Professional Documents

Culture Documents

Flowmeter Demonstration Lab Report

Uploaded by

Shalihan MustafaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flowmeter Demonstration Lab Report

Uploaded by

Shalihan MustafaCopyright:

Available Formats

Thermofluid lab: Flowmeter demonstration

________________________________________________________________________________________

____________

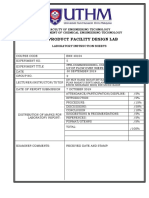

UNIVERSITI TEKNOLOGI MARA

FAKULTI KEJURUTERAAN KIMIA

THERMOFLUID LAB

(CGE 536)

EXPERIMENT

DATE PERFORMED

SEMESTER

PROGRAMME/CODE

GROUP

: FLOWMETER DEMONSTRATION

: 29/9/2015

:3

: THERMOFLUID LAB / CGE 536

: EH2433B

NAMA

MUHAMMAD EZWAN BIN MOHD

HANAFIAH

NUR AMANINA BINTI AHMAD

NIZAMUDDIN

NO PELAJAR

2014620734

2014260632

MUHAMMAD IKHMAL BIN YAHYA

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

2014418774

TITLE

ALLOCATED MARKS MARKS

%

5

5

5

5

5

10

10

10

20

10

5

5

5

100

ABSTRACT/SUMMARY

INTRODUCTION

AIMS/OBJECTIVES

THEORY

APPARATUS

PROCEDURES

RESULT

CALCULATIONS

DISCUSSION

CONCLUSIONS

RECOMMENDATIONS

REFERENCES

APPENDICES

TOTAL

Thermofluid lab: Flowmeter demonstration

Remarks :

Checked by:

CONTENT

PAGE

SUMMARY

INTRODUCTION

OBJECTIVES

THEORY

APPARATUS/MATERIALS

PROCEDURE

RESULT

CALCULATION

DISCUSSION

CONCLUSION

RECOMMENDATION/REFERENCE

APPENDICES

TABLE OF CONTENTS:

3

4-6

7

8-10

11

12

13

14-17

18

19

20

21-24

Thermofluid lab: Flowmeter demonstration

SUMMARY:

EXPERIMENT 1: Demonstration of the operation and characteristic

of three different basic

types of flowmeter

The experiment has been done to measure the flow rate and pressure

loses using three basic types of flow measuring techniques; rotameter,

venturimeter and orifice meter. After all apparatus have been set up, we must

measure the time taken of a known volume of water (3 litres) to accumulate in

the water tank to calculate the flow rate. Next, we have to record the

manometer reading (A-J) and the flow rate reading in different techniques. To get

accurate reading, we must repeat the experiment 3 times.

EXPERIMENT 2: Determination of the loss coefficient when fluid

flows through a 90 degree

elbow

The experiment has been done to determine the loss coeffient when fluid

flows through a 90 degree elbow. After all apparatus have been set up, the flow

rate have been taken by measure the time of a known volume of water to

accumulate in a tank. The reading in manometer I and J is record. At the end of

Thermofluid lab: Flowmeter demonstration

experiment, a graph of H against

V 2s

2g

for 90 degree elbow to determine the

coefficient of losses. To get accurate reading, we must repeat the experiment 3

times.

INTRODUCTION :

EXPERIMENT 1:

Fluid mechanics is the branch of physics that studies the behaviour of fluid

especially liquid in many form of application which is statics, dynamics and

thermodynamics. In order to study this behaviour of fluids, we need a device

known as flowmeter. Flowmeter is a device used to measure the flow rate or a

quantity of fluids flow through a pipe.

The hydraulic bench (Model: FM 110) is provided in the laboratory and

were connected to the flowmeter measurement apparatus (Model: FM 101) which

consists of venturi meter, orifice meter and rotameter.

