Professional Documents

Culture Documents

7 - Compression-Tanks.28123914

Uploaded by

Phanhai KakaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7 - Compression-Tanks.28123914

Uploaded by

Phanhai KakaCopyright:

Available Formats

Energy Efficient Building Design

College of Architecture

Illinois Institute Of Technology (IIT), Chicago

Volume of Pipes in System

Pressurization Tank Sizing

Color Codes

Nom InsideVolumeLengthVolume

Project Nam

User Input

Size

Diam per ftper size

per size

Project No.

Calculated

(ins)

(ins) (cu.ft.) (ft) (cu.ft.)

Reference Data

3/8

0.49

0.001

1/2

0.62

0.002

3/4

0.82

0.004

20

0.07

30

0.18

System Type Chilled Water

Date

Tank Identif. / Na

Tank Description

Cylindrical / Horizontal

Location (building Penthouse Equipt R

Volume System Equipt

Properties of Water

Equipt Dscr

Volume

Temp Sp.Vol

(replace/edit(cu.ft.)

Temp Sp.Vol

T deg FV ft3/lb % exp T deg FV ft3/lb % exp

0.00

0.00

1.05

0.006

1 1/4

1.38

0.010

1 1/2

1.61

0.014

30

0.42

0.00

2.07

0.023

20

0.47

2 1/2

2.47

0.033

30

1.00

3.07

0.051

20

1.03

Chillers - Evap 20

35

###

160

###

2.44

3 1/2

3.55

0.069

Chillers - Cond

40

###

0.12

170

###

2.81

4.03

0.088

50

###

0.12

180

###

3.19

5.05

0.139

60

###

0.25

190

###

3.56

6.07

CW Pumps

70

###

0.31

200

###

3.94

7.89

Boilers - WT

80

###

0.44

210

###

4.38

10

10.02 0.548

HW Pumps

90

###

0.62

220

###

4.81

12

11.94 0.777

Heat Exchangers

100

###

0.81

230

###

5.25

14

13.13 0.940

Cooling Coils

110

###

1.06

240

###

5.75

16

15.00 1.227

120

###

1.25

250

###

6.25

18

16.88 1.553

130

###

1.56

260

###

6.75

20

18.81 1.931

0.00

140

###

1.81

270

###

7.44

22

20.75 2.348

0.00

150

###

2.13

280

###

7.88

24

22.64 2.796

0.00

Cooling Towers

CHW Pumps

10

50

Heating Coils

Radtrs, Convtrs

Fan Coil Units

30

Terminal Equipt

Miscell Equipt

10

Equip Vol (ft 120

System Vol (ft3) =

270

Contigency Factor (

10

###

0.201

50

10.03

0.340

30

10.19

20

15.55

0.00

0.00

0.00

0.00

70

###

26

25.25 3.477

0.00

28

27.25 4.050

0.00

e = 100*( Vt - 0.016 ) / 0.016

30

29.25 4.666

0.00

t = Max temp of water (deg F)

32

31.25 5.326

0.00

Vt = Sp. Vol at temp t (ft3/lb)

34

33.25 6.030

0.00

36

35.25 6.777

0.00

a = Coeff of Exp of Steel (in / in) = 0.00000

Equiv gals of Water = 2,226

2.65

e = % Expansion of Water from 35 F to

Sys Vol + % age (ft3 ) =

297

Vs

Equiv lbs of Water =

0.00

30

a = Coeff of Exp of Copper (in / in) = 0.00

E = Net Pressurization Factor for diaphragm tanks

T

90

0.004

110

0.008

130

0.012

150

0.018

100

0.006

120

0.010

140

0.015

160

0.021

Total Volume of Pipes (ft3 150.3

E = Net Exp of water (gals) heated from T1 to T2

T

e=

100

120

150

200

280

0.006 0.010 0.018 0.034 0.070

E = exp 13.4

22.3

40.1

75.7

155.8

200

dt = T2-T1 = 160

(V2/V1 - 1) = 0.044

Sizing Data (Enter as required by tank type & sizing method)

