Professional Documents

Culture Documents

The Business of Bubbles - Recipe

Uploaded by

api-281581757Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Business of Bubbles - Recipe

Uploaded by

api-281581757Copyright:

Available Formats

THE BUSINESS OF BUBBLES

Ginger Beer A Recipe to Start The Process

Because of its low alcohol content, ginger beer

is a popular drink with British children. Dean

Madden from the National Centre for

Biotechnology Education, University of Reading,

UK, gives his recipe for introducing younger

students to the principles of fermentation, food

hygiene and the biochemistry of respiration.

The predecessors of modern carbonated soft

drinks were often brewed at home. In late 19th

century Britain, small beers were fermented

drinks with a very low alcohol content. These

were usually safer to drink than water, which was

often contaminated.

Image courtesy of iStockphoto

Ginger beer originated in England in the mid-1700s and was exported

worldwide. This was made possible by the use of strong earthenware

bottles that were sealed by a liquid- and gas-tight glaze (called Bristol

glaze). The British Excise Regulations of 1855 required that the drink

contained no more than 2% alcohol, and usually it was far less potent:

hence ginger beer became popular with children. By the start of the 20th

century it was produced commercially in almost every town in the United

Kingdom. The beer was often sold by street hawkers, and it was

sometimes dispensed from a beer engine an elaborate device like an

upright piano with beer pump handles that was pulled through the

streets by a pony.

In 1935 there were more than 3000 producers of ginger beer in the

United Kingdom: today, however, only one British firm makes a

traditional brewed product modern ginger beer is usually made with

flavourings and carbonated with pressurised carbon dioxide.

There are many recipes for ginger beer; the basic ingredients are ginger,

lemon, sugar and yeast. Real ginger beer is made from fresh root ginger

(Zingiber officinale), often with other flavourings such as juniper

(Juniperus communis), liquorice (Glycyrrhiza glabra) or chilli (Capsicum

annuum) which gives the product extra bite. Yarrow (Achillea

millefolium) is sometimes used to inhibit bacterial growth (as it was in

Birdwood High School PBL Unit

-1-

The Business of Bubbles

THE BUSINESS OF BUBBLES

normal beer before the introduction of hops). Jamaican ginger beer is

sometimes made with lime instead of lemon juice.

The following recipe is for one litre and can be scaled up and changed as

required some suggest that the ginger should be grated rather than

sliced and crushed. Others recommend boiling the mixture before adding

the yeast, to extract more flavour from the ingredients.

Compound

Source

Relative strength

Piperine

Black pepper

Gingerol

Fresh ginger

0.8

Shogaol

Dried ginger

1.5

Zingerone

Cooked ginger

0.5

Capsaicin

Chilli

150300

Ginger contains the pungent compound gingerol, which is similar in structure to chillis

capsaicin and peppers piperine. Heating converts gingerol to the less pungent zingerone;

drying converts it to shogaol, which is about twice as strong-tasting. It is thought that these

compounds evolved as a defence against herbivores as high concentrations are repellent to

most mammals.

Equipment and materials

Equipment

Sharp knife and chopping board

Lemon zester or grater

Lemon squeezer

Rolling pin

Large spoon

Kettle for boiling water

Thermometer

Large bowl or jug

Birdwood High School PBL Unit

-2-

The Business of Bubbles

THE BUSINESS OF BUBBLES

Clean tea towel to cover bowl

Sieve and funnel for straining liquid into

bottles

Plastic (PET) bottle and cap. Do not use

glass bottles!

Materials

1 l water

150 g root ginger (~130g when peeled)

Medium-sized lemon (preferably unwaxed)

140 g sugar (brown or white)

4 g cream of tartar (tartaric acid)

4 g dried ale or bread yeast, or 8 g fresh

Sterilising solution suitable for food use

Strong plastic bag in which to bruise ginger

Optional: Other spices such as chilli,

nutmeg, liquorice, vanilla, cardamom,

cloves, juniper, fennel, coriander, star

anise

Method

1.

Peel the ginger and cut it into slices 35

mm thick. Bruise the slices well by

placing them in a strong, clean plastic

bag and crushing them with a rolling pin.

2.

Place the ginger in a large bowl or jug.

Scrape the lemon zest over it, then add

the juice from the lemon.

Birdwood High School PBL Unit

-3-

The Business of Bubbles

THE BUSINESS OF BUBBLES

3.

Place the remaining ingredients except

for the yeast in the bowl, then carefully

pour on boiling water. Stir.

4.

Cover the bowl with a clean cloth and

leave the liquid to cool to 2530C (this

can take 6090 min).

