Professional Documents

Culture Documents

Aloka ProSound 2 Service Manual

Uploaded by

cucu67%(9)67% found this document useful (9 votes)

4K views244 pagesUltrasound Systems

The ProSound 2 has been developed to meet the demand for high image quality in a portable unit.

It features user-friendly simple operation with a variety of optional probes, making it ideal for today's increasingly diversifying examination environment thanks to its enhanced flexibility and ingenuity.

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentUltrasound Systems

The ProSound 2 has been developed to meet the demand for high image quality in a portable unit.

It features user-friendly simple operation with a variety of optional probes, making it ideal for today's increasingly diversifying examination environment thanks to its enhanced flexibility and ingenuity.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

67%(9)67% found this document useful (9 votes)

4K views244 pagesAloka ProSound 2 Service Manual

Uploaded by

cucuUltrasound Systems

The ProSound 2 has been developed to meet the demand for high image quality in a portable unit.

It features user-friendly simple operation with a variety of optional probes, making it ideal for today's increasingly diversifying examination environment thanks to its enhanced flexibility and ingenuity.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 244

SERVICE MANUAL

Prosound 2

VOLUME 1

English Edition

Document Number : MN2-2039

Document Revision : 0

Copyright? ALOKA CO.,LTD.

VOLUME 1

MN2-2039 Rev.0

ProSound ALPHA2 Service Manual

Contents of ProSound 2 SERVICE MANUAL VOLUME |

Chapter 1 INTRODUCTION

Chapter 2

Chapter 3

1

12

13

14

15

1-6

17

18

19

1-10

Lu

1-12

1-13

114

1-15

1-16

17

1-18

119

Service Manual

Contents of this Service Manual

Composition of this Service Manual

Contents of each VOLUME/Chapter

Precautions Against Electrical Hazards to Service engineer

Precautions Against Mechanical Hazards to Service engineer

Precautions Against Germ Hazards to Service engineer *+

Precautions for Keeping Electrical Safety -*

Precautions for Keeping Mechanical Safety

Precautions for Keeping Chemicals Safety

Precautions for Keeping Soft wares Safety

Precautions to Soft wares safety of maintenance too! ~

Precautions to handling of the patient date

Preparation to be Made at Service Center

Care to be Taken in the Field

Preparation when liquid crystal monitors are exchanged -~

Handling of S.M.D. PCB

System Symbols

About lead free solder

SERVICE PROCESS

21

2.2

Repair work on the description of Service Manual tones

Upgrade work on the description of Service Manual +++"

INSTALL/DISASSEMBLE

Disassembling Procedure(INDEX)

How to use this instruction

Parts identification/Unit layout

Dismounting Flowchart

Disassembling (Diagram) eee

Disassembling (Detailed procedure)

Prosound 2 Installation procedures

Disassembling (Notes)

12

PAGE

1

3-17

3-37

MN2-2039 Rev.0

ProSound ALPHA2 Service Manual

Chapter 4. SYSTEM OVERVIEW

Chapter 5

Chapter 6

4-1 System Specification

4.2. System Configuration

5-2 Precautions

5-3. Tools and Measuring Instruments Required

5-4 Location of the units

5-5 Position of Dip Switch and LED on each board *

5-6 IPF-1001 troubleshooting

5-7 System version(program version)

5-9 Troubleshooting of each part

5-10. Error message show on the LCD

6-3. Making Entries in Repair Report

6-4 Performance check

6-4-1 Function Check

6-4-2 Image Quality Check

6-4-3 Safety Check

PCB list oa

System Block Diagram

TROUBLE SHOOTING

5-1 Introduction

5-8 Abnormal gradation due to TEST PRESET is ON

PERFORMANCE CHECK

6-1 Introduction

6-2 Attention

6-4-3-1 Introduction

6-4-3-2 Checking Protected Earth Cable for Continuity ~

6-4-3-3 Leakage current

ProSound 2 Check Sheet

Revision History of the Service Manual

Revision History of VOLUME 1

22

4-1

a7

48

49

513

$17

5-18

521

5:25

61

61

61

62

63

68

6-12

612

6-12

613

614

Chapter 1

INTRODUCTION

Chapter 1

HN2-2039 Rev. 0

Chapter 1 Introduction

1-1 Service Manual

This service manual has been prepared for persons in charge of repair at the field.

This service manual is compiled according to the following basic principle, "For service, pick out a

faulty PCB and replace it with a new PCB.”

Make the best use of this service manual, making also reference to available technical support

information such as “Technical Bulletin”

1-2 Contents of this Service Manual

1

The equipment is repaired by PCB replacement. Therefore this service manval does not include the

circuit diagrams of the PCB unit. For the explanation of functions, Block Diagrams and list of each

PCB, whose circuit diagram is not included, refer to "Chapter 4 SYSTEM OVERVIEW”,

The Specification of System and System Block Diagrams are described in “Chapter 4 SYSTEM

OVERVIEW”.

For changes and modifications of as well as additions to specifications, if any, prompt information

will be given to you by means of “APPENDIX Manual Change Information”

}@IMPORTANT®@ — Always observe the manner specified for replacement, addition, or

deletion of “Manual Change” to prevent missing of necessary

information and keeping of erroneous information.

1-3 Construction of This Service Manual

The structure of Service Manual is as follows:

VOLUME I

1) Introduction. Chapter 1, 2

2) Service Instruction. Chapter 3, 5, 6

3) System Overview .-Chapter 4

WN2-2039 Rev. 0

Chapter 1 Introduction

1-4Contents of Chapter

VOLUME 1

Chapter 1_ INTRODUCTION

Describing the purpose of the Service Manual

Chapter 2_ SERVICE PROCESS

Giving information peculiar to the equipment and care to be taken before starting repair work

Chapter 3_ INSTALL/DISASSEMBLE

Disassembling Procedure illustrates the disassembly and assembly of main components. Be

sure to follow working procedures if specified

Chapter 4_ SYSTEM OVERVIEW

Describing Specification of System and System Block Diagram; It gives the overview of major

signals flows and mutual communication between the units in the system.

Chapter 5_ TROUBLESHOOTING

Describing precautions on actual repair work and shows the necessary tools and measuring

instruments. Also, it includes many hints on primary diagnosis and measures to be taken in the

field.

Chapter 6_ PERFORMANCE CHECK

Describing the procedure of checking for proper operation after repair and provides the forms

of check sheet.

MN2-2039 Rev. 0

Chapter 1 Introduction

1-5 Precautions Against Electrical Hazards to Serviceman

When disassembling the equipment after checking it for a trouble symptom, give care to the following:

1) Be sure to unplug the equipment before disassembly.

2) Be sure to tum off the main switch on the equipment when removing electrical parts such as PCBs,

probe, and cable,

3) Safety alert symbols

4) ‘The indication /A\, used on this equipment and in this service manual have the following meaning

“ Indicates a potentially hazardous situation which, if not avoided, may result in minor or

‘moderate injury. ”

“A caution message is inserted here.

1-6 Precautions Against Mechanical Hazards to Serviceman

‘When disassembling the equipment, give care to the following to protect serviceman from hazards:

1) Keep the working environment neat.

2) Wear working gloves to protect your hands from getting injured by burrs on the unit and casing.

3) Use only proper tools suited to work being made.

4) Be sure to observe the disassembly procedure shown in VOLUME 2: Chapter 3,

5) Take sufficient care not to damage component with undue load.

1-7 Precautions Against Germ Hazards to Serviceman

1) When it is necessary to touch the equipment, options and/or other peripheral devices at a customer

who uses intracorporeal (transesophageal, transurethral, transvaginal, transrectal) probes that need

sterilization, take special care to protect your hands against germs, irrespective of the usage of the

‘equipment: whether it is used in the operation room or not.

2) Service tools are subject to germ pollution in hospitals and, therefore, need periodical sterilization.

3) Be careful not to directly touch anything assumable to have germ pollution. If necessary, ask the

‘customer for effective protection against germs.

HN2-2039 Rev. 0

Chapter | Introduction

1-8Precautions for Keeping Electrical Safety =

1) Be sure to ground the equipment securely.

2) Perfectness in grounding, screw tightening, and cover installation is essential. Negligence of it

could cause a possibility of leakage current from outer fitting which may lead to serious damage to

a patient being diagnosed.

1-9 Precautions for Keeping Mechanical Safety

‘Take care to the following to prevent the equipment from being damaged or broken during disassembly

and reassembly work.

1) Be sure to observe the specified disassembly procedure.

2) Take care not to damage component parts by undue load.

3) Take care not to damage component parts by undue load.

4) Use only the specified screws and nuts. Using any other screws and/or nuts would affect not only

‘mechanical performance, but also electrical performance of the equipment. -

1-10 Precautions for Keeping Chemicals Safety

Whenever grease, oil or other chemicals is used for maintenance service, options and/or peripheral

devices, be sure to clean the equipment and/or devices after service work.