Maxim Water Temp - Tmax ( T2

% Exp of Water fr 35 F to T

Tank Material (Steel / Copper)

Coeff of Exp of Tank Materia

Tank Type (Open / Closed)

200

Average Operating Temp (F

3.94

Minim Water Temp - Tmin (F T1

40

Steel

Maxim Water Temp - Tmax ( T2

200

Pa / P1 =

0.588

7E-006

Specific Volume at Tmin (ft3 V1

###

Pa / P2 =

0.368

P1 / P2 =

0.625

Specific Volume at Tmax (ft

V2

###

Closed Type (Normal / Diaphragm) Normal

Open

System Volume (ft3)

Vs

297

Tank Size (% of System Volume)

Min Press at Highest Point (

P1

25.0

Max Press to open Safety Va P2

40.0

psi

2.31

= ft

Locatn w.r.t Pump (Suctn/Dischge) Suction

Atmospheric Pressure (psia) Pa

14.7

" Hg

1.33

= ft

System Height above Tank (

90

Atmospheric Pressure (ft.Wt A, Pa'

33.9

ft3

Pr. Loss fr Tank to Pump (ft.

20

Venting Pressure (ft.Wtr)

12

gals

Default Diameter (inches)

Pa' / Po = 0.097

24

Instructor: Varkie C. Thomas, Ph.D., P.E.

Skidmore, Owings Merrill LLP

3*a*dt =

7.5

0.003

= gals

8.334 = lbs

308386823.xls

Energy Efficient Building Design

Pump Head (ft Wtr)

PH

70

Instructor: Varkie C. Thomas, Ph.D., P.E.

College of Architecture

Illinois Institute Of Technology (IIT), Chicago

Maxim Operating Pressure (f Po

350

ft3

62.4 = lbs

Skidmore, Owings Merrill LLP

308386823.xls

Energy Efficient Building Design

College of Architecture

Illinois Institute Of Technology (IIT), Chicago

Pressurization Tank Sizing

Open Tank Sizing

Sizing assumes Open Tank is: (1) vented to atmosphere, (2) at

Vt

Basis of Sizing

(1) As a Percentage of Syst

Weight Volume

Tank Size

3' above highest point of system, & (3) connected to pump suc

gallons

lbs

ft3

D (in)

L (ft)

Vt =

Minimum Volume of Expansion Tank (gals)

111

928

15

24.0

4.7

Vt =

Vs * (% of System Volume / 100)

(2) Using Min, Max Temp, Exp 96

804

13

24.0

4.1

Vt =

Vs * (e/100) * 1.1

Exp Vol + 10%

from ASHRAE Systems 20 181

1508

24

24.0

7.7

Vt =

2 * Vs * [ (V2/V1 - 1) - (3ASHRAE 2000

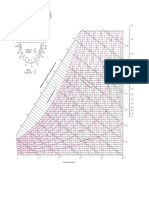

Closed Tank Sizing

V = +ve venting pressure (= 12 ft if unknown)

Fill Pressure (Pf): The tank location w.r.t. the piping system affects the initial fill or

F=

minim

frictional

pressloss

at the

from

tank.

tank to pump in order to

The tank can be at three possible locations with respect to the system as shown maintain +ve venting pressure (ft)

Pf = Initial or

Pf

Pa/Pf

A = atmospheric pressure (ft)

Min

Pa/Pf

Pf/Po 1-Pf/Po

Fill

Pressure

Location of Tank

ft H2O

- Pa/Po

H = system static head (ft) = distance between

(ft)

(1) Tank is above the piping Pf = V + F + 65.9 0.51

0.42

0.19 0.81

tank and highest point of system

(2) Tank is on suction side o

Pf = V + H + 135.9

0.25

0.15

0.39

0.61

(3) Tank is on discharge sid

Pf = V + PH + 115.9

0.29

0.20

0.33

0.67

110

Vs =

297

(1) Closed Tank:: T <= 16 T2 =

150

dt =

V2 at T2 0.016

Location of Tank

Denom Vt gals

E = e*Vs

40

Lbs

ft3

D (ft)