Venturi meter

Venture meter is a tube consists of three parts which is a short converging

part, throat and diverging part. Inside the venture meter, pressure difference is

4

Thermofluid lab: Flowmeter demonstration

created by reducing the cross sectional area of the flowing path. The pressure

difference is measured using the manometer. The pressure difference is useful to

calculate the flow rate of fluid through the pipe line. The inlet area of the venturi

is larger than the throat causing the velocity at the throat increases due to the

pressure decreases. As the conclusion, a pressure difference is created between

the inlet and the throat of the venturi. To understand the principle of venture

meter, we must know the Bernoullis equation.

Orifice meter

An orifice meter is generally a thin orifice plate with a hole in the middle. It

is placed in a pipe which a fluid flows. As the fluid reaches the orifice plate, the

fluid is forced to flow through the hole in the middle of the orifice plate. Vena

contracta which is the point of maximum convergence is produced downstream

of physical orifice. As this occurs, the velocity and the pressure will change. At

the vena contracta, the velocity and pressure change once again due to the fluid

expand. The flow rates can be obtained from Bernoullis equation by measuring

the pressure difference between normal pipe section and the vena contracta.

Thermofluid lab: Flowmeter demonstration

Rotameter.

Rotameter is a class of meters called as variable area meters. It consists of three

basic elements that are a uniformly tapered flow tube, a float and a

measurement scale. Rotameter is usually position vertically in the system with

smallest diameter at the end of the tapered flow tube at the bottom which is the

fluid inlet. When fluid flow through a float in tapered tube, pressure difference is

created. As the float moves upwards, the fluid flowing area increases due to the

decreasing of pressure difference.

EXPERIMENT 2:

The value of the loss coefficient is very important to accurately calculate

the flow rates and pressure drop in pipes. In long straight pipe, the pressure drop

is due to the friction in the pipe which is also known as major losses. The

pressure drop caused by fittings or valves is known as minor losses which will be

calculated at the end of the experiment. As pipes get shorter and more

complicated the proportion of losses due to fittings and valves gets larger, but by

convention is also known as minor losses. The type of pipe fitting contain in this

experiment is 90 degree elbow.

Thermofluid lab: Flowmeter demonstration

OBJECTIVE :

EXPERIMENT 1:

To obtain the flow rate measurement by utilizing three basic types of flow

measuring techniques; rotameter, venturi meter and orifice meter.

EXPERIMENT 2:

To investigate the loss coefficient of fluid through 90 degree elbow.

Thermofluid lab: Flowmeter demonstration

THEORY:

EXPERIMENT 1:

Bernoulli equation is applied to calculate the flow rate in both venturi meter and

orifice:

1. By determine point 1 and 2 at the flowmeter:

2. By using continuity equation, we can eliminate velocity,u 2:

Thermofluid lab: Flowmeter demonstration

3. Substituting this into and rearranging Bernoullis equation:

4. To get the actual result, coefficient discharge have to be consider in the

calculation:

In this experiment, Z1=Z2. Therefore, Z1 and Z2can be cancelling out.

A1 : Area at point 1

A2: Area at point 2

P1: Pressure at point 1

P2: Pressure at point 2

U1: Velocity at point 1

U2: Velocity at point 2

9

Thermofluid lab: Flowmeter demonstration

Values of discharge coefficient are determined by experimented, the

assumed values used in the software are:

CdVenturi meter= 0.98

Cd Orifice plate = 0.63

The head loss (h, metre) is recorded due to the height reading of

manometer. In this experiment, the head losseswill be compared with the flow

rate used. Pressure loss for venture meter is low while for the orifice the pressure

loss is medium.

EXPERIMENT 2:

To calculate the loss coefficient, the equation use is:

2

HL = K x

V

2g

Where,

HL= Head Loss

K= Loss Coefficient

V= flow velocity

g= Acceleration of gravity

10

Thermofluid lab: Flowmeter demonstration

The usual value use for g is 9.81N.

APPARATUS:

11

Thermofluid lab: Flowmeter demonstration

PROCEDURE:

EXPERIMENT 1:

1. Apparatus was placed on the bench, inlet pipe connected to bench supply and

outlet pipe into volumetric tank.

2. With the bench valve fully closed and the discharge valve fully opened, the

pump supply and the hydraulic bench was started up.