1-11 Precautions to ensure safety of software in ultrasound diagnostic equipment

Computer controlled medical equipment that involves starting up an operating system from a hard disk drive

could become infected with computer viruses.

Such equipment is usually infected via auxiliary storage, media or connections to a network.

Examples detailing route of infection

‘A) Infections caused during upgrades or maintenance by service engineer

An infected USB memory device was connected.

‘An infected floppy diskette was inserted.

A virus-infected USB hard disk drive was connected to remove data.

B) The end user connected an infected USB memory device for presetting, backing up images or copying.

‘An infected floppy diskette was inserted,

A virus-infected USB hard disk drive was connected to remove data,

1) Scan all media for viruses before connecting them to or inserting them in the equipment.

2) When an infection is detected, investigate the route of infection and its scope before removing the virus

3) Any connections to a network should as far as possible be routed via a firewall.

4) Software, files or services other than those designated by ALOKA must not be installed on or

uninstalled from the equipment. Nor must files other than those specified by ALOKA be modified or

edited.

WN2-2039 Rev. 0

Chapter 1 Introduction

1-12 Precautions for software safety of maintenance tools

These maintenance tools refer to the laptop computers and auxiliary storage devices that service engineers

carry around. (Any computer used for creating CD-Rs for installing upgrades is also regarded as a

maintenance tool.) Thus maintenance tools will include laptop computers, floppy diskettes, USB memory

devices, external hard disks, CD-Rs, ete.

1) Perform a virus scan of any tool that will be used to ensure that they are not infected by computer viruses.

Regularly perform virus scans of maintenance tools.

2) In unavoidable cases when for some reason safety cannot be confirmed, or when an unknown computer or

‘memory device is connected, be sure to perform a virus check after use.

3) Update with the most recent virus pattern data prior to performing a virus scan,

4) Ifa virus scan does not remove the cause for anxiety, use another virus scanner to check..

1-13 Precautions regarding handling of patient data

Extreme care must be taken to ensure that data (image data, patient database, DICOM communication log,

files) that has been saved to another media during equipment repair and may include patient data is guarded

against leakage, loss and theft. Delete any data that is no longer needed.

1) Work involving use of patient data should be performed in @ room that can be locked to prevent leakage,

loss or theft of such data,

2) Such data must be stored in a locked shelf or similar container.

3) If no lockable shelves are available, encrypt the files to reduce possible harm in the event of theft,

leakage or loss,

1-14 Preparation to be made at Service Center

1) When called by a customer on the telephone, note the followings:

© Name of equipment

Serial number of equipment

Name of hospital

‘Telephone number

‘Name of person in charge

Detail of trouble symptom as far as possible

@ State of connection to optional devices

2) Go over the “Technical Bulletin” and “Technical Notes” to see whether the complained trouble can

be mended by means of regular repairing method.

2-2039 Rev. 0

Chapter I Introduction

1-15 Care to be Taken in the Field

1) Check for trouble symptoms.

2) Check for connection to optional devices and other peripheral devices.

3) Record the contents of the battery backup memory.

4) After working, restore the equipment according to the above mentioned contents of memory if

necessary.

5) After completion of work, put back the peripheral devices to the original condition.

1-16 Precautions in replacing LCD monitors

1) Take particular care in installing and removing LCD panels as exposure to strong vibration and shock

could result in damage,

2) Do not strike the display, expose it to strong pressure or press sharp objects against it.

3) Remove wristwatches and other metal objects before starting work.

Operators must heed this warning to ensure their safety and prevent secondary disasters.

NN2-2039 Rev. 0

Chapter 1 Introduction

1-17

Handling of S.M.D. PCB

It is an Aloka's policy that neither repair nor modification of PCBs used for S.M.D. is made in the

field as a rule because of the following reasons:

[REMARKS] PCB does not need repairing or modifying in the field as a rule,

When handling a PCB, do not touch the IC unless it is necessary.

IC soiled with worker’s hands may cause corrosion. Additionally, foreign particles such as fine

solder dust could be the cause of short-circuited IC lead wires whose pitch is smaller than that of

the traditional ones.

‘* CAUTION ¢ — When handling a PCB, avoid touching the IC and connector pins on the i

devices to prevent ESD (Electro Static Discharge) damage. I

A service person should preferably wear an ESD wrist strap correctly |

grounded when handling a PCB. 1

Do not give excessively large shocks to the PCB.

When replacing the ROM (Read Only Memory) on the PCB, attempting to force the ROM into its

socket would cause the PCB to be subjected to an undue force, and the following faults may;

1) Damage to PCB intermediate-layer patterns

2) Peeling of chip devices (resistor, capacitor, diode, etc.)

3) Damage to a junction between electrode and internal element of chip devices

4) Peeling of patterns (especially those for mounting the parts) together with chip devices since

those patterns are rather fragile compared with PCBs used before

5) Damage to parts on the reverse side in the case of PCBs of both-side mounting type

Also, @ PCB mounted improperly or a warped PCB mounted as itis may cause the chip devices to

come off and the fine patterns to be cut.

Additionally, reuse of chip devices (including resistors, capacitors, diodes, etc.) is strictly inhibited

because of the following reason: Since the chip devices are lacking in lead wires, such as those

found in the traditional component parts, heat given to the PCB will be directly conducted to the

inside of chip devices. As a result, a thermal stress will occur due to a difference in thermal

expansion coefficient between each chip device and PCB, giving rise of the possibility of cracks

inside of or on the surface of chip devices or the possibility of thermal breaking (internal burning).

Very thin wiring pattems require extreme care in handling of the PCB

Be sure to observe the precautions mentioned above also to prevent the secondary accidents.

1-18 System Symbols

MN2-2039 Rev. 0

Chapter 1 Introduction

‘Symbols used by Aloka are described below, together with reference to IEC publication(s)

Symbol

Position

Various Places

Danger

Carefully read the pertinent items in the operation

‘manual, and handle the equipment with grate care.

ANSI standard 2535.3

1EC60601-1, Attached table D

BS 5378 PARTI, Appendix A

On the side of

probe connector

Biohazard

ANSI standard 2535.3

1807000 No.0659

BS 5378 PARTI, Appendix A

3

Left side panel | Be careful of explosion

Be careful of electric shock

Left side panel ANSI standard 2535.3

BS 5378 PARTI, Appendix A

Various places

Left side panel

Be careful of fire

BS 5378 PARTI, Appendix A

Be careful of acoustic power

Indicates the ON position of the switch.

16C60417-5007

Indicates the OFF position of the switch,

18C60417-5008

Indicates the STAND BY position of the switch.

8/0 |\C/O/|- PPS PE >

Power switch,

18C60417-5009

Alternating current

Rear panel

1BC60417-5032

Footswich | Protected aginst he effects of continuance immersion

MP-2345B

MP-2614B,

18C60529

WN2-2039 Rev. 0

Chapter | Introduction

No.

Symbol

Position

Meaning

[2

Various places

Electrostatic discharge (ESD) symbol

A symbol warning of no touching to the pins cropping

out. When touching to the pins cropping out or nearing

to them, there can be of malfunction or breaking down,

of the device by electrostatic discharge.

13

Left side panel

This mark indicates this product complies with

Directive 93/42/EEC relation to Medical Device.

WN2-2039 Rev. 0

Chapter 1 Introduction

1-19 About lead free solder

Consequently, the PCBs (printed circuit boards) inside and other parts use lead-free (Pb free) solder and

lead-free RoHS compliant components.

Use the label shown below for products that

contain some RoHS compliant mounted

components that are soldered using lead-free

solder,

Use the label shown below for products containing,

only RoHS compliant mounted components that

are soldered using lead-free solder

meets Ld

anf

Use lead-free solder for soldering internal boards, components and cables.

Do not use old solder that contains lead. It has a different melting point from lead-free solder and must not be

used.

Chapter 2

SERVICE PROCESS

Chapter 2

MN2-2039 Rev. 0

Chapter 2 Service Process

2-1 Repair work on the description of Service Manual

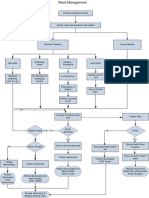

The typical processes for the repair work are shown as the Flow Chart on the next page. Do the repair

work according to this procedure. In the case of modification of the Technical Bulletin, Technical Notes

or Upgrade Kit, see the next item 3-2

Each procedures of flow chart are numbered to refer its detail shown from page 3-3. Furthermore, the

Flow Chart and its explanation show the time when each section of service manual are required on

repair work. This is a guide for the usage of service manual.

The service manual is very important for the repair work, especially readjustment and performance

check after completion of repair work. This is to keep the safety and quality of equipment. If you make

them, you have to describe that the treatment has been done according to the applied section of service

‘manual, on the repair report or the like

‘The circled numbers shown in the Flow Chart on next page, are corresponded to the procedure number

shown from page 3-3.

