Professional Documents

Culture Documents

Characteristics and Applications: Notes On Usage

Uploaded by

neerajtiwari36Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Characteristics and Applications: Notes On Usage

Uploaded by

neerajtiwari36Copyright:

Available Formats

TN-58 JIS Z 3241 DL5016-4A1

AWS A5.5 E8018-C3

EN 499 E 46 4 1Ni B 32

Characteristics and Applications:

TN-58 is an iron powder low hydrogen electrode for the welding of low temperature service steel in all

positions. The weld metal contains 1.0%Ni. It is suitable for the welding of LPG tanks. The welding can be

done with good X-ray soundness, high deposition rate, and good impact value at -40℃. Proper base metals

are also including high-carbon steel, low Manganese alloy steel, 540~610N/mm2 high tensile steel, cast iron,

steel pipe for low temperature service, pressure vessel, ASTM A225 Gr D/A333 Gr1&6/A607 Gr60/A707

Gr.L5.L6, etc..

Notes on Usage:

1. Be sure to clean up the contaminations on the base metal and welding seam so as not to derogate the

weld metal quality from particles.

2. Maintaining short arc length as possible is highly recommended. While welding with weave method, moving

range should be controlled within 3 times of the wire’s dia.

3. Dry the electrodes at 350~400℃ for 60 minutes before use. Take out a batch of half day consumption and

keep at 100~150℃ during welding process.

4. When the heat input is excessive, the impact value tends to be reduced. Therefore, perform welding with

selecting proper heat input depending on the required impact value.

5. Pre-heat at 50~100℃ while in welding thick plate.

Typical chemical composition of weld metal (wt%)

C Mn Si P S Ni

0.070 0.80 0.40 0.02 0.010 1.00

Typical mechanical properties of weld metal

YS (MPa) TS (MPa) EL % CVN -40℃ J

480 590 30 120

Welding position

Sizes and recommended current range (AC or DC<+>)

Diameter (mm) 3.2 4.0 5.0

Length (mm) 350 450 450

F 100-140 140-180 180-230

Amps

V&OH 90-130 120-160 -

0903

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Tests Conducted On Under Water Battery - YaduDocument15 pagesTests Conducted On Under Water Battery - YadushuklahouseNo ratings yet

- Steel Statistical Yearbook 2007Document23 pagesSteel Statistical Yearbook 2007rajatNo ratings yet

- Steel Bars, Alloy, Standard GradesDocument4 pagesSteel Bars, Alloy, Standard GradesGian SennaNo ratings yet

- ARUN Portfolio Brochure - (ARTUS 8)Document4 pagesARUN Portfolio Brochure - (ARTUS 8)Minh TBB GlobalNo ratings yet

- Record of Welder or Welding Operator Qualification TestsDocument1 pageRecord of Welder or Welding Operator Qualification TestsBalkishan DyavanapellyNo ratings yet

- #15 Adhesion Test Report (3M VHB APT & Alpolic Panels)Document5 pages#15 Adhesion Test Report (3M VHB APT & Alpolic Panels)Senthil KumarNo ratings yet

- Machine Design Examination 6Document5 pagesMachine Design Examination 6SYBRELLE CRUZNo ratings yet

- Heat Treatment Part 1Document32 pagesHeat Treatment Part 1Naman DaveNo ratings yet

- Shielded Metal WeldingDocument74 pagesShielded Metal WeldingwernhowNo ratings yet

- Presentation BSWDocument75 pagesPresentation BSWBharath100% (1)

- Weld Schedule For 135 TPH CFBC UltratechDocument4 pagesWeld Schedule For 135 TPH CFBC Ultratechpulakjaiswal85No ratings yet

- MSS SP-25Document32 pagesMSS SP-25ashams492No ratings yet

- Astm A 668 - 98 PDFDocument7 pagesAstm A 668 - 98 PDFRyan LasacaNo ratings yet

- ABB Universal ClampsDocument3 pagesABB Universal ClampsBoris CorralesNo ratings yet

- Cwi QuestionsDocument6 pagesCwi QuestionsGokul Thangam75% (4)

- Use O? AllDocument13 pagesUse O? AllHòa NguyễnNo ratings yet

- Alloy-Steel and Stainless Steel Bolting Materials For Low-Temperature ServiceDocument8 pagesAlloy-Steel and Stainless Steel Bolting Materials For Low-Temperature Servicesharon blushteinNo ratings yet

- Asme Sec I PT PG General 2005 PDFDocument77 pagesAsme Sec I PT PG General 2005 PDFarlyNo ratings yet

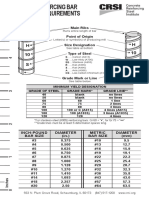

- Astm Reinforcing Bar Marking Requirements: (Inch-Pound)Document2 pagesAstm Reinforcing Bar Marking Requirements: (Inch-Pound)Babrak Khan NoorzoiNo ratings yet

- Machine Design REE 302: Tutorial 3 (Ch.2: Materials II)Document19 pagesMachine Design REE 302: Tutorial 3 (Ch.2: Materials II)Dull PersonNo ratings yet

- Itp Structural SteelDocument2 pagesItp Structural SteelSahad VarambankallanNo ratings yet

- US Series W X F (New) 8-19Document1 pageUS Series W X F (New) 8-19Heriberto MejiaNo ratings yet

- Modine Steam CoilsDocument8 pagesModine Steam CoilsBrijeshNo ratings yet

- Aalco Aluminium PDFDocument33 pagesAalco Aluminium PDFMihai NedeaNo ratings yet

- Selection of Welding Electrodes for RailwaysDocument43 pagesSelection of Welding Electrodes for Railwayssalman ali100% (1)

- Ras Markaz Crude Oil Park Project (Phase1)Document45 pagesRas Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- Technical Bulletin: Pickling Methods For Duplex Stainless SteelDocument3 pagesTechnical Bulletin: Pickling Methods For Duplex Stainless SteelPhoenix KukuruyukNo ratings yet

- Effect of Various Heat Treatments On Microstructure of Aisi 4130 SteelDocument6 pagesEffect of Various Heat Treatments On Microstructure of Aisi 4130 SteelДмитрий РыбаковNo ratings yet

- Ammendement in IRC 83 (Part IV) - 2020Document6 pagesAmmendement in IRC 83 (Part IV) - 2020Syed Abdullah MujeebNo ratings yet

- Metals and Non-Metals: Multiple Choice QuestionsDocument10 pagesMetals and Non-Metals: Multiple Choice QuestionsShreyansh DuggarNo ratings yet