Professional Documents

Culture Documents

KHT3212F Manual

Uploaded by

martin_jaitman0 ratings0% found this document useful (0 votes)

11 views45 pagesNN

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentNN

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views45 pagesKHT3212F Manual

Uploaded by

martin_jaitmanNN

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 45

001 06

E-address: infog@knuth.de

Hydraulic CNC shearing machine

OPERATOR’S MANUAL

Serial NO.:

Type:

Date: 1-9-2003

iu Hydraulic CNC shearing machine

Page 2 of 45

Contents

INTRODUCTION 3

MAIN PARAMETER TABLE (TABLE 1-1 5

‘TRANSPORTATION AND INSTALLATION 6

1. SHIPPING AND RECEIVING. ob

2. Storing conditions, si

3. Operation area of the machine. 6

4. UNLOADING. 7

& FOUNDATION (See Figure 1.3) 7

6. LEVELING....... 10

OPERATION SAFETY... n

LUBRICATION 13

MACHINE OPERATION... 16

1. Preparation 16

a) Add oil to the oil tank. 16

b) Install the square arm to the machine. 16

©) Apply the power to the machine 16

4) Install the foot pedal to the machine 0

©) Check the rotate direction of the motor . AT

2. Staring 18

a) Instruction of the control box 18

b) Gap adjustment. 19

©) Finely adjust the back-gauge. 21

MAINTENANCE. 7 2

1. INTRODUCTION 22

2. BACK GAUGE ADJUSTMENT .. 22

1) Correct the position of the back-gauge... 22

2) Correct the parallelism of the back-gauge. 2B

3. Blade adjustment. 23

1) How to adjust the bottom blade 23

4. Charge the nitrogen to the back eylinde 26

HYDRAULIC SYSTEM, 28

1. Hydraulic schematic diagram (Figure 6.1) 28

2. Valve location diagram ( Figure 6.2). 2

3. Hydraulic elements list (chart 6-1) 30

4. Main cylinder: (Figure 63) 31

5. back elinder and clamp cylinder (Figure 6.4) 32

ELECTRIC SYSTEM 33

Electric schematic diagram (Figure 7.1-1) 3

Electric schematic diagram (Figure 7.1-2) 34

Electric schematic diagram (Figure 7.1-3)... 35

Electric schematic diagram (Figure 7.1-4) 36

Electric cabinet and operation station (Figure 7.2). 37

Electric elements list table( Chart 7-1). 38

MECHANISM... 40

Gap adjustment and beam rotation device (Figure 8.1)... 40

‘TROUBLE SHOOTING.. 41

1) How to quiekly and exactly find the problem? Whereis the problem? 41

2) How to judge the type of problem? et 41

3) Trouble of hydraulic system 42

4) Trouble of electric system...

5) Trouble of mechanism...

lea

(NUTI Hydraulic CNC shearing machine

INTRODUCTION

Page 3 of 45

Proper installation and maintenance of your shear means added years of productive

life. This manual is designed to give you practical information on installing and

maintaining the shear

The following pages describe the major working parts of the shear and the last page

is devoted to possible causes of trouble and their elimination. A parts list and floor plan

for you machine are included in a separate booklet and should be referred to when

ordering parts.

The information contained in this manual will assist you in taking care of

adjustments that become necessary from time to time. By following these instructions

yours shear will give you many years of productive and trouble free service.

If the problem arises that is not covered in this manual, do not fail to contact our

service department. We want you shear to give satisfaction.

In write for information, please refer to you shear by model and serial number.

These can be found on the metal name plate.

