Professional Documents

Culture Documents

Rotary Dryer Design for Dicalcium Phosphate Production

Uploaded by

Ness SanchezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rotary Dryer Design for Dicalcium Phosphate Production

Uploaded by

Ness SanchezCopyright:

Available Formats

Production of Dicalcium Phosphate by Digestion

of Phosphate Rock with HCl

D-01

ROTARY DRYER

Objective:

To reduce the moisture content of filter cake from 25.0 % to 0.9%.

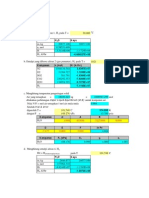

EQUIPMENT SPECIFICATION

EQUIPMENT NO. (TAG): D-01

ROTARY DRYER

DATA SHEET

DESCRIPTION (FUNCTION): To reduce the

moisture content of filter cake from 25.0 % to

0.9%

Dimensions

Material of Construction

Carbon Steel (SA 285, Grade C)

Inclination

5 degrees

Inside Diameter

Total Diameter

Length

1.31 m

1.39 m

8.02 m

Shell Thickness

8.17 mm

Insulation Thickness

32.30 mm

Technical Data

Rotational Speed

4.60 rpm

Number of Flights

Flight Depth

Motive Power Requirement

13

0.16 m

3.23 kW

Blower Power Requirement

Dryer Power Requirement

3.97 kW

1.61 kW

DCP Manufacturing Co., Inc.

221

Production of Dicalcium Phosphate by Digestion

of Phosphate Rock with HCl

PROCESS CONDITIONS

Feed

Component

Mass Flow Rate

Air

CaHPO42H2O

Ca(H2PO4)2

H2O

407.41 kg/hr

5.51 kg/hr

137.64 kg/hr

6,712.60 kg/hr

Inlet Temperature

30 C

170 C

Outlet

105 C

105 C

Temperature

DESCRIPTION OF DRYER CLASSIFICATION CRITERIA

1. Form of Feed: Wet Filter Cake

2. Mode of Operation: Continuous operation

3. Heating System: Steam-heated air

4. Gas Flow Pattern in Dryer: Cocurrent gas flow

CALCULATION OF HEAT DUTY

Using Ambient Temperature of 30 C and RH = 93% (Weather Past 2 Weeks in Manila, Philippines,

2015)

From Psychometric chart of Perrys Handbook: Humidity = 0.0252 kg of water per kg of dry air

Taking the humid heat of Air:

= 1.005 + 1.88 = 1.005 + 1.88(0.0252)

= 1.0524

Calculating for the amount of air needed:

382,642.7525

=

=

= 5,593.83

1.0524 (443.15 378.15)

DCP Manufacturing Co., Inc.

222

Production of Dicalcium Phosphate by Digestion

of Phosphate Rock with HCl

To find humidity of outlet Air:

=

+ 30

=

133.8868

+ 0.0252

= 0.05

5,593.8292

To find the relative humidity of outlet Air:

P at 105 C = 120,701.0447

2 =

1

0.0491 18.02

(0.0491

1

1

) + (1

)

18.02

28.84

101,325

2 = 7,387.04

=

2

7,387.0354

100% =

100% = 6.12 %

120,701.0447

Thus the outlet air does not exceed the capacity of the air to carry vapor since RH<100%

Allotting an allowance of 20%, for the possible heat losses and due to startup, shutdown and

cleaning. (vant Land, 2012)

= (1.20)(5,593.8292)

= 6,712.60

CALCULATION OF INSIDE DIAMETER & LENGTH

The allowable mass velocity of the air ranges from 2000 kg/hr-m2 up to 25,000 kg/hr-m2 (McCabe,

Harriot, & Smith, 1993). Assuming that the mass velocity of air = 5,000 kg/hr-m2

Then, the area of dryer,

=

6,712.5950

5,000

2

= 1.34 2

DCP Manufacturing Co., Inc.

