Professional Documents

Culture Documents

Introduction to Railway Engineering

Uploaded by

Andrea DeleonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Introduction to Railway Engineering

Uploaded by

Andrea DeleonCopyright:

Available Formats

INTRODUCTION

TO

RAILWAY ENGINEERING

RAILWAY ENGINEERING

The branch of Civil Engineering which deals

with the design, construction and

maintenance of the railway tracks for safe

and efficient movements of trains is called

Railway Engineering.

2

As per scope of this book, we shall study here

only about construction and maintenance of

railway tracks and not with the design of tracks.

SCOPE OF RAILWAY ENGINEERING

A part from design, construction and

maintenance of tracks, Railway engineering also

includes the study of the following important

topics :-

3

Contents

Introduction to railway

Classification of railways (on the basis of

gauge)

Components of railway track (rails, sleeper,

ballast)

Geometric design of railway track (cross

section, gradient, super elevation)

Maximum permissible speed

Railway points and crossings

Stations and yards

Platforms

Contents

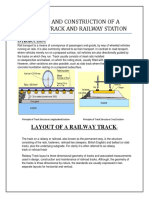

Rail transport is where a train runs along a set

of two parallel steel rails, known as a railway

or railroad. The rails are

anchored perpendicular to ties (or sleepers) of

timber, concrete or steel, to maintain a

consistent distance apart, or gauge. The rails

and perpendicular beams are placed on a

foundation made of concrete, or

compressed earth and gravel in a bed of

ballast.

Components of a railway track

(Permanent Way)

Rails

Sleepers

(Ties)

Ballast

What are the advantages of rail

transport?

It facilitate long distance travel and transport

of bulky goods which are not easily

transported through motor vehicles.

It is a quick and more regular form of

transport because it helps in the

transportation of goods with speed and

certainty.

It helps in the industrialization process of a

country by easy transportation of coal and

raw-materials at a cheaper rate.

It encourages mobility of labour ad thereby provides a

great scope for employment.

Railway is the safest form of transport. The chances of

accidents and breakdown of railways are minimum as

compared to other modes of transport.

The carrying capacity of the railways is extremely

large.

It is the largest public undertaking in the country. Their

charges are based on charge what the traffic can bear

principles which helps the poor. In fact, it is a national

necessity.

Disadvantages

The railway requires a large investment of capital.

Another disadvantages of railway transport is its

inflexibility. It routes and timings cannot be

adjusted to individual requirements.

Rail transport cannot provide door to door

service as it is tied to a particular track.

Intermediate loading or unloading involves

greater cost, more wear and tear and wastage of

time. The time cost of terminal operations are a

great disadvantage of rail transport.

Railway transport is unsuitable and

uneconomical for short distances and small

traffic of goods.

.

SYSTEMS OF RAILWAYS

The Railways can be provided on, above the

below the ground surface, suiting to the area.

Further, the Railways below the ground surface

can be constructed just below the ground

surface can be constructed just below the

ground level or at greater depths.

14

There are, therefore, the following four systems

of Railways :-

1. Surface railways;

2. Elevated railways;

3. Under ground railways;

4. Tube railways.

1) Surface railways :-The railways provided

over the ground surface are known as surface

railways.

Suitability :-This system is Railways is most

extensively used throughout the world

15

because this is the best system for

transporting people and goods. In

surface railways, the various means

like*level crossings,**over-bridge

or***under-bridge are to be provided for

crossing of the railway and road traffic

safely and efficiently.

2) Elevated railways :-The railways

provided at higher or elevated portion,

above the ground surface are called

high level or elevated railways.

In this system of Railways, a

16

continuous viaduct supported on piers, columns,

etc. is constructed and the track is carried on its

steel deck. This system is very costly because

buildings like stations, waiting halls, offices are

to be constructed at high levels requiring stair

cases, escalators, etc. but elevated railways

cause little obstruction due to piers, columns

supporting the track.

Suitability :- Elevated railways are suitable in

the heavily congested urban areas where the

under ground railways cannot be

17

constructed.

3) Under ground railways :- The railways

provided just below ground level are called

low level or underground railways.

In this system of Railways, tunnels are

constructed for carrying tracks through them

and a over - bridge is necessary at every road

crossing to carry the road traffic over the

railway traffic. Due to ventilation problems in

tunnels, electricity is the only source of

power for traction in under ground railways.

18

Advantages :-

i. This system provides rapid and unobstructed

transportation.

ii. This system helps in reducing traffic

congestion problems.

iii. This system provides safety during aerial

attack in war.

