Professional Documents

Culture Documents

Download

Uploaded by

Anizah IdrisOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Download

Uploaded by

Anizah IdrisCopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

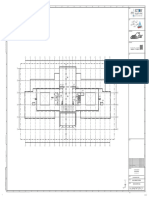

IF IN DOUBT ASK DO NOT SCALE

A A

B B

10 THICK PADS

620.12 400.14 R3

2

ty

p

560.07 280.06

32 typ

C 5 C

208.00

485.06

381.06

1500

104.00

D D

"A" "A"

104.00

381.06

485.06

180 NOM.

208.00

85.00

E E

38.00

180.13 660.00 180.13

F F

WELD PREPARATION

G END OF TUBES TO BE ACCURATELY CONTOURED TO MATE WITH ADJACENT MEMBERS 788.48 Ref G

SUCH THAT THE GAP BETWEEN TUBES IS A MAXIMUM OF 1.5mm. THEN A FULL

PREPARATION MUST BE MADE ALL AROUND THE SECTION AS DETAILED. 40 DIA THRO PADS

389.78 ref

WHERE A FILLET TYPE OF WELD IS REQUIRED WHERE A BACKING METAL EXISTS IN

44.50 ref

THE FORM OF THE MATING TUBE WALL A PREPARATION MUST BE MADE FOR THE

ENTIRE CIRCUMFERENCE.

00°

28 DIA THRO BEAM

REFERENCE SHOULD BE MADE TO THE SPECIFIC JOINT ON DETAIL DRAWING TO

210.

H DETERMINE THE DOMINANT TUBE MEMBER(S) FOR EXAMPLE THE MAIN LOAD BEARER H

FOLLOWED BY THE NEXT IN ORDER OF IMPORTANCE AND SO ON TO DETERMINE HOW

THE JOINT MUST BE CONFIGURED TO AVOID WEAKENING SECTIONS WELD

PREPARATIONS SHOULD BE SMOOTH AND ALL PARTS THOUROUGHLY CLEANED PRIOR

0

TO WELDING. 50 typ

10.0

00

1211.28

1365.68

120.00°

6.

d14

A VISUAL INSPECTION SHOULD BE MADE INITIALLY TO IDENTIFY ANY POOR OR BADLY

57

d1

FINISHED WELDS AND THESE SHOULD BE GROUND OUT AND RE WELDED.

85min. TYP.

73

J ALL WELDS SHOULD HAVE A GOOD VISUAL APPEARANCE AND BE SMOOTH TO ENSURE J

GOOD GALVANISING/PAINT ADHESHION AND PREVENT WATER TRAPS AND CREVICE

15°

CORROSION.

° 10°

15

WELD METAL SHOULD NOT BE REMOVED TO THE DETRIMENT OF THE WELD STRENGTH.

ANY RECTIFICATION DEEMED NECESSARY MUST BE CARRIED OUT PRIOR TO VSR.

TUBULAR STRUCTURES SHOULD BE VIBRATORY STRESS RELIEVED (VSR) IN

ACCORDANCE WITH EASAT SPECIFICATION EA6732. BY AN APPOINTED AGENT FOR THE

K PROCESS AFTER STRESS RELIEVING THE WELDS SHOULD BE CHECKED IN K

ACCORDANCE WITH THE DRAWING INSTRUCTIONS USING MPI AND DIE PENETRANT ON

THE CRITICAL WELDS.

THE STRUCTURE SHOULD THEN BE PRESSURE TESTED IN ACCORDANCE WITH EASAT

PROCEDURE EA10986 AND RECTIFIED IF REQUIRED.

RETEST AFTER ANY RECTIFICATION WORK

25 GROUT

L L

38.00

130

easat

520.00

Tel:01782 208028 Fax: 01782 208060

M Email: antenna@easat.co.uk M

TITLE :-

DETAILS OF SUPPORT

STRUCTURE FOR St Frieux

FABRICATION ± 1/16" OR 1.5mm

TOLERANCES

CONFIDENTIAL DRAWN BJ DATE 22:2:06 SCALE 1:10

FRACTIONAL ± 1/64" OR 0.5mm

THIS DESIGN IS THE PROPERTY OF EASAT ANTENNAS

N N

REVISION

LTD NEITHER THIS DRAWING OR THE DESIGN CONCEPTS

DECIMAL ± 0.008" OR 0.2mm

CONTAINED HEREIN, MAY BE USED OR REPRODUCED CHECKED AUTHORISED

IN WHOLE OR IN PART TO A THIRD PARTY WITHOUT

WRITTEN PERMISSION FROM THE COMPANY

DRG No. EA10944 ISS 1 REV 3

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

You might also like

- Circuit diagram analysisDocument1 pageCircuit diagram analysisXuNo ratings yet

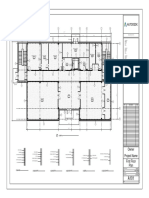

- 2Nd Sty Plan - Lighting Layout: Construction DrawingDocument1 page2Nd Sty Plan - Lighting Layout: Construction DrawingrajavelNo ratings yet