12

Thermofluid lab: Flowmeter demonstration

3. The bench valve was slowly opened until it is fully opened.

4. When the flow in the pipe is steady and there is no trapped bubble, bench

valve is started to close in order to reduced the flow to the maximum

measurable flowrate.

5. By using the air bleed screw, water lvl in the manometer was adjusted.

maximum reading of manometer was retained with the maximum measurable

flowrate.

6. Reading on manometer(A-J), Rotormeter and maximum measureable flowrate

was noted.

7. Step 6 is repeated for different flow rates. The flow rates can be adjusted by

utilizing both bench valve and discharge valve.

EXPERIMENT 2:

1. Repeat step (1-6) from experiment 1.

2. Complete the data table.

2

Vs

2g

3. Graph of H against

for 90 degree elbow was plotted to determined the

coefficient of losses.

RESULT

Demonstration of the operation and characteristic of three different basic types

of flowmeter

NO.

MANOMETER READING (MM)

C

D

E

F

G

13

Thermofluid lab: Flowmeter demonstration

1

2

3

4

NO.

265

295

338

374

263

290

327

255

ROTA

METER

(L/MIN)

5

253

256

256

241

259

277

301

315

VOL

(L)

TIME

(MIN)

0.5155

10

261

282

312

333

252

287

322

349

FLOWRA

TE

Q(L/MIN)

5.82

0.2618

11.16

262

287

322

348

239

203

143

57

104

105

1.8623

1.7570

10

15

20

0.2000

15.00

0.1363

21.53

248

235

210

166

FLOWRATE USING

BERNOULLI EQ

VENTURI

ORIFICE

1.0330

9.1939

249

238

215

170

10

2.7004

2.5648

104

104

3.4391

3.2702

10

10

Determination of the loss coefficient when fluid flows through a 90 degree elbow

No.

Volume

Time

(L)

(sec)

Flowrate,

Q

Differential Piezometer

Head, h' (mm)

(l/min)

Elbow (hI-hJ)

3

3

(m/s)

(mm)

1.7087

0.183

1

16.13

103

6.2790

0.351

0

15.00

0.471

8

0.01134

21.23

0.677

2

0.0233

11.16

3

V2/2g

30.93

5.82

12.00

8.36

14

103

Thermofluid lab: Flowmeter demonstration

CALCULATION

EXPERIMENT 1

For the venturi meter

Upstream pipe diameter

Cross sectional area

Throat diameter

= 26mm

A1

4

= 5.3093 10

m2

= 16mm

Cross sectional area of throat

Discharge coefficient

d2

4

A2

Cd ven

d2

4

4

= 2.0106 10

m2

=0.98

For the orifice plate

Upstream pipe diameter

= 26 mm

Cross sectional area of upstream pipe A1

Throat diameter

= 5.3093 10

m2

= 16mm

Cross sectional area of throat

Discharge coefficient

d2

4

Cdorifice

A2

d2

4

=0.63

15

= 2.0106 10

m2

Thermofluid lab: Flowmeter demonstration

Timed Flow rate, Qt (m3/s) = V = Volume Collected

t Timed to collect

= 0.003 m3/ 30.93

= 9.70 x 10-5 m3/s

Variable Area Flow Rate, Qa (m3/s) = Value from instrument reading (L/min)

60, 000

= 5 L / min

60, 000

= 8.33 x 105 m3/s

Orifice Plate Flow Rate, Qo (m3/s)

Cd A2

( )

2g H

A2 2

1( )

A1

0.016

( 2 4)

2(9.81)(0.023)

0.016 4

1(

)

0.026

(0.63)

=9.1939 x 105 m3/s

16

Thermofluid lab: Flowmeter demonstration

Cd A2

Venturi Meter Flow Rate, Qv (m3/s) =

( )

2g H

A 2

1( 2 )

A1

0.016

( 2 4)

2(9.81)(0.012)

0.016 4

1(

)

0.026

(0.98)