223

Production of Dicalcium Phosphate by Digestion

of Phosphate Rock with HCl

4( 1.3425 2 )

=

= 1.31

Drying diameter ranges from 1 to 3 m (McCabe, Harriot, & Smith, 1993), thus the computed drying

diameter is accepted.

The following empirical equation is used to calculate for the overall heat transfer coefficient from

Perrys Handbook with the index n = 0.67 (McCormick, 1962). The k value falls in the range 3.75

k 5.25 as suggested by AICHE for SI unit (vant Land, 2012). Assuming k = 4.75:

=

0.67

2)

=

1.3074

= 1,092.92

3

4.75(5,000

For the calculation of wet bulb temperature, the most economical operation of rotary dryer can be

achieved for Nt is in general between 1.5 and 2.5 (Mujumdar, 2014). Assuming the value of Nt = 2.

= ln (

)

2 = (

443.15

)

378.15

= 367.98

Calculating the logarithmic mean temperature difference:

() =

( ) ( )

( )

( )

(443.15 367.98) (378.15 367.98)

(443.15 367.98)

(

378.15 367.98)

= 32.5

DCP Manufacturing Co., Inc.

224

Production of Dicalcium Phosphate by Digestion

of Phosphate Rock with HCl

To calculate the length of the drier:

= ()

=

=

()

382,642.7525

1,092.9196

(1.3425 2 )(32.5 )

3

= 8.02

Checking L/D ratio:

8.0242

=

= 6.14

1.3074

L/D ratio is most efficient between 4 and 10 for industrial dryers (Mujumdar, 2014), therefore the

above diameter and length can be accepted.

CALCULATION OF RPM, FLIGHT DESIGN & RESIDENCE TIME

Speed values ranges 0.1 to 0.5 m/s (vant Land, 2012). Assuming the peripheral speed of rotation to

be 0.1 m/s.

To calculate the speed of rotation of the drier:

60

0.1 1

=

= 4.59

1.3074

=

The revolution of a drier varies between 2-5 rpm. Therefore, the above value can be accepted.

Flight Design:

. = 3, (D in feet)

. = 3 (1.3074

1

) = 12.87 13

0.3048

DCP Manufacturing Co., Inc.

225

Production of Dicalcium Phosphate by Digestion

of Phosphate Rock with HCl

Flight Depth:

=

1.3074

=

8

8

= 0.16

Using the following empirical equation for the residence time (in minutes) in dryer as recommended

by AICHE (vant Land, 2012):

= 5 0.5 = 5(210)0.5 = 0.3450

=

0.23 2

0.23(8.0242)

2(0.3450)((8.0242)(5,000)

+

=

+

0.9

0.9

416.67

(5)(4.5892) (1.3074)

(1.3425 )

= 89.28

Residence time of rotary dryer typically ranges at 5-90 minutes (Couper, Penney, Fair, & Walas,

2005), therefore the computed value is acceptable.

CALCULATION OF SHELL DRYER THICKNESS & OUTER DIAMETER

Considering the material to be used is Carbon Steel (SA 285, Grade C) because it can withstand up

to 343.33 C. For operating pressure of 0 psig (14.7 psia), the design pressure is 10 psig (24.7 psia)

or 170,253.5714 Pa (Hesse & Rushton, 1975)

Using the following formula for working stress:

=

where: Su: minimum specified tensile strength, 380 MPa (ASME SA285 Grade C, n.d.)

Fm : material factor, 0.92 for Grade C material

Fa: radiographing factor, 1.00 since radiographing is not employed

Fr: stress relieving factor, 1.00 since relieving is not employed

Fs : factor of safety, 0.25 for temperature less than 315.56 C

= 380 0.92 1.00 1.00 0.25

= 87.4

DCP Manufacturing Co., Inc.

