number of shoe: 98

PC22OLC 700 mm triple-shoe

Link pitch: 190 mm

Number of shoe: 102

10- 12

SELECTION OF TRACK SHOE

l Select the most suitable track shoe f;om the following table.

0

z

2

PC220 PC22OLC

Specification

Cate-

Specification

Cate-

gory gory

500 mm

A

600 mm

triple shoe triple shoe

A

600 mm

A

700 mm

triple shoe triple shoe

B

700 mm

B

800 mm

triple shoe triple shoe

C

800 mm

I 1

C

-

triple shoe

610 mm

flat shoe

I I

D

-

600 mm

I I

D

-

rubber shoe

1 -

. Category

Cate-

gory

A

B

t

C

Use Precautions when using

Rocky ground, l Travel in Lo when traveling on rough ground with obstacles

normal river soil such as large boulders and fallen trees.

Normal soil,

soft land

Extremely short

ground

(swampy ground)

D

t

Paved surface

. Cannot be used on rough ground where there are large

obstacles such as boulders and fallen trees.

l Travel in Hi speed only on flat ground, and when it is

impossible to avoid traveling over obstacles,

lower the travel speed to approx. half of Lo. speed.

. Use only for ground where A and B sink and

are impossible to use.

l Cannot be used on rough ground where there are large

obstacles such as boulders and fallen trees.

l Travel in Hi speed only on flat ground, and when

it is impossible to avoid traveling over

obstacles, lower the travel speed to approx.

half of Lo speed.

l The shoe are flat, so they have low gradeability.

* Categories B and C are wide shoe, so

there are restrictions on their use. Therefore,

before using, check the restrictions and con-

sider carefully the conditions of use before

recommending a suitable shoe width. If

necessary, give the customer guidance in

their use.

* When selecting the shoe width, select the

narrowest shoe possible within the range

that will give no problem with flotation and

ground pressure.

If a wider shoe than necessary is used, there

will be a large load on the shoe, and this

may lead to bending of the shoe, cracking

of the links, breakage of the pins, loosening

of the shoe bolts, or other problems.

8

8

s1

1024

ADDITIONAL CIRCUIT

Circuit for 1 -pump - 1 -actuator (1 PI A)

Control valve

NCBF

--

NCALI _ : NCBL

I

.-

I.H. travel

El

Arm-Lo

I

Arm-Hi

+

AI R

I

Service 1

BAR

Boom-Lo

Boom-Hi

d=

I I

Arm. swing

PPC shuttle valve

i 1

I 1

j /

I I

1 I

Swing

1

I I

tiain relief valve

I

i

4

Travel shuttle valve

I

Main relief valve

-_ __

PL PF

P3

1

I

I

I

Shuttle valve

---------- A

3-way valve

j

I J

205FO5810

* 210 kg/cm2, 250 kg/cm2, 280 kg/cm2

Set (select) the set pressure of the safety valve to match the actuator.

Circuit for 2-pump-l-actuator (2PlA)

Control valve

Ncsr

r-

r

_~NCAR NCAL 1

XH. travel

El

L\rm-Lo

I

Gervice 1

=,

A I

I

I

.---A

Boom-Hi

Swing

I

4rm-Hi

I

A3u

I

BAR

Bucket

oom-Lo

El

.H. travel

I

Main relief valve

Arm. swing

PPC shuttle valve

Main relief valve

PF

l-pump. Z-pump

3-way valve

A I

d\ A

I

I

I

1 To accumulator, solenoid

valve assy

3-way

valve

>

1

1 205FO58 I2

+ 210 kg/cm2, 250 kg/cm2, 280 kg/cm2

Set (select) the set pressure of the safety valve to match the actuator.

10- &9- l

HYDRAULIC TANK

1. Bypass valve

2. Filter element

3. Bypass filter

4. Filter check valve

5. Filler cap

6. Lift check valve

7. Sight gauge

8. Strainer

9. Hydraulic tank

10. Filter case

1 1. Hydraulic oil level sensor

Section B-B

!

- 11

Section A- A

Section C - C

Section D-D

205FO5016A

SPECIFICATIONS

Tank capacity: 240 Q

Oil amount: 150 Q

Pressure valve

Relief set pressure: 0.17 kO.007 kg/cm2

Suction set pressure: 0 - 0.046 kg/cm2

Bypass valve set pressure: 1. 05 *0.2kg/cm2

Filter check valve set pressure:

1.82 *0.2kg/cm2

Lift check valve set pressure: 4.2kg/cm2

1 O-20

OLSS (Open center Load Sensing System)

Motor

Cylinder

I I I

F205C5006-1

OLSS (Open center Load Sensing System) is

an energy-saved system to reduce the fuel

consumption by means of controlling the

swash plate angle (delivery) of the variable-

displacement swash-plate type piston pump.

Therefore this system acts to reduce the hy-

draulic loss during operation, to increase the

fine control and to control the pump delivery.

o-~-l

1. EFFECTIVE USE OF ENGINE

HORSEPOWER

In H mode, the set speed of the engine

and the actual speed of the engine are

always detected. As a result, even if the

load changes during operation, the dis-

charge amount (swash plate angle) of the

pump is controlled so that the load on

the engine (engine speed) is always main-

tained constant, thus ensuring effective

use of the engine horsepower.

