Professional Documents

Culture Documents

BCS Mechanical Question 1st Paper

Uploaded by

palash_mondalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BCS Mechanical Question 1st Paper

Uploaded by

palash_mondalCopyright:

Available Formats

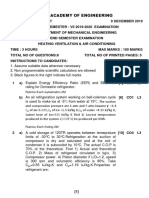

MECHANICAL ENGINEERING 1

st

Paper

BCS QUESTION ANALYSIS (27-30, 33)

No THERMODYNAMICS BCS

1. Explain the three laws of thermodynamics. 30

2.

What do you understand by Enthalpy? Show that for a constant pressure

process, the heat supplied to the gas is equal to the change of enthalpy.

30

3.

Write short notes on-

(i) Kirchhoffs Identity

(ii) Rankine Cycle

(iii)Zeroth Law of Thermodynamics

30

4.

Define second law of thermodynamics and show that no heat engine can be

more efficient than a reversible heat engine working between the same

temperature limits.

29

5. What is Rankine-cycle? Where it is used and why? Explain. 29, 28

No

BOILER

BCS

1. Write the differences between boiler mountings and accessories. 33

2.

In a boiler feed water supplied per hour is 205kg, while coal fired per hour is

23 kg. The net enthalpy rise per kg of water is 145 KJ. If the calorific value

of the coal is 2050 KJ/kg,

Calculate the boiler efficiency. (assume any other data if necessary)

33

3.

Discuss briefly, the working of an Economizer in a Boiler Plant giving a

neat sketch.

30, 27

4.

What is meant by Boiler Mountings? What are their functions?

30, 27

5.

The following observations were made in a boiler trail:

Coal used 250kg of calorific value 29,800 kj/kg, dryness fraction of steam

0.95, feed water temperature 34 C, water evaporated 2000 kg and steam

pressure of 11.5 bar.

Calculate the equivalent evaporation from and 100 C per kg of coal and

the efficiency of the boiler.

30

6.

Define steam boiler. Discuss the advantages of water tube boiler over fire

tube boiler.

29

7.

What is the difference between fire tube boiler and water tube boiler?

28, 27

8.

Describe with sketch the working procedure of any one of the fire tube

boiler.

28

9.

Describe in short:

(i) Fusible plug

(ii) Water level indicator

(iii)Super heater

28

10.

How steam generators are classified?

27

6.

Illustrate the following thermodynamic processes with Example:

(i) Isothermal

(ii) Adiabatic

(iii)Polytropic

29

7.

Define first law of thermodynamics and prove that heat and work are

interchangeable.

28

8. Define Heat Engine and Heat Pump. 28

9.

Explain the followings-

(i) Perfect gas

(ii) Combustion

(iii)Heat Exchanges

28

10. Distinguish between reversible and irreversible process. 28

11.

Draw Otto and Diesel cycle on P-V and T-S plane and indicate different

process on them.

28, 27

12.

What is a thermodynamic process? Distinguish between reversible and

irreversible process.

27

13. What is the thermodynamic cycle? 27

No ENGINE & TURBINE BCS

1. What is fuel? How fuels are classified? 29

2. Explain the difference between a four stroke and two stroke cycle. 28, 27

3. Distinguish between Engine and Machine 28

4. What is a steam turbine? 28

5. Describe advantages of a steam turbine over steam Engine. 28

6.

Define the term degree of reaction in case of water turbine and classify

turbines on the basis of this parameter.

27

No HEAT TRANSFER BCS

1.

An electric cable of aluminum (k= 240 W/mK) is to be isolated with rubber

(k=0.15 W/mK). The cable is to be located in air (k=6W/m

2

).

Calculate the critical thickness of insulation.

33

2. Define Gray body, Specula surface and diffuse surface. 33

3.

A composite wall is made of followings:

(i) An inner layer of 20 cm thick made of fire-clay brick (k=1.47 W/

(mK)).

(ii) Middle layer is made of earth brick of 15cm thick (k=0.24W/ (mK)).

(iii)The outer layer with different type of clay 10cm thick (k=0.09W/

(mK)).

If the temperature of the inner wall surface is 1050C,

Calculate the amount of heat loss through composite wall.

