Professional Documents

Culture Documents

Application Note

Uploaded by

tuandt2_1415Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application Note

Uploaded by

tuandt2_1415Copyright:

Available Formats

Application Note AN2134

PSoC Programmer

By: Alessandro Molini

Associated Project: Yes

Associated Part Family: CY8C26xxx

PSoC Designer Version: 4.2

Associated Application Notes: AN2014, AN2026

Abstract

This Application Note describes a simple programmer for the PSoCTM device.

Introduction Operational Theory

With this Application Note, I want to help the The program flow follows the specifics outlined in

beginner and the professional programmer in the Application Note AN2026 “In-System Serial

PSoC world with a simple, economic tool for Programming (ISSP) Protocol” and is shown in

Flash programming. This tool allows one PSoC- Figure 1. For a better understanding of the

based device to serve as a programmer for other procedures used here, the reader is encouraged

PSoC-based devices. The ICE-4000 In-circuit to review the material contained in AN2026.

Emulator is still necessary for debugging and

programming the first device. However, small- START

scale, simultaneous production programming,

and software development is possible.

Initialize Target Procedure

The heart of the project is a PSoC CY8C26443.

The necessary hardware has been reduced to a Verify Silicon ID Procedure

minimum. The device sends clock, data in/out

and Xres to the programming chip. Programming Program Procedure

is established through the PSoC serial COM port

connected to a MAX232. The download baud

rate is fixed at 19200, N, 8, 1. The hardware is Verify Procedure

complete with a 5V stabilized power supply. The

main peripherals are inside the PSoC. Secure Procedure

External Hardware Verify Checksum

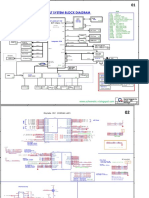

Figure 5 shows the CY8C26443 external Procedure

connections. The programmer chip will be

clocked at 24 MHz. Precautions should be taken END

for the rigorous 5V power-supply connections

with the programming chips, typically pre- Figure 1. Programming Flow

assembled on the production board. As the

EXECUTE MODE is planned for a clock at 2 The programmer uses the reset signal, Xres, to

MHz, it is wise to keep the programming wires as begin the start procedure. Hardware and

short as possible and insert serial resistances as software changes allow modification of this

specified in Application Note AN2014 “Design for application with the Power-On-Reset

programming (the essential cycle for the smaller

In-System Serial Programming (ISSP).” Two

devices, CY8C25xxx).

LEDs, green and red, will signal the programming

status as “in progress” or “in error.”

7/19/2004 Revision A -1-

AN2134

Other essential characteristics are the accuracy

and the stability of the frequency in EXECUTE

MODE. In all other phases, the frequency and SPI DATA

stability for the programming clock is not SCL

essential.

Clock Out

Internal Hardware P0[4]

The PSoC internal hardware is shown in Figure

2. The peripherals are a serial-synchronous

Master SPI to communicate commands and data

to the programming chip, as well as an CLOCK Execute

2 MHz Out

asynchronous serial receiver to receive the Intel

hexadecimal program from a PC. A timer/counter

produce a stable 2 MHz clock signal during the

EXECUTE MODE. Figure 3. P0[4] Function Switch

Vectors

The start of each procedure is the transmission of

vectors represented by specific data, organized

in groups of 22 bits. See Figure 4.

Figure 2. User Module Placement

Software

The software is separated into two sections: the

main program written in C and the interrupt

routine for asynchronous serial communication

written in assembly.

The main C program covers the initialization and

manages iterations with the programming chip.

The assembler interrupt section, rx8_1int.asm,

manages the ASCII record sent from the PC,

converts the record to binary, checks the

checksum and signals the correct reception to

Figure 4. Initialize 1 Vectors

the main C routine.

EXECUTE Procedure The transmission through the SPI, rigorously at 8

The most critical phase in the system is bits, is only possible by adding two 0 bits at the

EXECUTE MODE in which the programmer must beginning of each line. The resultant 24 bits will

send an accurate and stable frequency of at least be transmitted from the SPI in 3 transmissions.