Suitability :- Under ground railways are suitable

in the heavily congested urban areas where

the traffic intensity on roads is heavy.

19

Tube railways :- The railway provided

underground at a greater depth of about 18

m or more (up to 52 m) are called tube

railways.

This system of railways is so called as

the section of the underground tunnels,

carrying the track, is to avoid the interference

of the tracks with water and gas pipes,

sewerage systems and oil or drainage pipes,

etc

Some important features of the tube

railways are given below :-

20

i. The railways stations have to be of

cylindrical form.

ii. Escalators or moving stair cases are to be

constructed to reach the tube railways.

iii. Only electric traction to be used to avoid the

smoke and ventilation problems.

iv. Automatic signaling system is to be used.

21

V. Such a mechanism of the train is to be used

that it cannot start until all the doors are closed,

and it automatically stops, if the signal is at

STOP position.

This system of railways is used by the London

Post Office in transporting mails through a small

diameter tunnel with automatic control without

any driver.

22

REQUIREMENTS OF A GOOD TRACK

Gauge should be correct and uniform

Alignment of track should be correct

Transition curves should provided wherever

required

Perfect cross levels between rails

Gradient should be as gentle as possible

Points and crossings (turnouts) should be

designed and maintained properly

List of countries by rail transport network size

Rank Country

Railway length

(km)

Date of

information

1 United States 226,427 (2007)

2 Russia 128,000 (2006)

3 China 91,000 (2010)

4 India 64,215 (2011)

5 Canada 57,216 (2007)

137 Nepal 59 (2006)

138

United Arab

Emirates

52 (2009)

147 Western Sahara 5 (2008)

148 Laos 4 (2005)

149 Lesotho 3 (1995)

150 Monaco 2 (2002)

151 Vatican City 0.852 (2001)

World 1,370,782 (2006)

COMPONENT PARTS OF A PERMANENT

WAY :-

The following are the component parts of a

permanent way or a railway track :-

Formation or sub grade ;

Ballast ;

Sleepers ;

Rails ;

Fixtures and fastenings.

All these component parts of a permanent way

are illustrated in Fig given below :-

25

26

REQUIREMENTS OF AN IDEAL PERMANENT WAY

The following are the principal requirements of

an ideal permanent way or of a good

railway track :-

i. The gauge of the permanent way should be

uniform, correct and it should not get

altered.

ii. Both the rails should be at the same level on

tangent (straight) portion of the track.

iii. Proper amount of *superelevation should

27

be provided to the outer rail above the inner rail

on curved portion of the track.

iv. The permanent way should be sufficiently

strong against lateral forces.

v. The curves, provided in the track, should be

properly designed.

vi. An even and uniform gradient should be

provided through out the length of the track.

vii. The **tractive resistance of the track should

be minimum.

viii. The design of the permanent way should be

such that the load of the train is

28

uniformly distributed on both the rails so as to

prevent unequal settlement of the track.

ix. It Should provide adequate elasticity in

order to prevent the harshness of impacts

between the rails and the moving wheel

loads of a train.

x. It should be free from excessive rail joints

and all the joining should be properly

designed and constructed.

xi. All the components parts such as rails,

sleepers, ballast, fixtures and

29

fastenings, etc. should satisfy the design

requirements.

xii. All the fixtures and fastenings such as

chairs, bearing plates, fish plates, fish

bolts, spikes etc. should be strong enough

to withstand the stresses occurring in the

track.

xiii. All the *points and crossings, laid in the

permanent way, should be properly

designed and carefully constructed.

xiv. It should be provided with fence near

30

level crossings and also in urban areas.

xv. It should be provided with proper drainage

facilities so as to drain off the rain water

quickly away from the track.

xvi. It should be provided with safe and strong

bridges coming in the alignment of the

track.

xvii.It should be provided with safe and strong

bridges coming in the alignment of the

track.

xviii.It should be so constructed that

31

Elements of Railway tracks

The track on a railway or railroad, also known as the

permanent way, is the structure consisting of the rails,

fasteners, sleepers and ballast (or slab track), plus the

underlying sub grade.

For clarity it is often referred to as railway track or

railroad track.

33

Track Formation

Requirements for Choosing a Track System:

Trains running on Track do not cause excessive environmental pollution in the form

of noise and ground vibration.

1. Costs of the total service life of the track must be as low as possible.

2. Maintenance should be low and as inexpensive as possible

The purpose of track is to transfer train loads to the formation.

Running Rails

Track gauge (Rail gauge)

The distance between

the inner sides of the

heads of the two load

bearing rails that make

up a single railway line.

