Professional Documents

Culture Documents

4 Modern Developments 2

Uploaded by

ocallagrOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4 Modern Developments 2

Uploaded by

ocallagrCopyright:

Available Formats

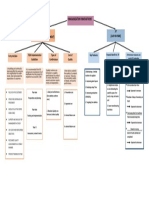

P58 - 2

Flexibility

Reduced idle time

Reduced WIP

Dedicated cell production Reduced unnecessary tasks

Benefits

Reduction in losses & Rets

Rapid response to change

Better staff motivation

Reduced staff T/O

P61 - 3

JIT Purchasing

Machine Cells

Set up time reduction

Approach Uniform loading

Kanban Pull system

JIT Total Quality

Employee involvement

Value adding V NVA

Difficult to predict demand

What if suppliers fail

Problems

Wider geographical spread of manufacturing

Premium price of supplies

P64 - 4

Right first time

Continuous improvement

Matters to the customer

Customer supplier relationship

Prevention rather than cure

Operatives personally responsible

Requirements of quality

Any level of defects unacceptable

Right first time applies to all departments

Introduce a quality certification programme

Emphasise cost of poor QC

1. World class manufacturing

Positive motivation

Cultural orientation

Change attitudes Workers decide how to work

Empowerment

4. Modern Developments 2 Responsibility to achieve targets

TQM

05/10/2004 - v8

Quality circles

Improved quality of O/P

Benefits Improved productivity

Job satisfaction & commitment

Costs & Benefits

Time to learn

Costs Training costs

Cost of mistakes while learning

Reduce no of parts

CAD Use parts used by other products

Improve physical charactaristics

Design for quality

Production engineering

Admin

Info systems

Distribution

P69 - KEY TERM

OPPOSITE TO THE COST + MODEL

REDUCE NO OF COMPONENTS

USE STANDARD COMPONENTS

Target costing DEALS WITH ATTAINABLE PRICE AND TRAIN STAFF

WORKS BACKWARDS TECHNOLOGY

CUT NVA ACTIVITIES

USE DIFFERENT MATERIALS

USE CHEAPER STAFF

BPR HOW IT CAN REMOVE NVA

HOW COSTS CAN BE CALCULATED IN A

Activity Based Approaches MORE MEANINGFUL WAY

ACTIVIT BASED

COST DRIVERS

P71 - KEY TERMS

C:\Documents and Settings\Rich\My Documents\Business\CPA\Professional 1\Strategic Management Accounting\4. Modern Developments 2.mmp - 05/10/2004 - -

You might also like

- Cost Recovery: Turning Your Accounts Payable Department into a Profit CenterFrom EverandCost Recovery: Turning Your Accounts Payable Department into a Profit CenterNo ratings yet

- Service-Oriented Modeling: Service Analysis, Design, and ArchitectureFrom EverandService-Oriented Modeling: Service Analysis, Design, and ArchitectureNo ratings yet

- DPU Reduction UpdatedDocument40 pagesDPU Reduction UpdatedUpendra PandeyNo ratings yet

- DPU ReductionDocument65 pagesDPU ReductionUpendra PandeyNo ratings yet

- How To Do Focuses ImprovementDocument39 pagesHow To Do Focuses Improvementashutoshpal21No ratings yet

- 5 WhyDocument4 pages5 WhyJoaquim ReisNo ratings yet

- Cost Chapter 6 PDFDocument1 pageCost Chapter 6 PDFDada ManatadNo ratings yet

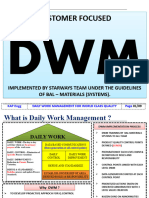

- 03 DWM Master - DWM - WHAT & WHYDocument12 pages03 DWM Master - DWM - WHAT & WHYVenuNo ratings yet

- Quality Culture: To Build Quality BusinessDocument26 pagesQuality Culture: To Build Quality BusinessJAFFERNo ratings yet

- Cost-Benefits AnalysisDocument1 pageCost-Benefits AnalysisPlay PocheNo ratings yet

- LCS Sales Pack Draft27Document297 pagesLCS Sales Pack Draft27Mircea Vladimir NituNo ratings yet

- The Best Laid Incentive Plan - Situational AnalysisDocument1 pageThe Best Laid Incentive Plan - Situational Analysiskartikeya gargNo ratings yet