2 MHz to the device in order for the chip to be

programmed.

Table1. Transmitted Bytes for Figure 4, Line 1.

To activate the command previously sent by the

Byte 1 Byte 2 Byte 3

SPI, the software switches pin P0[4] function

from SCLK, connected to the SPI, to CLOCK, 00110010 10000000 00000000

connected to the ExecuteClock Counter (cntr8).

This is shown in Figure 3. The software then

waits for the answer with a low signal from the

target chip, which is the signal from the target

that the previously sent command has been

completed.

7/19/2004 Revision A -2-

AN2134

Control Software The programming result is displayed by the

Operation does not require any particular LEDs. When programming is successful, the

download procedures. Any serial communication green LED lights. If programming is not

program can handle the download procedures successful, the red LED lights.

without problems. The required baud rate should

be at 19200, N, 8, 1. The start condition is A small Visual Basic application developed to

realized through the dispatch of any ASCII operate the programmer has been attached. The

character through the serial port. After this, a software does not have any controls. When the

delay of about 50 mS is needed for the Program button is clicked, a File Open dialog box

programmer to initialize the target. Then the Hex appears. Select the .hex file to be programmed

file can be transmitted. and click OK. The chip will be programmed and a

message box will appear saying, "The Device

has been Programmed." This message will

appear even if the programming failed. This is

because there is no feedback to the PC from the

programmer about the result of the operation.

Figure 5. External Connections

7/19/2004 Revision A -3-

AN2134

About the Author

Name: Alessandro Molini

Background: HW-SW industrial automation

designs, motion control, PLC,

and motor control.

Contact: alex.mol@tiscali.it

Cypress MicroSystems, Inc.

nd

2700 162 Street SW, Building D

Lynnwood, WA 98037

Phone: 800.669.0557

Fax: 425.787.4641

http://www.cypress.com/ / http://www.cypress.com/support/mysupport.cfm

Copyright 2003-2004 Cypress MicroSystems, Inc. All rights reserved.

PSoC™, Programmable System-on-Chip™, and PSoC Designer™ are trademarks of Cypress MicroSystems, Inc.

All other trademarks or registered trademarks referenced herein are the property of their respective owners. The

information contained herein is subject to change without notice. Made in the U.S.A.

7/19/2004 Revision A -4-

You might also like

- Vehicle Stability Control System DiagnosisDocument4 pagesVehicle Stability Control System DiagnosisAmil AnAmNo ratings yet

- Immobilizer and Smart Key Reset: T-SB-0057-18 July 6, 2018Document15 pagesImmobilizer and Smart Key Reset: T-SB-0057-18 July 6, 2018Konstantin BuNo ratings yet

- HP Pavilion TX1000 SchematicsDocument36 pagesHP Pavilion TX1000 Schematicsmeng798651100% (1)

- LT-856 RAX-LCD Installation and Wiring ManualDocument24 pagesLT-856 RAX-LCD Installation and Wiring ManualIatan AlexandruNo ratings yet

- CDS61236 Ethernet Superseal Connector Cable 1.8M (Rev A and Rev B)Document2 pagesCDS61236 Ethernet Superseal Connector Cable 1.8M (Rev A and Rev B)JAVIER ROMERONo ratings yet

- Grande PuntoDocument4 pagesGrande Puntocuick100% (1)

- Interfacing Nokia ScreenDocument4 pagesInterfacing Nokia ScreenDavid Sanderson100% (2)

- LCD MicrochipDocument40 pagesLCD Microchipgorea_grigNo ratings yet

- ACDC Pages 177-192 (Low Res) PDFDocument16 pagesACDC Pages 177-192 (Low Res) PDFmachevallieNo ratings yet

- SCHEMATICS (ACDC200P) Tig - 200p - Ac-Dc - SCH PDFDocument1 pageSCHEMATICS (ACDC200P) Tig - 200p - Ac-Dc - SCH PDFPOULIQUEN100% (1)

- PIC With LCD and ICSP Programmer Board - v3 - JRMDocument7 pagesPIC With LCD and ICSP Programmer Board - v3 - JRMm_menaka100% (2)

