Professional Documents

Culture Documents

En 10060 - Tolerances

Uploaded by

Ayush JainOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

En 10060 - Tolerances

Uploaded by

Ayush JainCopyright:

Available Formats

TOLERANCES

Hot rolled products tolerances

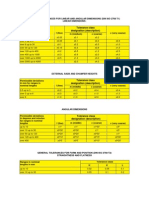

HOT ROLLED ROUND STEEL BARS DIAMETER TOLERANCES (EN 10060: 2003)

Diameter Normal Diameter Normal Diameter Normal Diameter Normal

(mm) tolerance (mm) (mm) tolerance (mm) (mm) tolerance (mm) (mm) tolerance (mm)

10 30 70 140

12 32 ±0,6 73 145

±1

13 ±0,4 35 75 150 ±2

14 36 80 155

15 38 85 160

16 40 90 165

±1,3

18 42 ±0,8 95 170

19 45 100 175

±2,5

20 ±0,5 48 105 180

22 50 110 190

±1,5

24 52 115 200

25 55 120 220 ±3

26 60 ±1 125 250 ±4

27 ±0,6 63 130 ±2

28 65 135

The bar diameter, measured at any point situated at least 100 mm from the end of the bar, shall be in accordance to the tolerances of the schedule.

Cold shearing may deform the bars ends. The condition of the ends may be agreed at time of inquiry and order.

HOT ROLLED ROUND BARS STRAIGHTNESS TOLERANCES (EN 10060: 2003)

Nominal diameter (mm) Tolerance (mm)

d ≤ 25 Not established

q

25 < d ≤ 80 q ≤ 0,4% di L

L

80 < d ≤ 250 q ≤0,25% di L

Note: the straightness shall be measured along the total lenght of the bar.

HOT ROLLED ROUND BARS ROUNDNESS TOLERANCES (EN 10060: 2003)

The roundness or ovality error is the difference between the bigger and the smaller diameter of the same section.

It shall be measured at least 100 mm from the ends of the bar and shall not exceed over 75% of tolerance on diameter.

WIRE RODS TOLERANCES

Wire rod in free cutting steels, case hardening steels, steels for

Wire rod in steels for cold heading and cold extrusion

quenching and tempering, steels for surface hardening, stainless steel

Tolerances in accordance to EN 10017: 2004 Tolerances in accordance to EU 108-72 grade A - UNI 7356-74

Diameter (mm) Tolerance (mm) Diameter (mm) Tolerance (mm)

from to from to

5,0 9,5 ±0,3 5,50 10,00 ±0,25

10,0 15,5 ±0,4 10,50 15,50 ±0,30

16,0 25,0 ±0,5 16,00 21,50 ±0,35

26,0 39,0 ±0,6 22,00 30,00 ±0,40

40,0 50,0 ±0,8

WIRE RODS ROUNDNESS TOLERANCES (EN 10017: 2004)

The roundness or ovality error is the difference between the bigger and the smaller diameter of the same section.

It shall be measured at least 100 mm from the ends of the bar and shall not exceed over 80% of tolerance on diameter.

TOLERANCES

Bright bars tolerances

BRIGHT STEEL PRODUCTS CLASSES TOLERANCES (EN 10278: 2002)

Tolerance class according to ISO 286-2

Delivery condition

h7 h8 h9 h10 h11 h12

Cold drawn - - R R R-H-S R-H-S

Turned - - R R R R

Ground R R R R R R

R= Round; H= Hexagon; S= Square.

The dimensional tolerances shall be chosen among those allowed in the table.

BRIGHT STEEL BARS RODACCIAI STANDARD DIMENSION TOLERANCES

Cold drawn hexagon

Cold drawn - Round Turned Ground

and square

Dimensional

h10 h11 h10 h9

tolerances

If not differently agreed at time of inquiry and order, the dimension tolerances for bright steel bars shall be in accordance to values provided in table.