- KK Pillar PDFDocument91 pagesKK Pillar PDFdiwesh26decNo ratings yet

- P2Mindmap (JoeFang)Document41 pagesP2Mindmap (JoeFang)Mubashar HussainNo ratings yet

- Operator Level Shopfloor KaizensDocument2 pagesOperator Level Shopfloor Kaizensch kishore kumarNo ratings yet

- MR Aseem MagowDocument13 pagesMR Aseem MagowSanjay KumarNo ratings yet

- Risk & Opportunities (Template)Document4 pagesRisk & Opportunities (Template)Ramdas PaithankarNo ratings yet

- Domestic Auto Parts Strategy MapDocument1 pageDomestic Auto Parts Strategy MapMacarena Bahamondes ArroyoNo ratings yet

- 18 Management ReviewDocument1 page18 Management Reviewkumarnitesh173No ratings yet

- Project Justification: Increase OEEDocument21 pagesProject Justification: Increase OEEKaran Singh RaiNo ratings yet

- 5 Why SampleDocument4 pages5 Why SampleadninNo ratings yet

- Case Study RajeevDocument1 pageCase Study Rajeevyatin rajput100% (1)

- Solving Deeper Why's Creates Lasting GainsDocument4 pagesSolving Deeper Why's Creates Lasting Gainsbodeks dexNo ratings yet

- Increased ROI through JIT implementation at Lucas TVSDocument9 pagesIncreased ROI through JIT implementation at Lucas TVSaroundthecapeNo ratings yet

- DM Pillar of TPMDocument26 pagesDM Pillar of TPMVinay75% (4)

- Transferencia Sorteadora Residente 6 JulioDocument6 pagesTransferencia Sorteadora Residente 6 JulioIrma SánchezNo ratings yet

- Improve Asset Performance with Integrated Asset ManagementDocument12 pagesImprove Asset Performance with Integrated Asset ManagementArun KarthikeyanNo ratings yet

- Supply Chain Management in Brief: Medhi CahyonoDocument7 pagesSupply Chain Management in Brief: Medhi CahyonoSetio TanoeNo ratings yet

- 1 Continuous Process ImprovementDocument45 pages1 Continuous Process ImprovementlisahunNo ratings yet

- Bisnis proses perusahaan dan daftar referensi prosedurDocument2 pagesBisnis proses perusahaan dan daftar referensi prosedurOktianti AdolinaNo ratings yet

- Kaizen - Strategy For Performance ExcellenceDocument47 pagesKaizen - Strategy For Performance ExcellenceDiklatpimempat Angkatanlimabelas100% (1)

- TCI Operations Training Program - GET: A Production & Equipment Management ToolDocument59 pagesTCI Operations Training Program - GET: A Production & Equipment Management Toolminingnova2No ratings yet

- Jishu HozenDocument85 pagesJishu HozenRakesh TigadiNo ratings yet

- 2 - Mohd Nordin Ab WahabDocument33 pages2 - Mohd Nordin Ab WahabDerick ChiaNo ratings yet

- Risk Register: Risk Control Measures in Place Scope/potential Consequences of RiskDocument3 pagesRisk Register: Risk Control Measures in Place Scope/potential Consequences of Riskviethuong96No ratings yet

- Tips Mejorar ConfibilidadDocument15 pagesTips Mejorar ConfibilidadJose Alexander Peña Becerra100% (1)

- 5.1.1.2_Process Effectiveness and Efficiency_other ExampleDocument2 pages5.1.1.2_Process Effectiveness and Efficiency_other Examplerc2834338No ratings yet

- Basic Vibration Analysis Training-1Document193 pagesBasic Vibration Analysis Training-1Sanjeevi Kumar SpNo ratings yet

- Cost Benefits AnalysisDocument1 pageCost Benefits AnalysisQuang Minh LeNo ratings yet

- Supply Chain Quality ManagementDocument4 pagesSupply Chain Quality ManagementkarimNo ratings yet

- Crystal Distribution Services, Inc.: PL003 2 04.02.2020 Qa Master Plan 07.20.2021 Jordan Nehl Jordan NehlDocument2 pagesCrystal Distribution Services, Inc.: PL003 2 04.02.2020 Qa Master Plan 07.20.2021 Jordan Nehl Jordan NehlJordanNo ratings yet

