Professional Documents

Culture Documents

Yeast Making: Ffps - Frequently Faced Problems

Uploaded by

Phanhai KakaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Yeast Making: Ffps - Frequently Faced Problems

Uploaded by

Phanhai KakaCopyright:

Available Formats

B RY G R A M

www. b r y a i r. c o m

Yeast Making

15

FFPs Frequently Faced Problems

Yeast Making involves growing the organism in suitable Media. High temperature drying of yeast destroys the

organism, the most critical requirement for quality yeast making.

General Recommendations

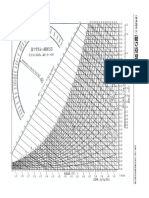

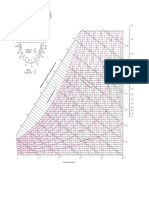

The quality of air required for drying of yeast has to be controlled and

moisture content kept between 10-14 grains/lb (1.6 gm/kg-2 gm/kg) or the

dewpoint of air must be in the region of 12-18F. (-11 to 7 C)

Solutions

The Background

The story of yeast is as old as the story of bread. For centuries, yeast has

been associated with bread making as a fermenting agent. The origin of

bread, though obscure, dates back to the Stone Age. Flat breads were

common in the late Stone Age, while raised bread developed around

4000 B.C. Traces of yeast were discovered in beer jars and beer breads were used as offerings in The ban tombs

in 2000 B.C. Fermentation, originally a matter of chance contamination of airborne yeast, was promoted by using a

piece of old dough. To this day, this is the method the most prestigious bakers choose. By 300 B.C., however,

yeast-making become a specialized profession. Yeast is now commonly available in packets and foil sachets in the

supermart. However, there is nothing new in its function of a raising agent for imparting that special light texture to

the bread we eat. Yeast is made up of living cells with the ability to change sugar into alcohol and carbon dioxide.

Making of Yeast

The yeast making process is as interesting as the bread it helps to make. Yeast making involves growing the

organism in suitable media. Pakmaya in Istanbul has been in the yeast making business since 1973. Located in

Izmir, the leading trade centre in Turkey, Pakmaya produces world-class instant and active dry yeast and exports

80% of its production worldwide. Yeast Making involves growing the organism in suitable Media. The crop is

harvested when a sufficient crop of cells has appeared. Pakmaya uses Saccharomyces cerevisal as the microorganism which is prepared in the laboratory as the seed yeast. This is then passed into a clear mineral salt-sugar

solution, used as the medium, where fermentation occurs. The temperature is kept constant for rapid growth to take

place. The yeast cells are then separated from the fluid in which they have grown by a filter process. The yeast

cells are mixed with starch cells and pressed into large cakes. Fresh yeast can survive only for a few weeks at

controlled temperature of 4C. Hence, it needs to be stored in specially constructed cold stores. On the other hand,

dry active yeast can be kept for two to three years without any loss of properties. Pakmaya, employing a special

technique, also manufactures dry yeast. Drying of yeast is intricate an intricate process, requiring cold dry air to

produce quality yeast without destroying the organism. The quality of air required for drying of yeast has to be

controlled and moisture content kept between 10-14 grains/ib (1.6 gm/kg-2gm/kg) or the dewpoint of air must be in

the region of 12-18F. (-11 to 7C)

The Solution

Bry-Air dehumidifiers maintain these stringent conditions in the drying area of yeast manufacturing. The

manufacture of yeast, as we have seen involves low temperature drying. Though elevated temperature ensures

faster drying, it can spoil the product quality. Bry-Air Equipment specializes in such applications. In conjunction with

air-conditioning plants, very dry air at low temperatures can be supplied for the product drying applications since

they are capable of maintaining RH as low as 1% or even lower at a constant level, regardless of ambient

conditions.