Various gauges used worldwide

Various gauges used worldwide

Gauge Width (mm) Used in

Standard Gauge 1435 England, USA, Canada,

China, Australia

Broad Gauge (BG) 1676

1670

India, Brazil, Argentina

Spain, Portugal

Broad Gauge (Russian

Gauge)

1524 Russia, Finland

Cape Gauge 1067 Japan, Newzealand

Meter Gauge (MG) 1000

915

India, France

Ireland

Narrow Gauge 672

610

India, Pakistan

S. Africa

TYPES OF GAUGES PREVALENT IN INDIA

The different gauges prevalent in India are of

the following these types :-

1. Broad gauge (1676),

2. Metre gauge (1000),

3. Narrow gauge (762 mm & 610 mm).

40

41

1. Broad Gauge :- When the clear

horizontal distance between the inner

faces of two parallel rails forming a

track is 1676mm the gauge is called

Broad Gauge (B.G)

This gauge is also known as standard

gauge of India and is the broadest

gauge of the world.

The Other countries using the Broad

Gauge are Pakistan, Bangladesh,

SriLanka, Brazil, Argentine,etc.50%

Indias railway tracks have been laid to

this gauge.

Suitability :- Broad gauge is suitable under the

following Conditions :-

(i) When sufficient funds are available for the

railway project.

(ii) When the prospects of revenue are very bright.

This gauge is, therefore, used for tracks in plain

areas which are densely populated i.e. for routes of

maximum traffic, intensities and at places which

are centers of industry and commerce.

2. Metre Gauge :- When the clear horizontal

distance between the inner faces of two

42

parallel rails forming a track is 1000mm, the gauge is

known as Metre Gauge (M.G)

The other countries using Metre gauge are France,

Switzerland, Argentine, etc. 40% of Indias railway tracks

have been laid to this gauge.

Suitability :- Metre Gauge is suitable under the following

conditions:-

(i) When the funds available for the railway project are

inadequate.

(ii) When the prospects of revenue are not very bright.

This gauge is, therefore, used for tracks in under-

developed areas and in interior areas

43

Where traffic intensity is small and prospects for

future development are not very bright.

3.Narrow Gauge :- When the clear horizontal

distance between the inner faces of two parallel

rails forming a track is either 762mm or 610mm,

the gauge is known as Narrow gauge (N.G)

The other countries using narrow gauge are

Britain, South Africa, etc. 10% of Indias railway

tracks have been laid to this gauge.

Suitability :- Narrow gauge is suitable under the

following conditions :-

44

( i) When the construction of a track with wider

gauge is prohibited due to the provision of sharp

curves, steep gradients, narrow bridges and

tunnels etc.

(ii) When the prospects of revenue are not very

bright.

This gauge is, therefore, used in hilly and very

thinly populated areas. The feeder gauge is

commonly used for feeding raw materials to big

government manufacturing concerns as well as

to private factories such as steel plants, oil

refineries, sugar factories, etc.

45

Factors Affecting the Adoption of a

Particular Gauge

The following are the factors which affect the

adoption of a particular gauge for the track :-

I. Intensity of Population.

II. Intensity of Traffic.

III. Industrial and Commercial development of the

Locality.

IV. Prospects of future development of the area.

46

V. Funds available for th railway project.

VI. Topographical and Geological Features of the

country.

Effects of Breaking the Gauge

One country should have only one gauge

throughout its various parts. But the policy of

India and its Topographical, Geological and

Financial conditions have led to adopt various

gauges in its different parts. The various effects

of breaking or change of gauge are discussed

below :-

47

1. Advantages of Breaking the Gauge :-

i). The most effective advantage of breaking the

gauge is to render the railway an economical and

profitable concern.

ii). It facilitates the provision of a steeper gradient,

sharp curves and narrow tunnels by adopting a

less wide gauge in hilly and rocky areas.

2. Disadvantages of Breaking the Gauge :-

i). It causes much inconvenience to the passengers

while changing the train at station, with change of

gauge.

48

ii). It causes delay in movement of people and

goods.

iii). It results in wastage of time.

iv). It involves extra labour for unloading and

reloading the goods. The goods are also likely to

be damaged or dislocated at the junction station,

having change of gauge.

v). It requires the provision of extra and costly

transshipment yards, godowns, sheds, etc. at

every junction station having change of gauge.

vi). It causes extreme difficulty in quick

movement of military and ammunition during war

days.

49

Which gauge is the best?