- Pilar H.A.:P1 Pilar H.A.:P2: A B C D E FDocument1 pagePilar H.A.:P1 Pilar H.A.:P2: A B C D E FclaudioNo ratings yet

- Pergola Design 2Document1 pagePergola Design 2raheemNo ratings yet

- C.LY70.SE.84.1-F2000/FLB001 01: NG - Erdgas / Natural GasDocument1 pageC.LY70.SE.84.1-F2000/FLB001 01: NG - Erdgas / Natural GasEngr. AtiqNo ratings yet

- H 5125610 3D251 R2 PDFDocument2 pagesH 5125610 3D251 R2 PDFomarNo ratings yet

- Fire Alarm Lantai 3Document1 pageFire Alarm Lantai 3Ilham AdiNo ratings yet

- Imt Manesar Cable Tray Layout-2ND BASEMENTDocument1 pageImt Manesar Cable Tray Layout-2ND BASEMENTALOK SINGHNo ratings yet

- Vu 1105 070822Document1 pageVu 1105 070822api-3698996No ratings yet

- Limita Zona Protectie Autostrada 50m Fata de Axul Drumului (Conf. OG43/1997-Anexa1, Lit. B)Document1 pageLimita Zona Protectie Autostrada 50m Fata de Axul Drumului (Conf. OG43/1997-Anexa1, Lit. B)ciciNo ratings yet

- PDF Pembahasan Osk Fisika 2023Document5 pagesPDF Pembahasan Osk Fisika 2023syakurahyNo ratings yet

- Bravo 1272m : Vacant 376m Penti 103mDocument1 pageBravo 1272m : Vacant 376m Penti 103mRufat AbdullayevNo ratings yet

- Fire Alarm Lantai 3 MezzanineDocument1 pageFire Alarm Lantai 3 MezzanineIlham AdiNo ratings yet

- Stone Chrusher - Functional Schematic Block AGEV1Document5 pagesStone Chrusher - Functional Schematic Block AGEV1Ahmed SalamaNo ratings yet

- 2Nd Sty Plan - Fire Services: Construction DrawingDocument1 page2Nd Sty Plan - Fire Services: Construction DrawingrajavelNo ratings yet

- Campus Map 8 5x11Document2 pagesCampus Map 8 5x11MeiNo ratings yet

- Vu 1205 070822Document1 pageVu 1205 070822api-3698996No ratings yet

- 1St Sty Plan - Power Layout: Construction DrawingDocument1 page1St Sty Plan - Power Layout: Construction DrawingrajavelNo ratings yet

- CS 4944 - JCT A B & C - CH5 SHAFT EX. DRAWING - R00 (Sheet 1of6)Document1 pageCS 4944 - JCT A B & C - CH5 SHAFT EX. DRAWING - R00 (Sheet 1of6)محمد طولانNo ratings yet

- Debussy - Petite Suite Arr. Guitar & PianoDocument2 pagesDebussy - Petite Suite Arr. Guitar & PianoBert Lietaert100% (1)

- A-109-Ablution & Residence - Basement, Ground, and First Floor PlansDocument1 pageA-109-Ablution & Residence - Basement, Ground, and First Floor PlansEmmanuel InfanteNo ratings yet

- Naffco: Verified By: Mohammad Jaber AlmajediDocument1 pageNaffco: Verified By: Mohammad Jaber AlmajediArun UdayabhanuNo ratings yet

- 2Nd Storey Plan - Elv Installation: Construction DrawingDocument1 page2Nd Storey Plan - Elv Installation: Construction DrawingrajavelNo ratings yet

- CABLE TRENCH & FOUNDATION LAYOUT - SitaburdiDocument1 pageCABLE TRENCH & FOUNDATION LAYOUT - Sitaburdisayanti.koley18No ratings yet

- Schematic - Class-D Sub Monoblok - 2021-07-18Document1 pageSchematic - Class-D Sub Monoblok - 2021-07-18Sneha NamdevNo ratings yet

- May 022010Document6 pagesMay 022010RSNo ratings yet

- Weekday Schedule: Outbound InboundDocument1 pageWeekday Schedule: Outbound Inboundrcoffey_3No ratings yet