5.

While the liquid is cooling, sterilise the

PET bottles using the sterilising solution.

Ensure that the bottles are thoroughly

rinsed with clean water after sterilising.*

6.

Add the yeast to the warm liquid in the

bowl and stir until it has dispersed.

7.

Cover the bowl with a clean cloth and

leave it in a warm place for 24 h.

8.

Skim off the yeast, leaving the sediment

in the bowl. Strain into the sterilised

plastic bottles, leaving a 35cm air gap

at the top.

9.

IMPORTANT! Allow the beer to ferment

at room temperature (~21C) for no

more than 48 h, then place the bottles in

a fridge. Drink within six days.

* There is no need to use boiled water to rinse

the bottles after sterilisation. The sterilising

step is to get rid of major contaminants left in

reused bottles. The tap water used for rinsing

should not introduce contaminants, and

should it do so, they will be quickly outcompeted by the relatively large inoculum of

yeast. The low pH of the liquid (from the

lemons) will also prevent bacteria (although

not yeast) from growing

Birdwood High School PBL Unit

-4-

Images courtesy of Dean

Madden

The Business of Bubbles

THE BUSINESS OF BUBBLES

Safety and other concerns

Glass bottles must NEVER be used, as the gas produced will cause

them to explode. This drink should always be made in plastic bottles,

and it should always be refrigerated and consumed within six days. The

short fermentation period and refrigeration ensure that the alcohol

content of the drink remains low.

As some religious groups object even to the consumption of products

that contain little or no alcohol but have been produced by brewing.

It is not a requirement to consume your product.

Preparation and timing

It takes approximately 90 minutes to prepare the drink, including a

cooling period of 60 minutes. The initial fermentation takes 24 hours,

followed by up to 48 hours fermentation in bottles. The bottles can be

sterilised in advance if desired.

Birdwood High School PBL Unit

-5-

The Business of Bubbles

You might also like

- Ginger Beer: A Traditional Fermented Low-Alcohol DrinkDocument5 pagesGinger Beer: A Traditional Fermented Low-Alcohol DrinkT4urus-Vega100% (2)

- Down To The Root - Make Your Own Root BeerDocument16 pagesDown To The Root - Make Your Own Root BeerjohodadaNo ratings yet

- Craft Your Own Perry With Fresh Fall PearsDocument3 pagesCraft Your Own Perry With Fresh Fall PearsAhmet MetinNo ratings yet

- Beer Cocktail Recipes: Ultimate Book for Making Refreshing & Delicious Beer Drinks at HomeFrom EverandBeer Cocktail Recipes: Ultimate Book for Making Refreshing & Delicious Beer Drinks at HomeNo ratings yet

- Brew Better Soda at HomeDocument7 pagesBrew Better Soda at Homekkd108100% (1)

- Off Flavors - More BeersDocument6 pagesOff Flavors - More BeersGars BièreNo ratings yet

- KK Beer Guide Booklet 091522 Print Ready - Small-MinDocument12 pagesKK Beer Guide Booklet 091522 Print Ready - Small-MinClifton SutherlandNo ratings yet

- Instructions On How To Make Hard CiderDocument3 pagesInstructions On How To Make Hard CiderkarnizsdjuroNo ratings yet

- Gin Cocktail Recipes: The Ultimate Book for Making Refreshing & Delicious Gin Based Cocktails at Home.From EverandGin Cocktail Recipes: The Ultimate Book for Making Refreshing & Delicious Gin Based Cocktails at Home.No ratings yet

- Home Brewing: 70 Top Secrets & Tricks To Beer Brewing Right The First Time: A Guide To Home Brew Any Beer You Want (With Recipe Journal)From EverandHome Brewing: 70 Top Secrets & Tricks To Beer Brewing Right The First Time: A Guide To Home Brew Any Beer You Want (With Recipe Journal)No ratings yet

- The Beginner's Guide to Beer Brewing: Fundamentals Of Beer BrewingFrom EverandThe Beginner's Guide to Beer Brewing: Fundamentals Of Beer BrewingNo ratings yet

- The Cordial Maker's Cookbook - Recipes & Instructions for Making Home Made Liqueurs, Aperitifs & Cordials in Your KitchenFrom EverandThe Cordial Maker's Cookbook - Recipes & Instructions for Making Home Made Liqueurs, Aperitifs & Cordials in Your KitchenNo ratings yet

- Research Paper BartendingDocument7 pagesResearch Paper Bartendingzufehil0l0s2100% (1)

- Brew Homemade Root Beer Under 40 CharactersDocument3 pagesBrew Homemade Root Beer Under 40 CharacterssanjosewhoreNo ratings yet

