Professional Documents

Culture Documents

11 Steel Connection Design As Per AISC 23052014

Uploaded by

Ahmad Badsha Quadri50%(2)50% found this document useful (2 votes)

2K views2 pagesVisit www.abqconsultants.com

This program Designs and

Optimises Steel Connection as per

AISC_ASD IX ed.

Written and programmed by

A B Quadri

www.abqconsultants.com

abquadri@yahoo.com

abquadri@gmail.com

9959010210

9959010211

Original Title

11 Steel Connection Design as Per AISC 23052014

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentVisit www.abqconsultants.com

This program Designs and

Optimises Steel Connection as per

AISC_ASD IX ed.

Written and programmed by

A B Quadri

www.abqconsultants.com

abquadri@yahoo.com

abquadri@gmail.com

9959010210

9959010211

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

50%(2)50% found this document useful (2 votes)

2K views2 pages11 Steel Connection Design As Per AISC 23052014

Uploaded by

Ahmad Badsha QuadriVisit www.abqconsultants.com

This program Designs and

Optimises Steel Connection as per

AISC_ASD IX ed.

Written and programmed by

A B Quadri

www.abqconsultants.com

abquadri@yahoo.com

abquadri@gmail.com

9959010210

9959010211

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

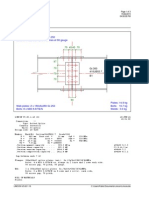

note : enter data in cells only

Connection Design as per AISC-ASD IX ed @ stiffner thk

thk plate

Section Data Bolt Row #1

x x mm

Outer Flange x x mm Bolt Row #2

Inner Flange x x mm

Bolt Row #3

Yeild Stress for Web , Flange and Connection Plate =

Yeild Stress for Bolts (ASTM A325) = 40 ksi =

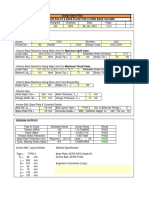

Calculation of n.a Yb and Moment of Inertia

.: = A * Y =

A

Actual Stresses

fb = P - M =

A Z

fb = P + M =

A Z

Actual Stresses 50 % section capacity

fb = P - M =

A Z

fb = P + M =

A Z

Verified by : Date :

Calculation Sheet

Revision note :

Project :

cont'd :

Prepared by : Date :

Job no :

Sheet No :

Ref Calculation Output

16 18

Left Right

Subject :

Description :

Gl 'F' , (4' - 5')

500 48 350 40

Web 802 24 820 16

500 48 350 40

Connection

Plate Size

600 x 18 600 x 18

o

/

o

40

345 Mpa

Z

o

n

e

b

e

l

o

w

N

A

i

n

C

o

m

p

r

e

s

s

i

o

n

1

0

9

8

Y

b

(

n

a

)

16

3

1

2

m

m

Loading

40

Load Case Axial (kn) Shear 'Y'(kn)

276 Mpa

o

/

o

8

9

8

Moment 'Z' (kn.m)

50 %

capacity

0.00 1181.42

350

Step 1

600

DL + LL 500 900 1500

(Governs) Comp

Tension @ top flange

Arm d cm

d = Y - Yb

A * d (cm4)

I-oo Moment

of Inertia

Row # 1 6 24 27.143 92.8 2518.90

Bolts nos dia

(mm)

Area (cm2)

Y(cm)( measured

from centre of

bottom flange)

A * Y ( cm2 )

61.57 102890.58

Row # 3 6 24 27.143 72.8 1976.04 41.57 46901.28

Row # 2 6 24 27.143 82.8 2247.47 51.57 72181.59

Row # 5 0 0 0.000 52.8 0.00 21.57 0.00

Row # 4 6 24 27.143 62.8 1704.60 31.57 27049.64

Row # 6 0 0 0.000 42.8 0.00 11.57 0.00

Web 46.77 16.62 777.14 -14.62 9991.47 3330.49

Flange 140.000 0 0.00 -31.23 136560.12 186.67

(from c/l of bottom flange)

Step 2

Bolts -21.45 <= 27.58 kn/cm2

I =

399091.84

Total 295.344 9224.16

CM4

OK

Compression 13.43 <= 20.68 kn/cm2 OK

Neutral Axis Yb 31.23 cm

kn/cm2 OK

Compression 9.25 <= 20.68 kn/cm2 OK

flange

Check :

Bolts -18.23 <= 27.58

flange

Prep By : A B Quadri- Abq Consultants - 9959010210 - em-abquadri@yahoo.com-12-2-826/2 Royal Residency, Besides Amba talkies, Mehdipatnam , Hyderabad-India. 500028-www.abqconsultants.com

Visit

www.abqconsultants.com

This program Designs and

Optimises Steel Connection as per

AISC_ASD IX ed.