33

4. Why do surfaces absorb differently for solar or earthbound radiation? 30

5. Differentiate between forced convection and free convection. 30, 28

6.

Illustrate the different processes of heat transfer and derive their heat flow

equation.

29

7.

Room air is maintained at 22C and outside air is at 32C. The room has

250mm thick brick wall consider Kwall =0.70w/m - C and hair = 10w/m2

C.

Find heat flow through the wall per unit area. (Neglect the effect of

radiation)

29

8.

Discuss the factors due to which Carnot heat Engine cycle is practicable

in practice.

28

9.

Describe the physical mechanism of convection.

How the convection heat transfer is co-efficient related to this mechanism?

27

10. Derive the expression for the quantity of heat flow through a thick cylinder. 27

11.

Draw the temperature profile for parallel flow heat exchanger, counter flow

heat exchanger, boiler and condenser.

27

12.

The glass window of a room have a total area to 100m2 and the glass is

4mm thick. Calculate the total quantity of heat that escapes from the room

by conduction per second when the inside surface of windows are at 25C

and outside surface at 10C, K=0.84 W/mK.

27

No REFRIGERATION & AIR CONDITIONING BCS

1. Define sensible heating and dehumidification. 33

2.

Draw a neat sketch of a household refrigerator system and explain its

working principle.

33

3.

What is Tonne of Refrigeration and COP?

30, 28, 27

4.

Define Newtons law of cooling. Deduce the equation of heat transfer by

steady state condition through a slab.

30

5.

Explain the important components of a simple Vapour Compression

Refrigeration system. Also discuss the functions of each components.

30

6.

Define primary and secondary Refrigerant with examples.

30

7.

What is Refrigerant? Name different types of refrigerants. Mention

important characteristics of refrigerant.

29

8.

Differentiate between window type air cooler and split type air cooler.

Can an air cooler converted into a heat pump? If so How?

29

9.

What should be the properties of an ideal refrigerant?

33, 30, 28

10.

Describe the factors which should be considered for solution of Air-

conditioner for an office room.

28

11.

How air conditioning is different from refrigeration?

28

12.

Describe briefly the working principle of a Vapour Compression

Refrigeration System with block and p-h diagram.

27

13.

What factors are responsible for human comfort? How Air-conditioning is

different from refrigeration?

27

No FLUID MECHANICS & PUMPS BCS

1. What is cavitation? Write the demerits of cavitation in a hydraulic machine. 33

2.

A pelton wheel develops 1750 KW under a head of 100m while running at

200 rpm and discharging 2500 liters of water per second. What is the unit

power of the wheel?

33

3.

Draw Rheological diagram for Newtonian fluid, Non-Newtonian fluid and

Ideal plastic.

33

4.

From the following figure, Calculate the rate of fluid flow :-

33

5.

Define the followings:-

(i) Shock wave

(ii) Oblique wave

(iii)Mack Cone

33

6. What is priming? Explain different types of priming? 30

7.

Explain the following terms-

(i) Manometric Head

(ii) Pump Losses

(iii)Pump Efficiencies

30

8.

Write Short Notes on-

(i) Cavitation

(ii) Rotodynamic Machine

30

9.

Draw the head-discharge and efficient discharge curve of a centrifugal pump

and show the position of maximum head and maximum efficiency.

29

10.

Explain the difference between a positive displacement machine and

rotodynamic machine.

28, 27

11.

Explain the term slip and cavitation with reference to reciprocating

pump.

What are the losses in a centrifugal pump?

27

12.

Derive the Bernoullis equation from the Euler equation of motion, meaning

clearly the assumptions made in the derivation. What are its limitations?

27

13. Name five flow measuring devices and describe any two of them. 27

14.

An open tank contains 5.0m of oil (=8.0 KN/m

3

). Find the pressure at the

bottom of the tank.

27

No SOLID MECHANICS BCS

1. Define Principle Stress and prove that at the plane of principle stress shear

stress is zero.

33

2. For the beam as shown in the following figure, draw the shear and moment

diagram

33

3. An aluminum bar is loaded as shown in the following figure. Find the

deformation at section B and C :-

33

4. What are the requirements of a good shaft coupling? Write the name of five

rigid coupling.

