Professional Documents

Culture Documents

Qcs 2010 Section 12 Part 2 Excavation PDF

Uploaded by

bryanpastor106Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Qcs 2010 Section 12 Part 2 Excavation PDF

Uploaded by

bryanpastor106Copyright:

Available Formats

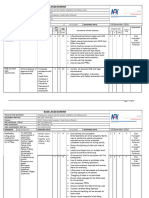

QCS 2010

Section 12

Part 2

Excavation

Page 1

2.

EXCAVATION ................................................................................................ 2

2.1

GENERAL ...................................................................................................... 2

2.1.1

2.1.2

Scope

References

2.2

EXCAVATION FOR STRUCTURES .............................................................. 2

2.2.1

2.2.2

2.2.3

2.2.4

2.2.5

2.2.6

2.2.7

2.2.8

Excavation Support

Removal of Water

Approvals

Inspection

Unsound Materials

Over-Excavation

Finishing to Excavation

Storage of Excavated Material

2.3

MATERIALS................................................................................................... 4

2.3.1

2.3.2

2.3.3

2.3.4

Excavated Material

Common Excavation

Rock Excavation

Blasting

2.4

DISPOSAL OF SURPLUS MATERIAL .......................................................... 4

2.4.1

General

QCS 2010

2

2

2

3

3

3

3

4

4

4

4

4

4

4

4

QCS 2010

Section 12

Part 2

Excavation

Page 2

2.

EXCAVATION

2.1

GENERAL

2.1.1

Scope

This Section specifies the requirements for the excavation for structures, culverts, headwalls,

catch basins, manholes, inlets, retaining walls and the like. The work includes all necessary

clearing and grubbing and the disposal of all material resulting from such excavation. The

work also includes the provision, and subsequent removal, of all necessary bailing, drainage,

pumping, sheeting, strutting, coffer dam construction and crib construction.

Rates for excavation shall include for excavation in any material. Excavation in any material

shall include common excavation, side shoring, support systems, excavation in artificial hard

material and shall be inclusive of all encountered impediments, including roots, boulders etc.

Blasting will not be permitted without the written approval of the Engineer.

Related Sections and Parts are as follows:

Section 1

Section 6

2.1.2

1

General

Roadworks

References

The following standards are referred to in this Part;

BS 1377

Method of test for soils for civil engineering purposes

2.2

EXCAVATION FOR STRUCTURES

2.2.1

Excavation Support

Prior to Commencing any structural excavation work which is 1.5 m or greater in depth, the

Contractor shall design an excavation support system.

Details of the excavation support system shall be submitted to the Engineer for review and

approval at least one week before any excavation work commences. Details of the

excavation support system shall be complete with, but not limited to, the following:

(a)

(b)

drawings of the structural support members showing materials, sizes and spacing,

calculations showing the maximum theoretical deflection of the support member.

The system is to be designed so that no members extend through surfaces exposed in the

finished construction, and no shoring or bracing is placed under permanent structures.

The Contractor shall submit to the engineer calculations of lateral earth pressure for the full

excavation depths, surcharge loads of any description, equipment loads, forces at various

stages of support during excavation, the maximum design loads to be carried by various

members of the support system and strut pre-load forces.

If the structure support system proposed includes tieback anchors, the Contractors

submitted details shall include drawings that show the profile of the soil in which each anchor

is to be installed.

Tieback anchors that project beyond the vertical limits of the Site boundary on to adjoining

property shall only be permitted if permission to do so is given by the owner of the property in

writing. Copies of such written permission shall be submitted to the along with excavation

support system proposals.

QCS 2010

QCS 2010

Section 12

Part 2

Excavation

Page 3

2.2.2

Removal of Water

At locations where the excavation extends below the groundwater table, a dewatering

system is to be provided which will lower ambient groundwater levels. The resulting

groundwater level shall be at a depth which is sufficiently below the excavation level so as to

allow the safe and proper execution of the work. The resulting foundation level shall be a

stable, dry sub-grade which is suitable for the execution of subsequent operations.