= 1.0330 x 10-4 m3/s

Rotameter % Error

= (Qa Qt) x 100

Qt

= (8.3333 x 105 9.70 x 10-5) x 100%

9.70 x 10-5

= -14.08%

Orifice Plate % Error

(Qo Qt) x 100

Qt

= (9.1939 x 105 9.70 x 10-5) x 100%

9.70 x 10-5

= -5.21%

Venturi Meter % Error

(Qv Qt) x 100

Qt

= (1.0330 x 10-4 9.70 x 10-5) x 100%

9.70 x 10-5

= 6.49%

This calculation is repeated for the 2 , 3 ,4 repeated experiment to find accurate data

Flow rate

17

Thermofluid lab: Flowmeter demonstration

No

Time flow rate

Qt (m3/s)

1

2

3

4

9.699 10

Rotameter

Flow Rate Qa

(m3/s)

8.3333

5

10

1.8599 10

2.5000 10

3.5894 10

1.6667

10

2.5000

10

3.3333

10

Venturi meter

Flow rate Qv

(m3/s)

Orifice Flow rate Q0

(m3/s)

1.0330 10

9.1939 10

1.8623 10

1.7570 10

2.7004 10

2.5648 10

3.4391 10

3.2702 10

Percentage error compare to time flowrate

No

1

2

3

4

average

Rotameter %

flow rate error

(%)

-14.08

-10.39

0

-7.13

7.90

Orifice plate %

flow rate error (%)

Venturi meter % flow

-rate error (%)

6.50

0.13

8.02

-4.19

4.71

-5.21

-5.53

2.59

-8.89

5.56

Average is calculated by change negative value to positive to determine the

accurate flowrate measurement .

EXPERIMENT 2

Theoritical value :

Elbow flanged regular 90= 0.3

18

Thermofluid lab: Flowmeter demonstration

H

6

5

f(x) = 0.12x + 1.94

H

Linear (H)

Linear (H)

2

1

0

0

10

15

20

25

The slope, K = 0.1228

% error =( 0.1228-0.3) x 100%

0.3

= 57.0%

DISCUSSIONS

Objective of this experiment 1 is to obtain the flow rate measurement by utilizing

three basic types of flow measuring techniques which is rotameter , venturi and orifice .The

flowrate is the volume of fluid which passes per unit time represented by unit Q.

19

Thermofluid lab: Flowmeter demonstration

Since the percentage error for this experiment from A-Z is not more than 15% so it is

considered as successful experiment . By referring percentage of error that we calculated by

comparing to time flowrate for rotameter , orifice and venture is 7.90% , 4.71% and 5.49% .

Its can be conclude that percentage error for orifice is the lowest and make it the best device

for calculate flow rate .

But from the theory, venturi meter is a more accurate than orifice and rota meter.

From the calculation, we determine that orifice meter is more accurate than others. Actually,

it should be the venturi meter. We found that one of the major factors that affect the readings

is the bubble in pipeline. Besides that, the position of eyes also gives effect to the manometer

reading.

For experiment 2, the objective is to investigate the lost coefficient of fluid through 90

degree elbow. From the graph that have been plotted, gradient (K) of the graph is 0.1228. But

the actual theoretical value is 0.3 for Elbow flanged regular 90. The percentage error for this

experiment is 57%. So it is considered the experiment is unsuccessful. We assumed the experiment is

considered fail because the percentage exceeded 15%. This occurrence may be caused by bubble that

trap inside the tube that connected to manometer.

CONCLUSION

As a conclusion for experiment 1, we can say that the most accurate flow meter is a

venturi meter. From this experiment, we determine that the flow rate % error for venturi

20

Thermofluid lab: Flowmeter demonstration

meter is higher than the orifice meter. From the theory, the more efficiency of flow meter has

a less flow rate % error.

As a conclusion for experiment 2, we can state that the loss coefficient is 0.1228.

Percentage difference for the experiment is 57%. The experiment is unsuccessful.