226

Production of Dicalcium Phosphate by Digestion

of Phosphate Rock with HCl

Using the following equation to calculate shell thickness with a corrosion allowance of 6.35 mm

(Hesse & Rushton, 1975) and efficiency of the joint 0.70 for double-welded butt joint since

radiographing is not employed (Sinnot, 2005):

=

+

2

1000

2 1.3074

1

=

+ 6.35

(2 87,400,000 2 0.70) 170,253.5714 2

170,253.5714

= 8.17

The minimum shell thickness of equipment vessel with 1.0668 - 1.524-m diameter is 8.128 mm

(Couper, Penney, Fair, & Walas, 2005), therefore above value can be accepted.

To calculate the outer diameter of the dryer:

= + 2 = 1.3074 + 2(8.1717

1

)

1000

= 1.32

CALCULATION OF THE INSULATION THICKNESS

To limit heat loss an insulation is to be given to the dryer. The chosen insulating material is brick.

From literature, its thermal conductivity equals to 0.72 W/mK. Mild steel however has a thermal

conductivity of 51.9220 W/mK.

=

2(2 1 )

ln( 2 ) ln( 3 )

1

2

+

106,289.6535 =

2(8.0242 )(443.15 303.15 )

0.6619

0.6619 +

ln(0.6537)

ln( 0.6619 )

+

51.9220

0.72

= 0.0323 = 32.30

DCP Manufacturing Co., Inc.

227

Production of Dicalcium Phosphate by Digestion

of Phosphate Rock with HCl

To calculate the total diameter of the dryer:

= + 2 = 1.3238 = 1.3238 + 2(32.2966

1

)

1000

= 1.39

CALCULATION OF THE LIVE LOAD & ROTATING LOAD

To calculate the volume of shell material:

(2 2 ) (1.32382 1.30742 )2 8.0242

=

=

4

4

= 0.27 3

To calculate the volume of insulating material:

=

(2 2 ) (1.38842 1.32382 )2 8.0242

=

4

4

= 1.10 3

To calculate the weight of unloaded dryer using the density of mild steel 7850 kg/m 3:

= 0.2710 3 7,850

= 2,127.43

To calculate the weight of insulating material using the density of brick 2165 kg/m3:

= 1.1040 3 2,165

= 2,390.26

To calculate the weight of the material in the dryer:

= (550.5535

1

) 89.2775

60

= 819.20 = 1,806

To calculate the total weight of the loaded dryer:

= 2,127.4269 + 819.2001 + 2,390.2589

= 5,336.89 = 11,765.62

DCP Manufacturing Co., Inc.

228

Production of Dicalcium Phosphate by Digestion

of Phosphate Rock with HCl

CALCULATION OF BLOWER POWER, MOTIVE POWER & POWER TO DRIVE A DRIER

Using the equation in (vant Land, 2012) for the calculation of motor power for rotation for rotary

dryers:

=

0.3 2 0.3

=

(1.3074)2 (8.0242)

4

4

= 3.23

To calculate the power requirement for blower:

(6,712.5950

1

3

)(

)(8,314

)(378.15 )

28.5740

101,325

3

= 7,289.15

= 2.72 105 = 2.72 105 (7,289.1505 )(20)

= 3.97

Using the following equation proposed by CE Raymond Division, Combustion Engineering Inc., to

calculate the power to drive a dryer with flights (Mujumdar, 2014):

=

(4.75 + 0.1925 + 0.33 )

100,000

where: N: expressed in rpm

Wmaterial, Wtotal: expressed in lbs

D: D + 2

Di: expressed in feet

4.75((4.75 4.29 1,806) + (0.1925 6.29 11,765.62) + (0.33 11,765.62))

100,000

= 2.52

0.75

1

= 1.89

DCP Manufacturing Co., Inc.

229

Production of Dicalcium Phosphate by Digestion

of Phosphate Rock with HCl

REFERENCES

ASME SA285 Grade C. (n.d.). Retrieved from Join-Win Steel Website: http://www.steel-jw.com

Capitaine, S. L., & Carlson, C. (n.d.). Rotary Kiln Refractory: The Working Layer vs. The Insulating

Layer. FEECO International.