Written and programmed by

:-

A B Quadri

www.abqconsultants.com

abquadri@yahoo.com

abquadri@gmail.com

9959010210

9959010211

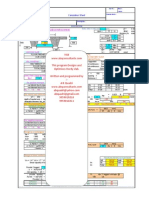

Allowable stresses in Bolts for Bearing type connection

Ft = ksi ( AISC IX ed pg 5-74 ) fv = Shear = kn

area of total nos of bolts cm2

= ksi actual tension in bolt

= kn / cm2 > = kn/cm2

= ksi

a) Calculate Plate Thickness.

Load in Bolt row # 1 = kn / per bolt

Load in Bolt row # 2 = kn / per bolt

Load to flange = kn Li

Load to web = kn Ldi

b) Plate Moment.

M = Pi * Li = Li = Ldi - 1/4 bolt dia = mm

fb = 0.75 fy = kn / cm2

t =

= mm mm thk provided

Design of Weld

Flange weld to cap plate.

Load to flange Pf = kn ( from nos of bolts )

Length of weld = Width of plate Lw =

Use E70XX weld Allowable stress = 0.3 * 70 ksi = kn/cm2

fw (all) = Kn / cm / mm thickness of weld

.: tw = = mm thk

.: use kn/cm

Design of Stiffneer

Maximum load in Bolt = kn M = h

.: Thickness of Stiffness required = t = = required

.: use

Prepared by : Date :

Job no :

Sheet No :

cont'd :

Verified by : Date :

Calculation Sheet

Revision note :

Ref Calculation Output

Step 3

Project :

Subject :

Description :

Bolts

(44)^2 - 2.15 fv2 900.00

217.15

43.853

30.236 -21.45 OK 4.14

100

48.51

106.73 kn.m 44

2

6.011

Step 4

97.03

86.57

1

0

0

48.51

Step 5

582.16 6

600 mm

14.479

25.85

6 * M

fb * Ldi

15.74 <= 18 OK

9.703

m

m

Step 5

1

0

0

100 mm

97.03 485.13 kn.cm

1.0135

Pf 9.57

Lw * fw

12 mm thk weld OK

OK

Prep By : A B Quadri- Abq Consultants - 9959010210 - em-abquadri@yahoo.com-12-2-826/2 Royal Residency, Besides Amba talkies, Mehdipatnam , Hyderabad-India. 500028-www.abqconsultants.com

6 * M 14.07 mm

h ^ 2 * 0.6 fy

16 mm thk stiffner

You might also like

- Moment Connection - Flush End Plate-19.01.06Document48 pagesMoment Connection - Flush End Plate-19.01.06kalpanaadhi83% (6)

- End Plate ConnectionDocument10 pagesEnd Plate ConnectionMohamed Tahar Allagui100% (1)

- Calculation Sheet: Base Plate & Anchor Bolt Design - Moment Connection Base Plate DataDocument1 pageCalculation Sheet: Base Plate & Anchor Bolt Design - Moment Connection Base Plate DataLaurence Arcon Banal0% (1)

- Bolted Moment ConnectionDocument3 pagesBolted Moment Connectionprabhu81100% (3)

- End Plate DesignDocument4 pagesEnd Plate DesignAgnon Fung100% (4)

- RD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryDocument25 pagesRD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryHanuman Sharma83% (6)

- Shear Connection - Beam - Steel Column - Fin PlateDocument30 pagesShear Connection - Beam - Steel Column - Fin Platekalpanaadhi100% (3)

- Base Plate Design Fixed RevisedDocument8 pagesBase Plate Design Fixed RevisedEngDbt80% (5)

- Gusset Plate Design for Cleveland Clinic Abu DhabiDocument4 pagesGusset Plate Design for Cleveland Clinic Abu Dhabikalpanaadhi75% (4)

- Connection Design MomentDocument4 pagesConnection Design MomentAkshit Dhawan100% (1)