Modified on: 2nd August 2011

You might also like

- Bakery Technology - Yeast and Sourdough.3 PDFDocument22 pagesBakery Technology - Yeast and Sourdough.3 PDFabs microNo ratings yet

- Three Course MenuDocument7 pagesThree Course MenuShreyash BhiwapurkarNo ratings yet

- Final Project of Baker YeastDocument27 pagesFinal Project of Baker YeastTeena Alawad100% (1)

- Beer Prod ProcessDocument12 pagesBeer Prod Processteklemariam negashNo ratings yet

- How Is Malt MadeDocument4 pagesHow Is Malt MadeMOSEXNo ratings yet

- Malting - WikipediaDocument4 pagesMalting - WikipediaguidogiglioNo ratings yet

- Essay Description of Beer Brewing TechnologyDocument8 pagesEssay Description of Beer Brewing TechnologyМария БортаNo ratings yet

- BREAD of Fermented Cereal PresentationDocument7 pagesBREAD of Fermented Cereal PresentationAhmad Nur AyanlehNo ratings yet

- YeastDocument9 pagesYeastDan PintilescuNo ratings yet

- Bakery Technology - Yeast and Sourdough PDFDocument1 pageBakery Technology - Yeast and Sourdough PDFZoran MiladinovićNo ratings yet

- Malting: Current Practice in MaltingDocument7 pagesMalting: Current Practice in MaltingLokraj PantNo ratings yet

- Microbiological Production of Foods Baker's YeastDocument21 pagesMicrobiological Production of Foods Baker's YeastMd. Babul AktarNo ratings yet

- Yeast Production - General DiscussionDocument8 pagesYeast Production - General DiscussionDonesh VarshneyNo ratings yet

- Pollen ProductionDocument35 pagesPollen Productionbotond77No ratings yet

- Week #50 - CoffeeDocument1 pageWeek #50 - CoffeeGareth James Parry100% (4)

- PDF YeastDocument7 pagesPDF YeastNur Akbar Arofatullah100% (1)

- Paper No.: 12 Paper Title: Food Packaging Technology Module - 14: Packaging of Food Grains and Their FloursDocument8 pagesPaper No.: 12 Paper Title: Food Packaging Technology Module - 14: Packaging of Food Grains and Their FloursM SNo ratings yet

- Why Make Cheese? Remote Dairy Farming and the Benefits of CheesemakingDocument53 pagesWhy Make Cheese? Remote Dairy Farming and the Benefits of CheesemakingMaturino SalerniNo ratings yet

- MaltingDocument20 pagesMaltingSagar ShahNo ratings yet

- Mbio313 Assignment 01 181-025-031Document7 pagesMbio313 Assignment 01 181-025-031Razia UrmiNo ratings yet

- Bakers Yeast Production and Applications DoxccDocument21 pagesBakers Yeast Production and Applications DoxccYisak IsacNo ratings yet

- 1 MaltingDocument9 pages1 MaltingSara SilesNo ratings yet

- Brewing Industry: From Homebrew to Modern ProductionDocument19 pagesBrewing Industry: From Homebrew to Modern ProductionRay MondyNo ratings yet

- EastDocument4 pagesEastIra MironovaNo ratings yet

- Sliced Bread: The Science ofDocument4 pagesSliced Bread: The Science ofGayatri PrameswariNo ratings yet

- Bakery NoteDocument33 pagesBakery NotealfinmantonyNo ratings yet

- FermentationDocument24 pagesFermentationAMAN JATNo ratings yet

- Ilide - Info Biology Project PRDocument49 pagesIlide - Info Biology Project PRKeshav Singh ThakurNo ratings yet

- Spawn Production TechnologyDocument8 pagesSpawn Production TechnologythosampaNo ratings yet

- Cheese Ripening: Technological Aspects: Eva-Maria Dusterhoft, Wim Engels, and Thom Huppertz, NIZO, Ede, The NetherlandsDocument4 pagesCheese Ripening: Technological Aspects: Eva-Maria Dusterhoft, Wim Engels, and Thom Huppertz, NIZO, Ede, The NetherlandsBianca AndreeaNo ratings yet

- The Occurrence of StarchDocument7 pagesThe Occurrence of StarchDonesh VarshneyNo ratings yet

- What Is Yeast?Document42 pagesWhat Is Yeast?rakamech0% (1)

- Cheese MakingDocument11 pagesCheese MakingmassimoNo ratings yet

- Yeast Process ProductionDocument32 pagesYeast Process ProductionIndah Riwayati100% (1)

- 096 Mushroom CultivationDocument20 pages096 Mushroom CultivationJoão Louro BarataNo ratings yet