Capitaine, S. L., & Carlson, C. (n.d.). Rotary Kiln Refractory: The Working Layer vs. The Insulating

Layer. Retrieved from FEECO International:

file:///C:/Users/NeilPatrick/Downloads/feeco.com-Rotary-Kiln-Refractory-The-WorkingLayer-vs-The-Insulating-Layer%20(1).pdf

Couper, J. R., Penney, W. R., Fair, J. R., & Walas, S. M. (2005). Chemical Process Equipment:

Selection and Design, Second Edition. Oxford: Elsevier Inc.

Geankoplis, C. J. (1995). Transport Processes and Unit Operations, 3rd Ed. Singapore: Prentice

Hall.

Hesse, H. C., & Rushton, J. H. (1975). Process Equipment Design. New York: D. Van Nostrand Co.

McCabe, W. L., Harriot, P., & Smith, J. C. (1993). Unit Operations of Chemical Engineering, 5th

Edition. Singapore: McGraw-Hill, Inc.

Mujumdar, A. S. (2014). Handbook of Industrial Drying, Fourth Edition. Florida: CRC Press.

Perry, R. H., & Green, D. W. (2008). Perry's Chemical Engineering Handbook, Eight Edition. New

York: McGraw-Hill.

Peters, M. S., & Timmerhaus, K. D. (1991). Plant Design and Economic for Chemical Engineers,

Fourth Edition. New York: McGraw-Hill.

Rotary Dryers, Cooler and Calciners. (n.d.). Retrieved from www.gea.com

Sinnot, R. K. (2005). Coulson and Richardson's Chemical Engineering Vol. 6, 4th Edition. Oxford:

Butterworth-Heinemann.

vant Land, C. (2012). Drying in the Process Industry. New Jersey: John Wiley & Sons, Inc.

Weather Past 2 Weeks in Manila, Philippines. (2015, August 26). Retrieved from Time and Date:

http://www.timeanddate.com/weather/philippines/manila/historic

DCP Manufacturing Co., Inc.

230

You might also like

- Rotary Drier DesignDocument29 pagesRotary Drier DesignDharamvir Singh80% (5)

- Chemical Engineering Design of The Spray DryerDocument6 pagesChemical Engineering Design of The Spray Dryervictor100% (1)

- Rotary Dryer Design for Pellets DryingDocument9 pagesRotary Dryer Design for Pellets DryingGohar AbbasNo ratings yet

- Rotary Dryer DesignDocument17 pagesRotary Dryer DesignArdian20No ratings yet

- Rotary DryerDocument11 pagesRotary DryerRiska Ristiyanti100% (1)

- Schematic Diagram of Flash Dryer ProcessDocument20 pagesSchematic Diagram of Flash Dryer ProcessKai Faheem100% (1)

- Rotary Drying: Heat and Mass Transfer DesignDocument22 pagesRotary Drying: Heat and Mass Transfer DesignRiza Dikromo100% (4)

- Rotary Thermal Dryer Design Book - FeecoDocument9 pagesRotary Thermal Dryer Design Book - Feecorajeevup2004No ratings yet

- Dryer DesignDocument39 pagesDryer DesignPrashanth Chidambaram75% (4)

- Design of Rotary DryerDocument2 pagesDesign of Rotary Dryernizar ahmad57% (7)

- Rotary DryerDocument8 pagesRotary DryerElmika TrầnNo ratings yet

- Heat Balance of Rotary DryerDocument2 pagesHeat Balance of Rotary Dryernizar ahmadNo ratings yet

- Rotary Drum DryersDocument12 pagesRotary Drum Dryersjanardhangajula100% (3)

- Rotary Dryer SizingDocument3 pagesRotary Dryer Sizingadil shidiq100% (1)

- Drying - 5 - 29 Oct 2020 PDFDocument25 pagesDrying - 5 - 29 Oct 2020 PDFshubhamNo ratings yet

- Rotary Dryer BrochureDocument1 pageRotary Dryer Brochurejanob7No ratings yet

- Rotary Dryer HandbookDocument34 pagesRotary Dryer HandbookMauricio Guanella100% (3)