NN2-2039 Rev. 0

Chapter 2 Service Provess

Demand of repair

(START)

Reception and

Investigation

‘Technical Bulletin, Technical Notes

Chapter 5

Selection and order of | Chapter 4

Required part(s) History

® Chapter2

At your site

Chapter 4, 5

Chapter 6

‘Work as normal?”

Check by customer

Fill repair report Repair again?

Approve by customer

Show comments of the

Demand to repair the prohibition to use on

defective part(s) the equipment

Report to customer

Leeman

WN2-2039 Rev. 0

Chapter 2 Service Process

Procedure 1 Reception of repair and investigation

Accept the repair request from the customer or distributor. At this time, the following points have

to be confirmed and checked,

© Model name/number, and serial number

Name of customer (Hospital), address, phone number, and name of person in charge

Configuration of the connection of peripheral devices

Software version or the like shown on the Maintenance display (if possible)

Detail of phenomenon appeared on the function of equipment

Make an examination what circuit may be defective as the function of equipment based on the

above information. If you need to know about the basic operation and special information for the

maintenance, refer to the following sections, or ask to the Technical Support,

© Chapters SYSTEM OVERVIEW

© Chapter 5 TROUBLESHOOTING

‘The reported phenomenon may be the original problem on the equipment. Because, refer to the

‘Technical Bulletin or the Technical Notes separately issued to check it whether defectiveness or not.

fit has been reported as the original problem, make a work according to the Technical Bulletin or

the Technical Notes.

Procedure 2 _ Selection of required parts and order

If you find the doubtful circuit, order the necessary parts. Then check the delivery date and decide

the date to visit on the consultation with the customer.

For the selection and order of parts, refer to the following sections,

© Chapter 4 SYSTEM OVERVIEW(PCB LIST)

© Chapter 5 ‘TROUBLESHOOTING

For the electrical parts such as UNIT, check the history information on the HISTORY of this

equipment separately issued.

MN2-2039 Rev. 0

Chapter 2 Service Process

Procedure 3 Preparation of visiting the customer ~

Check the required tools, measuring devices and parts to be replaced before the visiting the

‘customer. Then check the special information for the equipment reference with the following

section,

© Chapter 1 INTORODUCTION

Procedure 4 Confirmation of phenomenon

Confirm the appeared phenomenon and condition to happen it with the customer. If you don’t

know about the operation of equipment, refer to the Operation Manual attached to the equipment

Procedure $ Repair and

djustment

Repair the defective circuit with the brought parts. For the repair work, read the following section —

carefully,

© Chapter 1 INTORODUCTION

© Chapter 2 SERVICE PROCESS

‘And, examine the trouble reason depending on the situation with following section,

© Chapters ‘TROUBLESHOOTING

‘The electrical or mechanical readjustment may be requested depending on the replaced parts.

Because, refer to the following section after completion of repair,

© Chapter 5 ‘TROUBLESHOOTING

Procedure 6 Operation check

Check the system behavior to keep its condition as same as before in trouble, reference with the

following section. Be sure to do according to the description because check items are depending on.

the portion to be treated.

© Chapter 6 PERFORMANCE CHECK

WN2-2039 Rev. 0

Chapter 2 Service Process

Procedure 7 Judgment of the operation quality

If the result of “Procedure 6” is passed to the all standards, do the next “Procedure 8”. On the other

side, if not, make a judgment of “Procedure 10”,

Procedure 8 Confirm by customer, make repair report and approve

Reconfirm the solution of trouble phenomenon

obtain approval of customer.

‘The repair report shows not only the treatment but also the method of readjustment and operation

check. If they have been done according to the service manual, the followings have to be shown,

the customer. Then make a repair report and

"Readjusted acconting to the Chapter 5 of service manual.”

“Checked according to the Chapter 6 of service manual, and passed.”

Procedure 9 Presentation of report and order to repair parts

Fill the repair report with necessary item, and present it according to the certain procedure,

If the defective parts that trouble cause included is available to use again by repair, make an order

to do, If you cannot judge whether the part can be used again or not, ask to the Technical Support.

Procedure 10 Judgment of possibility to repair again

AAs the result of judgment on “Procedure 7”, if the trouble is not solved, judge the possibility to

‘make the repair work again.

If.available, return to “Procedure 5” and continue to work.

If unavailable, go to “Procedure 11”

Procedure 11 Indication of the prohibition to use

As the result of judgment on “Procedure 10”, if you judge that it is impossible to continue the

repair work at this time, indicate that the equipment is still out of order, and also show the

prohibition to use, on the equipment.

Procedure 12 Report to the customer

‘Report the reason why the trouble cannot be solved to the customer. Then consult about the plan of

next repair work

And do the same way from “Procedure 2”.

WN2-2039 Rev. 0

Chapter 2 Service Process

2-2 Upgrade work on the description of Service Manual a

‘The typical processes for the upgrade work are shown as the Flow Chart on the next page. Do the

upgrade work according to this procedure. In the case of repair work, see the previous item 3-1

Each procedures of flow chart are numbered to refer its detail shown from page 3-8. Furthermore, the

Flow Chart and its explanation show the time when each section of service manual are required on

upgrade work. This is a guide for the usage of service manual.

The service manual is very important for the upgrade work, especially readjustment and performance

check after completion of upgrade work. This is to keep the safety and quality of equipment.

‘The circled numbers shown in the Flow Chart on next page, are corresponded to the procedure number

shown from page 3-8.

WN2-2039 Rev. 0

Chapter 2 Service Process

‘Demand of upgrade

(START)

ion and order of | Technical Bulletin

quires parts/kits_| Technical Notes

Installation Procedure

}

© Chanter 6

At customer site

Do the repair work,

Yes according to item 3-1

® Installation Procedure

© Installation Procedure

Chapter 3

Chapter 6

No

Can recover?

Return unnecessary Show comments of the

parts, and report of prohibition to use on the

upgrade equipment

‘Completion

(END)

Report to customer

Consultation with

‘Technical Support

S$

1

}

i

|

i

|

i

|

|

i

|

i

j

|

i

j

|

|

i

|

|

|

|

i

i

i

i

i

i

i

|

i

|

i

|

i

|

WN2-2039 Rev. 0

Chapter 2 Service Process

Procedure 1 _ Selection of required parts / kits and order

‘Accept the upgrade request from the customer, distributor or person in charge of sales. At this time,

the following points have to be confirmed and checked to decide the parts and kits,

Document name that announced the upgrade or kit requested

‘Model name/number, and serial number

Name of customer (Hospital), address, phone number, and name of person in charge

‘Configuration of the connection of peripheral devices

Software version or the like shown on the Maintenance display

Make an examination what parts or kits are required based on the above information. For the

selection, refer to the following document separately issued, or ask to the Technical Support,

@ Technical Bulletin

© Technical Notes

To confirm the detail of upgrade, see the Installation Procedure attached with applied ‘Technical

Bulletin or ‘Technical Notes.

Depending on the upgrade, hardware, ot software, the other upgrade may be required. Check it

the Technical Bulletin or Technical Notes.

‘Then, confirm the delivery date of required parts or kits, and decide the date to visit on the

consultation with the customer.

Procedure 2 _ Preparation of visiting the customer

Check the required tools, measuring devices and parts or kits to be used before the visiting the

customer. Then check the special information for the equipment reference with the following

section and document,

© Chapter! INTRODUCTION

© Chapter2 SERVICE PROCESS

© Technical Bulletin, Technical Notes and/or Installation Procedure

MW2-2039 Rev. 0

Chapter 2 Service Process

Procedure 3 Operation check before upgrade

On the basis of work, the upgrade to the defective equipment is prohibited. Because, before

upgrade work, check the behavior of equipment whether normal or not according to following

section and document,

© Chapter 6 PERFORMANCE CHECK

© Operation Manual

Procedure 4 Judgment of the operation quality

If the result of “Procedure 3”

side, if not, goto

passed to the all standards, do the next “Procedure 5”. On the other

rrocedure 10”,

Procedure 5 Upgrade work

Do the upgrade work according to the following document,

© Installation Procedure attached with kit, Technical Bulletin or Technical Notes

Procedure 6 Operation check after upgrade

Check the system behavior to keep its condition as same as before the upgrade, reference with the

following section, Be sure to do according to the description because check items are depending on

the portion to be treated.

@ Section6 PERFORMANCE CHECK,

© Sections DISASSEMBLING PROCEDURE

© Installation Procedure, Up grade procedure,

Procedure 7 Judgment of the operation quality

If the result of “Procedure 6” is passed to the all standards, do the next “Procedure 8”. On the other

side, if not, make a judgment of “Procedure 11”

WN2-2039 Rev. 0

Chapter 2 Service Process

Procedure 8 Confirmation by customer

Reconfirm any functions of equipment with the customer. Then, iff need, introduce and explain

about the new functions and specification added by this upgrade.