33

5. A circular shaft can transmit a torque of 5 KN-m. If the torque is reduced to

4KN-m, then what is the maximum value of bending moment that can be

applied to the shaft?

33

6. Find the thickness of the metal, necessary for a steel cylindrical shell of

internal diameter of 25cm to withstand an initial pressure of 500kg/cm

2

. The

maximum hoop stress in the section is not to exceed 1500kg/cm

2

30

7. Explain the following terms-

(i) Principle Stress

(ii) Shear Stress

(iii)Bearing Stress

(iv) Hoop Stress

(v) Thermal Stress

(vi) Bending Moment

(vii) Stress

29, 27

8.

Consider a cantilever beam loaded by a concentrated load at the free end

together with a uniform load distribution over the half length of the beam

from the fixed support. Draw the shear force and bending moment diagram.

29

9.

Plot shear and bending moment diagrams for a simple beam with uniformly

distributed load.

28, 27

10. Draw stress-strain diagram for ductile and brittle materials and indicate

important point on them

31, 28, 27

11. A thin cylindrical pressure vessel of 500mm diameter is subjected to an

internal pressure of 2N/mm

2

. If the thickness of the vessel od 20 mm.

Find the hoop stress, longitudinal stress and the maximum shear stress.

27

No MACHINE DESIGN BCS

1.

For a both end fixed column made of AISI 1020 rolled steel (tensile

strength 650 MPa), Find the Buckling load under the following condition

(length of the column is 2.5m):-

(i) Column is round with cross-sectional area 475mm

2

(ii) Column is a circular tube with inner radius 50mm and cross-

sectional area 475mm

2

33

2.

What is equivalent length of a column? Write the relation between

equivalent length and actual length of a column for various conditions.

30, 27

3.

Explain the following terms in connection with design of machine

member subjected to variable load:

(i) Endurance limit

(ii) Size factor

(iii)Surface finish factor

(iv) Notch sensitivity

30, 27

4. What is the difference between basic size and normal size? 30

5. What is fit? Name three types of fits with their uses giving sketch. 30

6. Name three types of Fits with sketch and places of use. 28

7.

Discus the various types of power threads.

Give their relative advantages and disadvantages.

27

No Metallurgical BCS

1. What are the impurities contain in cast and what are their effects on cast

iron properties?

33

2. What are the defects in casting a metal? 33

3. Discuss the mechanical properties of metal which are associated with the

ability of the material of resist mechanical forces.

33

4. Define and discuss in brief the various heart treatment processes (at least

3), commonly employed in engineering practice.

33

Syllabus 1

st

Paper

Properties of gases and various, Law of thermodynamics and their corollaries, Ideal gases and their cycles.

Study of stream generators, their accessories and mountings, Steady state conduction of one dimensional heat

in different geometrics and composite structures. Transient heat conduction in solids with negligible internal

resistance and surface resistance. Laws of radiation heat transfer, Net radiation interchange between two

infinite parallel plates.

Concept of refrigeration and its application.Continuity, momentum and energy equation and their applications.

Pressure, velocity and flow measurement devices. Basic conception about pumps and turbines.

Stress analysis; axially loaded member, thermal and centrifugal stresses, stresses in thin and thick walled

cylinder and spheres. Shear force and bending moment diagram of beams. Combined stress. Types of fits,

Design for static and fatigue strength, Design of screws, fasteners and connections and columns.

You might also like

- HEAT TRANSFER THROUGH FREE AND FORCED CONVECTIONDocument8 pagesHEAT TRANSFER THROUGH FREE AND FORCED CONVECTIONZia AhmedNo ratings yet

- Development of Microstructure in Isomorphous AlloysDocument11 pagesDevelopment of Microstructure in Isomorphous Alloyshayder1920No ratings yet

- Question Paper Code:: Reg. No.Document4 pagesQuestion Paper Code:: Reg. No.Guru PrakashNo ratings yet

- UNIT-1: What Is The Difference Between Refrigeration & Air Conditioning?Document8 pagesUNIT-1: What Is The Difference Between Refrigeration & Air Conditioning?Udit NarayanNo ratings yet

- 2013Document31 pages2013Narayanan SrinivasanNo ratings yet

- Fluid Mechanics and Heat TransferDocument8 pagesFluid Mechanics and Heat Transfervenkat_nsnNo ratings yet