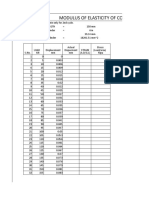

BRIGHT STEEL BARS DIMENSION TOLERANCES (EN 10278: 2002)

Nominal dimension (mm)

h7 h8 h9 h10 h11 h12 k13*

from to

1 3 0,010 0,014 0,025 0,040 0,060 0,100 +0,14

3 6 0,012 0,018 0,030 0,048 0,075 0,120 +0,18

6 10 0,015 0,022 0,036 0,058 0,090 0,150 +0,22

10 18 0,018 0,027 0,043 0,070 0,110 0,180 +0,27

18 30 0,021 0,033 0,052 0,084 0,130 0,210 +0,33

30 50 0,025 0,039 0,062 0,100 0,160 0,250 +0,39

50 80 0,030 0,046 0,074 0,120 0,190 0,300 +0,46

80 120 0,035 0,054 0,087 0,140 0,220 0,350 +0,54

120 180 0,040 0,063 0,100 0,160 0,250 0,400 +0,63

180 200 0,046 0,072 0,115 0,185 0,290 0,460 +0,72

*= Field not included in EN 10278.

For h tolerance the dimensions are all below the nominal dimensions. The maximum value corresponds to the nominal dimension, while the field amplitude of tolerance is listed

in the table.

Actual dimension of the bar shall be measured at least 150 mm from the end of the bar, in accordance to EN 10278.

The table includes also the K13 tolerance, which RODACCIAI uses for rough turned stainless steel products (1X process route). This deviation is over the nominal dimension.

TOLERANCES

BRIGHT STEEL BARS STRAIGHTNESS TOLERANCES (EN 10278: 2002)

Product form Steel group Nominal diameter (mm) Deviation max (mm)

< 0,25%C 1,0

≥ 0,25%C

alloy steels 1,5

Rounds

quenched and tempering steels

stainless steels

1,0

tool steels

< 0,25%C d ≤75 mm 1,0

≥ 0,25%C

alloy steels d ≤75 mm 2,0

quenched and tempering steels

stainless steels

d ≤75 mm 1,0

tool steels

Squares and hexagons

< 0,25%C d >75 mm 1,5

≥ 0,25%C

alloy steels d >75 mm 2,5

quenched and tempering steels

stainless steels

d >75 mm 1,5

tool steels

Unless otherwise specified, the tolerances of this table will be applied.

BRIGHT STEEL BARS OUT-OF-ROUND TOLERANCES (EN 10278: 2002)

Maximum deviation from out-of-round shall be no more than half the specified tolerance and in any case never above the upper

limit of tolerance.

Tolerance for wire products

This is a general table, it is therefore recommended to specify the tolerances required at time of order.

TOLERANCES FOR WIRE PRODUCTS (DIN 1782-93)

Diameter (mm) Tolerance

min max

0,112÷0,17 -0,004 +0,004

0,18÷0,27 -0,006 +0,006

0,28÷0,44 -0,008 +0,008

0,45÷0,70 -0,010 +0,010

0,71÷1,00 -0,015 +0,015

You might also like

- En 10263-2 2001Document7 pagesEn 10263-2 2001Luca TurraNo ratings yet

- BS en Iso 10644-2009 PDFDocument14 pagesBS en Iso 10644-2009 PDFMadheswaran Dharmapuri100% (1)

- Iso 286 2 2010Document15 pagesIso 286 2 2010Samsu100% (3)

- ISO 1035-4:1982 Hot-Rolled Steel Bar TolerancesDocument10 pagesISO 1035-4:1982 Hot-Rolled Steel Bar TolerancesRober Moises Chumbe SoveroNo ratings yet

- DIN HANdsfsDBOOK 1 PDFDocument6 pagesDIN HANdsfsDBOOK 1 PDFsohaiblatif3No ratings yet

- DIN ISO Equivalent FastenersDocument12 pagesDIN ISO Equivalent FastenersGunnie PandherNo ratings yet

- Iso 9445-2-2009Document14 pagesIso 9445-2-2009Necdet AydemirNo ratings yet

- Tolerance en 22768-1 - 2Document1 pageTolerance en 22768-1 - 2Vandamme Wouter100% (4)

- Hollow Bars (ISO2938)Document8 pagesHollow Bars (ISO2938)suku maranNo ratings yet