- KK PillarDocument117 pagesKK PillarMAngesh Gade100% (1)

- Toyota Production System - FinalDocument49 pagesToyota Production System - FinalUday Kumar GantiNo ratings yet

- JIT Quality Management Concepts in Indian ContextDocument11 pagesJIT Quality Management Concepts in Indian ContextKarran KapurNo ratings yet

- COPQDocument17 pagesCOPQJoni Mart sitio100% (1)

- Deloitte - EVM - MEM - Presentation1 - Clase BPM-PMDocument14 pagesDeloitte - EVM - MEM - Presentation1 - Clase BPM-PMAlejandro BravoNo ratings yet

- ITIL 4 Foundation Certification Learning Course - Day4Document73 pagesITIL 4 Foundation Certification Learning Course - Day4royvan000No ratings yet

- Objectives (2019 20)Document2 pagesObjectives (2019 20)Sekar KrishNo ratings yet

- CHANGE MANAGEMENT PROCESS TRAININGDocument37 pagesCHANGE MANAGEMENT PROCESS TRAININGFlavio ManriqueNo ratings yet

- Agenda for TPM OverviewDocument42 pagesAgenda for TPM OverviewSrinivasan VenkatNo ratings yet

- 105 165903 HFX2023Roles3Document2 pages105 165903 HFX2023Roles3sujoyNo ratings yet

- PFRS15Document17 pagesPFRS15Rheneir MoraNo ratings yet

- Manufacturing Planning and Control System FrameworkDocument9 pagesManufacturing Planning and Control System FrameworkFebriaji AjiNo ratings yet

- Domestic Auto Parts CEO Turnaround StrategyDocument7 pagesDomestic Auto Parts CEO Turnaround StrategyEriko Timothy GintingNo ratings yet

- 1.1 SMP For Mechanical Maintance of AirtubeDocument2 pages1.1 SMP For Mechanical Maintance of AirtubePRANAV KUMAR GAUTAMNo ratings yet

- PMP - EnglishDocument1 pagePMP - EnglishDalibor MihaljcicNo ratings yet

- Right-Sizing Your Cost Base For COVID-19: Rapid Cost Re-Calibration Solution To Maintain Business ContinuityDocument1 pageRight-Sizing Your Cost Base For COVID-19: Rapid Cost Re-Calibration Solution To Maintain Business ContinuityReza HaryoNo ratings yet

- Sales: Submit Faulty Material To Quality DeptDocument1 pageSales: Submit Faulty Material To Quality DeptYash DudaniNo ratings yet

- 3.internal & External IssuesDocument5 pages3.internal & External IssuesScha AffinNo ratings yet

- The Beauty of MaintainabilityDocument4 pagesThe Beauty of MaintainabilityYury FedichkinNo ratings yet

- 1 BookkeepingDocument44 pages1 Bookkeepingocallagr100% (2)

- Market ResearchDocument28 pagesMarket Researchocallagr100% (6)

- 1 Approaches To The OrganisationDocument19 pages1 Approaches To The Organisationocallagr100% (2)

- 9 Alternative Budgeting SystemsDocument1 page9 Alternative Budgeting SystemsocallagrNo ratings yet

- 1 Writing A Business PlanDocument31 pages1 Writing A Business Planocallagr100% (6)

- 7 BudgetsDocument1 page7 BudgetsocallagrNo ratings yet

- 2 Organisational EffectivenessDocument11 pages2 Organisational Effectivenessocallagr100% (1)

- Standard CostingDocument1 pageStandard CostingocallagrNo ratings yet

- 8 Behavioural Implications of BudgetingDocument1 page8 Behavioural Implications of Budgetingocallagr100% (2)

- 6 Planning and CTRLDocument1 page6 Planning and CTRLocallagr100% (1)

- 3 Modern DevelopmentsDocument1 page3 Modern DevelopmentsocallagrNo ratings yet

- 5 Modern Developments 3Document1 page5 Modern Developments 3ocallagrNo ratings yet

- 2 Production CostingDocument1 page2 Production CostingocallagrNo ratings yet

- 1 The Management AccountantDocument1 page1 The Management Accountantocallagr100% (1)

- 1 Writing A Business PlanDocument64 pages1 Writing A Business PlanocallagrNo ratings yet

- IIPAExamination StructureDocument1 pageIIPAExamination Structureocallagr100% (1)