- Dynamic Design of An Industrial Rotary DryerDocument10 pagesDynamic Design of An Industrial Rotary DryerAmp AunyamoneNo ratings yet

- 09 Dryer DesignDocument25 pages09 Dryer DesignFredrick MutungaNo ratings yet

- Energy calculation and analysis tool for industrial dryersDocument9 pagesEnergy calculation and analysis tool for industrial dryersAvijit Shaw100% (2)

- Dryer-Design ParametersDocument32 pagesDryer-Design ParametersGlenPalmer100% (1)

- Rotary Dryer Design & Working PrincipleDocument12 pagesRotary Dryer Design & Working PrincipleRafeek ShaikhNo ratings yet

- Raw grinding mill capacity calculationDocument6 pagesRaw grinding mill capacity calculationBùi Hắc HảiNo ratings yet

- Lifter DesignDocument6 pagesLifter DesignMarcelo GuarachiNo ratings yet

- Drum Dryer DesigningDocument31 pagesDrum Dryer Designingkalyan555No ratings yet

- Rotary Dryer Handbook PDFDocument43 pagesRotary Dryer Handbook PDFAhmad NilNo ratings yet

- Rotary Dryer CalculationDocument5 pagesRotary Dryer Calculationsushant_jhawer100% (2)

- Cyclone DesignDocument11 pagesCyclone DesignAnonymous NxpnI6jCNo ratings yet

- Design of Spray Dryer Used in Milk Industries - Process Equipment and DesignDocument27 pagesDesign of Spray Dryer Used in Milk Industries - Process Equipment and DesignKhalil KallangodanNo ratings yet

- Bag Filter Design CalculationsDocument2 pagesBag Filter Design CalculationsSnehendu Biswas69% (13)

- Rotary Dryer Handbook PDFDocument34 pagesRotary Dryer Handbook PDFNichol Salas ManioNo ratings yet

- Mechanism of Rotary DryerDocument2 pagesMechanism of Rotary DryermanzahuhuNo ratings yet

- Engineering Analysis of Rotary DryerDocument233 pagesEngineering Analysis of Rotary DryerAmp AunyamoneNo ratings yet

- Bag Filter Calculation1234567 IPDocument24 pagesBag Filter Calculation1234567 IPsujith kumarNo ratings yet

- 7 Rotary DryingDocument23 pages7 Rotary DryingAbiud Hernández Álvarez100% (1)

- Design and Simulation of a Multiple Effect Evaporator System for Black Liquor ConcentrationDocument68 pagesDesign and Simulation of a Multiple Effect Evaporator System for Black Liquor ConcentrationAhmed AliNo ratings yet

- Airstream Dryer PDFDocument12 pagesAirstream Dryer PDFAsikinNo ratings yet

- Design of DryersDocument39 pagesDesign of DryersAnara Alam100% (1)

- Advanced Control Rotary DryerDocument114 pagesAdvanced Control Rotary Dryerbizarrop100% (1)

- Sizing Dryer, Conveyor, ReactorDocument20 pagesSizing Dryer, Conveyor, ReactorirviNo ratings yet

- Bag Filter CalculationDocument2 pagesBag Filter Calculationjenifferrayen71% (7)

- How To Design and Size A BaghouseDocument25 pagesHow To Design and Size A BaghouseWalter MustafaNo ratings yet

- Fluidized Bed Dryer, Mass TransferDocument12 pagesFluidized Bed Dryer, Mass TransferSaswiny RitchieNo ratings yet

- Proposed Design of a 30-Ton Ice PlantDocument8 pagesProposed Design of a 30-Ton Ice Planteafz111No ratings yet

- A Proposed Design of Ice PlantDocument8 pagesA Proposed Design of Ice PlantNirob MahmudNo ratings yet

- Bufe Aaron A. Boiler FurnaceDocument6 pagesBufe Aaron A. Boiler FurnaceArabia, Elmo C.No ratings yet