(1) Tank is above the piping

0.42

96

798

13

24.0

4.1

(2) Tank is on suction side o

0.15

262

2185

35

24.0

11.1

(3) Tank is on discharge sid

0.20

204

1704

27

24.0

8.7

Using ASHRAE HdBk Syst 0.22

193

1608

26

24.0

8.2

Vs =

297

(2) Closed Tank:: 160 <= T <= T2 =

200

T1 to T2

DenomGallons

Lbs

ft3

D (ft)

(1) Tank is above the piping

0.42

189

###

25.2

24.0

8.0

(2) Tank is on suction side o

0.15

517

###

69.0

24.0

22.0

(3) Tank is on discharge sid

0.20

403

###

53.8

24.0

17.1

410

3419

55

24.0

17.4

(3) Closed Chilled Water Tank

T=

Vs =

297

(0.00041 x T - 0.0466) 79

Location of Tank

DenomGallons

Lbs

ft3

D (ft)

L (ft)

(1) Tank is above the piping

0.81

97

809

13

24.0

4.1

(2) Tank is on suction side o

0.61

129

1074

17

24.0

5.5

(3) Tank is on discharge sid

0.67

118

982

16

24.0

5.0

Using ASHRAE HdBk Syst 0.22

205

1709

27

24.0

8.7

297

(4) Closed Diaphragm Water Ta T =

120

Vs =

E=

0.01

Num = E*Vs = 22

Location of Tank

DenomGallons

Lbs

ft3

D (ft)

L (ft)

(1) Tank is above the piping

0.19

118

985

16

24.0

5.0

(2) Tank is on suction side o

0.39

57

478

24.0

2.4

(3) Tank is on discharge sid

0.33

67

560

24.0

2.9

241

2010

32

24.0

10.3

Using ASHRAE HdBk Syst 0.38

References: (1) 1987 ASHRAE Handbook, pp. 13.11 - 13.15

Instructor: Varkie C. Thomas, Ph.D., P.E.

Minim Volume of Pressurization Tank (gals)

Vt =

ASHRAE 1987

(Pa/Pf) - (Pa/Po)

for T <= 160 F

E = Net expansion of water (gals) heated from 40 F to

Vt =

Vs *

[(V2/V1) - 1] - (3* ASHRAE

(Pa/P1) - (Pa/P 2000

L (ft)

Using ASHRAE HdBk Syst 0.22

90

at the top of the system

L (ft)

(0.00041 x T - 0.0466) 79

Location of Tank

Vt =

PH = pump head (ft) reqd to maintain +ve press

Vt =

(0.00041*T - 0.046 ASHRAE 1987

( Pa/Pf) - (Pa/P 160 <= T <= 280

(1) Tank Size is half of a hot water tank operating at 200

Vt =

(0.00041*T - 0.0466) * Vs

2 * [(Pa/Pf) - (Pa/Po)]

ASHRAE 1987

(2) Tank Size can be estimated from:

Vt =

Vt =

Vt =

(0.00041*T - 0.0466) * Vs

1 - (Pf/Po)

E * Vs

ASHRAE 1987

[ 1 - (Pf/Po) ]

for T <= 160 F

Vs *

[(V2/V1) - 1] - (3*a

ASHRAE

[ 1 - (P1/P2) ] 2000

(2) 2000 ASHRAE Handbook pp. 12.3 - 12.5

Skidmore, Owings Merrill LLP

308386823.xls

Energy Efficient Building Design

Instructor: Varkie C. Thomas, Ph.D., P.E.

College of Architecture

Skidmore, Owings Merrill LLP

Illinois Institute Of Technology (IIT), Chicago

308386823.xls

Energy Efficient Building Design

College of Architecture

Illinois Institute Of Technology (IIT), Chicago

mosphere, (2) at least

ted to pump suction

2 ft if unknown)

pump in order to

stance between

aintain +ve press.

Tank (gals)

ed from 40 F to T

operating at 200 F

Instructor: Varkie C. Thomas, Ph.D., P.E.

Skidmore, Owings Merrill LLP

308386823.xls

Energy Efficient Building Design

Instructor: Varkie C. Thomas, Ph.D., P.E.