- Typ-Base PlateDocument11 pagesTyp-Base PlateManoj Jaiswal100% (2)

- DESIGN CALCULATION SHEET FOR SUPPORTING BEAMDocument29 pagesDESIGN CALCULATION SHEET FOR SUPPORTING BEAMTamkwokkwong86% (7)

- Connection Design SheetDocument47 pagesConnection Design SheetStephen James100% (1)

- Base Plate With Moment & Axial CompressionDocument2 pagesBase Plate With Moment & Axial CompressionAnonymous b3NKZUb100% (3)

- Moment Connection Design-BS CODEDocument5 pagesMoment Connection Design-BS CODEMuthukumaran SivalingamNo ratings yet

- Att-5 - End-Plate Shear ConnectionDocument7 pagesAtt-5 - End-Plate Shear Connectioncravikumar1971100% (3)

- Moment Connection Portal FrameDocument18 pagesMoment Connection Portal Frametmssorin100% (1)

- P 5.0.1 Loading Condition For Columns: 5.0 Analysis of ColumnDocument6 pagesP 5.0.1 Loading Condition For Columns: 5.0 Analysis of Columnanimesh91No ratings yet

- Bolted ConnectionDocument86 pagesBolted ConnectionPooja MistryNo ratings yet

- End Plate-Beam To Column Moment ConnectionDocument81 pagesEnd Plate-Beam To Column Moment ConnectionHemant Ramesh Narkar50% (6)

- End Plate-Splice ConnectionDocument76 pagesEnd Plate-Splice ConnectionHemant Ramesh Narkar100% (6)

- Anchor Bolt DesignDocument2 pagesAnchor Bolt Designmail2meanwar7865No ratings yet

- Moment ConnectionsDocument15 pagesMoment ConnectionsHector Aguana100% (1)

- Bolted splice design of 410UB53.7 beamDocument3 pagesBolted splice design of 410UB53.7 beamconorkellysligoNo ratings yet

- Example Beam Column Design IS800Document3 pagesExample Beam Column Design IS800Goutam Chakraborty100% (4)

- Beam SpliceDocument17 pagesBeam SpliceBoddu Ramakrishna100% (1)

- Design of Anchor BoltDocument3 pagesDesign of Anchor Boltdsananda100% (2)

- Steel SectionsDocument69 pagesSteel SectionsGautam SharmaNo ratings yet

- Pinned and fixed base plate design calculations for I-section and tube columnsDocument7 pagesPinned and fixed base plate design calculations for I-section and tube columnsabdul karee100% (6)

- Beam To Beam Web - Shear ConnectionDocument2 pagesBeam To Beam Web - Shear ConnectionGautam SharmaNo ratings yet

- End Plate DesignDocument26 pagesEnd Plate DesignNitesh SinghNo ratings yet

- Brace ConnectionDocument10 pagesBrace ConnectionAhmed Ben HmidaNo ratings yet

- Baseplate Design Input DataDocument166 pagesBaseplate Design Input DataAnonymous ciKyr0t86% (7)

- BASE PLATE DESIGN OPTIMIZATIONDocument45 pagesBASE PLATE DESIGN OPTIMIZATIONMuhammed Ali60% (5)

- PULL-OUT CAPACITY OF HOLDING DOWN BOLTS CALCULATIONSDocument1 pagePULL-OUT CAPACITY OF HOLDING DOWN BOLTS CALCULATIONSatokku100% (2)

- Moment Connection Beam Column IS & BS SECTION FOR IS800Document29 pagesMoment Connection Beam Column IS & BS SECTION FOR IS800pjuvvadi86% (7)

- Moment Connection DETAIL 2Document5 pagesMoment Connection DETAIL 2way2vaseemNo ratings yet

- RCC82 Pilecap DesignB2Document97 pagesRCC82 Pilecap DesignB2AnbalaganVNo ratings yet

- Steel Beam To Column-Welded ConnectionDocument2 pagesSteel Beam To Column-Welded ConnectionAbukalam MullaNo ratings yet

- FIN PLATE - Beam To BeamDocument71 pagesFIN PLATE - Beam To BeamHemant Ramesh Narkar100% (3)

- Combined Gusset Plate DesignDocument3 pagesCombined Gusset Plate Designkalpanaadhi100% (3)