Historically..

the choice of gauge was partly arbitrary and

partly a response to local conditions

Narrow-gauges - cheaper to build and can

negotiate sharper curves

Broad-gauges - give greater stability and

permit higher speeds.

Coning of Wheels

Coning of wheels is a method of beveling the wheels to avoid depreciation to the

wheels and rims. Normally the wheels are conned by a cone of semi-angle. It is

based on the theorem of coning.

Introduction

Railway wheels are usually beveled by means of a cone semi-angle of the

arrangement of 1/20 (rad.). The rails are also fixed at this identical angle to the

perpendicular. The width of the wheel is generally 140 mm and the rail top is

approximately 80 mm. The proportions of the region of liaison between an

encumbered wheel and rail reckon on the exact shapes of the wheel pace and

rail head. It also depends on the extent of the load occupied.

51

Coning of Wheels

The space between the inner borders of wheel rims is by and large kept less than

the measurement of the track. This results in a gap between the wheel rims and

running ends of the rails which is approximately equal to 1 cm, (3/8) on both

side. More often than not, the tread of wheels is perfectly the dead centre of the

beginning of the rail, since the wheel is chamfered to keep it in this middle

position involuntarily. Thus the wheels are beveled at an inclination of 1 in 20.

Advantages of coning the wheels

(i) Coning the wheels reduces the depreciation of the wheel rims and rails.

Depreciation is caused because of the friction action of rims with inner faces of

the rail top.

(ii) Coning also gives an option of lateral drift of the hinge with is wheels.

(iii) Coning also prevents, to some extent, the slipping of the wheels.

54

Theory of Coning

On a railway level track, the moment the hinge loco motes towards one rail, the

wheel tread width above the rail steps-up but reduces over the other rail. This

forbids the auxiliary movement and hinge pulls back to its original position. This

is possible only if the diameters on both rails are equal and the pressure on both

the rails is also equal.

On a coiled path, because of rigidity of the wheel bottom either of the wheels

has to slip by a measure equal to the differentiation of length or else the axle has

to move outward a bit so that a tread with longer diameter is formed over the

outer rail whereas a slighter diameter tread is formed over the inner rail.

55

FISH PLATE AND FISH BOLTS

BEARING PLATE (BENEATH THE

SLEEPER)

HIGH SPEED RAILS

Passenger rail transport that operates

significantly faster than the normal speed of

rail traffic.

The U.S. Department of Transportation's

reasonably expected to reach sustained

speeds of more than 125 mph (201 km/h)

WORLD RECORD

The world record for conventional high-speed

rail is held by the V150 of France, a specially

configured and heavily modified train which

clocked 574.8 km/h (357.2 mph) on a test run.

Aerodynamic designs (to reduce drag, lift, and

noise), air brakes, regenerative braking,

stronger engines, dynamic weight shifting, etc

High Speed train in France (> 574 Kmph)

RAILWAY POINTS AND CROSSINGS

POINTS AND CROSSINGS

To divert trains from one track to another, a

special arrangement is made.so that

the inside flange of the wheel can move on

the diverted track.

Such arrangement is called POINTS AND

CROSSINGS

A Right Hand Diversion

Points + crossings =

TURNOUT

POINTS AND SWITCHES

A railroad switch or points is a mechanical

installation enabling railway trains to be

guided from one track to another at a railway

junction.

POINTS AND SWITCHES

Electric, Hydraulic

or Manual

CROSSINGS

It is a special form of construction to provide

flange way clearance between two rails to be

crossed.

To achieve this, a gap is provided from throat

to nose of crossing over which the wheel

jumps.

Components of CROSSING of a Right Hand Turnout

Throat

To ensure that the wheel negotiates the gap

properly and doesnt strike the nose, the

outer rail is guided with the help of CHECK

RAILS.

CROSSINGS

Characteristics of a good crossing:

Should be rigid

Frog and wing rails should be protected

against damage so that the wheels do not

bump into the gap.

Frog should be of sufficient thickness.

Types of crossings

Acute angle (V-Crossing)

Obtuse angle crossing

Square Crossing

CAPACITY OF RAILWAY TRACK

Maximum number of trains that can run safely

on any length of track per hour.

Maximum number of trains that can be

handled in a yard TERMINAL CAPACITY.

Specification of Indian Railways

1. Sleeper density = no. of sleepers per rail

length.

Generally, 1 sleeper in every meter length.

Depends on: axle load, speed, strength of

sleeper, depth of ballast.

Sleeper density = n+ x (x = 7 usually)

n = length of each rail

2. Rails: 13 m long (for BG track)

Example: If sleeper density is n + 6 for a BG

track, calculate the number of sleepers in 960

m length of railway.