The Contractor is to design the dewatering methods and settling basins so that no critical

amounts of soil, sand or silt are removed during either the dewatering operations.

Complete working drawings showing the type of dewatering and groundwater control system

proposed shall be submitted to the Engineer for his review. The Contractors submittal shall

include drawings that show the arrangement, location and depths of the proposed

dewatering system. A complete description of the equipment and materials to be used and

the procedures to be followed to be given, together with details of required standby

equipment and standby power supply. The Contractor shall also indicate his proposed

location(s) for the discharge of extracted groundwater.

The dewatering system design should also include the details of measures required to

prevent damage due to settlement of roads, pavements, utilities, sewers, buildings and other

structures outside the excavation but within the area affected by the dewatering.

2.2.3

Approvals

The designs of the structure excavation support system and the dewatering systems

specified above is to be prepared by and signed by a qualified engineer experienced in this

type of design work. Approval of the designs and shop drawings will not relieve the

Contractor of the adequacy and performance of these temporary works.

2.2.4

Inspection

In addition to the provisions of Part 13 of Section 1, the Contractor shall also undertake the

following described in the following Clauses unless otherwise instructed by the Engineer.

Following a detailed inspection of all adjacent structures, the Contractor shall prepare a

report on the pre-construction condition of all structures that may be affected during

construction of the Works. The report will include photographs, drawings and sketches with

levels and dimensions fully illustrating the structure's condition. In particular, it shall note any

existing damage or structural inadequacy. Deficiencies and damage are to be suitably

marked on the structure in a way that it is not permanently defaced.

Three (3) copies of the Report shall be submitted for the approval of the Engineer. Once

approved, five (5) additional copies shall be supplied to the Engineer.

The Contractor shall carry out a survey of levels of undisturbed ground before commencing

any excavations.

When the excavation has been carried down to formation level the Contractor shall advise

the Engineers Representative that the excavation is ready for inspection and the Engineers

Representative shall, without reasonable delay, inspect the excavation unless he considers it

unnecessary.

2.2.5

Unsound Materials

Any loose, improperly compacted, soft or other unsuitable material which is encountered

below or adjacent to structural foundation levels shall be completely removed, backfilled with

a suitable material and compacted to 95% of the maximum dry density as determined by BS

1377 Part 4. Backfilling shall be done in layers with an unconsolidated thickness not

exceeding 200 mm up to the foundation level. The limits of such work shall be as directed by

the Engineer. Alternatively, the Engineer may instruct that removed material be replaced with

Class C25 concrete.

QCS 2010

QCS 2010

Section 12

Part 2

Excavation

Page 4

2.2.6

Over-Excavation

Any over excavation is to be backfilled with Class C25 concrete at the Contractors expense.

2.2.7

Finishing to Excavation

All rock or other hard foundation material is to be cleaned of all loose material. All seams or

crevices are to be cleaned and grouted. All loose and disintegrated rock and thin strata is to

be removed.

When the structure is to rest on material other than rock, excavation to final grade should not

be made until just before the structure is to be placed/constructed and special care is to be

taken not to disturb the excavated surface. The surface required shall be rolled and

compacted to 95% of the maximum dry density.

2.2.8

Storage of Excavated Material

Excavated material is not to be stored or deposited in such a way as to endanger structures

or cause an obstruction of any kind.

2.3

MATERIALS

2.3.1

Excavated Material

All excavated material will be the property of the Owner and no material shall be removed,

transported and disposed of without the prior written approval of the Engineer.

2.3.2

Common Excavation

Common excavation consists of the excavation and satisfactory disposal of all soils, certain

strata and rock boulders less than one (1) cubic metre in volume. Strata which are altered

and weathered and are in place, but which are not firm enough, or in the opinion of the

Engineer are not rigid enough to have all the characteristics of rock excavation is to be

classified as common excavation.