Furthermore, if need, make a report to be approved by the customer. The report shows not only the

treatment but also the method of operation check. If it has been done according to the service

‘manual, the following has to be shown,

“Checked according to the Chapter 6 of service manual, and passed.”

Procedure 9 Return of unnecessary parts and report of completion

According to the Technical Bulletin or Technical Notes, return the unnecessary replaced or unused

parts as soon as possible if suggested.

And, if the report of upgrade is suggested on the same document, report it with the information

required

Procedure 10 Work for the abnormal behavior of equipment

On the result of judgment in “Procedure 4”, if the equipment does not work normal, solve the

problem according to item 3-1 “Repair work on the description of service manual” shown in this

section.

‘When the problem is solved, retum to “Procedure 5” of this item and continue to do the upgrade

work.

Procedure 11 Judgment of possibility to recover

AAs the result of judgment on “Procedure 7”, if the problem has been made by this upgrade, judge

the possibility to recover it.

If available, return to “Procedure S” and continue to work.

If unavailable, go to “Procedure 12”.

MN2-2039 Rev. 0

Chapter 2 Service Process

a Procedure 12 Indication of the prohibition to use

As the result of judgment on “Procedure 11”, if you judge that it is impossible to recover at this,

time, indicate that the equipment is the out of order, and also show the prohibition to use, om the

equipment.

Procedure 13 Report to the customer

Report to the customer that the upgrade has not been completed because of the problem on the

upgrade work. Then make a schedule to fix and complete it.

Procedure 14 Asking to the Technical Support

Report to the Technical Support about the happening of problem on the upgrade work, make an

examination to solve and order the additional parts. Before the asking, check the following points,

© Name of kit, or the issue number of Technical Bulletin or Technical Notes showing the upgrade

Model name/number, and serial number

Configuration of the connection of peripheral devices

Software version or the like shown on the Maintenance display

Indication of equipment such as Upgrade

Detail of phenomenon appeared on the function of equipment

Chapter 3

INSTALL/DISASSEMBLE

Chapter 3

WN2-2039 Rev. 0

Chapter 3 Install/Disassemble

SSD-PROSOUND2 Disassembling Instruction

0. How to use this Instruction

7, Paris Identification / Individual Unit Layout

2. Dismounting Flowchart

3. Removing of Probe holder

“4, Removing of Cover, Handie ASSY, Air filter

'5, Monitor{iPF-1007], SW Key Top, OSD peb

‘6. Removing of operation Panel [PNL-PROSOUND2], Small parts around the operation Panel

7. Removing of Di

imaging unit (USM-33"]

8, Removing of Power supply unit{EU-6041"], Fan

9. Removing of Bottom Cover, Panel click hinge, Panel Cable Cover

10. Removing of Base, main body free stop hinge-click hinge

Caution

I The system must be disassembled only by the qualified personnel.

Ifyou tighten the screws/bolts excessively on the plastic covers during the assembling

Procedure, this could result to have a crack on them.

I Ifthe screws/bolts were fixed with anti-loosening, you must redo it when you removed.

WN2-2039 Rev. 0

Chapter 3 Install/Disassemble

0. How to use this Instruction

Basically follow the instruction below to refer this document.

a) Find the index No. from the part that you need to disassemble.

b) Refer the Disassembling Diagram and Flowchart to start the work from the proper point.

c) Refer the Detailed Procedure when it’s necessary.

In order to proceed the work smoothly, refer this document with keeping the following points in

mind.

4) Index

Jeemoving of Power Supply Unit [EU-6043" & EU-6044"], AC Outlot [JB-2817/-2¢

and AC Distributor [JB-283*]

6 Remavina of PC Raards and VO hoards of [LISM.28"1 ” ~

+ The index number corresponds to the number of Disassembling Diagram and

Flowchart.

2) Flowchart

=

nw Te PR HELP

FT

Flowchart represents the flow of disassembling parts/units. It flows from left side to right

side.

It is necessary that the part/unit at the left side, connected with a line, is already

disassembled when you need to do it on a particular part/unit.

The number indicated on each part/unit corresponds to the index No. of Disassembly

Diagram.

NN2-2039 Rev. 0

Chapter 3 Install/Disassemble

3) Disassembly Diagram

TadexNo.] © ooniss;

oon

baa33)

5) 22 ame

5g) Some ent

Ooms

(cq Bind ate PEL)

It represents the disassembly of parts/units and the circled numbers put on the parts

indicate the order of dismantlement.

The comment: (Details x-x) under the part name indicates there is Detailed Procedure of

Disassembly x-x in latter part of this document for your reference.

‘The description of “BNK3x8 Fe,Ni,3” or lke, indicates the type of screws and the number at

the end represents the amount of it.

The index No. of Disassembly Diagram corresponds to the number of Flowchart.

3. Detailed Procedure of Disassembly

smoving of Covers, Foot Switch, USB Cable and Dust Filter

moving of Connector Panel Cover

Index No.

1 ‘Sub-index No.

4, Loosen one screw to open the connector|

panel cover.

BNK3"12 Fe, Nit

+ It provides more detailed procedure that could not see in the Disassembly Diagram.

‘The Index No. of Detailed Procedure of Disassembly corresponds to the Index No. of Disassembly

Diagram and the Sub-Index No. corresponds to the number of (Details x-x).

WN2-2039 Rev. 0

Chapter 3 Install/Disassemble

arts Identification / Individual Unit Layout

USM unit

Monitor unit

IPF-1001

Power supply unit

Probe holder

MP-PH-PROSOUND2

PNL-PROSOUND2

NN2-2039 Rev. 0

Chapter 3 Install/Disassemble

‘The Disassembling Instruction is composed based on the Flowchart so follow the order of this

chart to disassemble the equipment.

‘The numbers of Flowchart correspond to the Index No. of Disassembly Diagram and Detailed

Procedure of Disassembly.

Cie" CE= |Gle= bree eH Ee =

ofem, He eoe hf koa =I lo

HN2-2039 Rev.

Chapter 3. Install/Disassemble

[ 3. Remove the Probe holder _[ disassemble ]

Remove the Probe holder

robe holder ASSY

NN2-2039 Rev. 0

Chapter 3. Install/Disassemble

[disassemble ]

[ 4. Disassemble the Covers, Handle ASSY, Air filter

Handle ASSY @

Heragon socket countersunk

head serew 4% 14F NEC, 4

NSB Fe, 1

Disassemble the Cover

Handle side Cover.2_~“ 4

® :

Handle top Cover

S3xFe NEC, 1

(etate-2)

Captive Screw, 3

BNKS*10Fe-Ni, 2

LeDassy.

@ BNK3%8 Fe-Ni, 15

‘easy

MN2-2039 Rev. 0

Chapter 3 Install/Disassemble

Disassemble the Cover

Airter

@ Aemaccone

(detaa-4)

@ -Prce.cabitot

Comecor cover

‘Captive Screw, 1

@ Pome senetick (eetaie-6)

Tapping screw 3x8 FON, 4

(aetai-s)

MN2-2039 Rev. 0

Chapter 3 Install/Disassemble

[Disassemble the MonitorfIPF-1001],SW Key Top.OSD pcb__[ disassemble]

Disassemble the Monitor{IPF-1001], SW Key Top, OSD pcb

\PF-1004

@®

BNK3*8 FeNi 3

@ 220

O80 sv Keyto»_ G

BNK3*16Fo-Ni, 2

Spacer, 2

NN2-2039 Rev. 0

Chapter 3 Install/Disassemble

6. Disassemble the operation Panel[PNL-PROSOUND2], small parts around the

operation panel._[ disassemble ]

Disassemble the operation Panel

Operation Panel unt

@

CNKG*6 FEN, 2

(eetai2)

@ lean

(aotai6-1)

WN2-2039 Rev. 0

Chapter 3 Install Disassemble

Disassemble the small parts around the operation Panel

oO Operation Panel unit STC knob, 6 @

coaarein?