College of Architecture

Skidmore, Owings Merrill LLP

Illinois Institute Of Technology (IIT), Chicago

308386823.xls

Energy Efficient Building Design

College of Architecture

Illinois Institute of Technology (IIT), Chicago

PRESSURIZATION TANKS

Pressurization tanks include expansion tanks and compression tanks. The term expansion tank is used with low

pressure systems where the tank is located at the highest point of the piping system (open or closed) and the ta

water surface is at atmospheric pressure. The height location of the expansion tank determines the static press

head available to the terminal equipment. The term compression tank applies to pressurized closed piping syste

Make-up water is supplied through the pressurization tank.

Pressurization tank types include (1) Open and (2) Closed

Closed pressurization tank construction can be:

A regular tank where the pressurizing air or gas is in contact with the liquid.

A diaphragm tank where the air charge and liquid are permanently separated by a diaphragm to prevent

corrosion of the tank or contamination of the fluid.

System Volume

Pressurization tank size is based on the volume capacity of the system. System volume consists of:

the physical inside volume of all the pipe sections in the system. The pipe volume is converted into gallon

liquid using the density of the liquid.

the liquid storage capacity of all the equipment in the system. The physical volume storage capacity of th

terminal equipment, primary equipment and miscellaneous equipment, etc., that is converted to liquid

volume using liquid density.

Open Tank Sizing

Open tank sizing assumes that the tank is:

vented to the atmosphere

at least three feet above the highest point in the piping system

connected to the suction side of the pump

Tank Volume

The tank volume size in gallons is estimated as a percentage of the total system volume The minimum reco

volume is 6% in accordance with 1987ASHRAE Handbook. An alternative to sizing the tank based on percenta

system volume, the system liquid expansion volume can be used to determinethe tank size. This expansion

is the difference in volumes at the maximum temperature of the piping system and at the minimum temperatur

Closed Tank Sizing

Fill Pressure: The tank location with respect to the piping system affects the initial fill or minimum pressure Pf

at the tank. The tank can be at three possible locations with respect to the system.

(1)

(2)

(3)

Pf = V + F + A

Pf = V + H + A

Pf = V + PH + A

Tank is above the piping system

V

= positive venting pressure; (assumes 12 ft of liquid if not known)

F

= frictional pipe losses from tank to pump that must be overcome in order to

obtain positive air venting pressure (ft of liquid as specified in input)

A

= atmospheric pressure (ft of liquid)

Tank is on suction side of the pump

H

= system static head = distance between tank and highest point of piping syste

Tank is on discharge side of the pump

PH = pump head (ft of liquid) required to maintain positive pressure attop of system

In all three cases, the atmospheric pressure A is added to obtain absolute pressure

You must specify either the initial fill pressure Pf or the system static head H.

Instructor: Varkie C. Thomas, Ph.D., P.E.

Skidmore, Owings Merrill LLP

308386823.xls

Energy Efficient Building Design

College of Architecture

Illinois Institute of Technology (IIT), Chicago

Tank Sizing Equations (closed tanks)

is used with low

losed) and the tanks

Vt =

s the static pressure

osed piping systems.

[( ) ( ) ]

Vt =

Pa

Pf

Pa

Po

(1) Tank with operating temperatures below 160 F

Vt = minimum volume of pressurization tank (gal)

E

= net pressurization of water in the system when heated from min to max temp (gal)

Pa = pressure in tank when water first enters tank (ft of water absolute); At atmos.press.