- Column Base Plate DesignDocument1 pageColumn Base Plate DesignBunkun15No ratings yet

- Design Calculation Steel Structure Power PlantDocument58 pagesDesign Calculation Steel Structure Power Plantrajeshdebnath100% (2)

- Base PlateDocument12 pagesBase PlateD SRINIVAS100% (1)

- BS5950 End Plate DesignDocument4 pagesBS5950 End Plate DesignSimon Lsm67% (3)

- Vertical Bracing Connection Calc SheetsDocument17 pagesVertical Bracing Connection Calc Sheetskarthicksip90% (10)

- Excel Anchor Bolt Calculator-1Document2 pagesExcel Anchor Bolt Calculator-1teesk200350% (2)

- Eaves Connection Design and AnalysisDocument37 pagesEaves Connection Design and AnalysisHui LiuNo ratings yet

- 19 Design of Fixed Steel Base Plate 23052014Document1 page19 Design of Fixed Steel Base Plate 23052014Ahmad Badsha QuadriNo ratings yet

- UB254 To UB457Document7 pagesUB254 To UB457ihpeterNo ratings yet

- Base Plate Design - BS CodeDocument3 pagesBase Plate Design - BS Codemicheleling669667% (3)

- Beam SpliceDocument7 pagesBeam SpliceJuan BradleyNo ratings yet

- Bolted Moment Connection Design CalculationsDocument63 pagesBolted Moment Connection Design CalculationsblueswanNo ratings yet

- Purlin Cleat 220908Document24 pagesPurlin Cleat 220908kalpanaadhi100% (2)

- HAMTeK annexure 5.3a - Design of Base Plate and Anchor BoltsDocument7 pagesHAMTeK annexure 5.3a - Design of Base Plate and Anchor BoltsVenkatesha HebbarNo ratings yet

- Design of anchor bolts and base plate for a fixed base columnDocument4 pagesDesign of anchor bolts and base plate for a fixed base columnSuryaSinghNo ratings yet

- MOMENT EndplateDocument8 pagesMOMENT Endplatemoseslugtu6324No ratings yet

- Baseplate Biaxial MZDocument26 pagesBaseplate Biaxial MZD SRINIVAS100% (1)

- Four Bolt Unstiffened End PlateDocument7 pagesFour Bolt Unstiffened End PlateRnD2013No ratings yet

- Analysis and Design of R.C.C CIRCULLAR TANK As Per IS 3370: Calculation SheetDocument3 pagesAnalysis and Design of R.C.C CIRCULLAR TANK As Per IS 3370: Calculation SheetAhmad Badsha QuadriNo ratings yet

- 28-1 Design of Anchored Sheet Pile Wall in Granular Soil-2 23052014Document2 pages28-1 Design of Anchored Sheet Pile Wall in Granular Soil-2 23052014Ahmad Badsha Quadri100% (1)

- 28 Design of Anchored Sheet Pile Wall in Granular Soil-1 23052014Document3 pages28 Design of Anchored Sheet Pile Wall in Granular Soil-1 23052014Ahmad Badsha QuadriNo ratings yet

- 31 Design of RCC Beams For Biaxial Moment Shear Torsion and Axial Loads As Per Is 456 2000 23052014Document2 pages31 Design of RCC Beams For Biaxial Moment Shear Torsion and Axial Loads As Per Is 456 2000 23052014Ahmad Badsha QuadriNo ratings yet

- 28 Design of Anchored Sheet Pile Wall in Granular Soil-1 23052014Document3 pages28 Design of Anchored Sheet Pile Wall in Granular Soil-1 23052014Ahmad Badsha QuadriNo ratings yet

- 24-Optimised Design For Built Up Steel Beams For Mezzanine For PEB As Per AISC 23052014Document5 pages24-Optimised Design For Built Up Steel Beams For Mezzanine For PEB As Per AISC 23052014Ahmad Badsha QuadriNo ratings yet

- 26 Design of Singly Reinforced Continous RCC Beam As Per Is456-2000 23052014Document1 page26 Design of Singly Reinforced Continous RCC Beam As Per Is456-2000 23052014Ahmad Badsha QuadriNo ratings yet

- Design of Steel Chimney and RCC Foundation As Per Indian Code 22052014Document12 pagesDesign of Steel Chimney and RCC Foundation As Per Indian Code 22052014Ahmad Badsha Quadri58% (19)