- Cold Storage DesignDocument30 pagesCold Storage DesignMarjohn Lucidos100% (1)

- Plant Design of Cryogenic Distillation of Air To Oxygen and NitrogenDocument34 pagesPlant Design of Cryogenic Distillation of Air To Oxygen and Nitrogenkumar100% (1)

- Compression Test Pile (Debond 12m)Document3 pagesCompression Test Pile (Debond 12m)Anonymous S7Cq7ZDgPNo ratings yet

- Heat Exchanger Design for Cooling Kerosene Using Light Crude OilDocument15 pagesHeat Exchanger Design for Cooling Kerosene Using Light Crude OilCharito Sollera AlbaricoNo ratings yet

- Analisa Peralatan Mekanis GMS PasuruanDocument13 pagesAnalisa Peralatan Mekanis GMS PasuruanBang RegarNo ratings yet

- Assignment 2 Fluid Particles and ProcessesDocument29 pagesAssignment 2 Fluid Particles and ProcessesSenanLg100% (3)

- He SelectionDocument7 pagesHe SelectionKaizerNo ratings yet

- TANK Module Package: Sample PrintoutDocument20 pagesTANK Module Package: Sample PrintoutSIVANo ratings yet

- Cooling Tower Report FinalDocument7 pagesCooling Tower Report FinalNhlaka ZuluNo ratings yet

- Distillation Column DesignDocument27 pagesDistillation Column DesignManisha DeenaNo ratings yet

- Refrigeration Saturday ClassDocument54 pagesRefrigeration Saturday ClassJonas Dela PeñaNo ratings yet

- Air Conditioning Calculation - R0Document28 pagesAir Conditioning Calculation - R0harikrishnanpd3327No ratings yet

- Model Based Optimization of Drilling Fluid Density and ViscosityDocument34 pagesModel Based Optimization of Drilling Fluid Density and ViscositySai KumarNo ratings yet

- Passport Applicationform 2015Document2 pagesPassport Applicationform 2015genesisrdomingoNo ratings yet

- GranulatorDocument2 pagesGranulatorNess SanchezNo ratings yet

- AutoCAD Shortcuts 11x8.5 MECH-REV PDFDocument11 pagesAutoCAD Shortcuts 11x8.5 MECH-REV PDFKristijan BorasNo ratings yet

- Differential Equations HandoutsDocument4 pagesDifferential Equations HandoutsEllimacOdnumrebNo ratings yet

- Plant Location Selection FactorsDocument52 pagesPlant Location Selection FactorsNess SanchezNo ratings yet

- Absensi Utility Week 51 (Rev.1) & Absensi Utility Week 52 (Rev.1)Document3 pagesAbsensi Utility Week 51 (Rev.1) & Absensi Utility Week 52 (Rev.1)muhamad syaifuddinNo ratings yet

- Intensive and Extensive PropertiesDocument7 pagesIntensive and Extensive PropertieswaveletNo ratings yet

- Dowcal 10 Tech Data Sheet PDFDocument2 pagesDowcal 10 Tech Data Sheet PDFReply choiceNo ratings yet

- NeetDocument2 pagesNeetUmesh ShivappaNo ratings yet

- Effectiveness of Roof Insulation in Tropical Climates - Csa - 20101128Document12 pagesEffectiveness of Roof Insulation in Tropical Climates - Csa - 20101128cming_11100% (1)

- PriceListHirePurchase NormalDocument54 pagesPriceListHirePurchase NormalAfzaal AwanNo ratings yet

- CHE486 Lab 6 Property Measurement To Send WsDocument23 pagesCHE486 Lab 6 Property Measurement To Send WsRazali RamlanNo ratings yet

- Cryogenic Reactor Cooling Spec SheetDocument2 pagesCryogenic Reactor Cooling Spec SheetLibinNo ratings yet

- of 3-Phase-Separator PDFDocument25 pagesof 3-Phase-Separator PDFD K SNo ratings yet