Pf = initial fill or minimum pressure of tank (ft of water absolute)

Po = maximum operating pressure of tank (ft of water absolute)

( 0 . 041 x T - 0 . 0466 ) x V s

[( ) ( )]

Pa

Pf

gm to prevent

( 0 . 041 x T - 0 . 0466 ) x V s

Vt =

[ ( )]

verted into gallons of

ge capacity of the

onverted to liquid

Vt =

Pa

Po

e Vs

[ ( )]

1-

Pf

Po

Pf

Po

(2) Tank with operating temperatures between 160 F and 280 F

T

= maximum average operating temperature (oF)

Vs = system volume calculated from the piping system dimensions (gal)

Error: Denominator is Pa/Pf - Pa/Po

(3) Chilled Water Tank

Error: Denominator is 1 - Pf/Po

Tank sizing for chilled water systems will result in tanks of very small size

because of the low pressurization coefficients (40 F to 90 F temperature range). Fo

reason, closed compression tanks applied to chilled water systems are sized as follo

(1) regular tank size is half the equivalent hot water size

(2) the piping system is considered to be operating from 70 F to 200 F

(4) Diaphragm Water Tank

Specific Volume of Water

(ASHRAE Chapter-6, Table-4)

e = net pressurization factor for water Tmp Press

Sp.Vol Expansion

F

psia

###

###

The lowest temperature of chilled water equals the mini 32

design temperature. This can be assumed to be 35 o 40

inimum reco The highest temperature is the highest anticipated ambie 50

ed on percentaThe net pressurization factor e is obtained from table be 60

his expansion Source: 1987 ASHRAE Handbook, Table 2, p. 13.15

70

mum temperature.

80

Net Pressurization Facto Typical make-up water su 90

for Diaphragm Water Ta and expansion tank piping100

plain steel tanks

110

###

###

###

###

Press.

120

###

###

F

90

Factor

e

0.004

130

140

###

###

100

110

0.006

0.008

150

160

###

###

120

130

0.010

0.012

170

180

190

###

###

###

140

150

0.015

0.018

200

210

###

###

160

0.021

220

230

###

###

240

250

###

###

260

280

###

###

300

###

Highest

um pressure Pf Temp

me in order to

###

###

###

nt of piping system

e attop of system

Instructor: Varkie C. Thomas, Ph.D., P.E.

Skidmore, Owings Merrill LLP

Sp.Vol

Exp: ft3

ft3 / (F.lb) ft3 / gal / (F.gal)

* 1,000,000

* 1,000,000

###

###

###

0.0175

###

0.0160

ft3 / lb

0.0160

0.0160

###

###

0.0161 1.6667

0.0161 1.7500

0.0161 2.0000

0.0161 2.1667

0.1338

0.1339

8.6900

10.6845

0.1342

0.1344

13.5480

15.4570

0.0162 2.4286

0.0162 2.5000

0.0163 2.7778

0.0163 2.9000

0.0163 3.0909

0.1348

0.1350

18.0111

18.8850

0.1354

0.1358

0.1362

21.4167

22.6086

24.3415

0.0164 3.2500

0.0165 3.4615

0.1366

0.1371

25.7855

27.6485

0.0165 3.6429

0.0166 3.8000

0.0166 3.9375

0.0167 4.1176

0.1376

0.1381

29.2453

30.6292

0.1386

0.1392

31.8401

33.3988

0.0168 4.2778

0.0168 4.4211

0.0169 4.6000

0.0170 4.7619

0.1398

0.1403

34.7843

36.0240

0.1410

0.1417

37.5564

38.9429

0.0171 4.9091

0.0173 5.2500

0.0175 5.5769

0.1423

0.1438

0.1454

40.2033

43.1035

45.8781

308386823.xls

Energy Efficient Building Design

College of Architecture

Illinois Institute of Technology (IIT), Chicago

PROPERTIES OF LIQUIDS

Liquid

o max temp (gal) Water

; At atmos.press.

Glycol

Brine

rature range). Fo Diesel

s are sized as follows:

Petrol

Properties

-30

Density (lb/cu ft)

Specific Gravity ( = Density / 6

Kinematic viscosity (sq ft/sec)

Specific heat (Btu/lb oF)

Density (lb/cu ft)

67.98

Specific Gravity ( = Density / 6 1.09

Kinematic viscosity (sq ft/sec) ###

0.70

Specific heat (Btu/lb oF)

Density (lb/cu ft)

78.59

Specific Gravity ( = Density / 6 1.26

Kinematic viscosity (sq ft/sec) ###

Specific heat (Btu/lb oF)

0.66

Density (lb/cu ft)