2.3.3

Rock Excavation

Rock excavation consists of the excavation and satisfactory disposal of all unaltered and

unweathered firm and rigid igneous, metamorphic and sedimentary solid rock that in the

opinion of the Engineer can only be excavated by the use of pneumatic hammers or other

such similar apparatus.

2.3.4

Blasting

Blasting will not be permitted without prior approval. (Refer to Section 6: Roadworks).

2.4

DISPOSAL OF SURPLUS MATERIAL

2.4.1

General

All materials arising from site clearance or excavation which are surplus, suitable or

unsuitable for use in the Works will become the property of the Owner and will not be

disposed of by the Contractor either off the Site to an approved tip without written approval

from the Engineer. If directed, or otherwise agreed by the Engineer, the Contractor may

dispose of surplus material on the Site in an approved manner as directed by the Engineer.

END OF PART

QCS 2010

You might also like

- Qcs 2010 Section 11 Part 1.3 Regulatory Document - WORKING at HEIGHTSDocument145 pagesQcs 2010 Section 11 Part 1.3 Regulatory Document - WORKING at HEIGHTSbryanpastor106100% (5)

- Appointment Letter Staff Nurse Job DescriptionDocument3 pagesAppointment Letter Staff Nurse Job DescriptionRenita ChrisNo ratings yet

- 00-Site InstructionDocument7 pages00-Site InstructionSyed Munawar AliNo ratings yet

- Qcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work SysteDocument20 pagesQcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work Systebryanpastor106No ratings yet

- Will The Real SMART Goals Please Stand Up?: Robert S. Rubin Saint Louis UniversityDocument2 pagesWill The Real SMART Goals Please Stand Up?: Robert S. Rubin Saint Louis UniversityKyoko TakayanagiNo ratings yet

- Regulationsof Internal Water Installationsand ConnectionDocument66 pagesRegulationsof Internal Water Installationsand ConnectionHenrik Gal de OcampoNo ratings yet

- Normal Operating Procedures for Parks Machinery and TasksDocument7 pagesNormal Operating Procedures for Parks Machinery and TasksHafiezul HassanNo ratings yet

- Task Based Risk Assessment for Pipe Transportation and InstallationDocument2 pagesTask Based Risk Assessment for Pipe Transportation and InstallationBeyar. ShNo ratings yet

- Complete Office Fitout SWMSDocument30 pagesComplete Office Fitout SWMSPonraj MNo ratings yet

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDocument9 pagesPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDan Dumbravescu100% (1)

- RA0128 - Installation of UPS SystemDocument17 pagesRA0128 - Installation of UPS SystemExplore the world TodayNo ratings yet

- Construction IssuesDocument31 pagesConstruction IssuesFaisar NgNo ratings yet

- Risk Assessment SK GraphiteDocument8 pagesRisk Assessment SK GraphiteWasim KhanNo ratings yet

- Brick Masonry - EHS Risk AssessmentDocument2 pagesBrick Masonry - EHS Risk Assessmentnagarjuna100% (3)

- CIA Sec 3Document90 pagesCIA Sec 3Rock StarNo ratings yet

- Method Statement MS - DSD-016/M02 Rev. 00: Souq Residences Fzco, Golden Mile, Palm Jumeirah, DubaiDocument8 pagesMethod Statement MS - DSD-016/M02 Rev. 00: Souq Residences Fzco, Golden Mile, Palm Jumeirah, DubaiSIBINNo ratings yet

- RA - 18 - For Concrete Topping On Hollow Core SlabDocument14 pagesRA - 18 - For Concrete Topping On Hollow Core SlabIbrahim EsmatNo ratings yet

- Omegadyne Inc. Safety StatementDocument17 pagesOmegadyne Inc. Safety StatementStephanie BakerNo ratings yet

- Risk Assessment (Park Bench)Document2 pagesRisk Assessment (Park Bench)BaileyNo ratings yet

- 38 Through Installation Job Safe Practice Ladder and Rack InstallationDocument1 page38 Through Installation Job Safe Practice Ladder and Rack InstallationsalmanNo ratings yet