- EMU BLACK ECU pin functions referenceDocument4 pagesEMU BLACK ECU pin functions referenceadrianNo ratings yet

- RS232 Communication Using PIC18F4520 S USART PIC Micro Controller Tutorial Extreme ElectronicsDocument24 pagesRS232 Communication Using PIC18F4520 S USART PIC Micro Controller Tutorial Extreme ElectronicsHectorLopez100% (1)

- Aspire+5542+ +5542g.schematicDocument61 pagesAspire+5542+ +5542g.schematicAndres LañaNo ratings yet

- D400 System Block Diagram: Sis M650Document35 pagesD400 System Block Diagram: Sis M650Ashok JangraNo ratings yet

- Grand Am Continental Tire Sports Integrating ECU PDFDocument31 pagesGrand Am Continental Tire Sports Integrating ECU PDFsenthilvlNo ratings yet

- The City Stuns with Style and InnovationDocument20 pagesThe City Stuns with Style and InnovationAlimi JasmanNo ratings yet

- Compal LA-8861PDocument1 pageCompal LA-8861PSchema666No ratings yet

- Read Me For Install Wow5.00.8R2Document1 pageRead Me For Install Wow5.00.8R2Faiza Al HarthyNo ratings yet

- Acer Aspire 3 A315-22 NB8607 Rev1.0Document55 pagesAcer Aspire 3 A315-22 NB8607 Rev1.0Carlos Yuvini Hernandez100% (1)

- GT-E1200 Training Manual HWDocument45 pagesGT-E1200 Training Manual HWjhonathan28No ratings yet

- Marantz 4300 Owners ManualDocument22 pagesMarantz 4300 Owners Manualcool dudeNo ratings yet

- Lsi-Plus 3.5.1Document75 pagesLsi-Plus 3.5.1Adrian AmzarNo ratings yet

- Acer+E5 574+Quanta+ZRWDocument48 pagesAcer+E5 574+Quanta+ZRWnelsonNo ratings yet

- Hitech HMIDocument8 pagesHitech HMICearEo AraGon100% (1)

- Schematic Diagram Blackberry Gemini 8520 byDocument22 pagesSchematic Diagram Blackberry Gemini 8520 bylachiondo0% (1)

- PDFDocument17 pagesPDFGermautos VolkswagenNo ratings yet

- U0401 - TSB 07 - 2 - 2Document2 pagesU0401 - TSB 07 - 2 - 2Oscar SerranoNo ratings yet

- Range Rover - 1997 - 6th EditionDocument579 pagesRange Rover - 1997 - 6th Editionainginer50% (2)

- RDM6300Document4 pagesRDM6300Raheel IttefaqNo ratings yet

- RF - ZE520KL Trouble Shooting Guide - 0714Document31 pagesRF - ZE520KL Trouble Shooting Guide - 0714Luiz BeltrameNo ratings yet

- STC 12Document439 pagesSTC 12Marcano Figueroa bethania LeonorNo ratings yet

- 4 AfeDocument36 pages4 AfeJuan ContrerasNo ratings yet

- GT-S5230 Service Schematics Rev0.6Document5 pagesGT-S5230 Service Schematics Rev0.6Alberto MarsicoNo ratings yet

- London Zafira A wiring diagramDocument3 pagesLondon Zafira A wiring diagramG G100% (1)

- Topswitch - GX: Flyback Quick Selection CurvesDocument12 pagesTopswitch - GX: Flyback Quick Selection Curvessteviej85No ratings yet

- MT6572 HSPA Smartphone Application Processor 1.0Document64 pagesMT6572 HSPA Smartphone Application Processor 1.0MechDRNo ratings yet

- Radius Gm300Document8 pagesRadius Gm300Demian Malfor KlentorNo ratings yet

- OMNIBUS F4 V3 Documentation SpecificationDocument6 pagesOMNIBUS F4 V3 Documentation SpecificationbenitoNo ratings yet