- Diagram - XAS 57-97 DD WUXDocument1 pageDiagram - XAS 57-97 DD WUXCovid 55100% (1)

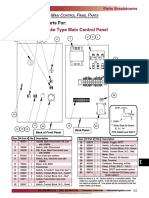

- p165 NI Main Control Panel PartsDocument1 pagep165 NI Main Control Panel PartsFRANCISCO JAVIER RUEDA LOPEZNo ratings yet

- Legenda:: Traseu Lapte CrudDocument4 pagesLegenda:: Traseu Lapte CrudUdrea NicolaeNo ratings yet

- Citi Housing SocietyDocument1 pageCiti Housing SocietyAhmad NawazNo ratings yet

- T - DO1013 - Rev2Document9 pagesT - DO1013 - Rev2jorgekarlosprNo ratings yet

- DS450 2009 Wiring DiagramDocument1 pageDS450 2009 Wiring Diagrambobby brownNo ratings yet

- Diagrama ZT315Document26 pagesDiagrama ZT315percyctba FilhoNo ratings yet

- Module 5 - Course Project Site FinalDocument10 pagesModule 5 - Course Project Site Finalapi-607203670No ratings yet

- P.HM5L 20-M0300 LAY001lDocument1 pageP.HM5L 20-M0300 LAY001lĐứcNo ratings yet

- Atlascompressor 11cvDocument1 pageAtlascompressor 11cvdenilsonNo ratings yet

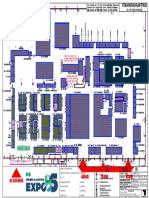

- P4c02-Snw-Tv-Mec-Sgt-Sho-2010 - Ecs-Street Level Ducting Layout Key Plan-P4c02-Snw-Tv-Mec-Sgt-Sho-2011Document1 pageP4c02-Snw-Tv-Mec-Sgt-Sho-2010 - Ecs-Street Level Ducting Layout Key Plan-P4c02-Snw-Tv-Mec-Sgt-Sho-2011ManojNo ratings yet

- 1St Sty Plan - Fire Services: Construction DrawingDocument1 page1St Sty Plan - Fire Services: Construction DrawingrajavelNo ratings yet

- Vu 1202 070822Document1 pageVu 1202 070822api-3698996No ratings yet

- MHL360 669-859Document177 pagesMHL360 669-859diego milanNo ratings yet

- Retaining wall design detailsDocument1 pageRetaining wall design detailsFadliNo ratings yet

- X0231 PDW Ecb DG 20003 AaDocument1 pageX0231 PDW Ecb DG 20003 AajianranrenNo ratings yet

- MariborDocument2 pagesMariborburcucukNo ratings yet

- 0320289-TE-DAD-6410-006-00 SEPARATOR 10HHA30AT001-ModelDocument1 page0320289-TE-DAD-6410-006-00 SEPARATOR 10HHA30AT001-ModelVivek VinayakumarNo ratings yet

- A2 Km. 186+580 ST PDFDocument1 pageA2 Km. 186+580 ST PDFciciNo ratings yet

- Subway LevelDocument1 pageSubway LevelManojNo ratings yet

- Lower DevelopmentDocument1 pageLower DevelopmentManojNo ratings yet

- Steeldeck 3F PDFDocument1 pageSteeldeck 3F PDFlouie n. gustoNo ratings yet

- Steeldeck 3F PDFDocument1 pageSteeldeck 3F PDFlouie n. gustoNo ratings yet

- DR-CST-800-0003 - Rev ADocument1 pageDR-CST-800-0003 - Rev APinak ProjectsNo ratings yet

- B01 TL104MDocument1 pageB01 TL104Malysamir.eetdNo ratings yet

- Di Ma Dangwa YerusalemDocument2 pagesDi Ma Dangwa YerusalemJibuin King NkanjohsonNo ratings yet

- Pavilion B2Document1 pagePavilion B2Razvan OrzataNo ratings yet

- Week 9 Presentation Compilation 2Document3 pagesWeek 9 Presentation Compilation 2Yosef AbateNo ratings yet

- Peavey 6505PLUS 112 SchematicDocument9 pagesPeavey 6505PLUS 112 SchematicR .GNo ratings yet

- (HalcyonMusic) Nasuo - Honey Jet CoasterDocument6 pages(HalcyonMusic) Nasuo - Honey Jet CoasterTri hieuNo ratings yet

- 2022 Livelaw (SC) 331: Hemant Gupta V. Ramasubramanian, JJDocument7 pages2022 Livelaw (SC) 331: Hemant Gupta V. Ramasubramanian, JJMAHIMANo ratings yet

- A 529 Wardrobe DetailsDocument1 pageA 529 Wardrobe DetailsEmmanuel InfanteNo ratings yet