Length of each rail = 13 m

Total no. of rails in 960 m = 960/13 = 74

No. of sleeper in each rail = 13 + 6 = 19

So, no. of sleeper in 74 rails = 74 x 19 = 1406

3. Materials required per KM length of track

1. No. of rails per km = (1000/13) x 2 = 154

2. Weight of rail per km = (154 x 13) x 60 = 120,120 kg

(@ 60 kg/m)

3. No. of sleepers per km = (154/2) x (13 + 7) = 1540

4. No. of fish plates per km = 77 x 2 = 154

5. No. of bolts per km = 154 x 4 = 606

6. No. of bearing plates per km = 1540 x 2 = 3080

7. No. of fasteners = (1540 x 12)

8. Quantity of ballast per km = (0.2 x 3.35 x 1000)

cubic meter

You might also like

- Railway Engineering: IntroductionDocument49 pagesRailway Engineering: IntroductionPadma Shahi100% (1)

- Lec 5 Introduction To Railway PDFDocument40 pagesLec 5 Introduction To Railway PDFIrfanButtNo ratings yet

- Unit-III Railway EngineeringDocument208 pagesUnit-III Railway EngineeringShanmugaraj Muthuraj100% (2)

- Railway Track Engineering 1Document75 pagesRailway Track Engineering 1chyousuf80% (5)

- Railway PDFDocument42 pagesRailway PDFSarankumar ThathuruNo ratings yet

- Railway Engineering Vtu NotesDocument10 pagesRailway Engineering Vtu NotesHanamant HunashikattiNo ratings yet

- Module #6 Railway Alignment Design and Geometry REES 2010Document35 pagesModule #6 Railway Alignment Design and Geometry REES 2010Muhammed AliNo ratings yet

- Geometric DesignDocument15 pagesGeometric DesignHanamant HunashikattiNo ratings yet

- RAILWAY PLANNING: AN INTRODUCTION TO TRACK COMPONENTSDocument139 pagesRAILWAY PLANNING: AN INTRODUCTION TO TRACK COMPONENTSrenisha mNo ratings yet

- CH 2 Railw-1Document49 pagesCH 2 Railw-1seyoum GNo ratings yet

- AAiT - Lecture 04 Railway Track Structure - Part IIDocument66 pagesAAiT - Lecture 04 Railway Track Structure - Part IImenur blatuNo ratings yet

- Chapter-3 TrackDocument77 pagesChapter-3 TrackGoytom yigezuNo ratings yet

- Chapter - 3-Geometric Design of Highways Cross Sectional ElementsDocument17 pagesChapter - 3-Geometric Design of Highways Cross Sectional ElementsTewodros Abate100% (1)

- Chapter-7 Organization of Train OperationDocument31 pagesChapter-7 Organization of Train OperationBabangida Gida NessreNo ratings yet

- Curves and Superelevation OptimizationDocument43 pagesCurves and Superelevation OptimizationGunjan KumarNo ratings yet

- Chapter 4 Geometric DesignDocument65 pagesChapter 4 Geometric DesignISABIRYE BAKALINo ratings yet

- Switches and TurnoutsDocument40 pagesSwitches and TurnoutsKaushal Mehta100% (1)

- Chapter-1 Basics of RailwayDocument75 pagesChapter-1 Basics of RailwayDinaras IbrahimNo ratings yet

- Indian Railways Permanent Way ManualDocument334 pagesIndian Railways Permanent Way ManualParamvir chahliaNo ratings yet

- Track AlignmentDocument68 pagesTrack AlignmentcezarNo ratings yet

- Railway Engineering 2 TractionDocument21 pagesRailway Engineering 2 Tractionraghav Varma100% (1)

- Railway Engineering-2Document40 pagesRailway Engineering-2sivaraman assocaiatesNo ratings yet

- Chapter-5 SwitchesDocument46 pagesChapter-5 SwitchesBabangida Gida NessreNo ratings yet

- Geometric Design of RailwaysDocument36 pagesGeometric Design of RailwaysEngr Nissar Kakar50% (2)

- Railway EngineeringDocument2 pagesRailway EngineeringChaitanya DaraNo ratings yet

- Construction of TracksDocument74 pagesConstruction of TracksCooldeep LastlongerNo ratings yet

- Geometric Design of Railways TracksDocument21 pagesGeometric Design of Railways TracksJACOB CHIMIDZINo ratings yet