- 101 Old Time Receipts for Beer, Wine, Whiskey, other Spirits and AccoutrementsFrom Everand101 Old Time Receipts for Beer, Wine, Whiskey, other Spirits and AccoutrementsNo ratings yet

- How To Make Wine From JuiceDocument16 pagesHow To Make Wine From Juicealex_077100% (1)

- Ginger Beer Step by Step GuideDocument4 pagesGinger Beer Step by Step GuidemaximpashninNo ratings yet

- Cordial Making at Home - Make Your Favorite Cordials and Liqueurs Better & Cheaper Than Store BoughtFrom EverandCordial Making at Home - Make Your Favorite Cordials and Liqueurs Better & Cheaper Than Store BoughtNo ratings yet

- Cocktail Training: Equipment Basic EquipmentDocument16 pagesCocktail Training: Equipment Basic EquipmentJaheer AbbasNo ratings yet

- Rice BeerDocument8 pagesRice BeerPied7PiperNo ratings yet

- The Joy of Brewing Cider, Mead, and Herbal Wine: How to Craft Seasonal Fast-Brew Favorites at HomeFrom EverandThe Joy of Brewing Cider, Mead, and Herbal Wine: How to Craft Seasonal Fast-Brew Favorites at HomeNo ratings yet

- Learn About Gin Production and Popular BrandsDocument4 pagesLearn About Gin Production and Popular BrandsdadgummyNo ratings yet

- 5 Gallon Kit: Using Steeping Grains Brewing With Extract Fermentation BottlingDocument28 pages5 Gallon Kit: Using Steeping Grains Brewing With Extract Fermentation BottlingSurendra Ramkissoon100% (1)

- Winemaking Made Easy: Learn how to create the perfect house wineFrom EverandWinemaking Made Easy: Learn how to create the perfect house wineNo ratings yet

- The Everything Hard Cider Book: All you need to know about making hard cider at homeFrom EverandThe Everything Hard Cider Book: All you need to know about making hard cider at homeNo ratings yet

- History of BartendingDocument44 pagesHistory of BartendingryarafinanNo ratings yet

- The Key IngredientsDocument4 pagesThe Key Ingredientsk_168911826No ratings yet

- Fundamentals of Bar & Beverage KnowledgeDocument53 pagesFundamentals of Bar & Beverage KnowledgeAudrey RNo ratings yet

- Home Brewing: 70 Top Secrets & Tricks To Beer Brewing Right The First Time: A Guide To Home Brew Any Beer You WantFrom EverandHome Brewing: 70 Top Secrets & Tricks To Beer Brewing Right The First Time: A Guide To Home Brew Any Beer You WantNo ratings yet

- DIY Apple CiderDocument3 pagesDIY Apple CiderGeorge LeongNo ratings yet

- Home Brew Recipe Bible: An Incredible Array of 101 Craft Beer Recipes, From Classic Styles to Experimental WildsFrom EverandHome Brew Recipe Bible: An Incredible Array of 101 Craft Beer Recipes, From Classic Styles to Experimental WildsNo ratings yet

- Gingerbeer Plant GingerbeerDocument2 pagesGingerbeer Plant Gingerbeerdluker2pi1256No ratings yet

- The Ultimate Frozen Drink Directory - 775 New & Classic Frozen Cocktail RecipesFrom EverandThe Ultimate Frozen Drink Directory - 775 New & Classic Frozen Cocktail RecipesNo ratings yet

- Beer Brewing Made Easy With Recipes (Boxed Set): 3 Books In 1 Beer Brewing Guide With Easy Homeade Beer Brewing Recipes: 3 Books In 1 Beer Brewing Guide With Easy Homeade Beer Brewing RecipesFrom EverandBeer Brewing Made Easy With Recipes (Boxed Set): 3 Books In 1 Beer Brewing Guide With Easy Homeade Beer Brewing Recipes: 3 Books In 1 Beer Brewing Guide With Easy Homeade Beer Brewing RecipesNo ratings yet

- A Beginner's Guide To BeermakingDocument7 pagesA Beginner's Guide To BeermakingShaheer MuhammadNo ratings yet

- LiquorDocument26 pagesLiquorDanny RamosNo ratings yet

- How To Make Your Own Red Dragon Fruit WineDocument8 pagesHow To Make Your Own Red Dragon Fruit WineShakura Ahseyia0% (1)

- Alcaholic Beverages: by Vikash PrasadDocument9 pagesAlcaholic Beverages: by Vikash PrasadRo NyNo ratings yet