- VEHICLE STABILITY CONTROL BRAKE DIAGNOSTICSDocument5 pagesVEHICLE STABILITY CONTROL BRAKE DIAGNOSTICSJohn Mark CorralesNo ratings yet

- Block Diagram PDFDocument3 pagesBlock Diagram PDFKo Sai Mownlain100% (1)

- Pectel C2 ECU: ECU Offload Tool SoftwareDocument7 pagesPectel C2 ECU: ECU Offload Tool SoftwareJorge Arilio Gonzalez ArangoNo ratings yet

- MyCANIC User ManualDocument19 pagesMyCANIC User ManualSaddam Basim100% (2)

- Coban TK303 Auto Gps Tracker - User ManualDocument25 pagesCoban TK303 Auto Gps Tracker - User ManualAlberto CastañedaNo ratings yet

- How To Reset An Acer BIOS Password PDFDocument5 pagesHow To Reset An Acer BIOS Password PDFrahul2222222No ratings yet

- ZXNVM S (N) 9200 (H) Series Network Video Recorder User Manual20141230Document197 pagesZXNVM S (N) 9200 (H) Series Network Video Recorder User Manual20141230shujath_ali_1No ratings yet

- Philips Az787-61 Ver 1 0Document26 pagesPhilips Az787-61 Ver 1 0Roman servisNo ratings yet

- 321 Aim Pectel T6 100 EngDocument5 pages321 Aim Pectel T6 100 EngmisdeismoNo ratings yet

- Block Diagram: LGA 775-Pin SocketDocument20 pagesBlock Diagram: LGA 775-Pin SocketRajesh DhanambalNo ratings yet

- Reprogramming and Blank Programming Readme Version 3.7: Revision Date ModificationDocument6 pagesReprogramming and Blank Programming Readme Version 3.7: Revision Date ModificationJose FernandezNo ratings yet

- EN Module (54) Bosch ME1788 - OBD2Document5 pagesEN Module (54) Bosch ME1788 - OBD2Juan Carlos MartinezNo ratings yet

- Samsung DVD Vr350 Vr355 Vr357 Chassis Nexus 4th Gen EtDocument256 pagesSamsung DVD Vr350 Vr355 Vr357 Chassis Nexus 4th Gen Etdanielradu27No ratings yet

- DC Motor Speed Control BC201Document24 pagesDC Motor Speed Control BC201ROSEMARIO PORFIRIONo ratings yet

- Subject: Information of New Auto Transmission & Tcu Models: Musso & Korando With Btra Auto Transmission ConditionDocument1 pageSubject: Information of New Auto Transmission & Tcu Models: Musso & Korando With Btra Auto Transmission Conditionfrancisca19No ratings yet

- Tk103ab User ManualDocument21 pagesTk103ab User ManualpinyotNo ratings yet

- Linha HP COMPAQ PRO 6300 SMALL FORM FACTOR-14269 - Div PDFDocument65 pagesLinha HP COMPAQ PRO 6300 SMALL FORM FACTOR-14269 - Div PDFredepiresNo ratings yet

- Pic ManualDocument30 pagesPic Manualgg.ganapathy100% (2)

- Micro HopeDocument48 pagesMicro Hopeviolator100% (1)

- PIC LAB ManualDocument13 pagesPIC LAB ManualxyzzyzNo ratings yet

- Arquitectura de PSoC - EasypsocDocument41 pagesArquitectura de PSoC - EasypsocRednaxela SaenzNo ratings yet

- PLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.From EverandPLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.No ratings yet

- Peavey PR15D Service ManualDocument12 pagesPeavey PR15D Service ManualMartín SayagoNo ratings yet

- LG 55UN7300PUC UAX3E Schematic Diagram and Service ManualDocument72 pagesLG 55UN7300PUC UAX3E Schematic Diagram and Service Manualaze1959100% (1)

- Description: KV Package (Top View)Document13 pagesDescription: KV Package (Top View)Martín SayagoNo ratings yet

- HUAWEI JAT-LX3 Telcel-Mx Software Upgrade Guideline - R1Document8 pagesHUAWEI JAT-LX3 Telcel-Mx Software Upgrade Guideline - R1jorge1952No ratings yet