(cae :

Paneluppercover QA ieotens)_

G ®

.,_testemald_ Gy

Panel cushion, 2

o@——_i___*

Rubber Key sh

Caetai8-4)

@

BNK3*8 Fe-Ni, 4 ©

anol Cover fixing plate

BNK3x6 Fei, 4

Panel main peb

'BSB-S05E, 4

BNK3x6 Fei, 23

Encoder fixing plato, 2

aria Tapping screw 2x8 PENI, 2

(detail)

@ amseasn

rut, 2

tooth lock washer, 2

WN2-2039 Rev. 0

Chapter 3 Install/Disassemble

7. Disassemble the USM uni{USM-33)] __[ disassemble ]

Disassemble the USM unit{USM-33*]

‘BNK3*8 FeNNi, 22

NK3*B Fei 1

Hexagon Post(0-SUB) Inch sized/16(4.8mm),

2

‘ASB-SIIE,2

‘ASB-S10E. 3

Pos: BF

EP546500""

‘BSE-ST7.7E, 10

POB:Back End

EPs40700"

®

CNKGHOF ON, 6

ASB-313E, 3

Pep hag plate (5

ENK3*8 Fei

BNK3*12 Fei,

wN2-2039 Rev. 0

Chapter 3 Install/Disassemble

8. Disassemble the Power unit[EU-6041*], Fan [disassemble ]

Disassemble the Power unit(EU-6041*], Fan

een iO)

Rowe Cable one

CNKG=G FeNi 3

®

BNKGWB Fe? |

aaiea

{unt pce

EPsaes00"

ENKExTOFON, 1

CNKIK6 Fe 5

(Protective earth termina:

NA Fe, 1

sw4 SUS, 1

PW4FeNi 1

CO-EU-60t1-5, 1

‘Tooth look washer B4S-Fe-N, 1

(aetais-2)

B Tapping screw

S*10F EN 4

uN2Pos

@ aon

BSBSHE, 5

WN2~2039 Rev. 0

Chapter 3 Install/Disassemble

9. Disassemble Bottom Cover, Panel hinge, Panel Cable Cover _[ disassemble ]

Disassemble the Bottom Cover, Panel hinge, Panel Cable Cover

Panel right hinge ASS)

BNKS=10FeNLEC, 5

HB4*14SUS-EC,2

Gy Panel Cable Cover

'B Tapping screw

3KBFeNi, 1 (detalo-t)

uname

'BNK@*10Fe-NFEC, 2

HB4*14SuS-EC, 2

MN2-2039 Rev. 0

Chapter 3 InstallDisassemble

10. Disassemble the Base, Main body hinge

[disassemble ]

Disassemble the Base, Main body hinge

@ anveeruehnoge

BNK@*10 FeNVEG, 3

HB414SUS-EC, 2

(etal 10-1)

Mon boty ran nga,

fenna~8 Fe, 3

@ Waite fr

Ha 145US-EC, 1

HB4*108US-EC, 6

(deta10-2)

NN2-2039 Rev. 0

Chapter3 Install/Disassemble

3. Removing Probe holder _ [detailed ]

3-1 Removing of Probe holder

@Pulling a knob at Probe holder and move

the probe holder to up side. (CW wise) to

release catch hole2 from Guide pin2.

@Probe holder slide to the front side to

release the catch holet from Guide pint

WN2-2039 Rev. 0

Chapter3 Install/Disassemble

Fixing of Probe holder

© Adjust the catch hole1 of Probe holder to

Guide pint which located fron side.

after that, Probe holder slide to rear side to

fix Guide pin1 in the catch hole.

Guide pint

Probe holder

(@Probe holder rotate to CW(Clockwise) around

Guide pint as a central pivot and put a Guide

pin2 in to the catch hole2.

catch hole2

MN2-2039 Rev. 0

Chapter3 Install/Disassemble

4 Procedures for removing covers, handle assembly and air fiter [Detailed procedures]

4-4 Procedure for removing LCD assembly

Remove the surrounding screws and tilt the LCD

monitor 30° backwards to remove the LCD

assembly.

@Remove PNG3.

[Top of equipment]

WN2-2039 Rev. 0

Chapter’ Install/Disassemble

[Top of equipment]

renee!

Front of equipment

Precautions in removing the LCD assembly

@Make sure that cables and cores do not protrude

beyond the plate end (indicated by red dotted line)

[Inside LCD monitor]

@Make sure that the LCD monitor OSD cable is

above the lower end of the PCBs (red line)

20

Front of equipment

MN2-2039 Rev. 0

Chapter Install/Disassemble

@Route the two cables around the metal notch,

(to prevent cable pinching)

@Place the CBLO1 (thick) cable facing the front of

the equipment and in front of the CBLO4 (thin)

cable.

Stack the connectors,

[Top of equipment]

@Be sure not to damage the CBLOI cable.

21

WN2-2039 Rev. 0

Chapter3 Install/Disassemble

Hexagon socket head

cap screw

S4*14Fe.

‘EC, 4

4-2 Procedure for removing handle assembly

@Remove the handle side cover and the screws

(and the screws on the rear side).

4-3 Procedure for removing handle cover

open the handle cover in the direction of the

arrows and remove it from the display assembly.

22

NN2-2039 Rev. 0

Chapter3 Install/Disassemble

4-4 Procedure for removing air filter cover

Press the two tabs.

(Pull the filter rearwards to remove it

4-5 Procedure for removing power cable hook

Remove the four screws on the inside.

B titanium screws 3x8

FeNi,4

ee

WN2-2039 Rev. 0

Chapter3 Install/Disassemble

4-6 Procedure for removing connector cover

Slide the cover in the direction indicated.

WN2-2039 Rev. 0

Chapter3 Install/Disassemble

6. Removing of Operation panel [PNL-PROSOUND2], and small parts of panel

[detailed ]

6-1 Removing of table cushions

@Pull the cushion straight.

Point of assemble the table cushion

Panel front end side

(Panel top side) at above image.

o @ Mount the short side to operation panel

end side, (Longer side to panel axis side)

1

1 Panel behind(axis) side

(Panel bottom side) at above

MN2-2039 Rev. 0

Chapter3 Install/Disassemble

6-2 Removing of operation pane! unit. =

CNK3%6 Fe-Ni, 2

@Remove the table cushions, then remove

the screws.

@Pull up the front of panel at fast, then slide it

to rear side to release.

BNK3*8 Fe-Ni, 1

HN2-2039 Rev. 0

Chapter3 InstallDisassemble

@Remove screw and release the earth cable.

@Remove P501.

Point of assemble the P501

@At the left image, one turn the cable to

CCW(counter clockwise), after that connect

P501.

NN2-2039 Rev. 0

CChapter3 Install/Disassemble

63

ixing of trackball cable

@Fold a cable of track ball as left image.

6-4 Fixing of rubber key sheet.

@ Press the back side of a projection rubber

Gu Rubber key sheet | to sure projection neck over the PCB. To

press is you should better use stick (diameter

approx. 1.5mm)

\ Switch POB

MN2-2039 Rev. 0

Chapter3 Install/Disassemble

7. Removing of [USM-33] _[detalled]

7-1 Removing of cable

@Remove the screw of anchor mount of

cable.

@remove two connectors.

@BNK3*12 Fe-Ni, 1

WN2-2039 Rev. 0

Chapter3 Install/Disassemble

8. Removing of Power supply unit{EU-6041"], Cooling FAN _ [detailed]

cBLOs

8-1 Point of removing Power supply unit

@Fix the position of CBLO1 and CBLO4 as a

left image to avoid conflict with CBLO2.

CNK3»8Fe-Ni, 2

82 Removing of Plate nut of AC IN

OF the screw and remove plate nut.

MN2-2039 Rev. 0

Chapter’ Install/Disassemble

N4Fe-Ni, 1

SW4 SUS, I

PW4 Fe-Ni, I

CO-EU-6041-5

Washer B4S-Fe-Ni, 1

8-3 Removing of grounding terminal

@Remove the nut and remove the grounding

terminal

84 Wiring of FAN cable

@ Place the cooling FAN cable as a left

image and avoid conflict with FAN. blade.

32

WN2-2039 Rev. 0

Chapter 3 Install/Disassemble

9, Procedures for removing bottom cover, panel hinges and panel cables

[Detailed procedures]

9-4 Procedure for removing panel cable cover

@

Remove screws and the panel cable cover

@Remove the left panel hinge.

B ftanium serews

3x8 FenNi 1 CBLOZ

Routing CBLO2

@

P501

@Route CBLO2 as shown in the figure.

100 mm

—_——_

WN2-2039 Rev. 0

Chapter 3 Install/Disassemble

710. Procedures for removing base and hinges [Detailed procedures]

10-1 Procedure for routing CBLO7

[Hinge side]

Place the CBLO7 between the horizontal plane and

the opening for installing the power supply.

Arm side]

Install CBLO7 facing downwards.

MUN2-2039 Rev. 0

Chapter 3 Install/Disassemble

HB4x10SUS-EC , 6

] 10-2 Procedure for removing base

Remove screws and the right and left arms

WN2-2039 Rev. 0

Chapter 3 Install/Disassemble

Rev.

SSD-PROSOUND 2 ##{t3:48

INSTALLATION PROCEDURES

OM EARBIS, SSD-PROSOUND 2 OMRSOM, BHORALL TOMAS.

BRL: ISAKS(N—(HOPUHABTSCL)

This installation procedure is provided for reference in installation of SSD-PROSOUND 2

Tool required: Phillips screwdriver (Provide it beforehand)

HAREM Sb, DRRSIS, REMIT SO CRELTECCE,

Note) Keep the cushion and the belt and the packing bag, etc. for reusing it when

transporting the SSD-PROSOUND2.