(Engine speed, oil pressure sensing

control)

2. CUT-OFF CONTROL

l The cut-off control is a function to re-

duce relief loss during operations.

If the load increases, the discharge

pressure of the main pump is in-

creased; if the load comes close to

the relief pressure, the discharge vo-

lume is decreased.

l This function is carried out with the

CO valve.

For details of the operation of the CO

valve, see HYDRAULIC PUMP.

3. FLOW CONTROL

PNC (pump neutral control)

l When the control levers are at neu-

tral, the pump discharge volume is

kept to the minimum to reduce the

wasteful flow of oil when the control

valve is at neutral.

PFC (pump fine control)

l When the lever is operated, the ne-

cesary flow is ordered to the pump

based on the flow command that

corresponds with the lever travel.

This reduces the wasteful flow of oil

that occurs during fine control.

l At the same time, by increasing the

pump discharge pressure to the opti-

mum value according to the lever tra-

vel, the fine control performance is

improved.

l This function is carried out with the

NC valve and jet sensor.

For details of the operation of the NC

valve and jet sensor, see HYDRAULIC

PUMP.

Main pump delivery

_

Pump delivery volume Q

205F05121A

(Note) H.0: Heavy duty operation mode,

G.0: General operation mode.

F.0: Finishing operation mode,

L.0: Lifting operation mode

Loss when there is no cut-off

Pump discharge volume (P/min.)

F205C5008

Lever travel (mm)

205FO5145

o-;o-2

HYDRAULIC PUMP

a

e

View Z

205FO5017

a. Jet sensor output pressure Pt IN port

b. Jet sensor output pressure Pd IN port

c. Jet sensor output pressure Pt IN port

d. Jet sensor output pressure Pd IN port

e. CO cancel pressure PSOR IN port

f. CO cancel pressure PSOF IN port

1. Front servo valve

2. Front CO l NC valve

3. Rear CO l NC valve

4. Rear servo valve

5. TVC valve

6. Charging pump

7. Rear main pump

8. Front main pump

1. FRONT MAIN PUMP AND REAR MAIN PUMP

(HPVOSO +0901

a

r? \

a.

b.

;:

e.

View Z

View X

Front main pump discharge PPI port

Front main pump discharge PP~ port

Suction PS port

Servo valve output pressure kls port

Charging pump pressure PCI port

b

9.

h.

i.

j.

k.

f. Front main pump output pressure Pal port I.

hij kl

View Y

205FO5018

Servo valve output pressure Pcin port

Servo valve output pressure Pc2n port

Front main pump output pressure PPI port

Rear main pump output pressure PP~ port

Charging pump pressure Pc 2 port

Servo valve output pressure Pcse port

1 o-22

cc

1. Front drive shaft

2. Front cradle

3. Front pump case

4. Front rocker cam

5. Front piston

6. Front cylinder

7. Front valve plate

8. Front end cap

9. Impeller

10. Coupling

11. Rear end cap

12. Rear valve plate

13. Rear cylinder

14. Rear piston

15. Rear rocker cam

16. Rear pump case

17. Rear cradle

18. Rear drive shaft

19. Servo piston

Section C - C

205FO5019

1 O-23

2. SERVO VALVE

* The drawing shows the servo valve for

front main pump

b c d

\ i

Section A-A

Section B-B

Section D-D Section E - E

a. Servo actuator port

b. Servo actuator port

c. Servo actuator port

d. NC valve output pressure Pi pick-up port

e. Servo valve drain Pdr OUT port

f. Rear main pump output pressure Pa2 IN port

g. Front main pump output pressure Pal IN

port

Section C -C

Section F - F Section G-G

205F65020

h. CO l NC valve drain Pdr IN port

i. CO * NC valve output pressure Pi IN port

j. Charging pump pressure Ppo OUT port

k. Rear main pump output pressure PP~ OUT

POfl

I. Front main pump output pressure PPI OUT

port

1. Lock nut 8. Pin

2. Cover 9. Control piston

3. Plug 10. Lock nut

4. Spring 1 1. Plug

5. Body 12. Lock nut

6. Spring 13. Cover

7. Arm 14. Sleeve

li 16

Section A- A

FUNCTION

Discharge volumes 01 and Q2 of main pumps

PPI and PP~ are controlled individually by

their own servo valve.

The relationship between pump discharge vo-

lume Q and input signal Pi sent to the

servo valve is as shown in the graph on the

right. Q changes in proportion to Pi.

205FO5021

15. Guide spool

16. Spring

17. Plug

18. Cover

19. Lock nut

(cc/rev) ,,Y

CO * NC valve output pressure Pi (kg/cm*)

205FO5022

OPERATION

1) Operation for increasing pump discharges (rocker cam angle changes to the large)

b Pi

NC valve

i

CO valve

TVC valve

Charging pump pressure PC is sent to port

a.

Signal pressure Pi from the NC valve is

sent from port b to chamber c.

As signal pressure Pi rises, the pressure in

chamber C pushes control piston (9) to

the left in the direction of the arrow. The

piston stops in a position where it is

balanced with the force of springs (4) and

(6).

At the same time, arm (7) uses servo piston

(20) as a fulcrum, moves to the left in the

same way as control piston (91, and while

fluctuating, moves guide spool (15) to the

left.

205F05023A

l The movement of guide spool (15) closes

port a and port d, and connects port d with