- Printer Setting Tools Instructions - V3.2Document3 pagesPrinter Setting Tools Instructions - V3.2André PontiniNo ratings yet

- Operating Manual For IOS OSDocument2 pagesOperating Manual For IOS OSjeffprox69No ratings yet

- Graphic Presentations of The Adding Driver MethodDocument8 pagesGraphic Presentations of The Adding Driver MethodPENUNJANG MEDIKNo ratings yet

- Graphic Presentations of The Driver's Intallation PDFDocument6 pagesGraphic Presentations of The Driver's Intallation PDFOmar BecerraNo ratings yet

- Operating Manual For Android OSDocument1 pageOperating Manual For Android OSjeffprox69No ratings yet

- Firstly, Change The Picture Format To Be (Max Size:) and Add The Logo by " Iprinter - Exe"Document3 pagesFirstly, Change The Picture Format To Be (Max Size:) and Add The Logo by " Iprinter - Exe"Martín SayagoNo ratings yet

- 76MM Program Manual V2.2 PDFDocument31 pages76MM Program Manual V2.2 PDFgopalkaushikNo ratings yet

- 80MM Printer Programmer Manual-2019 PDFDocument33 pages80MM Printer Programmer Manual-2019 PDFMaria Paola Gonzalez RivadeneiraNo ratings yet

- Jagged Cutter 9V DC Bluetooth Printer ManualDocument16 pagesJagged Cutter 9V DC Bluetooth Printer ManualMartín SayagoNo ratings yet

- AP3041 Ic Driver Placa Simply Syled37i Que Se QuemaDocument14 pagesAP3041 Ic Driver Placa Simply Syled37i Que Se QuemaAndres Alegria0% (1)

- CCE TV HPS-2071B Diagrama EsquematicoDocument1 pageCCE TV HPS-2071B Diagrama EsquematicoDaniel AvecillaNo ratings yet

- CH341DS1Document14 pagesCH341DS1tranquangluong86No ratings yet

- 58MM Thermal Reciept Printer Operating Manual-20170214 PDFDocument14 pages58MM Thermal Reciept Printer Operating Manual-20170214 PDFblackozz01No ratings yet

- Single N-Channel Trench MOSFET 30V, 66.3A, 6.0m : Features General DescriptionDocument6 pagesSingle N-Channel Trench MOSFET 30V, 66.3A, 6.0m : Features General DescriptionjosiasNo ratings yet

- Electrical Service Manual Original Manual Issue Date: 4/2010Document51 pagesElectrical Service Manual Original Manual Issue Date: 4/2010Marcyo LimaNo ratings yet

- CH341A Mini Programmer Schematic and Drivers One Transistor PDFDocument4 pagesCH341A Mini Programmer Schematic and Drivers One Transistor PDFMartín SayagoNo ratings yet

- Model No. SA-AKX12LM-K - PanasonicDocument108 pagesModel No. SA-AKX12LM-K - PanasonicSimon MariñoNo ratings yet

- 24A 500V N-Channel MOSFET Features Ultra-low RDS(on) and Fast SwitchingDocument7 pages24A 500V N-Channel MOSFET Features Ultra-low RDS(on) and Fast SwitchingNelson Naval CabingasNo ratings yet

- Infineon IKW50N60T DS v02 06 enDocument13 pagesInfineon IKW50N60T DS v02 06 enBasil MathewNo ratings yet

- Datasheet K50t60Document13 pagesDatasheet K50t60Martín SayagoNo ratings yet

- DatasheetDocument13 pagesDatasheetMundo GGNo ratings yet

- Generador 555 PDFDocument1 pageGenerador 555 PDFMartín SayagoNo ratings yet

- Msi h81m E33 DatasheetDocument1 pageMsi h81m E33 DatasheetMartín SayagoNo ratings yet

- Schematic diagram component locations and connectionsDocument8 pagesSchematic diagram component locations and connectionsMartín SayagoNo ratings yet