21

Thermofluid lab: Flowmeter demonstration

RECOMMENDATION:

There are some precautions and suggestions that can be taken for safety and to

get better result when conducting the experiment of Flow Measurement

Apparatus experiment. The recommendations are as followed:

1. Before starting the experiment, students must follow all the instructions

from the supervisor and do general set-up procedures .

2. Avoid error in taking readings and make sure eyes of observer are parallel

to the reading scale.

3. The observer must be fixed to one person only to measure the apparatus

reading to avoid perspective errors.

4. The experiment must be conduct at least twice to obtained average result.

5. Make sure to follow the shut-down procedures after finishing the

experiment.

REFERENCE:

https://en.wikipedia.org/wiki/Flow_measurement

https://www.mathesongas.com/pdfs/.../flowmeter-product-line-overview

Lab manual, Faculty of Chemical Engineering, UiTM Shah Alam

https://www.youtube.com/watch?v=Ml0bhxtur9I

Google search keyword rotameter , venture , orifice ,flowrate

demonstration

www.engineeringtoolbox.com/

22

Thermofluid lab: Flowmeter demonstration

APPENDICES

Figure 1: APPARATUS

Figure 2: Venturi meter and manometer

23

Thermofluid lab: Flowmeter demonstration

Figure 3: Rotometer and Discharge Valve

Figure 4: 90 degree elbow

24

Thermofluid lab: Flowmeter demonstration

Figure 5: Orifice meter

Figure 6: Control Valve

25

You might also like

- Energy Losses in Pipes: Experiment # 4Document4 pagesEnergy Losses in Pipes: Experiment # 4محمد جوادNo ratings yet

- 12 Experiment #2: Bernoulli'S Theorem DemonstrationDocument12 pages12 Experiment #2: Bernoulli'S Theorem DemonstrationYasir A. Al-ShataifNo ratings yet

- Lab Report 2Document16 pagesLab Report 2Limmy Yingran0% (1)

- Impact of Jet Lab ReportDocument7 pagesImpact of Jet Lab ReportMohamad Hilmy HaririeNo ratings yet

- LAB REPORT - Discharge Over WeirsDocument9 pagesLAB REPORT - Discharge Over WeirsLuli LolNo ratings yet

- Bernoulli S Principle Demonstration Lab ReportDocument18 pagesBernoulli S Principle Demonstration Lab ReportHasan RabyNo ratings yet

- Comparing Flow Measurement Methods Using Bernoulli's Equation and Continuity EquationDocument3 pagesComparing Flow Measurement Methods Using Bernoulli's Equation and Continuity EquationRazali RamlanNo ratings yet

- Experiment BernoulliDocument17 pagesExperiment BernoulliHafiniHambali94% (33)

- Lab Report For Venturi MeterDocument9 pagesLab Report For Venturi MeterFirzana AmiraNo ratings yet

- Mechanics of Fluids Lab Impact of A JetDocument10 pagesMechanics of Fluids Lab Impact of A JetpatrickNX942088% (17)

- Flow Rate Measurement Using Venturi, Orifice & RotameterDocument13 pagesFlow Rate Measurement Using Venturi, Orifice & RotameterxxxxxNo ratings yet

- Lab Manual 3.1 - LEVEL 1 - Determination of Head Loss in Pipes Due To Friction, Fittings, Sudden Expansion and Contraction.Document4 pagesLab Manual 3.1 - LEVEL 1 - Determination of Head Loss in Pipes Due To Friction, Fittings, Sudden Expansion and Contraction.Coi50% (2)

- Free N Forced Vortex ReportDocument18 pagesFree N Forced Vortex ReportAuza100% (1)

- (Exp # 5) Energy Losses in BendsDocument16 pages(Exp # 5) Energy Losses in BendshamZA17% (12)

- Fluid Flow Experiment ResultsDocument10 pagesFluid Flow Experiment ResultsAlimah AzeliNo ratings yet

- DiscussionDocument3 pagesDiscussionsiti zulaikha100% (2)

- Flow Meter Demonstration Lab ReportDocument21 pagesFlow Meter Demonstration Lab Reportmhd badhrul bin baharNo ratings yet