59.20

Specific Gravity ( = Density / 6 0.95

Kinematic viscosity (sq ft/sec) ###

Specific heat (Btu/lb oF)

0.47

Density (lb/cu ft)

46.10

Specific Gravity ( = Density / 6 0.74

Kinematic viscosity (sq ft/sec) 11.00

Specific heat (Btu/lb oF)

0.47

67.55

1.08

190.00

0.73

78.21

1.25

77.50

0.67

57.40

0.92

161.50

0.48

45.50

0.73

9.80

0.48

Temperature

30

60

100

150

62.42

62.37

62.00

61.20

1.00

1.00

0.99

0.98

0.00

12.17

7.39

4.76

1.00

1.00

1.00

1.00

67.11

66.55

65.74

64.68

1.08

1.07

1.05

1.04

85.40

48.60

22.60

12.50

0.76

0.78

0.81

0.85

77.71

77.21

76.09

1.25

1.24

1.22

34.70

21.80

8.90

0.68

0.69

0.71

56.10

54.90

53.00

51.10

0.90

0.88

0.85

0.82

80.70

48.30

29.10

7.50

0.49

0.50

0.51

0.52

44.90

44.70

44.30

42.40

0.72

0.72

0.71

0.68

8.80

7.00

5.50

3.00

0.49

0.50

0.51

0.52

PROPERTIES OF HIGH TEMPERATURE HOT WATER

Temp

deg F

212

220

240

260

280

300

350

400

450

Satur.

Press

psig

0

2.5

10.3

20.7

34.5

52.3

119.9

232.6

407.9

Density Specific Kinem Sp. Heat

lb/cu ft Gravity = ViscosBtu/lb oF

Density/62.4sq ft/sec

0.96

1.006

59.81

3.2

0.96

1.007

59.63

3

0.95

1.01

59.1

2.7

0.94

1.015

58.51

2.5

0.93

57.94

2.3

1.02

0.92

57.31

2.1

1.26

0.89

55.59

1.9

1.044

0.86

53.65

1.7

1.067

0.83

51.55

1.5

1.095

Instructor: Varkie C. Thomas, Ph.D., P.E.

Skidmore, Owings Merrill LLP

210

59.81

0.96

3.20

1.01

63.12

1.01

6.40

0.88

Increase in Frictional Pressure Loss

due to Pipe Age

Hydraulic Handbook by Colt Industries

Multipliers

Pipe Age

Years

0

5

10

15

20

25

30

35

40

45

50

60

Small

1 - 3

1

1.4

2.2

3.6

5

6.3

7.25

8.1

8.75

9.25

9.6

10

Medium Large

4 to 12 14 - 48

1

1

1.35

1.3

1.9

1.6

2.7

1.8

3.5

2

4.2

2.1

4.73

2.2

5.2

2.3

5.58

2.4

5.93

2.6

6.23

2.86

7

3

308386823.xls

Energy Efficient Building Design

College of Architecture

Illinois Institute of Technology (IIT), Chicago

ressure Loss

olt Industries

Instructor: Varkie C. Thomas, Ph.D., P.E.

Skidmore, Owings Merrill LLP

308386823.xls

You might also like

- SilencersDocument79 pagesSilencersArshid SiddiquiNo ratings yet

- NoiseDocument220 pagesNoisemedrascomNo ratings yet

- Practice ABCDocument68 pagesPractice ABCMDCITYNo ratings yet

- Physical properties data tables and referencesDocument32 pagesPhysical properties data tables and referencesmidooooo198767% (3)

- Printable Spencerian Practice Sheets PDFDocument5 pagesPrintable Spencerian Practice Sheets PDFPhanhai Kaka100% (3)

- Balancing of Distribution SystemDocument35 pagesBalancing of Distribution Systemebru_alpaslan50% (2)

- (Mayu) Shin - I - Bunpou PDFDocument177 pages(Mayu) Shin - I - Bunpou PDFPhanhai Kaka100% (1)

- FoamDocument13 pagesFoamPhanhai KakaNo ratings yet

- Nature and the Environment Document SummaryDocument6 pagesNature and the Environment Document SummaryblackcatnogoNo ratings yet