A 3%

B RBOBRHERS ARBAMSNS,

S RACKET SHRORRAG SSUES, WRRRBORRAHIKLS.

BS PMF ORS, WARMABLORTSCE,

BEAN LMBUNOAT 3 MBs, MUAIFLEUCE,

ZX CAUTION

IN This system must be installed only by the qualified personnel.

I§ The environmental conditions for the place of installation of the SSD-PROSOUND 2 system

and the specifications of the power supply must satisfy the requirements stated in the

‘operator's manual.

ll See the operator's manual for the connection of the probe.

Hi Do not install optional equipment of other models.

Total Page : 12

MS5-5039

MN2-2039 Rev. 0

Chapter 3 Install/Disassemble

HRRVAR [List of Accessory Parts ~

FRONREAM HOTU SPHBLTHE.

Check to assure all he belowisted accessory parts to have been included in the shipping case.

& % a # a &

No. Parts Name Appearance Quantity

4

FoF

1 Probe Holder dset

(MP-PH-PROSOUND2) wv

2 | Bay—I0 __ fl

Power Cable

IIAP HI-FI

3 | Echo Copier Control Cable 1

(AUW1-100)

RAS

User Manual

4 Safety Instruction — 1 set

How to Use

Measurement

5 | mite — Son ieene 1

6 | aaeee = A

Installation Procedures

REAR as ‘i

Test Certificate

MS5-5039

WN2-2039 Rev. 0

Chapter 3 Install/Dsassemble

Rev.1

1. BARORYALAR 41. Removing of Packing material

2. FO-PRIF ORY 2. Installation of Probe Holder

3. ERT —FILORRAR 3. Cable Connection Procedure

4, Operation method of Operation panel

4, PARAL, S=SA ORD os ;

and Monitor moving

5. Transfer method of

5. 3

ead SSD-PROSOUND2

MS5-5039

WN2-2039 Rev. 0

Chapter 3 Install/Disassemble

PAHORYALAR

ARIES ARLES

Rev.1

Removing of Packing material -

—hOIRYALI Removing of Operation Panel Protection sheet

DRE SAILORS hE EIS EFA

t.

@Lift and remove the protection sheet of the

operation panel upwards.

Protection sheet

KAA RORUALBI Removing of Panel Pad

© ETF

~ Packing Tape

ONAL AE TH SRAT—-FEMM

Fe.

@Remove the packing tape which is fixing the

panel pad.

RAWAIE

Panel Pad

MS5-5039

MN2-2039 Rev. 0

Chapter 3 Install/Dsassemble

Rev.1

QiR TE NAILED LEAL ARIE TIL SF

EPRAASIFAE THO RUAT

@Open operation panel a little, then slide the

panel pad to the center and remove it.

RRILOE

Panel Pad

boyd /LHRF—FORYMHLAIR Removing of Trackball Packing Tape

Dh yA ILE ILI TO BAREF FERRI

t.

@Remove the 2 packing tape which is fixing the

trackball

Packing Tape

MS5-5039

WN2-2039 Rev. 0

Chapter 3 Install/Disassemble

Rev.t

Installation of Probe Holder

EV—-RFORYHtAH Installation of Jelly-bottle Cup

Fa-FANS

Probe Holder - DEV-BtOMBERLERBT, FOI

AN a WEICARTRUTTS.

@insert the jelly-bottle cup into the probe

holder by pushing the side of the jelly-bottie

cup.

ey-RIt

Jelly-bottle Cup

ree

Completion drawing

MS5-5039

BAKE 1

Guide pint

WN2-2039 Rev. 0

Chapter 3 Install/Disassemble

Rev.1

ORMMM OAKEY 1IcFO—-PHLIFOF

WRASRDETRAAAT ARSE, FLT

RA ISAREY 1 BBL.

@uJbin the transformed hole 1 of probe holder

to the guide pin 1 of the front side of

SSD-PROSOUND2, and slide the probe

holder to backward and insert the guide pin

1 into the transformed hole 1

FO-FhyF

Probe Holder

HaFey2

Guide pin 2

Hake 1

Guide pin 1

MS5-5039

ALS R ARSE HILAIRE 2E

Lao.

@Tum the probe holder downward centering on

the guide pin 1, and Insert the guide pin 2 into

the transformed hole 2.

WN2~2039 Rev. 0

Chapter 3 Install/Disassemble

Rev.t

Jo: LY ORY ALA Removing of Probe Holder

OFO—-PAIIO YAS VGA, EAAIE

ELIF, SUVR2EAAFEY 2 DONT,

QIO-PHNFEREM MSAD ARSE. FIL

LRA EHIFEY 1 DONT.

DLift probe holder upward by pulling the

protuberance of a probe holder, and remove

the transformed hole 2 from the guide pin 2.

@Slide the probe holder to the front of

70: ‘SSD-PROSOUND2 and remove the

Probe Holder

Protuberance transformed hole 1 from the guide pin 1.

Hakev2 OD FR2

Guide pin2 Transformed hole 2

FWRI

Guide pint = @ Transformed hole 1

MS5-5039

MN2-2039 Rev. 0

Chapter 3 Install/Disassemble

‘7—JWVOWKAK Cable Connection Procedure

‘Screw, 1

ORLE 1 RAL THER REMITS.

@Unfasten the screw and open the connector

window.

HR

‘Connector Window

QBOEINK7—F NERS S.

KIS—IET AT—F Vs RIET

@Connect the cables as in the figure.

3Pass the Echo copier control cable through

ditch.

Ia—se 7 He —F IL

Echo Copier Control Cable

(LI—3E 7 OTF RIT

Pass the Echo copier control cable through ditch.

MS5-5039

WN2-2039 Rev. 0

Chapter 3 Install/Disassemble

Rev.t

QFROMBAIR EL, RABIES.

@Caryy out wiring in accordance with the chart below.

$2GRE Recorder ‘SSD-PROSOUND 2

REMOTE PRINTER ee

VIDEO IN, VIDEO OUT ‘Connector Pane!

$82:310 WRESIA FITS IRR TER

~ACIN Connect with the insulated transformer (option)

[PTUs900-tW(100V systom)/ PTU4000-2012005ysem))

@O7-F ERRLIR, MEAL TLE

Be

@After connecting the cables, close the

connector window and tighten the screw.

‘Connector Window

MS5-5039

MN2-2039 Rev. 0

Chapter 3 Install/Disassemble

Operation method of

Operation panel and Monitor movi

48% ILOMMEBE Operation method of Operation panel

4, TENA IL,

DIRE HILO Rime HS RTE TILE BAK,

QIN ALO Seine LIF CHRP NNAILE

FACS,

SR PENA ILEPAC OBIS, E—SOMSEBL

THDFALSE CEL

Hold the tip of the operation panel and open it.

@Lift the tip of the operation panel and close it.

3 3When closing the operation panel, return tit

RIES of the monitor to the original position before

Operation Panel closing the panel

E=S5]M OWE Operation method of Monitor moving

DELSOLMEHOTHILbSH. EBORE

BETS.

(VASP 30", F 10")

Tit the monitor by moving the upper part of

it, and adjust it at desired angles

(The tilt angle: up: 30°,down: 10°)

MS5-5039

WN2-2039 Rev. 0

Chapter 3 Install/Disassemble

5. Transfer method of

SEOeMAE SSD-PROSOUND2

EOBHAK Transfer method of SSD-PROSOUNDZ

KRECBHT OHI, T= FOMSEBL KR

PERAILEALSS

jefore moving SSD-PROSOUND2, return

tit of the monitor to the original position and

close the operation panel.

OMFELIZATIFSH, MEOPREHS, K

BEM Li tBatS,

@Slide the handle upwards, lift

‘SSD-PROSOUND2 by holding center at the

handle and move.

JO=“I7—FJ_ @IO-FRUGRT—F ABREN THOR

Probe Cable Blk, DORI —-JILI97IBSTITHY

SRECEHTS.

IDI 7 ig BA CR VIEL TY

SRETIS.

@in case the probe cable and power cable

exists, before moving SSD-PROSOUND2,

twist up the cables to the cable hook as in

the figure.

XXIn case of the probe cable,

bend cable at the middle, and

twist up cable to the hook

Fa-F7—F

Power Cable

MS5-5039

NN2-2039 Rev. 0

Chapter3 Install/Disassemble

Disassembling (Notes)

ae

NN2-2039 Rev. 0

Chapter 3 Install/Disassemble

HIN2-2039 Rev. 0

Chapter3 Install)Disassemble

GAIN KNOB STC KNOB

To CLEAN UP

MN2-2039 Rev. 0

Chapter3 Install/Disassemble

TRACK BALL CABLE

L-TB-13 DHCDF-8/36-P1.00-BT14

GAIN (L-RE-7) MENU (L-RE-7)

Connect to J101 Connect to J102

Chapter 4

SYSTEM OVERVIEW

Chapter 4

41 Equipment

specifications

Scanning system

Operating modes

Simultaneously loaded probes

Operating modes,

WN2-2039 Rev. 0

Chapterd System Overview

Written precautions

‘These specifications for “Ver. 2“ describe equipment characteristics

when used with normal combinations of sofware and hardware, Thus

the functional specifications described here may not be available when

only the software requirements are met.