- Me2202 PDFDocument15 pagesMe2202 PDFvis3012No ratings yet

- eNGINEERING THERMODYNAMICS QUESTION PAPERDocument11 pageseNGINEERING THERMODYNAMICS QUESTION PAPERAbubakkar Siddiq100% (3)

- ElementsDocument10 pagesElementsNur Amira Mardiana ZulkifliNo ratings yet

- Thermal Engineering - Department of Mechanical EngineeringDocument8 pagesThermal Engineering - Department of Mechanical EngineeringPrashant KumarNo ratings yet

- Mec 108 Exam Jan 2022Document1 pageMec 108 Exam Jan 2022Inyiama CynthiaNo ratings yet

- Ae 1201 - Aero Engineering ThermodynamicsDocument4 pagesAe 1201 - Aero Engineering ThermodynamicsRameez FaroukNo ratings yet

- IES CONV Mechanical Engineering 2001Document7 pagesIES CONV Mechanical Engineering 2001Amit ShuklaNo ratings yet

- HEAT TRANSFER Previous PaperDocument8 pagesHEAT TRANSFER Previous PaperVibin KrishnaNo ratings yet

- ME-207 B.Tech. (2nd Year) TD(Thermodynamics) Model SetDocument2 pagesME-207 B.Tech. (2nd Year) TD(Thermodynamics) Model SetMuzaffar AlamNo ratings yet

- T D AssignmentDocument8 pagesT D AssignmentVineet K. MishraNo ratings yet

- Q. P. Code: 37785: Page 1 of 2Document2 pagesQ. P. Code: 37785: Page 1 of 2Joyce VicenteNo ratings yet

- The Oxford College of EngineeringDocument2 pagesThe Oxford College of EngineeringNarayana Swamy GNo ratings yet

- Heat Transfer: Anna University Question BankDocument6 pagesHeat Transfer: Anna University Question BankaeroacademicNo ratings yet

- At Least TWO Questions From Each Part. Data Hand Book and Steam Tables Is PermittedDocument2 pagesAt Least TWO Questions From Each Part. Data Hand Book and Steam Tables Is PermittedPruthvi HareeshNo ratings yet

- Cycle Test SOMDocument7 pagesCycle Test SOMRyan GomezNo ratings yet

- M Tech I Sem II Mid TDDocument4 pagesM Tech I Sem II Mid TDMir Mustafa AliNo ratings yet

- B.Tech. Degree Examination: Instructions: Each Module Carries 12 MarksDocument3 pagesB.Tech. Degree Examination: Instructions: Each Module Carries 12 MarksKalidindi sai tharunNo ratings yet

- BUET EXAMS Questions 2-4-16Document5 pagesBUET EXAMS Questions 2-4-16tanveerhossain1100% (1)

- Eme 21062010Document2 pagesEme 21062010Bhavesh PipaliyaNo ratings yet

- R059210304 ThermodynamicsDocument8 pagesR059210304 ThermodynamicsKushagra GuptaNo ratings yet

- EI6403-Applied Thermodynamics and Fluid Dynamics PDFDocument13 pagesEI6403-Applied Thermodynamics and Fluid Dynamics PDFHarish prajenNo ratings yet

- Transformer Design 2bDocument13 pagesTransformer Design 2bCaloy FelicianoNo ratings yet

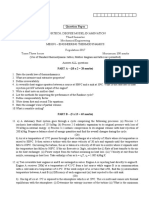

- MIT ACADEMY OF ENGINEERING COURSE CODE: ME401T END SEMESTER EXAMINATION HEATING VENTILATION & AIR CONDITIONINGDocument5 pagesMIT ACADEMY OF ENGINEERING COURSE CODE: ME401T END SEMESTER EXAMINATION HEATING VENTILATION & AIR CONDITIONINGVishal GaikwadNo ratings yet

- Applied Thermodynamics QBDocument12 pagesApplied Thermodynamics QBapi-25999517100% (1)

- Assignment 5Document2 pagesAssignment 5pradeep.kumarNo ratings yet

- 15 ANNA UNIVERSITY QUESTION PAPER THERMODYNAMICS TITLEDocument62 pages15 ANNA UNIVERSITY QUESTION PAPER THERMODYNAMICS TITLERed RedNo ratings yet