- Analysis and Design of R.C.C CIRCULLAR TANK As Per IS 3370: Calculation SheetDocument3 pagesAnalysis and Design of R.C.C CIRCULLAR TANK As Per IS 3370: Calculation SheetAhmad Badsha QuadriNo ratings yet

- 15 Design of RCC Dome 23052014Document3 pages15 Design of RCC Dome 23052014Ahmad Badsha Quadri50% (2)

- 22 Analysis and Design of RCC Beam For Bi-Axial Moment Shear Torsion and Axial Load 23052014Document3 pages22 Analysis and Design of RCC Beam For Bi-Axial Moment Shear Torsion and Axial Load 23052014Ahmad Badsha QuadriNo ratings yet

- 21 AISC Check of Steel I Sections For PEB 23052014Document4 pages21 AISC Check of Steel I Sections For PEB 23052014Ahmad Badsha QuadriNo ratings yet

- 20 Design of RCC Retaining Wall 23052014Document2 pages20 Design of RCC Retaining Wall 23052014Ahmad Badsha QuadriNo ratings yet

- 19 Design of Fixed Steel Base Plate 23052014Document1 page19 Design of Fixed Steel Base Plate 23052014Ahmad Badsha QuadriNo ratings yet

- 14 Design of RCC Combined Footing 23052014Document2 pages14 Design of RCC Combined Footing 23052014Ahmad Badsha QuadriNo ratings yet

- 18 Preliminary Design of Concrete Shear Wall For Tall Buildings 23052014 1Document1 page18 Preliminary Design of Concrete Shear Wall For Tall Buildings 23052014 1Ahmad Badsha QuadriNo ratings yet

- 16 Selection of Concrete Filled Steel Pipe Columns 23052014Document1 page16 Selection of Concrete Filled Steel Pipe Columns 23052014Ahmad Badsha QuadriNo ratings yet

- 9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 4Document3 pages9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 4Ahmad Badsha QuadriNo ratings yet

- 14 Design of RCC Combined Footing 23052014Document2 pages14 Design of RCC Combined Footing 23052014Ahmad Badsha QuadriNo ratings yet

- 10 Design of Cantilever RCC Beam 23052014 2Document1 page10 Design of Cantilever RCC Beam 23052014 2Ahmad Badsha QuadriNo ratings yet

- 12 Design of Hordy Slab 23052014Document1 page12 Design of Hordy Slab 23052014Ahmad Badsha QuadriNo ratings yet

- 13 Design of RCC Footing 23052014Document3 pages13 Design of RCC Footing 23052014Ahmad Badsha QuadriNo ratings yet

- 9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 5Document2 pages9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 5Ahmad Badsha QuadriNo ratings yet

- 10 Design of Cantilever RCC Beam 23052014 1Document1 page10 Design of Cantilever RCC Beam 23052014 1Ahmad Badsha QuadriNo ratings yet

- 9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 3Document2 pages9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 3Ahmad Badsha Quadri100% (1)

- 1 Design of RCC Corbels-23052014Document9 pages1 Design of RCC Corbels-23052014Ahmad Badsha QuadriNo ratings yet

- 9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 2Document2 pages9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 2Ahmad Badsha QuadriNo ratings yet

- 9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 1Document9 pages9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 1Ahmad Badsha QuadriNo ratings yet

- 8 Design of Simply Supported RCC Beams 23052014-2Document1 page8 Design of Simply Supported RCC Beams 23052014-2Ahmad Badsha QuadriNo ratings yet

- Progibb LV Plus PGR - Low Voc FormulationDocument2 pagesProgibb LV Plus PGR - Low Voc FormulationDodik Novie PurwantoNo ratings yet

- Mechanical Specifications For Fiberbond ProductDocument8 pagesMechanical Specifications For Fiberbond ProducthasnizaNo ratings yet

- B. Pharmacy 2nd Year Subjects Syllabus PDF B Pharm Second Year 3 4 Semester PDF DOWNLOADDocument25 pagesB. Pharmacy 2nd Year Subjects Syllabus PDF B Pharm Second Year 3 4 Semester PDF DOWNLOADarshad alamNo ratings yet

- TILE QUOTEDocument3 pagesTILE QUOTEHarsh SathvaraNo ratings yet

- 1.2 - Sewing Machine and Special AttachmentsDocument3 pages1.2 - Sewing Machine and Special Attachmentsmaya_muth0% (1)