- Philosophy of NursingDocument1 pagePhilosophy of Nursingapi-508609843No ratings yet

- Assignment No. 8 (Culture 1)Document10 pagesAssignment No. 8 (Culture 1)eman zahraNo ratings yet

- Addition and Subtraction: FreebieDocument12 pagesAddition and Subtraction: Freebieapi-459326447No ratings yet

- President Rajapaksa's Address On 73rd Independence DayDocument8 pagesPresident Rajapaksa's Address On 73rd Independence DayAdaderana OnlineNo ratings yet

- Mathematics: Quarter 1-Module 2: Place Value and ValueDocument7 pagesMathematics: Quarter 1-Module 2: Place Value and ValuekristofferNo ratings yet

- The Problem and Its Background: San Celestino Integrated National High School Senior High SchoolDocument35 pagesThe Problem and Its Background: San Celestino Integrated National High School Senior High SchoolWinzel RavenNo ratings yet

- The Behavior Survival Guide For Kids PDFDocument177 pagesThe Behavior Survival Guide For Kids PDFmelycr17100% (1)

- Story Time Lesson PlanDocument2 pagesStory Time Lesson Planapi-289591676No ratings yet

- Marketing Management - Gold GymDocument23 pagesMarketing Management - Gold Gymakshaykg67% (3)

- Enhancing Content Literacy in Physical EducationDocument7 pagesEnhancing Content Literacy in Physical Educationapi-549544904No ratings yet

- Business Plan Format by SEDADocument13 pagesBusiness Plan Format by SEDATumiso MabokelaNo ratings yet

- Bynd Artisan - Passion Made Possible AmbassadorDocument11 pagesBynd Artisan - Passion Made Possible AmbassadorSTBNo ratings yet

- BMAM&GBR PostShowDocument15 pagesBMAM&GBR PostShowctyvteNo ratings yet

- Purposes of BudgettingDocument2 pagesPurposes of BudgettingFarhanaNo ratings yet

- Labor Congress v. NLRC Ruling Favors WorkersDocument3 pagesLabor Congress v. NLRC Ruling Favors WorkersRal CaldiNo ratings yet

- Analytics for Competitive Advantage Using Data Decisions OperationsDocument15 pagesAnalytics for Competitive Advantage Using Data Decisions OperationshariniNo ratings yet

- Master PEMDAS Rule and Laws of Exponents in Solving Quadratic EquationsDocument2 pagesMaster PEMDAS Rule and Laws of Exponents in Solving Quadratic EquationsLeizylAlcantaraNo ratings yet

- Strengths of Teaching Methods HandoutDocument5 pagesStrengths of Teaching Methods HandoutZaw Htet MyintNo ratings yet

- Spot Speed Lab ReportDocument9 pagesSpot Speed Lab Reportwanfaiz123No ratings yet

- Southern Expressway-New Toll Fees 1Document4 pagesSouthern Expressway-New Toll Fees 1Ada DeranaNo ratings yet

- Approaches and Models For Change Management PDFDocument15 pagesApproaches and Models For Change Management PDFChristian Di FeoNo ratings yet

- Fu PDFDocument1 pageFu PDFomerNo ratings yet

- Islam Unveiled: A Review of Robert Spencer's BookDocument5 pagesIslam Unveiled: A Review of Robert Spencer's Bookbassam.madany9541No ratings yet

- George W Cecil: George Woodruff Is The Name ofDocument22 pagesGeorge W Cecil: George Woodruff Is The Name ofArmando Díaz VargasNo ratings yet

- Cybersecurity Quiz Questions and AnswersDocument18 pagesCybersecurity Quiz Questions and AnswerslaloNo ratings yet

- RAPSDocument13 pagesRAPSibadwonNo ratings yet

- ISER Wolfgang The Act of Reading PDFDocument151 pagesISER Wolfgang The Act of Reading PDFelpis2014100% (10)

- Marketing of Agricultural Inputs: FertilizerDocument7 pagesMarketing of Agricultural Inputs: FertilizerShivam SharmaNo ratings yet

- CSDRDocument1 pageCSDRbrijeshnarainsaxenaNo ratings yet

- Listening Test: 30 MinutesDocument9 pagesListening Test: 30 MinutesMar John Louie BacanayaNo ratings yet