- Risk Assessment-LandscpaeDocument4 pagesRisk Assessment-LandscpaeSeguNo ratings yet

- Blasting and Painting ProcedureDocument27 pagesBlasting and Painting ProcedurePerlie BellomosNo ratings yet

- WSH Guidelines - Working Safely On Roofs - FinalDocument40 pagesWSH Guidelines - Working Safely On Roofs - FinalSyamir Islam100% (1)

- RA - 15 - For Production Delivery Installation of Precast Pre-Stressed ElementsDocument30 pagesRA - 15 - For Production Delivery Installation of Precast Pre-Stressed ElementsIbrahim EsmatNo ratings yet

- Precautions for Semi-Automatic and Automatic WeldingDocument8 pagesPrecautions for Semi-Automatic and Automatic WeldingFaiz IshakNo ratings yet

- Fix&WP Inspection ReportDocument15 pagesFix&WP Inspection ReportEngineer FazalNo ratings yet

- AsbestosDocument4 pagesAsbestoskoketsoNo ratings yet

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDocument2 pagesProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (2)

- QCS 2010 Section 8 - SewerageDocument202 pagesQCS 2010 Section 8 - Seweragemrtoloz71% (7)

- MSRA For Testing and Flushing of FF Sprinkler SystemDocument22 pagesMSRA For Testing and Flushing of FF Sprinkler SystemkiranramNo ratings yet

- RA Ug Fire Pipe Installation and Hyrant SystemDocument17 pagesRA Ug Fire Pipe Installation and Hyrant SystemvinayNo ratings yet

- Dellag La 3-36Document2 pagesDellag La 3-36FAIYAZ AHMEDNo ratings yet

- Method Statement For Construction Block PavingDocument11 pagesMethod Statement For Construction Block PavingMunaku TafadzwaNo ratings yet

- Blank Health and Safety InpectionDocument5 pagesBlank Health and Safety Inpectionوأكثرهم كارهونNo ratings yet

- Toolboxtalk2 Housekeeping PDFDocument2 pagesToolboxtalk2 Housekeeping PDFSajid HussainNo ratings yet

- RISK ASSESSMENT ACTIVITYDocument2 pagesRISK ASSESSMENT ACTIVITYdak comeiNo ratings yet

- Driving in Qatar - at A Glance PDFDocument6 pagesDriving in Qatar - at A Glance PDFlinkdanuNo ratings yet

- Hard Land Scape Risk AssessmentDocument4 pagesHard Land Scape Risk AssessmentvivekanandhanNo ratings yet

- Risk Assessment for LV Panel Removal WorksDocument22 pagesRisk Assessment for LV Panel Removal WorksAnandu AshokanNo ratings yet

- Falling Hazards in The Workplace - Protection & OSHA Standards PDFDocument4 pagesFalling Hazards in The Workplace - Protection & OSHA Standards PDFMuhammad MalikNo ratings yet

- RA - 12 - For Painting WorksDocument17 pagesRA - 12 - For Painting WorksIbrahim EsmatNo ratings yet

- SDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiDocument5 pagesSDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- Abu Dhabi Sign ManualDocument4 pagesAbu Dhabi Sign ManualAbdullah MansoorNo ratings yet

- Method Statement For Stone WorksDocument10 pagesMethod Statement For Stone WorksvisanuNo ratings yet

- Final Risk AssessmentDocument8 pagesFinal Risk Assessmentapi-514194726No ratings yet

- RA For Nitoflor FC150Document4 pagesRA For Nitoflor FC150kkhafajiNo ratings yet

- Ms 03 Fit Out WorksDocument18 pagesMs 03 Fit Out WorksHichem ZerradNo ratings yet

- RA Termite PDFDocument1 pageRA Termite PDFMohammad Arif RasheedNo ratings yet

- Kahramaa General Specification of Mainlaying Materials - 2005Document78 pagesKahramaa General Specification of Mainlaying Materials - 2005Lepanto Sakyod100% (1)