- ADIET Digital Image Processing Question BankDocument7 pagesADIET Digital Image Processing Question BankAdarshNo ratings yet

- DR-M260 User Manual ENDocument87 pagesDR-M260 User Manual ENMasa NourNo ratings yet

- Railway Airport Docks and HarbourDocument21 pagesRailway Airport Docks and HarbourvalarmathibalanNo ratings yet

- Swatchh Bharat AbhiyanDocument13 pagesSwatchh Bharat AbhiyanHRISHI SHARMANo ratings yet

- F-16c.1 Ginkgo Ginkgolic AcidDocument2 pagesF-16c.1 Ginkgo Ginkgolic AcidNarongchai PongpanNo ratings yet

- Hypophosphatemic Rickets: Etiology, Clinical Features and TreatmentDocument6 pagesHypophosphatemic Rickets: Etiology, Clinical Features and TreatmentDeysi Blanco CohuoNo ratings yet

- Flexibility Personal ProjectDocument34 pagesFlexibility Personal Projectapi-267428952100% (1)

- Seed SavingDocument21 pagesSeed SavingElectroPig Von FökkenGrüüven100% (2)

- 40 26Document3 pages40 26Maxi452No ratings yet

- Maureen L. Walsh - Re-Imagining Redemption. Universal Salvation in The Theology of Julian of NorwichDocument20 pagesMaureen L. Walsh - Re-Imagining Redemption. Universal Salvation in The Theology of Julian of NorwichAni LupascuNo ratings yet

- 7890 Parts-Guide APDocument4 pages7890 Parts-Guide APZia HaqNo ratings yet

- TIA Selection Tool: Release Notes V2022.05Document10 pagesTIA Selection Tool: Release Notes V2022.05Patil Amol PandurangNo ratings yet

- Panasonic 2012 PDP Troubleshooting Guide ST50 ST Series (TM)Document39 pagesPanasonic 2012 PDP Troubleshooting Guide ST50 ST Series (TM)Gordon Elder100% (5)

- Current Relays Under Current CSG140Document2 pagesCurrent Relays Under Current CSG140Abdul BasitNo ratings yet

- Chap 2 Debussy - LifejacketsDocument7 pagesChap 2 Debussy - LifejacketsMc LiviuNo ratings yet

- Garlic Benefits - Can Garlic Lower Your Cholesterol?Document4 pagesGarlic Benefits - Can Garlic Lower Your Cholesterol?Jipson VargheseNo ratings yet

- Emerson EPC48150 1800 FA1EPC48300 3200 FA1 V PDFDocument26 pagesEmerson EPC48150 1800 FA1EPC48300 3200 FA1 V PDFRicardo Andrés Soto Salinas RassNo ratings yet

- Basic First AidDocument31 pagesBasic First AidMark Anthony MaquilingNo ratings yet

- Embankment PDFDocument5 pagesEmbankment PDFTin Win HtutNo ratings yet

- KINETIC THEORY OF GASES TUTORIALDocument6 pagesKINETIC THEORY OF GASES TUTORIALMat SyafiqNo ratings yet

- Material and Energy Balance: PN Husna Binti ZulkiflyDocument108 pagesMaterial and Energy Balance: PN Husna Binti ZulkiflyFiras 01No ratings yet

- A Compilation of Thread Size InformationDocument9 pagesA Compilation of Thread Size Informationdim059100% (2)

- HVCCI UPI Form No. 3 Summary ReportDocument2 pagesHVCCI UPI Form No. 3 Summary ReportAzumi AyuzawaNo ratings yet

- Coleman Product PageDocument10 pagesColeman Product Pagecarlozz_96No ratings yet

- IEEE T&D Insulators 101 Design CriteriaDocument84 pagesIEEE T&D Insulators 101 Design Criteriasachin HUNo ratings yet

- The Voice of God: Experience A Life Changing Relationship with the LordFrom EverandThe Voice of God: Experience A Life Changing Relationship with the LordNo ratings yet

- From Raindrops to an Ocean: An Indian-American Oncologist Discovers Faith's Power From A PatientFrom EverandFrom Raindrops to an Ocean: An Indian-American Oncologist Discovers Faith's Power From A PatientRating: 1 out of 5 stars1/5 (1)