- Experiment 2 - Stability of Floating BodyDocument4 pagesExperiment 2 - Stability of Floating BodyKhairil Ikram0% (1)

- MEHB221 Thermofluids Lab 2012Document6 pagesMEHB221 Thermofluids Lab 2012Asyraf Hakim Muhammad Azmi50% (2)

- Bioproduct Facility Design Lab: Faculty of Engineering Technology Department of Chemical Engineering TechnologyDocument18 pagesBioproduct Facility Design Lab: Faculty of Engineering Technology Department of Chemical Engineering TechnologyAswini Purushothanan0% (1)

- Energy Losses in BendsDocument10 pagesEnergy Losses in BendsAngelica Joyce BenitoNo ratings yet

- Lab Report Impact of JetDocument13 pagesLab Report Impact of Jetjo100% (1)

- Pitot Tube ExperimentDocument3 pagesPitot Tube ExperimentinstrutechNo ratings yet

- CHE465 Lab Manual Weir Flow MeasurementDocument20 pagesCHE465 Lab Manual Weir Flow MeasurementMohd Sharu Mamat67% (3)

- Bernouli Lab ReportDocument18 pagesBernouli Lab ReportUgeswran Thamalinggam100% (3)

- Relationship between pressure and temperature of saturated steamDocument7 pagesRelationship between pressure and temperature of saturated steamSeng SoonNo ratings yet

- Fluid Lab 2 - Bernoulli ExpDocument19 pagesFluid Lab 2 - Bernoulli ExpCik Tiem Ngagiman89% (65)

- Lab Report Flow Rate MeasurementDocument12 pagesLab Report Flow Rate Measurementnorsiah92% (12)

- 6-Energy Loss in BendsDocument12 pages6-Energy Loss in BendsMaysara Maawia Mukhtar60% (10)

- Impact of A Jet Lab ReportDocument3 pagesImpact of A Jet Lab ReportSaiful IslamNo ratings yet

- Impact of A JetDocument11 pagesImpact of A JetMuhammad Hakim Jaffar0% (1)

- Venturimeter LAB ReportDocument7 pagesVenturimeter LAB ReportJames Roy100% (1)

- Lab V - Energy Losses in Bends-LO6Document6 pagesLab V - Energy Losses in Bends-LO6Rymshah MoezNo ratings yet

- Lab 1 - Impact of JetDocument7 pagesLab 1 - Impact of JetMichael York100% (1)

- SEO Flow Weirs Lab ReportDocument20 pagesSEO Flow Weirs Lab ReportGua HantuNo ratings yet

- Lab Report On Fitting LossDocument13 pagesLab Report On Fitting LossJyiou Yimushi100% (1)

- University of Mauritius: Faculty of Engineering Mechanical & Production Engineering DepartmentDocument17 pagesUniversity of Mauritius: Faculty of Engineering Mechanical & Production Engineering Departmenthansley100% (1)

- Stability of Floating BodiesDocument10 pagesStability of Floating Bodiesfjranggara91100% (1)

- Bernoulli Theorem DemonstrationDocument27 pagesBernoulli Theorem DemonstrationmanzahuhuNo ratings yet

- Calibrating a Venturi MeterDocument10 pagesCalibrating a Venturi MeterAgyeman EmmanuelNo ratings yet

- Impact of Water JetDocument12 pagesImpact of Water JetIqbal Buddy100% (1)

- Energy Losses in BendsDocument8 pagesEnergy Losses in BendsVikramSingh0% (3)

- Bernoullis Equation Lab ReportDocument12 pagesBernoullis Equation Lab ReportgeduyoxNo ratings yet

- Introduction Impact JetDocument4 pagesIntroduction Impact JetIniaan SaminathanNo ratings yet

- Bernoulli's Theorem ExperimentDocument17 pagesBernoulli's Theorem ExperimentMimi Hashim95% (19)

- V Notch PracticalDocument13 pagesV Notch PracticalAnushaBheenuck0% (2)