- En 10278 PDFDocument3 pagesEn 10278 PDFErnestoNo ratings yet

- Iso 2768-2 PDFDocument11 pagesIso 2768-2 PDFAndrew Barley100% (3)

- En 10084 DIN Case Hardening Steels Technical Delivery ConditionsDocument39 pagesEn 10084 DIN Case Hardening Steels Technical Delivery ConditionsAlessandroAleotti100% (1)

- Din 434Document1 pageDin 434RaduZapciroiuNo ratings yet

- Iso 2768 1 PDFDocument12 pagesIso 2768 1 PDFHung80% (5)

- Iso 4042 PDFDocument25 pagesIso 4042 PDFAditya Pratap100% (6)

- Mechanical Properties - Bolt, Nut, FastenersDocument4 pagesMechanical Properties - Bolt, Nut, FastenersmegatornadoNo ratings yet

- Din 8062-3 2009 PDFDocument10 pagesDin 8062-3 2009 PDFkoalaboi33% (3)

- En 10051 PDFDocument2 pagesEn 10051 PDFSrikanth Reddy0% (1)

- Jis 1196Document19 pagesJis 1196VISHAL kUMARNo ratings yet

- Din en Iso 7090Document8 pagesDin en Iso 7090Jennifer Owens100% (2)

- Iso 7379Document2 pagesIso 7379Ahmed ElsafouryNo ratings yet

- Dinen 10079 - 200706 - enDocument46 pagesDinen 10079 - 200706 - enAnonymous dvrhf5No ratings yet

- Iso 68-1 PDF - Google SearchDocument2 pagesIso 68-1 PDF - Google SearchDeniz Tuncbilek0% (1)

- DIN 936 DIV 5655: Hexagon Thin Nuts Hexagon Nuts, (H D)Document3 pagesDIN 936 DIV 5655: Hexagon Thin Nuts Hexagon Nuts, (H D)linijatzNo ratings yet

- ISO 3269 SamplingDocument4 pagesISO 3269 Samplingscribd14341No ratings yet

- DIN EN10278 1999 Dimensions and Tolerances of Bright Steel ProductsDocument15 pagesDIN EN10278 1999 Dimensions and Tolerances of Bright Steel ProductsKovács Zsolt100% (1)

- ISO 8062 3 2007 Casting Tolerance PDFDocument1 pageISO 8062 3 2007 Casting Tolerance PDFPankajMakwanaNo ratings yet

- Iso 4014Document16 pagesIso 4014Emílio BeckerNo ratings yet

- ISO Tolerance Part 2Document50 pagesISO Tolerance Part 2hieu01np86% (7)

- Iso 2338Document6 pagesIso 2338stanyeah100% (2)

- BS en 10060 2003Document12 pagesBS en 10060 2003VeraNo ratings yet

- Ford Fastener Standard for WashersDocument17 pagesFord Fastener Standard for WashersRico MalibiranNo ratings yet

- DIN EN 10277-2 Bright Steel 1999Document11 pagesDIN EN 10277-2 Bright Steel 1999Hans GoetheNo ratings yet

- ISO 6411 Centre HoleDocument9 pagesISO 6411 Centre HoleMarioNo ratings yet

- 2370 Ed1 ENDocument5 pages2370 Ed1 ENanhthoNo ratings yet

- Din 929 - 01-00Document5 pagesDin 929 - 01-00qualidade1fameqNo ratings yet

- BS en 10297 1Document46 pagesBS en 10297 1Somnath DaschoudhuriNo ratings yet

- ISO 2768 TolerancesDocument2 pagesISO 2768 TolerancesJan Van de Velde100% (2)

- En 10283Document16 pagesEn 10283vasea100% (4)

- En 10139Document2 pagesEn 10139releone11No ratings yet

- BS en 10060-2003 Hot Rolled Round Steel Bars For General Purposes. Dimensions and Tolerances On Shape and DimensionsDocument12 pagesBS en 10060-2003 Hot Rolled Round Steel Bars For General Purposes. Dimensions and Tolerances On Shape and Dimensionshand42100% (2)