- Geometric Design Lect 6,7,8-2Document64 pagesGeometric Design Lect 6,7,8-2pritam BhowmikNo ratings yet

- Geometric Design: CEE 320 Steve MuenchDocument55 pagesGeometric Design: CEE 320 Steve MuenchRohit Mathur100% (4)

- Railway EngineeringDocument138 pagesRailway Engineeringrenisha m100% (1)

- Railway Track FasteningsDocument20 pagesRailway Track FasteningsFaisal RasoolNo ratings yet

- LECTURE NO 10 (Intersection)Document40 pagesLECTURE NO 10 (Intersection)Arman AliNo ratings yet

- AAiT - Lecture 03 Railway Geometry - Part I - 1792848699 PDFDocument33 pagesAAiT - Lecture 03 Railway Geometry - Part I - 1792848699 PDFAnonymous FaJn5qPbBNo ratings yet

- lectut-CEN-307-pdf-CEN 307 Geometric Design of Track Part 1 and 2 PDFDocument73 pageslectut-CEN-307-pdf-CEN 307 Geometric Design of Track Part 1 and 2 PDFama kumarNo ratings yet

- FCE 346 - 2018 (2014) - Unit - 3 PDFDocument65 pagesFCE 346 - 2018 (2014) - Unit - 3 PDFbernie3sanders-1No ratings yet

- Components of Railway EngineeringDocument25 pagesComponents of Railway EngineeringSayan DebNo ratings yet

- Transportation EngineeringDocument149 pagesTransportation EngineeringadeolaodukoyaNo ratings yet

- 1.3 - Frequency of Inspection With Various Track Recording ModesDocument31 pages1.3 - Frequency of Inspection With Various Track Recording ModesChiranjibNo ratings yet

- Railway Management EngineeringDocument3 pagesRailway Management EngineeringipolyzoNo ratings yet

- BALLAST SpecificationsDocument39 pagesBALLAST SpecificationsRajaram KulapakaNo ratings yet

- 1.2 - Highway ClassificationDocument65 pages1.2 - Highway ClassificationAbdullahi Abdi HashiNo ratings yet

- Track Tolerances: Neethu Narayanan B060128CE Murshid B060471CEDocument20 pagesTrack Tolerances: Neethu Narayanan B060128CE Murshid B060471CEGAUTAM DUANo ratings yet

- Components of A BridgeDocument4 pagesComponents of A BridgeBhemalee Tono DimalaluanNo ratings yet

- A6 PDFDocument8 pagesA6 PDFDhurbaNo ratings yet

- Geometric Design of The TrackDocument12 pagesGeometric Design of The TrackTarun SKNo ratings yet

- Modes of Transport and Railway EngineeringDocument113 pagesModes of Transport and Railway EngineeringSeetunya Jogi100% (4)

- Fundamentals of Safety Planning and DesignDocument108 pagesFundamentals of Safety Planning and DesignJeremy Mark SorianoNo ratings yet

- Newirpwm PDFDocument416 pagesNewirpwm PDFPiyush MauryaNo ratings yet

- Railway Engineering: By: Rohit RanaDocument26 pagesRailway Engineering: By: Rohit Ranavikash sharmaNo ratings yet

- Railway & Airport Engineering: UNIT - 1 & 2Document95 pagesRailway & Airport Engineering: UNIT - 1 & 2Civil RguktNo ratings yet

- Introduction To Highway Engineering: 1. Importance of TransportationDocument7 pagesIntroduction To Highway Engineering: 1. Importance of TransportationFrancis AguisandaNo ratings yet

- Ce 404-Sec11Document20 pagesCe 404-Sec11Yasser AlghrafyNo ratings yet

- Exercise: Lucy Consulting EngineersDocument8 pagesExercise: Lucy Consulting EngineersAXMEDNo ratings yet

- Handbook of Railroad Construction; For the use of American engineersFrom EverandHandbook of Railroad Construction; For the use of American engineersNo ratings yet

- Railway EngineeringDocument26 pagesRailway EngineeringmarekmanyielNo ratings yet

- Railways, Harbour, Tunneling and Airports PDFDocument102 pagesRailways, Harbour, Tunneling and Airports PDFRanjitha SR RanjuNo ratings yet

- Layout and Construction of A Railway Track and Railway StationDocument12 pagesLayout and Construction of A Railway Track and Railway StationAli Hassan LatkiNo ratings yet

- Railways, Runways and Transportation ModesDocument40 pagesRailways, Runways and Transportation ModesUsman Afzal100% (1)

- Components of A Railway TrackDocument128 pagesComponents of A Railway TrackBlessings Mushayi100% (1)