- Pelton Wheel TurbineDocument8 pagesPelton Wheel TurbineSiew LynNo ratings yet

- Lab 4 (Thermofluids Lab)Document32 pagesLab 4 (Thermofluids Lab)Adnan Nanda0% (1)

- Faculty of Chemical EngineeringDocument32 pagesFaculty of Chemical EngineeringArif HanafiNo ratings yet

- Experiment 4 - Flow MeasurementDocument24 pagesExperiment 4 - Flow MeasurementKhairil Ikram67% (6)

- Bernoulli Equation Full ReportDocument6 pagesBernoulli Equation Full ReportChala1989No ratings yet

- FM CompleteDocument19 pagesFM Completenini jasniNo ratings yet

- Mech. Engg. DepartmentDocument37 pagesMech. Engg. DepartmentHamza AhmadNo ratings yet

- Experiment 3Document3 pagesExperiment 3MaisarahNo ratings yet

- Lab 4 (Flowmeter Demonstration)Document23 pagesLab 4 (Flowmeter Demonstration)Muhamad Baihakhi ShamsudinNo ratings yet

- Fluids Lab Experiment:07 Name: Estimation The Volume Flow Rate Using Venturi-Meter ApparatusDocument5 pagesFluids Lab Experiment:07 Name: Estimation The Volume Flow Rate Using Venturi-Meter ApparatusDarivan DuhokiNo ratings yet

- MAPUA HYDRAULICS LAB ENERGY LOSSES IN BENDSDocument7 pagesMAPUA HYDRAULICS LAB ENERGY LOSSES IN BENDSJohn Michael Menoza ZapantaNo ratings yet

- Flow Meter Procedure: Rotameter, Venturi, OrificeDocument3 pagesFlow Meter Procedure: Rotameter, Venturi, OrificeZafirah Zaidi100% (1)

- Lab Manual Sem1 2015 2016-11092015Document26 pagesLab Manual Sem1 2015 2016-11092015Putri SaidatinaNo ratings yet

- Page For Main Menu: Typical Results Using The Equipment Below. Return To Lab Experiments PageDocument13 pagesPage For Main Menu: Typical Results Using The Equipment Below. Return To Lab Experiments PagepaniuatuiNo ratings yet

- Well Design - PE 413: Chapter 1: Fracture PressureDocument44 pagesWell Design - PE 413: Chapter 1: Fracture PressureWeny AstutiNo ratings yet

- CHE515 - Lesson Plan - Mar 2015 - July2015Document5 pagesCHE515 - Lesson Plan - Mar 2015 - July2015EZWANNo ratings yet

- Gas BehaviourDocument136 pagesGas BehaviourEZWANNo ratings yet

- Report 5 Calculate ViscosityDocument18 pagesReport 5 Calculate ViscosityEZWANNo ratings yet

- Full Text 01Document81 pagesFull Text 01EZWANNo ratings yet

- Refrigerant UnitDocument33 pagesRefrigerant UnitSiti ZulaihaNo ratings yet

- Non Aqueous Drilling FluidsDocument8 pagesNon Aqueous Drilling FluidsEZWANNo ratings yet

- Refregeration UnitDocument24 pagesRefregeration UnitEZWANNo ratings yet

- Spreadsheet Use For Partially Full Pipe Flow CalculationsDocument36 pagesSpreadsheet Use For Partially Full Pipe Flow Calculationsadooo meee0% (1)

- Vortex and VorticityDocument121 pagesVortex and VorticityVictor MarchantNo ratings yet

- 2Document1 page2David GaoNo ratings yet

- CS TheoryDocument403 pagesCS TheoryAnonymous scnl9rHNo ratings yet

- SeepageDocument25 pagesSeepagesheikh jamilNo ratings yet

- Build Up TestDocument4 pagesBuild Up TestDavid AhouaNo ratings yet

- Ex 01Document23 pagesEx 01Sadia HasanNo ratings yet

- Numerical Modelling of Second Grade Fluid Flow Past A Stretching SheetDocument34 pagesNumerical Modelling of Second Grade Fluid Flow Past A Stretching SheetSarifulNo ratings yet