- Toolbox Talk 9: Critical Risks - ExcavationsDocument2 pagesToolbox Talk 9: Critical Risks - ExcavationsPravin GowardunNo ratings yet

- Manual Soyal 321H-331H-721H-725H-757H-enDocument8 pagesManual Soyal 321H-331H-721H-725H-757H-enGatita GamerNo ratings yet

- Toolbox Talk - Ladders: Planning and Assessment of RisksDocument3 pagesToolbox Talk - Ladders: Planning and Assessment of RisksRedouan Lerhrissi100% (1)

- Carpentry Risk Assessment WordDocument6 pagesCarpentry Risk Assessment WordPrince TeruyaNo ratings yet

- SWP-SF010A - 6 Daily Vibratory Roller Compactor Rev. ADocument1 pageSWP-SF010A - 6 Daily Vibratory Roller Compactor Rev. ACliffordNo ratings yet

- SWMS - Blind IstallationDocument12 pagesSWMS - Blind IstallationParasNo ratings yet

- Worker WelfareDocument2 pagesWorker WelfareNibu P ShajiNo ratings yet

- Fire Prevention & Control Procedure (Rev 1) (24-08-2019)Document35 pagesFire Prevention & Control Procedure (Rev 1) (24-08-2019)Pradip PaulNo ratings yet

- Trenching Excavation PosterDocument1 pageTrenching Excavation PosterBarnum Pebble DarrelNo ratings yet

- Decommissioning Plan for Eight Point Wind Energy CenterDocument16 pagesDecommissioning Plan for Eight Point Wind Energy CenteradiNo ratings yet

- Excavation Risk Assessment SheetDocument3 pagesExcavation Risk Assessment SheetYounis KhanNo ratings yet

- Qcs 2010 Part 8.02 EarthworksDocument20 pagesQcs 2010 Part 8.02 EarthworksRotsapNayrbNo ratings yet

- QCS Section 6 Part 2Document10 pagesQCS Section 6 Part 2mimrusfanNo ratings yet

- 06-1 QCS 2014Document10 pages06-1 QCS 2014Raja Ahmed HassanNo ratings yet

- The Fabrication of Materials: Materials TechnologyFrom EverandThe Fabrication of Materials: Materials TechnologyRating: 5 out of 5 stars5/5 (1)

- QCS 2010 Section 25 Part 2 Glass PDFDocument5 pagesQCS 2010 Section 25 Part 2 Glass PDFbryanpastor1060% (1)

- QCS 2010 Section 25 Part 4 Glazed Curtain WallDocument10 pagesQCS 2010 Section 25 Part 4 Glazed Curtain Wallbryanpastor106100% (1)

- Qcs 2010 Section 25 Part 3 WorkmanshipDocument4 pagesQcs 2010 Section 25 Part 3 Workmanshipbryanpastor106No ratings yet

- Qcs 2010 Section 13 Part 2 Mortar and GroutDocument6 pagesQcs 2010 Section 13 Part 2 Mortar and Groutbryanpastor106No ratings yet

- Qcs 2010 Section 13 Part 5 Masonry Laying PDFDocument11 pagesQcs 2010 Section 13 Part 5 Masonry Laying PDFbryanpastor106No ratings yet

- Qcs 2010 Section 12 Part 1 General PDFDocument4 pagesQcs 2010 Section 12 Part 1 General PDFbryanpastor106No ratings yet

- Qcs 2010 Section 13 Part 3 Accessories PDFDocument3 pagesQcs 2010 Section 13 Part 3 Accessories PDFbryanpastor106No ratings yet

- Qcs 2010 Section 25 Part 1 General PDFDocument3 pagesQcs 2010 Section 25 Part 1 General PDFbryanpastor106No ratings yet

- QCS 2010 Section 11 Part 2.3.07 She Procedures - Contractors InitialDocument15 pagesQCS 2010 Section 11 Part 2.3.07 She Procedures - Contractors Initialbryanpastor106No ratings yet