- June 2023 BillingDocument10 pagesJune 2023 BillingEsther AkpanNo ratings yet

- 02 - AFT - Know Your Pump & System Curves - Part 2ADocument8 pages02 - AFT - Know Your Pump & System Curves - Part 2AAlfonso José García LagunaNo ratings yet

- W2AEW Videos (Apr 29, 2017) Topics Listed NumericallyDocument12 pagesW2AEW Videos (Apr 29, 2017) Topics Listed Numericallyamol1agarwalNo ratings yet

- FM200 Clean Agent System Installation GuideDocument6 pagesFM200 Clean Agent System Installation Guidehazro lizwan halimNo ratings yet

- TRISCO Version 13 AnnouncementDocument42 pagesTRISCO Version 13 AnnouncementGiuseppe OnorevoliNo ratings yet

- Hanoi 2023 Peoples Picks AwardsDocument113 pagesHanoi 2023 Peoples Picks AwardsNguyen Anh VuNo ratings yet

- Compression Molding of Gypsum Blocks Using Ecological Brick MachinesDocument11 pagesCompression Molding of Gypsum Blocks Using Ecological Brick Machinessami fanuaelNo ratings yet

- JASA 1st Anniversary Issue 2012 PDFDocument103 pagesJASA 1st Anniversary Issue 2012 PDFSuresh NatarajanNo ratings yet

- Cap Tikus As Symbol of Social Closeness in The Life of The Minahasa PeopleDocument3 pagesCap Tikus As Symbol of Social Closeness in The Life of The Minahasa PeopleEdwinNo ratings yet

- Doctors Appointment - 4!14!17 Acid RefluxDocument11 pagesDoctors Appointment - 4!14!17 Acid RefluxRay Edwin Anderson IIINo ratings yet

- CH 2 Atoms, Ions, and MoleculesDocument64 pagesCH 2 Atoms, Ions, and MoleculesBritney SimmsNo ratings yet

- ABRACON's Tuning Fork Crystals and Oscillators for 32.768kHz RTC ApplicationsDocument13 pagesABRACON's Tuning Fork Crystals and Oscillators for 32.768kHz RTC Applicationsdit277No ratings yet

- Captain Marvel (DC Comics) : Shazam! Navigation SearchDocument34 pagesCaptain Marvel (DC Comics) : Shazam! Navigation SearchAce Orense Cupid Uranus Ace Sphinx Galzu Acetr444 son of Multiverses Chaos Gaeia Eros ACETR444No ratings yet

- SRWM M.PDocument34 pagesSRWM M.PAmare BayeNo ratings yet

- Kodak Film StructureDocument40 pagesKodak Film StructureThu Thu SheinNo ratings yet

- Mibk - TDS PDFDocument3 pagesMibk - TDS PDFMardianus U. RihiNo ratings yet

- CSS9 TQ PT 3rd4thDocument8 pagesCSS9 TQ PT 3rd4thJevan Hope BaltazarNo ratings yet

- Is This Normal or ADHDDocument52 pagesIs This Normal or ADHDDianaNo ratings yet

- 10 Tips To Protect Yourself From Unhealthy AirDocument2 pages10 Tips To Protect Yourself From Unhealthy AirAnonymous XuFb6TNo ratings yet

- FH400 73158464 Pca-6.140Document431 pagesFH400 73158464 Pca-6.140IgorGorduz100% (1)

- Astm F477-08Document4 pagesAstm F477-08ALARCONISTANo ratings yet

- 6013 GCS-CONTROLS enDocument5 pages6013 GCS-CONTROLS enMuhammad SyaqirinNo ratings yet

- Mcu-R4nek0n+submittal 04212020Document2 pagesMcu-R4nek0n+submittal 04212020Jaime A. AlvarezNo ratings yet

- Final 401Document8 pagesFinal 401Hong Chul NamNo ratings yet

- Potensi Energi Listrik Yang Dihasilkan Dari Emisi Gas Metana Di Tpa Suwung Provinsi BaliDocument8 pagesPotensi Energi Listrik Yang Dihasilkan Dari Emisi Gas Metana Di Tpa Suwung Provinsi BaliNuyul FaizahNo ratings yet

- 21734Document67 pages21734Jeef100% (4)

- Tests On Cement: IS: 4031 Part 4 1988 (Indian Standards)Document1 pageTests On Cement: IS: 4031 Part 4 1988 (Indian Standards)Lorna BacligNo ratings yet

- Sony Ericsson K610i, K610m, and V630i Service ManualDocument53 pagesSony Ericsson K610i, K610m, and V630i Service ManualJane TodoroskiNo ratings yet