- Hidromiel BebidasDocument14 pagesHidromiel BebidasRuben 867No ratings yet

- Chapter 8 Beverage ManagementDocument32 pagesChapter 8 Beverage ManagementNatasha AzlanNo ratings yet

- Alcoholic BeveragesDocument101 pagesAlcoholic BeveragesAmazing Grace Dela Cruz100% (2)

- BEVARAGTES Tia ReportingDocument34 pagesBEVARAGTES Tia Reportingommme talNo ratings yet

- Powerpoint CocktailsDocument19 pagesPowerpoint CocktailsNmbre Batoon CaidocNo ratings yet

- Bar Basics Equipment and TechniquesDocument10 pagesBar Basics Equipment and Techniquessrikanth_krishnamu_3100% (1)

- Ginger Beer With Ginger BugDocument2 pagesGinger Beer With Ginger BugCarmen Guerrero OntiverosNo ratings yet

- Assignment of F & B Service On Alcoholic Beverage GinDocument12 pagesAssignment of F & B Service On Alcoholic Beverage Ginmohitfm87No ratings yet

- Mixology BasicsDocument22 pagesMixology BasicsAmit Shrivastava100% (1)

- Making Apple CiderDocument4 pagesMaking Apple Ciderra$h100% (1)

- Beverages 2Document15 pagesBeverages 2pawanNo ratings yet

- Ginger Beer RecipeDocument1 pageGinger Beer RecipeSalimanga IssahNo ratings yet

- Do You Enjoy or Are You Good at Computing - A4cDocument1 pageDo You Enjoy or Are You Good at Computing - A4capi-281581757No ratings yet

- Do You Enjoy or Are You Good at Electrotechnology - A4cDocument1 pageDo You Enjoy or Are You Good at Electrotechnology - A4capi-281581757No ratings yet

- Do You Enjoy or Are You Good at Biology - A4cDocument1 pageDo You Enjoy or Are You Good at Biology - A4capi-281581757No ratings yet

- Stage 1 General MathematicsDocument1 pageStage 1 General Mathematicsapi-281581757No ratings yet

- Do You Enjoy or Are You Good at Music - A4cDocument1 pageDo You Enjoy or Are You Good at Music - A4capi-281581757No ratings yet

- Subtopic 1 2Document1 pageSubtopic 1 2api-281581757No ratings yet

- Do You Enjoy or Are You Good at English - A4cDocument1 pageDo You Enjoy or Are You Good at English - A4capi-281581757No ratings yet

- Do You Enjoy or Are You Good at Economics - A4cDocument1 pageDo You Enjoy or Are You Good at Economics - A4capi-281581757No ratings yet

- Do You Enjoy or Are You Good at Art - A4cDocument1 pageDo You Enjoy or Are You Good at Art - A4capi-281581757No ratings yet

- Class A: Student Test Scores Student Test ScoresDocument6 pagesClass A: Student Test Scores Student Test Scoresapi-281581757No ratings yet

- Performance Standards For Stage 1 General MathematicsDocument2 pagesPerformance Standards For Stage 1 General Mathematicsapi-281581757No ratings yet

- Topic 2 - MeasurementDocument2 pagesTopic 2 - Measurementapi-281581757No ratings yet

- Are You Ready Unit 2015Document5 pagesAre You Ready Unit 2015api-281581757No ratings yet

- Subtopic 1 1Document2 pagesSubtopic 1 1api-281581757No ratings yet

- 1478 What7-12yearoldsarereallyusing May2015Document1 page1478 What7-12yearoldsarereallyusing May2015api-281581757No ratings yet

- RightsDocument1 pageRightsapi-281581757No ratings yet

- STD 0910Document3 pagesSTD 0910api-281581757No ratings yet

- Joy of Stats Statisticstask ADocument2 pagesJoy of Stats Statisticstask Aapi-281581757No ratings yet

- Viva PreparationDocument2 pagesViva Preparationapi-281581757No ratings yet

- Business of Bubbles ChecklistDocument1 pageBusiness of Bubbles Checklistapi-281581757No ratings yet

- The Business of Bubbles - Logo and PackagingDocument1 pageThe Business of Bubbles - Logo and Packagingapi-281581757No ratings yet

- The Business of Bubbles - Pepsi HistoryDocument1 pageThe Business of Bubbles - Pepsi Historyapi-281581757No ratings yet

- Are You Ready Assessment Rubric 2015Document1 pageAre You Ready Assessment Rubric 2015api-281581757No ratings yet

- The Business of Bubbles - StartingDocument2 pagesThe Business of Bubbles - Startingapi-281581757No ratings yet