- Qcs 2010 Section 13 Part 4 Unit Masonry PDFDocument12 pagesQcs 2010 Section 13 Part 4 Unit Masonry PDFbryanpastor106100% (1)

- Qcs 2010 Section 11 Part 2.3.08 She Procedures - The Report and InvesDocument39 pagesQcs 2010 Section 11 Part 2.3.08 She Procedures - The Report and Invesbryanpastor106No ratings yet

- Qcs 2010 Section 11 Part 2.3.16 She Procedures - Learning Event ReporDocument9 pagesQcs 2010 Section 11 Part 2.3.16 She Procedures - Learning Event Reporbryanpastor106No ratings yet

- Qcs 2010 Section 11 Part 2.3.09 SHE Procedures - PERSONAL PROTECTIVE PDFDocument12 pagesQcs 2010 Section 11 Part 2.3.09 SHE Procedures - PERSONAL PROTECTIVE PDFbryanpastor106No ratings yet

- Qcs 2010 Section 13 Part 1 GeneralDocument4 pagesQcs 2010 Section 13 Part 1 Generalbryanpastor106No ratings yet

- Qcs 2010 Section 12 Part 3 Filling PDFDocument4 pagesQcs 2010 Section 12 Part 3 Filling PDFbryanpastor106100% (1)

- Qcs 2010 Section 11 Part 2.3.10 She Procedures - The Safe Use of CranDocument26 pagesQcs 2010 Section 11 Part 2.3.10 She Procedures - The Safe Use of Cranbryanpastor106100% (7)

- Qcs 2010 Section 11 Part 2.3.15 She Procedures - Environmental ProtecDocument43 pagesQcs 2010 Section 11 Part 2.3.15 She Procedures - Environmental Protecbryanpastor106No ratings yet

- Qcs 2010 Section 11 Part 2.3.13 She Procedures - Fire Precautions DurDocument10 pagesQcs 2010 Section 11 Part 2.3.13 She Procedures - Fire Precautions Durbryanpastor106No ratings yet

- Qcs 2010 Section 11 Part 2.3.01 She Procedures - Risk IdentificationDocument31 pagesQcs 2010 Section 11 Part 2.3.01 She Procedures - Risk Identificationbryanpastor106No ratings yet

- Qcs 2010 Section 11 Part 1.6 Regulatory Documents - HUMAN FACTORS PDFDocument74 pagesQcs 2010 Section 11 Part 1.6 Regulatory Documents - HUMAN FACTORS PDFbryanpastor106No ratings yet

- Qcs 2010 Section 11 Part 2.4 Risk Assessment GuidesDocument84 pagesQcs 2010 Section 11 Part 2.4 Risk Assessment Guidesbryanpastor106100% (1)

- Qcs 2010 Section 11 Part 2.3.14 SHE Procedures - ASBESTOSDocument17 pagesQcs 2010 Section 11 Part 2.3.14 SHE Procedures - ASBESTOSbryanpastor106No ratings yet

- Qcs 2010 Section 11 Part 2.3.12 She Procedures - Control of Working ADocument9 pagesQcs 2010 Section 11 Part 2.3.12 She Procedures - Control of Working Abryanpastor106No ratings yet

- Qcs 2010 Section 11 Part 2.1 Safety, Health and Environment (She) ManDocument30 pagesQcs 2010 Section 11 Part 2.1 Safety, Health and Environment (She) Manbryanpastor10675% (8)

- Qcs 2010 Section 11 Part 1.5 Regulatory Document - OTHER HAZARDOUS A PDFDocument124 pagesQcs 2010 Section 11 Part 1.5 Regulatory Document - OTHER HAZARDOUS A PDFbryanpastor106100% (1)

- Qcs 2010 Section 11 Part 1.4 Regulatory Document - SAFE USE OF PLANT PDFDocument130 pagesQcs 2010 Section 11 Part 1.4 Regulatory Document - SAFE USE OF PLANT PDFbryanpastor106No ratings yet

- Qcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEDocument75 pagesQcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEbryanpastor106100% (1)