- Mushroom Spawn Production MethodsDocument3 pagesMushroom Spawn Production MethodsbalapsiNo ratings yet

- Brew Beer Like A Yeti - Chapter Three: GrainDocument22 pagesBrew Beer Like A Yeti - Chapter Three: GrainChelsea Green PublishingNo ratings yet

- Cereal Breakfast Food ProcessDocument12 pagesCereal Breakfast Food ProcessDani CostaNo ratings yet

- CHEESE: A GUIDE TO MANUFACTURING AND PACKAGINGDocument27 pagesCHEESE: A GUIDE TO MANUFACTURING AND PACKAGINGElvis DsouzaNo ratings yet

- Cultivation of White Button MushroomDocument21 pagesCultivation of White Button MushroomMeenuNo ratings yet

- Corn Starchmanufacturing 170416190429 PDFDocument51 pagesCorn Starchmanufacturing 170416190429 PDFAjay Sharma100% (1)

- Cheese GoudaDocument24 pagesCheese GoudaJhon Jairo ZambranoNo ratings yet

- CHEESE: A Concise Guide to Cheese History, Manufacturing, Exporting Countries and TypesDocument27 pagesCHEESE: A Concise Guide to Cheese History, Manufacturing, Exporting Countries and TypesNicoleta Mihaela BuzaNo ratings yet

- Distilled spirits guide to base ingredientsDocument9 pagesDistilled spirits guide to base ingredientsned_nickNo ratings yet

- Production & Downstream Processing of Baker's Best FriendDocument26 pagesProduction & Downstream Processing of Baker's Best FriendMelissaNo ratings yet

- A Brief History of BakingDocument6 pagesA Brief History of BakingGloria Le Thi EsquivelNo ratings yet

- Beverage Technology - Chapter Two - 2Document67 pagesBeverage Technology - Chapter Two - 2teklitNo ratings yet

- GAYODocument5 pagesGAYOAbas S. AcmadNo ratings yet

- Cultivation of White Button MushroomDocument21 pagesCultivation of White Button MushroomDeepti SinglaNo ratings yet

- Importance of Yeast in Food and Other IndustriesDocument43 pagesImportance of Yeast in Food and Other IndustriesResna N K Resi100% (1)

- Proizvodnja SiraDocument16 pagesProizvodnja Siramilan tosicNo ratings yet

- Raw Materials: Mixing and Kneading The DoughDocument3 pagesRaw Materials: Mixing and Kneading The Doughelvina_andreaNo ratings yet

- Mushroom Supervised ProjectDocument5 pagesMushroom Supervised Projectjennethalim734No ratings yet

- The Use of Grape By-Products As A Nutrient Rich Cattle Feed: Digitalcommons@University of Nebraska - LincolnDocument15 pagesThe Use of Grape By-Products As A Nutrient Rich Cattle Feed: Digitalcommons@University of Nebraska - LincolnMohamed MahmoudNo ratings yet

- Litreview CocoaDocument15 pagesLitreview Cocoaapi-534320285No ratings yet

- Alwadi International School Grade 9 Biology 20. Biotech and Genetic Engineering NotesDocument38 pagesAlwadi International School Grade 9 Biology 20. Biotech and Genetic Engineering NotesMohammed HelmyNo ratings yet

- Button MushroomDocument5 pagesButton MushroomJohn WickNo ratings yet

- The Irish Cookbook The Ultimate Guide To Irish Classic Recipes And Its History FoodFrom EverandThe Irish Cookbook The Ultimate Guide To Irish Classic Recipes And Its History FoodRating: 5 out of 5 stars5/5 (2)

- Sourdough Mastery: A Comprehensive Guide to Perfecting the Art of Bread MakingFrom EverandSourdough Mastery: A Comprehensive Guide to Perfecting the Art of Bread MakingNo ratings yet

- SilencersDocument79 pagesSilencersArshid SiddiquiNo ratings yet

- NoiseDocument220 pagesNoisemedrascomNo ratings yet

- Practice ABCDocument68 pagesPractice ABCMDCITYNo ratings yet

- FoamDocument13 pagesFoamPhanhai KakaNo ratings yet

- Grammar Reference CardDocument29 pagesGrammar Reference CardPhanhai KakaNo ratings yet