- Din en 10083 3 2007Document58 pagesDin en 10083 3 2007PedroNo ratings yet

- Iso 4032-2012 PDFDocument9 pagesIso 4032-2012 PDFBao100% (1)

- Iso 4035Document10 pagesIso 4035xcvNo ratings yet

- Din 580Document1 pageDin 580safaozhanNo ratings yet

- Hot-Rolled Products TolerancesDocument3 pagesHot-Rolled Products TolerancesAndrew TanNo ratings yet

- Polyurethane Pneumatic Tubing Shore 98 A Data Sheet PDFDocument1 pagePolyurethane Pneumatic Tubing Shore 98 A Data Sheet PDFnikhilnv123No ratings yet

- L-9517-9154-08-B Data Sheet RESM enDocument12 pagesL-9517-9154-08-B Data Sheet RESM enAlex ZXNo ratings yet

- Current ratings flexible cables non-existing types tablesDocument1 pageCurrent ratings flexible cables non-existing types tablesvanessa quispeNo ratings yet

- T14 Conductor ResistanceDocument1 pageT14 Conductor ResistancebcostiucNo ratings yet

- Resistencias SMD WIN-1524917Document4 pagesResistencias SMD WIN-1524917Ignacio Barriga NuñezNo ratings yet

- CORSON (C7025) : Cu-Ni-Si ALLOYDocument2 pagesCORSON (C7025) : Cu-Ni-Si ALLOYstrip1No ratings yet

- Current Sense Low Value Resistors: Part Number StructureDocument3 pagesCurrent Sense Low Value Resistors: Part Number StructureraveendraNo ratings yet

- Lab-1 PRC ReportDocument4 pagesLab-1 PRC ReportShanzayNo ratings yet

- Cycloidal Follower Displacement: Theta (Deg)Document24 pagesCycloidal Follower Displacement: Theta (Deg)navdinNo ratings yet

- DIN16742 2013A Eng Plastics Moulded Parts Tolerance Acceptance ConditionsDocument1 pageDIN16742 2013A Eng Plastics Moulded Parts Tolerance Acceptance ConditionsNoe MarinNo ratings yet

- Tolerancije Limova I CeviDocument4 pagesTolerancije Limova I CeviZoran Tanja JarakovićNo ratings yet

- 7MPa Concrete Blocks TDS - v2Document7 pages7MPa Concrete Blocks TDS - v2Slinky BillNo ratings yet

- KoenigDocument14 pagesKoenigUday GurijalaNo ratings yet

- Know Your Personality TypeDocument2 pagesKnow Your Personality TypeAyush JainNo ratings yet

- Indian Standard For Drinking Water As Per BIS Specifications - 2010Document26 pagesIndian Standard For Drinking Water As Per BIS Specifications - 2010Ayush Jain100% (1)

- European Immigration Lawyers Network - Brochure - English2010Document4 pagesEuropean Immigration Lawyers Network - Brochure - English2010Ayush JainNo ratings yet

- Titan Medical Systems Pvt. Ltd. Vs Collector of Customs On 12 November, 2002Document4 pagesTitan Medical Systems Pvt. Ltd. Vs Collector of Customs On 12 November, 2002Ayush JainNo ratings yet

- European Immigration Lawyers Network - Brochure - English2010Document4 pagesEuropean Immigration Lawyers Network - Brochure - English2010Ayush JainNo ratings yet

- Indian Standard For Drinking Water As Per BIS Specifications - 2010Document26 pagesIndian Standard For Drinking Water As Per BIS Specifications - 2010Ayush Jain100% (1)

- CG Module 1 NotesDocument64 pagesCG Module 1 Notesmanjot singhNo ratings yet

- KINETIC THEORY OF GASES TUTORIALDocument6 pagesKINETIC THEORY OF GASES TUTORIALMat SyafiqNo ratings yet

- Idioms & Phrases Till CGL T1 2016Document25 pagesIdioms & Phrases Till CGL T1 2016mannar.mani.2000100% (1)

- Acuity Assessment in Obstetrical TriageDocument9 pagesAcuity Assessment in Obstetrical TriageFikriNo ratings yet