Electronic linear

Convex scanning

B, BB, BM, M

Electronic probes 2

B, BIB, BM, M

M mode display _ Moving bar display

Scanning speed: Can be set to one of 7 levels

(1, 1.5, 2, 3,4, 6, 8 See/Plane)

Diagnostic distance 3 ~ 24 em (Each probe has restrictions on diagnostic distance)

Display mode

Probe frequency

Electronic systems

‘Transmission frequency

Electronic systems

‘Transmission format

‘Transmission voltage

Electronic systems

‘Transmission power control

Electronic linear: B, B-Zoom, 2B, B/M, .M, *FAM.

Electronic convex: B, B-Zoom, 2B, , B/M, M, *FAM.

*FAM is for Ver. 2.0 and later versions and only after

Freeze

4 types (high, resolution, standard and penetration)

‘Adjustable to image frequency

2.14, 2.5, 3.0, 3.75, 5.0, 6.0, 7.5, 10.0, 13.0MHz.

(Each probe has frequency restrictions)

Single transmission

Burst transmission (only dual polarity transmission,

‘number of waves: max. 2)

Harmonic

Extended

‘Max. #80V

Control of transmission voltage via console operations

Monitoring of transmission voltage ‘The CPU monitors transmission voltage values to enable

Focus system

‘Transmission:

Reception:

Reception adder method

Reception method

termination of transmission and shutting down output of

transmission power in the event of trouble.

Digital focus (max. 4 levels) + audio lens

Digital format dynamic focus + audio lens

Digital adder

Conforms to reception apodization

Simultaneous reception Monochrome:

Max, 2-directions

WN2-2039 Rev. 0

Chapterd System Overview

Image quality adjustment

BGain

MGain

STC

Contrast

AGC

FIC

Frame correlation

Smoothing (B)

Post processing

View Gamma

Scanning line density

30-90 4B

330 dB from B Gain setting

S-level slide control

16-levels

Blevels

On/Off control (M only)

16-levels (monochrome)

‘Smooth type: 4-levels (Low, Mid], Mid2, High)

Horizontal Smooth : (Off, Low, High)

5 types (linear, slopel, slope?, slope’, reject)

‘View gamma 5 types (linear, A, B, C, D)

Changes with display

setting)

(diagnostic distance, zoom

Relief 4 types (Off + 3 levels, B, M) =

Image Frequency Select 4 types (resolution, STD1, STD2, penetration)

piu

‘Image gradation Monochrome: 8-bit, 256-levels

Number of displayable scan lines Max. 1024 lines (with frame correlation off)

Display memory ‘Monochrome: 512 x 512% 8 bit x 4 planes

Cine Memory ‘Monochrome: 65536 x 512 * 8 bit

Image display synchronization

‘method Ultrasonic frame synchronization

Ping-pong method, can be tured On/Off

Cine memory function

Cine Memory Maximum scan lines 65536

Scroll memory Maximum scan lines 2048

Store memory Review max. 999 pages ~

Image display function

i/* mode horizontal display Provided

Bode image Zoom Write zoom provided

(read zoom available only in freeze mode)

Position movement Yes

Horizontal and vertical flipping Yes

M mode image No

Request function (changes display mode after freeze) ‘Yes

Data storage and output

Format of stored still images

Storage media

DICOM_RLE Lossless

BMP, JPEG

‘Compact flash card

‘Management of patient data

Internal patient database

Displayed information

Automatic display

Character entry

Graphic display

Measuring functions

Language

Basic B mode measurements

Basic M mode measurements

Obstetrical measurements

Gynecologic measurements

Cardiac function measurements

Left ventricular analysis,

Bmode

M mode

B mode

M mode

Urology department

‘measurements

Other measurements

Report functions

Wk2-2039 Rev. 0

Chapter System Overview

Entry of patient information and storage in equipment

‘Management of images stored for each patient

Date, time, imaging frequency, image direction mark,

diagnostic distance, gain, contrast, frame rate,

transmission voltage (% indication), focus mark,

BSA/GWP/PSA, preset name, audio output (MI, TI)

Hospital name, patient number (ID), patient name,

patient age, sex, height, weight, body area, gestational

‘week, comment (can be manipulated using track ball)

annotation text (can be manipulated using track ball),

sonographer

Range mark, time mark, puncture guide line (with depth

indication), ‘body mark (user settable), cursor (with

sample gate, M-window and angle mark), cine scale

English

Distance, surface and boundary length, angle, volume,

stenosis rate, ratio, histogram and bone angle

‘measurements

Distance (amplitude), time, heart rate, speed and stenosis

rate measurements

Gestational week measurement, fetal weight

measurement, amniotic fluid index measurement, AE

pocket, twin and triplet handling, fetal cardiac functions,

graph function

Uterine, thickness of endometrium, cervix, ovary and

follicle measurements,

Pombo( wall), Teichholzwall), Gibson(wall), Single

Plane Ellipsoid, Bi-plane Ellipsoid, Bullet, Simpson,

Modified Simpson

Pombo(wall), Teichholz(wall), Gibson(wall)

Lax(wall), SAX, APX

Mitral valve, Aortic valve, Tricuspid valve, Pulmonary

valve

Prostatic volume, seminal vesicle, bladder capacity,

testicular volume, kidney volume, thickness of renal

cortex and adrenal measurements

Peripheral vein analysis (stenosis rate measurement),

histogram measurement, congenital hip dislocation

measurement

Materal measurement report, _ gynecological

measurement report, cardiac function measurement

report, urology department measurement, report output

function

MN2-2039 Rev. 0

Chapter4 System Overview

VO signals

Data input and output ~

USB USBI.1 TypeA (LowS.: 1.5Mbps / FullS.: 12MBps)

(One of the 2 ports provided is available for user

operations)

RS-232C ALK-3 communications (D-Sub 9-pin) 1 system

Analog and video YO

‘Monochrome video printer composite

output 2 systems

Control signal (Prin/Busy) 1 system

TV monitor

10.4-inch LCD

Monitor resolution: VGA

Power supply

Power supply voltage

100 V system 100-120 V AC #10%

200 V system 200-240 V AC+10%

(PTU: 1900* W is used as an option)

Power consumption 100 VA

Cabinet dimensions Width:430 mm, Depth with panels installed: 250 mm Height: 400 mm

Depth with panels removed: 500 mm.

Weight: 8.0 kg or less (equipment only)

Classification according to protection against

electrical shock: Class 1 equipment

Classification according to degree of protection

against electrical shock: BF type equipment only

Operating environment

Ambient temperature +10 t0 40°C. :

Relative humidity 30 to 75%

Atmospheric pressure 700 to 1060 hPa

HN2-2039 Rev. 0

Chapterd System Overview

Major optional equipment

Photographic equipment

Monochrome video printer (analog) $SZ-310

Po3*

Foot switch MP-2345B

3-pedal foot switch MP-2614B

Isolating transformer unit (same as SSD-900 isolating transformer)

PTU 1900 1 W (100 V system, white)

PTU 1900 2 W (200 V system, white)

4-2

MN2-2039 Rev. 0

Chapterd System Overview

‘System configuration

This ultra sound diagnostic system (ProSound 2) is comprised of the following ur

Cabinet PSC-141*

Video storage unit USM-33*

Main panel PNL-PROSOUND2

Observation monitor IPF-1001

Optional equipment

Monochrome printer (analog) SSZ-310, P93*

Foot switch MP-2345B

3-pedal foot switch MP-2614B

Software option None

System block diagram

‘The following pages provide a list and a system block diagram of all the PCBs (except those in the

power supply unit and external options) in this system,

List of ProSound 2 PCBs__Ver.1.0.0, _Ver.1.0.7

ProSound 2 Unitmodule | PCB model Name Description

‘Main body PSC-141

Main Panel PNL-PROSOUND2 Operation panel serially connected tothe host

| Probe connector, probe switch, HVS (high voltage switch), probe code

Elan probe transmission cei, variable voltage power supply circuit

eee cael pera for transmission circuits, circuits for protecting reception circuits, channel

reduction circuits, initial stage PreAmp, variable gain amplifier (VGA is a

unit that adjusts ‘signal level to suit BeamFormer input), HVS control,

channeling reduction control, generation of electronic probe transmission

| trigger, voltage detection circuit

‘AD, digital delay circuit, 16-channel control, digital beam processor,

EPS46500** | RXBF frame correlation, line correlation, space filter, voltage supervision circuit,