- TendderPackage 1Document59 pagesTendderPackage 1Andrea DeleonNo ratings yet

- Allahabad Junction PicturesDocument15 pagesAllahabad Junction PicturesAndrea DeleonNo ratings yet

- Masterplan PDFDocument110 pagesMasterplan PDFAndrea DeleonNo ratings yet

- Determination of Ultimate Pile Bearing Capacity From A Seismic Method of Shear Wave Velocity in Comparison With Conventional MethodsDocument5 pagesDetermination of Ultimate Pile Bearing Capacity From A Seismic Method of Shear Wave Velocity in Comparison With Conventional MethodsAndrea DeleonNo ratings yet

- 1.9 GroutingDocument21 pages1.9 GroutingAndrea DeleonNo ratings yet

- Agnihotra 2018 Mithapur RD Arora Colony Alipur Mithapur Jalandhar Punjab 144022 India enDocument3 pagesAgnihotra 2018 Mithapur RD Arora Colony Alipur Mithapur Jalandhar Punjab 144022 India enAndrea DeleonNo ratings yet

- Strength Evaluation of Concrete Using Marble Powder and Crushed Tile Aggregates As Partial Replacement of Cement and Coarse AggregatesDocument3 pagesStrength Evaluation of Concrete Using Marble Powder and Crushed Tile Aggregates As Partial Replacement of Cement and Coarse AggregatesAndrea DeleonNo ratings yet

- Summary SheetDocument3 pagesSummary SheetAndrea DeleonNo ratings yet

- Evaluation of Concrete Strength Using Marble Powder and Crushed Tile AggregatesDocument43 pagesEvaluation of Concrete Strength Using Marble Powder and Crushed Tile AggregatesAndrea DeleonNo ratings yet

- 24 (2013) Liquefaction Study of Subsurface Soil in Part of Delhi University, North CampusDocument9 pages24 (2013) Liquefaction Study of Subsurface Soil in Part of Delhi University, North CampusAndrea DeleonNo ratings yet

- Correlation Between Shear Wave VelocityDocument10 pagesCorrelation Between Shear Wave VelocityAndrea DeleonNo ratings yet

- 3 Describe Image PTEA StrategiesDocument5 pages3 Describe Image PTEA StrategiesPrasad Bhopal G67% (9)

- GPSDocument31 pagesGPSAndrea DeleonNo ratings yet

- Effect of Waste Material On ConcreteDocument41 pagesEffect of Waste Material On ConcreteAndrea DeleonNo ratings yet

- First LVL Slab Drg-ModelDocument1 pageFirst LVL Slab Drg-ModelAndrea DeleonNo ratings yet

- Slab Design:-Out House Room: (One Long & One Short Edge Discontineous) (Two Way)Document8 pagesSlab Design:-Out House Room: (One Long & One Short Edge Discontineous) (Two Way)Andrea DeleonNo ratings yet

- Bar Bending Schedule of Main Slab: 1 Slab Reinforcement Detail (Grid A)Document8 pagesBar Bending Schedule of Main Slab: 1 Slab Reinforcement Detail (Grid A)Andrea DeleonNo ratings yet

- Final House Plan-Mode3lDocument1 pageFinal House Plan-Mode3lAndrea DeleonNo ratings yet

- ScariDocument64 pagesScariancutza_schNo ratings yet

- Effect of RBI-81 On CBR and Swell Behaviour of Expansive SoilDocument4 pagesEffect of RBI-81 On CBR and Swell Behaviour of Expansive SoilAndrea DeleonNo ratings yet

- Questions On Introduction To Indian RailwaysDocument11 pagesQuestions On Introduction To Indian RailwaysAndrea DeleonNo ratings yet

- Objective TypeADocument3 pagesObjective TypeAAndrea DeleonNo ratings yet

- CE - GATE2014 With Complete Solution PDFDocument37 pagesCE - GATE2014 With Complete Solution PDFAndrea DeleonNo ratings yet

- Kumar 2014Document4 pagesKumar 2014William Segundo Araujo NavarroNo ratings yet

- WeatheringDocument23 pagesWeatheringAndrea DeleonNo ratings yet

- Disaster Management CycleDocument15 pagesDisaster Management CycleSid Singh100% (1)

- Mix Proportions For RHADocument1 pageMix Proportions For RHAAndrea DeleonNo ratings yet

- Utilization of Waste Crushed Tile Materials As Coarseaggregate in ConcreteDocument11 pagesUtilization of Waste Crushed Tile Materials As Coarseaggregate in ConcreteAndrea DeleonNo ratings yet