- Balancing of Distribution SystemDocument35 pagesBalancing of Distribution Systemebru_alpaslan50% (2)

- (Mayu) Shin - I - Bunpou PDFDocument177 pages(Mayu) Shin - I - Bunpou PDFPhanhai Kaka100% (1)

- 4 X 6 inDocument1 page4 X 6 inPhanhai KakaNo ratings yet

- Nature and the Environment Document SummaryDocument6 pagesNature and the Environment Document SummaryblackcatnogoNo ratings yet

- Grammar Reference Card Adjectives Final2 0Document1 pageGrammar Reference Card Adjectives Final2 0Rina MargaritaNo ratings yet

- Squadron Signal 6015 Soviet Aircraft of TodayDocument82 pagesSquadron Signal 6015 Soviet Aircraft of TodayArdavan Kazemi100% (2)

- Physical properties data tables and referencesDocument32 pagesPhysical properties data tables and referencesmidooooo198767% (3)

- 33.Uploads-downloads-DOWN 64DF6E44CA656ABFBG33 Sausage DryingDocument1 page33.Uploads-downloads-DOWN 64DF6E44CA656ABFBG33 Sausage DryingPhanhai KakaNo ratings yet

- 32.Uploads-downloads-DOWN - F11B00DF2423BABEBG32 - Engine Testing Room For AutomobilesDocument1 page32.Uploads-downloads-DOWN - F11B00DF2423BABEBG32 - Engine Testing Room For AutomobilesPhanhai KakaNo ratings yet

- Printable Spencerian Practice Sheets PDFDocument5 pagesPrintable Spencerian Practice Sheets PDFPhanhai Kaka100% (3)

- Leather Storage: Ffps - Frequently Faced ProblemsDocument2 pagesLeather Storage: Ffps - Frequently Faced ProblemsPhanhai KakaNo ratings yet

- Do Thi Id1Document1 pageDo Thi Id1Phanhai KakaNo ratings yet

- 31.Uploads-downloads-DOWN 17C7C39CB9F6A97EBG31 Dynamite StorageDocument1 page31.Uploads-downloads-DOWN 17C7C39CB9F6A97EBG31 Dynamite StoragePhanhai KakaNo ratings yet

- Maintaining the Sultan's Vintage Car CollectionDocument1 pageMaintaining the Sultan's Vintage Car CollectionPhanhai KakaNo ratings yet

- 28.uploads Downloads DOWN DB425AEBD06A0289BG28 MushroomDocument1 page28.uploads Downloads DOWN DB425AEBD06A0289BG28 MushroomPhanhai KakaNo ratings yet

- 27.Uploads-downloads-DOWN 83915B42C61BD757BG27 Printer RollerDocument1 page27.Uploads-downloads-DOWN 83915B42C61BD757BG27 Printer RollerPhanhai KakaNo ratings yet

- 30.Uploads-downloads-DOWN 1B01F1A4DF91062DBG30 Bridge CorrosionDocument2 pages30.Uploads-downloads-DOWN 1B01F1A4DF91062DBG30 Bridge CorrosionPhanhai KakaNo ratings yet

- Maintaining the Sultan's Vintage Car CollectionDocument1 pageMaintaining the Sultan's Vintage Car CollectionPhanhai KakaNo ratings yet

- 17.uploads Downloads DOWN D22A32D31D1BBFC8Brygram17 SoleLeatherDocument1 page17.uploads Downloads DOWN D22A32D31D1BBFC8Brygram17 SoleLeatherPhanhai KakaNo ratings yet

- T-S ChartDocument1 pageT-S ChartPhanhai KakaNo ratings yet

- PCB Assembly humidity controlDocument1 pagePCB Assembly humidity controlPhanhai KakaNo ratings yet

- Maintain Bowling Alleys at 30% RHDocument1 pageMaintain Bowling Alleys at 30% RHPhanhai KakaNo ratings yet

- 13.uploads Downloads DOWN 9812E97C19F9B525Brygram13 FertilizerDocument1 page13.uploads Downloads DOWN 9812E97C19F9B525Brygram13 FertilizerPhanhai KakaNo ratings yet