- The Business of Bubbles JournalDocument13 pagesThe Business of Bubbles Journalapi-281581757No ratings yet

- What Is ElliDocument2 pagesWhat Is Elliapi-281581757No ratings yet

- The Business of Bubbles - Coke HistoryDocument1 pageThe Business of Bubbles - Coke Historyapi-281581757No ratings yet

- Personal DevelomentDocument1 pagePersonal Develomentapi-281581757No ratings yet

- Script Jungle CruiseDocument24 pagesScript Jungle CruiseronnyNo ratings yet

- Show Don't Tell: Writing Workshop Practice ExercisesDocument11 pagesShow Don't Tell: Writing Workshop Practice ExercisesChristine Joy Tanglao AsasNo ratings yet

- International Meat Crisis PDFDocument174 pagesInternational Meat Crisis PDFTanisha JacksonNo ratings yet

- Argumentative EssayDocument4 pagesArgumentative Essayapi-527619279No ratings yet

- Racy Telenovelas Drive Social ChangeDocument19 pagesRacy Telenovelas Drive Social Changebhavith akulaNo ratings yet

- Animal Word Search Puzzle Sample3Document2 pagesAnimal Word Search Puzzle Sample3tebugreenNo ratings yet

- Superstitions Micro TeachingDocument17 pagesSuperstitions Micro Teachingacerca80100% (1)

- Bali Cattle Breeding SchemeDocument2 pagesBali Cattle Breeding Schemesyaiful48100% (1)

- Paket Buffet Umum 2019Document3 pagesPaket Buffet Umum 2019Ikhasul AmalNo ratings yet

- Autonomic Nervous System-1Document46 pagesAutonomic Nervous System-1a-tldNo ratings yet

- Vector Borne DiseasesDocument23 pagesVector Borne DiseasesKanishk BhatiaNo ratings yet

- Anatomical TermsDocument8 pagesAnatomical TermsDAGUMAN, FIONA DEI L.No ratings yet

- Sexual OffencesDocument21 pagesSexual Offencesniraj_sdNo ratings yet

- Eucoelomates Lab ReportDocument13 pagesEucoelomates Lab Reportsatvindar singhNo ratings yet

- Rapid Assessment SheetDocument5 pagesRapid Assessment SheetElise HowardNo ratings yet

- Lower Genital Tract InfectionDocument51 pagesLower Genital Tract InfectionSarisa SupawimonNo ratings yet

- Office Head Titles MunicipalityDocument2 pagesOffice Head Titles MunicipalityGeo AngeloNo ratings yet

- When Whales Walked Worksheet Part 5 1Document2 pagesWhen Whales Walked Worksheet Part 5 1api-284221392No ratings yet

- Advances in Understanding The Urine-Concentrating MechanismDocument26 pagesAdvances in Understanding The Urine-Concentrating MechanismKiara Lopez RelaizaNo ratings yet

- Oxford Discover 2Document4 pagesOxford Discover 2Gabuu2550% (4)

- Action Potential of NeuronsDocument3 pagesAction Potential of NeuronscheaterxorcistNo ratings yet

- Lab6 Fossilization PDFDocument9 pagesLab6 Fossilization PDFjimmypsNo ratings yet

- OZ 02 The Marvelous Land of OzDocument62 pagesOZ 02 The Marvelous Land of Ozbunnycat666No ratings yet

- Gamefowl Fighting Styles!Document27 pagesGamefowl Fighting Styles!Lawrence TumaponNo ratings yet

- Urgent Care Grants - RedRoverDocument5 pagesUrgent Care Grants - RedRovergabyNo ratings yet

- Types of ClaimsDocument14 pagesTypes of ClaimsCatherine Joy ManaloNo ratings yet

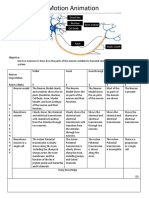

- Neurons Stop Motion AnimationDocument2 pagesNeurons Stop Motion Animationapi-495006167No ratings yet

- Muscle and Tendon Injuries - Evaluation and Management (2017, Springer-Verlag Berlin Heidelberg)Document440 pagesMuscle and Tendon Injuries - Evaluation and Management (2017, Springer-Verlag Berlin Heidelberg)Joaquin Villagra Jara100% (3)

- Animal Trafficking Lesson PlanDocument4 pagesAnimal Trafficking Lesson Plankurucz barbaraNo ratings yet

- (Original Size) Green & Brown Monstera Plant Fun Facts Data InfographicDocument1 page(Original Size) Green & Brown Monstera Plant Fun Facts Data InfographicMani MNo ratings yet