- Meng HMTDocument12 pagesMeng HMTMiskir AimNo ratings yet

- Atht Model Ques 2017Document1 pageAtht Model Ques 2017Jeyakumar VenugopalNo ratings yet

- Thermal ScienceDocument8 pagesThermal ScienceSamiullah MohammedNo ratings yet

- Thermal Engg AM11 ME2301Document0 pagesThermal Engg AM11 ME2301Prasath SubbuNo ratings yet

- Tut 6,7,8 - 2013Document3 pagesTut 6,7,8 - 2013SourabhNo ratings yet

- Me8391 - EtdDocument3 pagesMe8391 - Etdsyed1188No ratings yet

- R&a.c Mid-I & II ImpDocument3 pagesR&a.c Mid-I & II ImpsaankyaNo ratings yet

- Coaching - I TEDocument2 pagesCoaching - I TEtagoreboopathyNo ratings yet

- SUB: Heat & Mass Transfer (EME 504) : Assignment-IDocument2 pagesSUB: Heat & Mass Transfer (EME 504) : Assignment-IdearsaswatNo ratings yet

- ThermoDocument3 pagesThermopranavNo ratings yet

- ME6301 Engineering Thermodynamics Question BankDocument15 pagesME6301 Engineering Thermodynamics Question BankAnantha Kumar0% (1)

- RK University: InstructionsDocument3 pagesRK University: InstructionsNilesh MalviyaNo ratings yet

- 6.thermal EngineeringDocument7 pages6.thermal EngineeringprasanthprpNo ratings yet

- NR-222001-Thermal Engineering and Heat TransferDocument8 pagesNR-222001-Thermal Engineering and Heat TransferSrinivasa Rao GNo ratings yet

- Engg Thermodynamics QBDocument3 pagesEngg Thermodynamics QBrajasekaran2323No ratings yet

- Heat & MassQuestion BankDocument9 pagesHeat & MassQuestion Banksiva_marimuthu_2No ratings yet

- QP 2010Document25 pagesQP 2010samy_175No ratings yet

- Tutorial SheetDocument5 pagesTutorial Sheetpradeep.kumarNo ratings yet

- Sem 4 QBDocument31 pagesSem 4 QBArvind ThankappanNo ratings yet

- ME350 End 2Document2 pagesME350 End 2SHIVANANDA DALEINo ratings yet

- HMT Unit 1Document9 pagesHMT Unit 1rp0212No ratings yet

- Mechanical Engineering PapersDocument34 pagesMechanical Engineering PapersshivarajeshNo ratings yet

- Thermodynamics Exam Questions Focus on Cycles, Processes, and Efficiency CalculationsDocument26 pagesThermodynamics Exam Questions Focus on Cycles, Processes, and Efficiency CalculationsSuhas G MNo ratings yet

- 13A03302122016Document2 pages13A03302122016EhteshTubeNo ratings yet

- 9A03501 Thermal Engineering IIDocument4 pages9A03501 Thermal Engineering IIsivabharathamurthyNo ratings yet

- Rac Assignment 1Document4 pagesRac Assignment 1Guru Ravindra ReddyNo ratings yet

- Heat TransferDocument8 pagesHeat Transferbarlang123No ratings yet

- IES CONV Mechanical Engineering 1991Document7 pagesIES CONV Mechanical Engineering 1991GURURAJ CNo ratings yet

- 2000 Part IPaper 3Document8 pages2000 Part IPaper 3tominthedungeon9481No ratings yet

- IT'S ALL ABOUT THE PERIODIC TABLE OF ELEMENTS CROSSWORD PUZZLEDocument1 pageIT'S ALL ABOUT THE PERIODIC TABLE OF ELEMENTS CROSSWORD PUZZLERonaldGomezNo ratings yet

- MagnetDocument34 pagesMagnetAyein HboNo ratings yet

- Calderas RondomatDocument8 pagesCalderas RondomatDiego Navarro PinoNo ratings yet