- Grammar Reference Card Adjectives Final2 0Document1 pageGrammar Reference Card Adjectives Final2 0Rina MargaritaNo ratings yet

- 4 X 6 inDocument1 page4 X 6 inPhanhai KakaNo ratings yet

- Squadron Signal 6015 Soviet Aircraft of TodayDocument82 pagesSquadron Signal 6015 Soviet Aircraft of TodayArdavan Kazemi100% (2)

- 33.Uploads-downloads-DOWN 64DF6E44CA656ABFBG33 Sausage DryingDocument1 page33.Uploads-downloads-DOWN 64DF6E44CA656ABFBG33 Sausage DryingPhanhai KakaNo ratings yet

- 32.Uploads-downloads-DOWN - F11B00DF2423BABEBG32 - Engine Testing Room For AutomobilesDocument1 page32.Uploads-downloads-DOWN - F11B00DF2423BABEBG32 - Engine Testing Room For AutomobilesPhanhai KakaNo ratings yet

- Grammar Reference CardDocument29 pagesGrammar Reference CardPhanhai KakaNo ratings yet

- Leather Storage: Ffps - Frequently Faced ProblemsDocument2 pagesLeather Storage: Ffps - Frequently Faced ProblemsPhanhai KakaNo ratings yet

- Do Thi Id1Document1 pageDo Thi Id1Phanhai KakaNo ratings yet

- 31.Uploads-downloads-DOWN 17C7C39CB9F6A97EBG31 Dynamite StorageDocument1 page31.Uploads-downloads-DOWN 17C7C39CB9F6A97EBG31 Dynamite StoragePhanhai KakaNo ratings yet

- Maintaining the Sultan's Vintage Car CollectionDocument1 pageMaintaining the Sultan's Vintage Car CollectionPhanhai KakaNo ratings yet

- 28.uploads Downloads DOWN DB425AEBD06A0289BG28 MushroomDocument1 page28.uploads Downloads DOWN DB425AEBD06A0289BG28 MushroomPhanhai KakaNo ratings yet

- 27.Uploads-downloads-DOWN 83915B42C61BD757BG27 Printer RollerDocument1 page27.Uploads-downloads-DOWN 83915B42C61BD757BG27 Printer RollerPhanhai KakaNo ratings yet

- 30.Uploads-downloads-DOWN 1B01F1A4DF91062DBG30 Bridge CorrosionDocument2 pages30.Uploads-downloads-DOWN 1B01F1A4DF91062DBG30 Bridge CorrosionPhanhai KakaNo ratings yet

- Maintaining the Sultan's Vintage Car CollectionDocument1 pageMaintaining the Sultan's Vintage Car CollectionPhanhai KakaNo ratings yet

- 17.uploads Downloads DOWN D22A32D31D1BBFC8Brygram17 SoleLeatherDocument1 page17.uploads Downloads DOWN D22A32D31D1BBFC8Brygram17 SoleLeatherPhanhai KakaNo ratings yet

- T-S ChartDocument1 pageT-S ChartPhanhai KakaNo ratings yet

- PCB Assembly humidity controlDocument1 pagePCB Assembly humidity controlPhanhai KakaNo ratings yet

- Maintain Bowling Alleys at 30% RHDocument1 pageMaintain Bowling Alleys at 30% RHPhanhai KakaNo ratings yet

- 13.uploads Downloads DOWN 9812E97C19F9B525Brygram13 FertilizerDocument1 page13.uploads Downloads DOWN 9812E97C19F9B525Brygram13 FertilizerPhanhai KakaNo ratings yet

- Yeast Making: Ffps - Frequently Faced ProblemsDocument1 pageYeast Making: Ffps - Frequently Faced ProblemsPhanhai KakaNo ratings yet

- 11.uploads Downloads DOWN 7ED44AD7836805A0Brygram11 SemiconductorDocument1 page11.uploads Downloads DOWN 7ED44AD7836805A0Brygram11 SemiconductorPhanhai KakaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)