- Goodman - Service Instructions RT6100004r13 May 2009Document69 pagesGoodman - Service Instructions RT6100004r13 May 20094iscribd100% (1)

- Turbinas Evaporativas de GasDocument158 pagesTurbinas Evaporativas de GasluijamurNo ratings yet

- Env MonitoringDocument4 pagesEnv Monitoringlovet essampongNo ratings yet

- Thermochemistry 2019Document85 pagesThermochemistry 2019Zenqi PWNo ratings yet

- Hussein Farhat - Lab 6Document7 pagesHussein Farhat - Lab 6husseinfarhatmNo ratings yet

- Carrier 48 TM PagesDocument11 pagesCarrier 48 TM PagesLuis MorenoNo ratings yet

- Uniformity and VariabilityDocument4 pagesUniformity and VariabilityMarija MarticNo ratings yet

- Chemical Engineering Review QuestionsDocument19 pagesChemical Engineering Review QuestionsMarcela Godoy100% (16)

- Surface Observation FormDocument4 pagesSurface Observation Formhadprince2023No ratings yet

- Heat Dissipation in Sealed Electrical Enclosures: Sealed Enclosure Temperature RiseDocument6 pagesHeat Dissipation in Sealed Electrical Enclosures: Sealed Enclosure Temperature RiseĐào Mạnh LượngNo ratings yet

- Applications of Thermodynamics To Flow Processes: Che 406 Chemical Engineering ThermodynamicsDocument24 pagesApplications of Thermodynamics To Flow Processes: Che 406 Chemical Engineering ThermodynamicsJAN JERICHO MENTOYNo ratings yet

- Liquid in Glass Thermometer PrincipleDocument6 pagesLiquid in Glass Thermometer PrincipleInstrumentation ToolsNo ratings yet

- Distillation Technology and Modelling Techniques: Part 1: Concepts in DistillationDocument4 pagesDistillation Technology and Modelling Techniques: Part 1: Concepts in DistillationcsandrasNo ratings yet

- Heat Transfer MethodsDocument4 pagesHeat Transfer MethodsKartikNo ratings yet

- Dmet13 Robles L06Document17 pagesDmet13 Robles L06John Marc E. TameraNo ratings yet

- MCQ in Power Plant Engineering Part 1 ME Board ExamDocument15 pagesMCQ in Power Plant Engineering Part 1 ME Board ExamAaron Choco De GuzmanNo ratings yet

- My Courses: Dashboard ME 157-ME Topic 5 Board ExamDocument4 pagesMy Courses: Dashboard ME 157-ME Topic 5 Board ExamLEANDRO LAHINDONo ratings yet

- What Are The Two Types of IonsDocument2 pagesWhat Are The Two Types of Ionsugna100% (2)

- Chapter 4a Unsteady State Diffusion and Convective Mass TransferDocument15 pagesChapter 4a Unsteady State Diffusion and Convective Mass Transferkiran367No ratings yet

- TIR100-2 Instruction ManualDocument20 pagesTIR100-2 Instruction ManualEmil CalilovNo ratings yet

- Liquid StateDocument16 pagesLiquid StateFozia ShaikhNo ratings yet

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Quantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationFrom EverandQuantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationRating: 1 out of 5 stars1/5 (1)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Introduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandIntroduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 2.5 out of 5 stars2.5/5 (3)

- Control of Power Electronic Converters and Systems: Volume 1From EverandControl of Power Electronic Converters and Systems: Volume 1Rating: 5 out of 5 stars5/5 (1)

- Machinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeFrom EverandMachinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeRating: 3.5 out of 5 stars3.5/5 (4)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Design of Foundations for Offshore Wind TurbinesFrom EverandDesign of Foundations for Offshore Wind TurbinesRating: 5 out of 5 stars5/5 (3)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Three Laws of Nature: A Little Book on ThermodynamicsFrom EverandThree Laws of Nature: A Little Book on ThermodynamicsRating: 4.5 out of 5 stars4.5/5 (10)