Knuth Wekzeugmaschinen GmbH

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- SVM182 - Vantage 400 - Service ManualDocument166 pagesSVM182 - Vantage 400 - Service Manualmartin_jaitman100% (4)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hyd-Mech S-25A Operation and Maintenance ManualDocument77 pagesHyd-Mech S-25A Operation and Maintenance Manualmartin_jaitman33% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Sullair LS120Document172 pagesSullair LS120martin_jaitman100% (1)

- Sullair Supervisor Controller Manual - 02250146-049Document32 pagesSullair Supervisor Controller Manual - 02250146-049martin_jaitman82% (11)

- SVM175 - Ranger 305D - Service ManualDocument198 pagesSVM175 - Ranger 305D - Service Manualmartin_jaitman0% (1)

- m3 Plasma-Shield Gas Boxes 0558005487Document88 pagesm3 Plasma-Shield Gas Boxes 0558005487martin_jaitman100% (1)

- Nova Full Manual 1206Document157 pagesNova Full Manual 1206martin_jaitman100% (2)

- Hydmech S-25a BrochureDocument2 pagesHydmech S-25a Brochuremartin_jaitmanNo ratings yet

- QTIYOS9BMJI5TQDocument4 pagesQTIYOS9BMJI5TQquiensabe0077No ratings yet

- EPP-360 Plasma Power Source 0558007676Document46 pagesEPP-360 Plasma Power Source 0558007676martin_jaitmanNo ratings yet

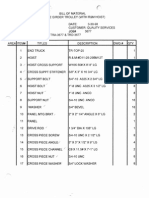

- Bill of MaterialDocument15 pagesBill of Materialmartin_jaitmanNo ratings yet

- Overhead CraneDocument2 pagesOverhead Cranemartin_jaitmanNo ratings yet

- Metric To Imperial ConversionDocument1 pageMetric To Imperial Conversionmartin_jaitmanNo ratings yet

- A2 PDFDocument3 pagesA2 PDFLelli KurniaNo ratings yet

- MPMVP Winmpm Manual v1.12Document201 pagesMPMVP Winmpm Manual v1.12martin_jaitmanNo ratings yet

- EDGE X-5 JET EDGE Waterjet Parts Drawings Asset 10987Document1 pageEDGE X-5 JET EDGE Waterjet Parts Drawings Asset 10987martin_jaitmanNo ratings yet

- Liftmaster SL570 S3 Owners ManualDocument34 pagesLiftmaster SL570 S3 Owners Manualmartin_jaitmanNo ratings yet

- F Series Handpunch Modem: Installation InstructionsDocument8 pagesF Series Handpunch Modem: Installation Instructionsmartin_jaitmanNo ratings yet

- FSM 480 Surface Grinder 19x9Document3 pagesFSM 480 Surface Grinder 19x9martin_jaitmanNo ratings yet

- Shell Spirax s1 Atf TasaDocument2 pagesShell Spirax s1 Atf Tasamartin_jaitmanNo ratings yet

- Powerful Demag CC 1500 CraneDocument42 pagesPowerful Demag CC 1500 Cranemartin_jaitmanNo ratings yet

- CNC Precision Lathes V-Turn 410 With 3-Axis Position IndicatorDocument5 pagesCNC Precision Lathes V-Turn 410 With 3-Axis Position Indicatormartin_jaitmanNo ratings yet

- Medallist Series Water Conditioner Owners GuideDocument58 pagesMedallist Series Water Conditioner Owners Guidemartin_jaitmanNo ratings yet

- Overhead CraneDocument2 pagesOverhead Cranemartin_jaitmanNo ratings yet

- Guidelines For The Welded Fabrication of Nickel-Containing Stainless Steels For Corrosion Resistant ServicesDocument0 pagesGuidelines For The Welded Fabrication of Nickel-Containing Stainless Steels For Corrosion Resistant ServicesSai FujiwaraNo ratings yet

- Io-347j 9.2013Document24 pagesIo-347j 9.2013martin_jaitmanNo ratings yet

- LC RO BrochureDocument2 pagesLC RO Brochuremartin_jaitmanNo ratings yet

- Knuth Lathe Sinus D 400 - 3000Document5 pagesKnuth Lathe Sinus D 400 - 3000martin_jaitmanNo ratings yet

- Rigid Universal Milling Machine for Drilling and MillingDocument5 pagesRigid Universal Milling Machine for Drilling and Millingmartin_jaitmanNo ratings yet