- SanCoP7 AgendaDocument2 pagesSanCoP7 AgendaNicolaGreeneNo ratings yet

- Early Years and Childcare Safeguarding AuditDocument4 pagesEarly Years and Childcare Safeguarding AuditEarly Years Careers100% (1)

- Separation Processes Lecture 1 IntroductionDocument14 pagesSeparation Processes Lecture 1 Introductionabood assrfndyNo ratings yet

- California ProfileDocument3 pagesCalifornia ProfileLigaya BacuelNo ratings yet

- W H G Kingston "Dick Cheveley": PrefaceDocument159 pagesW H G Kingston "Dick Cheveley": PrefaceGutenberg.orgNo ratings yet

- Analysis of Drinking Water Quality Parameters (A Case Study of Hanumangarh Town)Document8 pagesAnalysis of Drinking Water Quality Parameters (A Case Study of Hanumangarh Town)Editor IJTSRDNo ratings yet

- Cereal Based Functional BeveragesDocument7 pagesCereal Based Functional BeveragesCorina ParicanazaNo ratings yet

- Water For Injections BP: What Is in This Leaflet?Document2 pagesWater For Injections BP: What Is in This Leaflet?Mohamed OmerNo ratings yet

- E 242 - 95 R00 - Rti0mi1sruq - PDFDocument5 pagesE 242 - 95 R00 - Rti0mi1sruq - PDFLeón SuárezNo ratings yet

- Tap ChangerDocument5 pagesTap ChangerRavindra AngalNo ratings yet

- Pharmaceutical Microbiology - B.pharmDocument383 pagesPharmaceutical Microbiology - B.pharmkeyurNo ratings yet

- ANPATH1 ReviewerDocument17 pagesANPATH1 ReviewerRashid DayaoNo ratings yet

- Holy Childhood High School Chemistry 601 Topic: Electronic StructureDocument6 pagesHoly Childhood High School Chemistry 601 Topic: Electronic StructureBriana BartonNo ratings yet

- Papers Traducir CompletoDocument12 pagesPapers Traducir CompletoJuan Jesus Barreda TalaveraNo ratings yet

- What Are OPPE and FPPE?Document1 pageWhat Are OPPE and FPPE?adyNo ratings yet

- Journal Titles and DetailsDocument30 pagesJournal Titles and DetailsMinerva Medical Treatment Pvt LtdNo ratings yet

- Department of The Navy Core Values CharterDocument1 pageDepartment of The Navy Core Values CharterShaun JohnsonNo ratings yet

- Folder Hexa EngDocument8 pagesFolder Hexa EngMuresan MVNo ratings yet

- SECTION 03380 Post-Tensioned Concrete Rev 1Document30 pagesSECTION 03380 Post-Tensioned Concrete Rev 1Abdalrahman AntariNo ratings yet

- Hector: Genuine AccessoriesDocument18 pagesHector: Genuine AccessoriesssgfdfgNo ratings yet

- CH 2Document20 pagesCH 2Vivek SinghNo ratings yet

- Neuro EcDocument234 pagesNeuro EcFeynman2014100% (1)

- Apcosil 605Document1 pageApcosil 605rihtak123No ratings yet

- LV CB Catalogue PDFDocument260 pagesLV CB Catalogue PDFBoobesh Kumar SekarNo ratings yet

- Impact of Excessive Mobile Phone Usage On Human JCSB 1000235Document5 pagesImpact of Excessive Mobile Phone Usage On Human JCSB 1000235nidNo ratings yet

- Chery Amulet 1,6 Engine Service ManualDocument76 pagesChery Amulet 1,6 Engine Service ManualG x HxhNo ratings yet

- Effectiveness of Breathing Exercise On Reducing Pain Perception and State Anxiety Among Primi ParturientsDocument8 pagesEffectiveness of Breathing Exercise On Reducing Pain Perception and State Anxiety Among Primi ParturientsPutra SpNo ratings yet

- Track A Beast ManualDocument21 pagesTrack A Beast ManualboltojamNo ratings yet