- MC FLUIDS REVIEW: DENSITY, PRESSURE, BUOYANCY PRINCIPLESDocument122 pagesMC FLUIDS REVIEW: DENSITY, PRESSURE, BUOYANCY PRINCIPLESsashicahhNo ratings yet

- Installation of Stream Gauges at Roshi Khola To Monitor River Water DischargeDocument18 pagesInstallation of Stream Gauges at Roshi Khola To Monitor River Water DischargeKukuh Prasetyo Pangudi UtomoNo ratings yet

- Lid Driven FlowDocument8 pagesLid Driven Flowmanoj0071991No ratings yet

- Dustin Jay Ulzoron Me 212 SN: 2018190022 Msme Homework #2: P 2mpa T 600K 5 KG/S P 200kpaDocument4 pagesDustin Jay Ulzoron Me 212 SN: 2018190022 Msme Homework #2: P 2mpa T 600K 5 KG/S P 200kpaJay Dustin UlzoronNo ratings yet

- Excel Chart To Calculate Friction Loss in Pipelines Using Hazen Williams FormulaDocument1 pageExcel Chart To Calculate Friction Loss in Pipelines Using Hazen Williams FormulaRaghuveer Rao PallepatiNo ratings yet

- Pipenet Network PDFDocument14 pagesPipenet Network PDFMohamedNo ratings yet

- SedimentationDocument5 pagesSedimentationAduchelab AdamsonuniversityNo ratings yet

- The Exam Is Closed Book and Closed NotesDocument6 pagesThe Exam Is Closed Book and Closed NotesPengintaiNo ratings yet

- Thrust Enhancement of A Convergent-Divergent Nozzle by Using CFDDocument9 pagesThrust Enhancement of A Convergent-Divergent Nozzle by Using CFDsalman khanNo ratings yet

- 7 Fluid Dynamics Tutorial SolutionDocument25 pages7 Fluid Dynamics Tutorial SolutionAldhaAhmadyaningratNo ratings yet

- Design and Optimisation of a Water Vortex Hydropower PlantDocument1 pageDesign and Optimisation of a Water Vortex Hydropower PlantJeff Barnard50% (2)

- Orifice Meter ReportDocument19 pagesOrifice Meter ReportDilli Babu PNo ratings yet

- Chapter1 Porous MediumDocument25 pagesChapter1 Porous MediumTalal GhanemNo ratings yet

- Hydrodynamics of Foaming Systems in Packed TowersDocument9 pagesHydrodynamics of Foaming Systems in Packed TowersdoufethiNo ratings yet

- CE 324 - Fluid Flow in Pipes - Pipes in Series, Pipes in Parallel, and Pipe Network PDFDocument23 pagesCE 324 - Fluid Flow in Pipes - Pipes in Series, Pipes in Parallel, and Pipe Network PDFjrpogicocNo ratings yet

- Two Dimensional Flow of Water Through SoilDocument28 pagesTwo Dimensional Flow of Water Through SoilMinilik Tikur SewNo ratings yet

- Lubricants For AUMA Products Grease or Oil Filling in The Gear HousingDocument1 pageLubricants For AUMA Products Grease or Oil Filling in The Gear HousingTEDDY KENCONONo ratings yet

- FLOW-3D Modeling of Catastrophic Dam BreachesDocument68 pagesFLOW-3D Modeling of Catastrophic Dam BreachesJorgeZafraNo ratings yet

- Dimensionless Group AnalysisDocument43 pagesDimensionless Group Analysis13670319No ratings yet

- TM - 2124 Kimia Fisika Hidrokarbon (Chapter Xi) NewDocument166 pagesTM - 2124 Kimia Fisika Hidrokarbon (Chapter Xi) Neweri dian ismayaNo ratings yet

- Abstract/Summary: V K M DP DLDocument17 pagesAbstract/Summary: V K M DP DLAdnan Nanda100% (1)

- HysecdesDocument4 pagesHysecdesHudanAchmadNo ratings yet