- 11.uploads Downloads DOWN 7ED44AD7836805A0Brygram11 SemiconductorDocument1 page11.uploads Downloads DOWN 7ED44AD7836805A0Brygram11 SemiconductorPhanhai KakaNo ratings yet

- MOM'S HOMEMADE CHILI RECIPES FOR COLD DAYSDocument4 pagesMOM'S HOMEMADE CHILI RECIPES FOR COLD DAYSMat UyinNo ratings yet

- The Adventure of The Abbey Grange: Arthur Conan DoyleDocument13 pagesThe Adventure of The Abbey Grange: Arthur Conan DoyleTim BonineNo ratings yet

- Science: Given The Drawings Inside The Box, Answer Question 16-18Document9 pagesScience: Given The Drawings Inside The Box, Answer Question 16-18Jonabel Delos SantosNo ratings yet

- Basic Belgian Waffle RecipeDocument7 pagesBasic Belgian Waffle RecipepingusorNo ratings yet

- RecipeDocument1 pageRecipeJennifer RubicineNo ratings yet

- The Iceman ComethDocument3 pagesThe Iceman ComethAdrian HernandezNo ratings yet

- Palakova TayariDocument25 pagesPalakova TayarijadigeetaNo ratings yet

- Culinary Math Lesson on Yield Percent, Costing Recipes & BeveragesDocument10 pagesCulinary Math Lesson on Yield Percent, Costing Recipes & BeveragescindibellamyNo ratings yet

- Lớp 9 Reported SpeechDocument3 pagesLớp 9 Reported SpeechThảo PhươngNo ratings yet

- Explore Asian CuisineDocument18 pagesExplore Asian CuisineSenthil KumarNo ratings yet

- An Eggy ExperimentDocument3 pagesAn Eggy Experimentapi-260628215No ratings yet

- STP Analysis of HorlicksDocument8 pagesSTP Analysis of HorlicksHarshit SrivastavaNo ratings yet

- Chef Dennis - Taste of Autumn PDFDocument15 pagesChef Dennis - Taste of Autumn PDFLauren Grow50% (2)

- Cosmopolitan January-2016 PreviewDocument20 pagesCosmopolitan January-2016 PreviewTammy Hanson100% (2)

- Edition 1 2019 20Document7 pagesEdition 1 2019 20api-268652510No ratings yet

- Request For Judicial Notice in Support of Defendant City 02-05-15 (m130393)Document39 pagesRequest For Judicial Notice in Support of Defendant City 02-05-15 (m130393)L. A. PatersonNo ratings yet

- Data Stok 25kDocument4,367 pagesData Stok 25kRosiati NarniNo ratings yet

- Heladera Beko - Manual de UsuarioDocument71 pagesHeladera Beko - Manual de UsuarioPedro FontenlaNo ratings yet

- 10 Laws For The CommunityDocument2 pages10 Laws For The CommunitysantasantitaNo ratings yet

- Lessons From Umm Ma'bad's LifeDocument3 pagesLessons From Umm Ma'bad's LifeFayyaz Abbasi100% (1)

- The West Wing-102 - Post Hoc, Ergo Propter HocDocument53 pagesThe West Wing-102 - Post Hoc, Ergo Propter Hocv642336No ratings yet

- Korean PhrasesDocument54 pagesKorean Phrasescolderas jethNo ratings yet

- NaOCl Test ProcedureDocument11 pagesNaOCl Test ProcedureTrivik BhavnaniNo ratings yet

- TOEIC Advanced Audioscript PDFDocument47 pagesTOEIC Advanced Audioscript PDFAmine ChafiiNo ratings yet

- Price List For JulyDocument5 pagesPrice List For JulyQim SvNo ratings yet

- Activities Week 4Document13 pagesActivities Week 4api-357680810No ratings yet

- Surplus Catalog 2013Document64 pagesSurplus Catalog 2013pajocagaNo ratings yet

- Liberian Daily Observer 12/3/2013Document22 pagesLiberian Daily Observer 12/3/2013Liberian Daily Observer NewspaperNo ratings yet

- Unit 9Document19 pagesUnit 9PhạmThanhThủyNo ratings yet

- GEcdhsDocument611 pagesGEcdhslivhatchNo ratings yet