- Baseline Program Rev 3A Presentation 25 July 2020Document24 pagesBaseline Program Rev 3A Presentation 25 July 2020Shakti Sourava RautrayaNo ratings yet

- Chapter 10 AP GP PDFDocument3 pagesChapter 10 AP GP PDFGeorge ChooNo ratings yet

- Oecumenius’ Exegetical Method in His Commentary on the RevelationDocument10 pagesOecumenius’ Exegetical Method in His Commentary on the RevelationMichał WojciechowskiNo ratings yet

- Antennas Since Hertz and MarconiDocument7 pagesAntennas Since Hertz and MarconiTaiwo Ayodeji100% (1)

- SB Z Audio2Document2 pagesSB Z Audio2api-151773256No ratings yet

- Fundermax Exterior Technic 2011gb WebDocument88 pagesFundermax Exterior Technic 2011gb WebarchpavlovicNo ratings yet

- DENSO COMMON RAIL INJECTOR REPAIR GUIDEDocument22 pagesDENSO COMMON RAIL INJECTOR REPAIR GUIDEMarcoNo ratings yet

- Private Schools Provide Better EducationDocument2 pagesPrivate Schools Provide Better EducationcitraNo ratings yet

- KAC-8102D/8152D KAC-9102D/9152D: Service ManualDocument18 pagesKAC-8102D/8152D KAC-9102D/9152D: Service ManualGamerAnddsNo ratings yet

- Reiki BrochureDocument2 pagesReiki BrochureShikha AgarwalNo ratings yet

- 3D Area Clearance Strategies for Roughing ComponentsDocument6 pages3D Area Clearance Strategies for Roughing ComponentsMohamedHassanNo ratings yet

- Canon imageFORMULA DR-X10CDocument208 pagesCanon imageFORMULA DR-X10CYury KobzarNo ratings yet

- Handouts For TLG 3 1Document5 pagesHandouts For TLG 3 1Daniela CapisnonNo ratings yet

- Hyperbaric WeldingDocument17 pagesHyperbaric WeldingRam KasturiNo ratings yet

- Product ListDocument4 pagesProduct ListyuvashreeNo ratings yet

- Reflective Essay 4Document1 pageReflective Essay 4Thirdy AngelesNo ratings yet

- 7890 Parts-Guide APDocument4 pages7890 Parts-Guide APZia HaqNo ratings yet

- Transport of OxygenDocument13 pagesTransport of OxygenSiti Nurkhaulah JamaluddinNo ratings yet

- CAE The Most Comprehensive and Easy-To-Use Ultrasound SimulatorDocument2 pagesCAE The Most Comprehensive and Easy-To-Use Ultrasound Simulatorjfrías_2No ratings yet

- Placenta Previa Case Study: Adefuin, Jay Rovillos, Noemie MDocument40 pagesPlacenta Previa Case Study: Adefuin, Jay Rovillos, Noemie MMikes CastroNo ratings yet

- 12 Week Heavy Slow Resistance Progression For Patellar TendinopathyDocument4 pages12 Week Heavy Slow Resistance Progression For Patellar TendinopathyHenrique Luís de CarvalhoNo ratings yet

- The Art of Now: Six Steps To Living in The MomentDocument5 pagesThe Art of Now: Six Steps To Living in The MomentGiovanni AlloccaNo ratings yet

- Young Women's Sexuality in Perrault and CarterDocument4 pagesYoung Women's Sexuality in Perrault and CarterOuki MilestoneNo ratings yet

- Taking Back SundayDocument9 pagesTaking Back SundayBlack CrowNo ratings yet

- A6 2018 D Validation Qualification Appendix6 QAS16 673rev1 22022018Document12 pagesA6 2018 D Validation Qualification Appendix6 QAS16 673rev1 22022018Oula HatahetNo ratings yet

- Are Hypomineralized Primary Molars and Canines Associated With Molar-Incisor HypomineralizationDocument5 pagesAre Hypomineralized Primary Molars and Canines Associated With Molar-Incisor HypomineralizationDr Chevyndra100% (1)