- Constructionequipment 130411074220 Phpapp01Document88 pagesConstructionequipment 130411074220 Phpapp01phankhoa83No ratings yet

- Effect of SR, Na, Ca & P On The Castability of Foundry Alloy A356.2Document10 pagesEffect of SR, Na, Ca & P On The Castability of Foundry Alloy A356.2jose.figueroa@foseco.comNo ratings yet

- Homework ClassDocument11 pagesHomework ClassHossain100% (1)

- Regresi SederhanaDocument6 pagesRegresi SederhanaTrii WulLandarii127No ratings yet

- Particle Size Reduction TechniquesDocument10 pagesParticle Size Reduction TechniquesJay ShahNo ratings yet

- Electrical Plant Load AnalysisDocument36 pagesElectrical Plant Load AnalysisJesus EspinozaNo ratings yet

- Innovative Lesson PlanDocument12 pagesInnovative Lesson PlanMurali Sambhu33% (3)

- Interface Requirements SpecificationDocument27 pagesInterface Requirements Specificationdhanoj6522No ratings yet

- Automate Distribution of Quantity in MIGODocument8 pagesAutomate Distribution of Quantity in MIGOyougesh100% (2)

- XCKN2145G11: Limit Switch XCKN - TH - Plastic Roller Lever Var - Length - 1NO+1NC - Snap - Pg11Document2 pagesXCKN2145G11: Limit Switch XCKN - TH - Plastic Roller Lever Var - Length - 1NO+1NC - Snap - Pg11Boby SaputraNo ratings yet

- h2 PR Final Key SP 13Document3 pagesh2 PR Final Key SP 13George ConstantinouNo ratings yet

- Binder 1Document36 pagesBinder 1BobbyNo ratings yet

- Design of Low Head Weirs for Great Ruaha RiverDocument2 pagesDesign of Low Head Weirs for Great Ruaha RiverJames LaurentNo ratings yet

- C34 January 2014 (IAL)Document44 pagesC34 January 2014 (IAL)SandyDavidNo ratings yet

- F 0177 914 Continuous Emission MonitorDocument2 pagesF 0177 914 Continuous Emission MonitorKUNALNo ratings yet

- Proceeding Book SIBE 2017Document625 pagesProceeding Book SIBE 2017Yochanan meisandroNo ratings yet

- List of Eligible Candidates Applied For Registration of Secb After Winter 2015 Examinations The Institution of Engineers (India)Document9 pagesList of Eligible Candidates Applied For Registration of Secb After Winter 2015 Examinations The Institution of Engineers (India)Sateesh NayaniNo ratings yet

- Fractional Brownian Motions in Financial Models, Simulation and PricingDocument111 pagesFractional Brownian Motions in Financial Models, Simulation and Pricingnahv_08No ratings yet

- Is 15894-2018Document25 pagesIs 15894-2018surender kumarNo ratings yet

- Chemistry Paper (Chap 1-4)Document2 pagesChemistry Paper (Chap 1-4)XarOonNo ratings yet

- ModelDocument3 pagesModelCarlo ThornappleNo ratings yet

- BIS 14665 Part 2Document6 pagesBIS 14665 Part 2Sunil ChadhaNo ratings yet

- Nob Tool CatalogueDocument2 pagesNob Tool CatalogueFoton y JacNo ratings yet

- Foundations On Friction Creep Piles in Soft ClaysDocument11 pagesFoundations On Friction Creep Piles in Soft ClaysGhaith M. SalihNo ratings yet

- 25 Most Frequently Asked DSA Questions in MAANGDocument17 pages25 Most Frequently Asked DSA Questions in MAANGPranjalNo ratings yet

- Clinical Microscopy ReviewerDocument31 pagesClinical Microscopy ReviewerbokbokbokNo ratings yet

- Subsurface Remote Sensing of Kelp ForestsDocument20 pagesSubsurface Remote Sensing of Kelp Forestsjpeterson1No ratings yet

- Selection of Dryers I - IndiaDocument38 pagesSelection of Dryers I - Indiasilvership2291100% (1)

- 4PH0 1P Que 20160119 PDFDocument28 pages4PH0 1P Que 20160119 PDFschlemielzNo ratings yet

- Answer: 60% Answer: Geography 55%: Harmonic Mean-Is Good at Handling Large OutliersDocument2 pagesAnswer: 60% Answer: Geography 55%: Harmonic Mean-Is Good at Handling Large Outliersroshia maeNo ratings yet