- Supercritical Fluid Extraction of Organic Compounds From Solids and Aqueous Solutions PDFDocument60 pagesSupercritical Fluid Extraction of Organic Compounds From Solids and Aqueous Solutions PDFÁlvaro Cornejo PerdomoNo ratings yet

- Development of Sodium Leak Detectors For PFBRDocument13 pagesDevelopment of Sodium Leak Detectors For PFBRWilliam MunnyNo ratings yet

- Axens HydrocrackingDocument12 pagesAxens HydrocrackingapminshullNo ratings yet

- JEE Saarthi Circular Motion DPP 28-06-2021Document6 pagesJEE Saarthi Circular Motion DPP 28-06-2021Laxmikant KhodeNo ratings yet

- Ponchon Savarit PDFDocument71 pagesPonchon Savarit PDFAnonymous UFa1z9XUANo ratings yet

- G Scheme First Semester Curriculum All Branches 03012013Document53 pagesG Scheme First Semester Curriculum All Branches 03012013Anuja KhamitkarNo ratings yet

- Disha 1000 Mcq-Pages Geography PDFDocument82 pagesDisha 1000 Mcq-Pages Geography PDFHarshit AroraNo ratings yet

- Soal Bahasa Inggris Xi DoneDocument12 pagesSoal Bahasa Inggris Xi DoneWinda SariNo ratings yet

- Science Experiments 4th GradeDocument8 pagesScience Experiments 4th GradeNarayanNo ratings yet

- Class 8 Science Books Chapter 12Document12 pagesClass 8 Science Books Chapter 12mugilee.psNo ratings yet

- Chemistry-Grade 12 PDFDocument317 pagesChemistry-Grade 12 PDFviktoria dizon75% (4)

- Benzoic Acid Manufacturers, Suppliers, Exporters, Dealers in IndiaDocument4 pagesBenzoic Acid Manufacturers, Suppliers, Exporters, Dealers in IndiaKaran ShroffNo ratings yet

- Oxygen Transport and Oxygen Dissociation CurvesDocument6 pagesOxygen Transport and Oxygen Dissociation CurvesFarah SalehNo ratings yet

- 2021 08 06 Nasa STD 5020b - Final PDFDocument114 pages2021 08 06 Nasa STD 5020b - Final PDFGianluca FacchiniNo ratings yet

- Macropoxy 646 SEDocument4 pagesMacropoxy 646 SESleyda MunozNo ratings yet

- Force and Motion - Summative TestDocument2 pagesForce and Motion - Summative TestAiza Conchada100% (2)

- Water-Tube Boilers - Part 1: General Requirement: National Standard of The People'S Republic of ChinaDocument21 pagesWater-Tube Boilers - Part 1: General Requirement: National Standard of The People'S Republic of ChinaNATTHAPONG BUNSOMPOPNo ratings yet

- Bio PlasticDocument6 pagesBio PlasticMaliha JahanNo ratings yet

- Nozzle Clogging Behavior of Ti-Bearing Al-Killed ULC SteelDocument8 pagesNozzle Clogging Behavior of Ti-Bearing Al-Killed ULC SteelEstéfano Aparecido VieiraNo ratings yet

- Thais Daboit: Ra Su Me Ve Ju As Su Sa As KeDocument11 pagesThais Daboit: Ra Su Me Ve Ju As Su Sa As KeThaís DaboitNo ratings yet

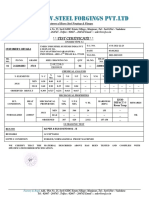

- AV-Steel Forgings Test CertificateDocument1 pageAV-Steel Forgings Test CertificateNirmit GandhiNo ratings yet

- Kane equations - Example 1Document8 pagesKane equations - Example 1Khisbullah HudhaNo ratings yet

- M.sc. - ChemistryDocument129 pagesM.sc. - ChemistryAsim AliNo ratings yet

- ch.1 RadioactvityDocument22 pagesch.1 Radioactvitykarim adelNo ratings yet

- The 12-Volt Bible For BoatsDocument17 pagesThe 12-Volt Bible For BoatsJuan Pedreno BernalNo ratings yet

- Graphene From Fundamental-From Fundamental To Future ApplicationsDocument40 pagesGraphene From Fundamental-From Fundamental To Future ApplicationsMustaque Ali100% (2)