PreSTC generation, correlation memory

B mode mass memory with eapacity 10 store and control US line 65536

records, scan converter (2-dimensional interpolation), video memory (to

| store 2048 records for M mode), video encoder, output to LCD monitor and

we peripheral equipment, CPU for controlling the entire system, flash memory

eee eee card for generating characters and graphics and storing the programs that

run the system, compact flash cards for storing data, USB hub function,

Ethemet port, secondary power startup control circuit, video signal

distribution, interface for peripheral units, foot switch connector

| Viewing LCD monitor IPE-1001 10.4-inch LCD monitor

Power Supply unit, EU-6041 AC inlet, UNI, UN2, +12 V cooling fan

P5469 | UNI | AC inlet, fuse, DC output, +3.3 V generator circuit

-5'V generator circuit, 12 V generator, #90 V stabilizer circuit

| mpsage | UN2 —_| PEC cireuit (PFC high frequency control circuit: +380 V DO), generating

eee | #5 Vstb DC, +12 VDC, +5 V DC and +90 V DC from +380 V

O-A8y GE02-2NN

motazaag waisks puoidey,

Probe (Option)

Linear

Convex

Ethernet

TITLE

USB Menory

USI-158 System block

WN2-2039 Rev. 0

CChapter4 System Overview

use 1

wan seamrre

Bus

Bridge

vu

BF

ctrl

Tat

[ine] Frane

1 |eorr_| [eorr

for oF

Sean

Conv

Denod Jf LOG [Siena

{ Process|

x Bean Process

sorau soa

icine)_Ff scrot)

S/P converter |[ Dela

(Beseriatizer) || Ade

Rx Bean Forner

wu E rs-2a00

Power tr

Ctrl Switch

SORA

‘cen,

mV!

ctr

fe NTSC/PAL

|

|

x

E604

‘POWER SUPPLY

SYSTEM BLOCK DIAGRAM

tse

ProSound 2

soration Unit |

TU PROSOUNDZ. |

Panel

AL Prosouno|

Foot SW

(oerian)

Lo

T1001

aw

Printer

(PT 0M

ReSR na

Chapter 5

TROUBLESHOOTING

Chapter 5

S41

5-2

MWN2-2039 Rev. 0

Chapters Troubleshooting

Introduction

‘This trouble shooting makes integral part of the Service Manual. And it has been prepared for the

persistent purpose of providing for repairing guidelines.

‘What has been described herein, moreover, is subject to the prerequisite for repair to be made by

replacing a PCB.

Precautions

To prevent a new problem (secondary disaster) from taking place in the process of trouble shooting

as described herein, every engineer concerned should duly take the following precautions:

1) Never remove any part ftom the electric system, including PCB, probe, cable, ete, before

powering off the equipment.

2) Do not proceed to a disassembly of equipment without observing the established disassembly

procedure, Be careful enough for wrongly disassembling the equipment would damage or break

itdown,

3) To make certain of a voltage and/or a signal waveform, it is necessary to thoroughly know the

specification and handling procedure relating to a measuring instrument employed

4) To ground a measuring instrument probe or the like, it is naturally necessary to know where a

signal to determine is grounded. Before using the instrument, moreover, make certain for

which the grounding terminal is intended, analog,

al, alternating current, direct current, high

voltage or low voltage.

eoce eee ee eee ee eee eee

J@CAUTION® Failure to ground properly might result in an incapability of observing any

1 accurate voltage or waveform or in a probability of burning out the 1

1 ‘measuring instrument or ultrasound diagnostic equipment or both. 1

5) Do not fit a measuring instrument probe or the like to a measuring point before turning off the

ultrasound diagnostic equipment.

1

| @CAUTION® To determine an especially high voltage it might rupture a circuit in i

I the ultrasound diagnostic equipment. Besides, it might endanger an 1

I engineer or engineers concerned. 1

MN2-2039 Rev. 0

ChapterS Troubleshooting

6) To replace or repair a PCB, make certain of its compatibility, ete, in accordance with the

“History of SSD-Prosound2’

If a wrong ROM should be mounted on a PCB, employ the ROM originally employed in the

user's equipment or select an appropriate one in accordance with the History.

@CAVTION@ Ifan incompatible PCB should be inserted into the equipment, there are

possibilities that the equipment may be burt out. If such incompatible PCB

‘moreover, it should be fully noted that another problem might take place

'

'

' :

i should remain inserted in the equipment after completion of a repair,

!

1 newly.

'

1

I

1

1

1

7) Without definitively knowing that failure has taken place, do not unnecessarily change any controls

and/or switches on a PCB from their original settings.

To determine whether or not a problem is the failure, see Chapter 6 "Performance Check"

fa readjustment is required, see Chapter 5"Troubleshooting,"

j @CAUTION® An unnecessary change of controls'or switches settings might bring about

1 anew problem, probably making the equipment unrepairable.

8) While you are shooting trouble in accordance with the present procedure, it may be necessary to

consult with Technical Support. In such a case, provide at least the following information:

i) Equipment model number,

ii) Equipment serial number,

iii) History of equipment (repairs and/or modifications so far made), and software version, and

iv). Specific problem situations (Send a photo or photos.)

WN2~-2039 Rev. 0

Chapters Troubleshooting,

Pray

Fig6-1 ‘The Configuration On Display

To give an explanation about the situations of a problem, it is necessary to clarify to which it relates

out of the elements composing the scene, while referring to the illustration given above. Related

component elements may be roughly classified as follows:

© Ultrasound Image : An ultrasound tomographic image; its contour varies

with an image mode, a probe, etc.

© = Memory Area A full size of memory required to display an

ultrasound image.

© Gray Scale An indicator of image gradients; its pattern varies

with a setting of enhancement, gamma or the like.

© Character A component of the text relating to a hospital name, ID,

automatic display, et.

© Graphic ‘A.component of scale marks, active marks, body marks, et

WN2-2039 Rev. 0

ChapterS Troubleshooting

$3 Tools and Measuring Instruments Required

‘The tools and measuring instruments, which are required for a repair on a standard basis, are as

follows:

1) Oscilloscope

Sensitivity SsmVidiv.

Frequency band DC~SOMHz

‘Maximum input voltage: 400V or more

2) Multi Meter

Class: 0.5 class

Range + ACY, DCV, DCA, 2

3) Test Piece:

Made by RMI (Radiation Measurements, INC.)

RML-412 or RMI-403GS

4) Probe

Convex uST-9137

MN2-2039 Rev. 0

Chapter § Troubleshooting

5-4 Schematic layout of unit

USM unit

Monitor unit

IPF-1001

Power supply unit

PNL-PROSOUND2

WN2-2039 Rev. 0

Chapter $ Troubleshooting

5-5 Location of PCB DIP switches and LEDs

‘The following drawings show DIP switch and LED location on PCBs.

EP5464

MODEL

Pi. P2it, Sel dolsRUMSK.

ead

RF 4 VIAL Y FORE

SWI : 2-30FF

2 ite ie tite = Vi a aE i

jae thrigga 1-UMigeagt = ih

Monti

EL

EP5467

8. SM Mt9 Sil ET SS

MEINE 4) RIMES

MN2-2039 Rev. 0

Chapter 5 Troubleshooting

LED1: Power control status

Off: The 5 V standby voltage is not provided, or it is provided but the power switch on the operation panel

is not set to On.

On: The power switch on the operation panel is tumed on and the system is powered up,

This LED is connected to the power control IC (IC8). This IC receives the power supply On signal, outputs

the startup signal to the power supply unit and turns on the LED.

Flashing: Indicates the state lasting from when the power supply is tumed off on the operation panel and

until the power supply is actually turned off

‘When IC8 receives the power supply Off signal, it outputs a ShutDown request to the CPU and causes the

LED to flash. The CPU returns a Shut_Down_Done signal for data save.

IC8 outputs a power Off signal to the power supply unit to turn off the unit, The LED flashes at this time.

When the power switch is held down, the IC8 tums off the power supply unit without waiting for the

‘Shut_Down_Done signal

In this period, the LED flashes for about 4 seconds

LED2—LEDG6: These are status LEDs for the USB hub.

LED2~LEDS: Currently not used (do not go on)

LED6: When a USB memory card is inserted, the LED senses the USB hub (IC44) and lights.

LED7, LED8: These are CPU direct status LEDs and are normally off.

(One or both LEDs light during halt, standby, reset and other conditions.

‘They light to indicate that the CPU for some reason is not running even though power is provided.

LEDS

Indicates that the system is operating normally.

This LED goes on and off repeatedly during periodic tasks.

Regular flashing indicates that the system is operating normally.

LEDIO

ights to indicate file access.

This LED lights at the start of file access using middleware in a file library function and goes off when

access ends.

It flashes during USB, CF and CD access.

Software that makes direct calls to the middleware and does not cause the LED to light need to be

handled with care,

LEDIL

Indicates the A drive is being mounted