Professional Documents

Culture Documents

Ultrasound v. Radiography For Thermowells

Uploaded by

Christian R. TaylorOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultrasound v. Radiography For Thermowells

Uploaded by

Christian R. TaylorCopyright:

Available Formats

Ultrasound v. Radiography on Thermowells

Radiographic Testing of flanged thermowells is not the ideal NDT application to achieve Volumetric

NDT and Evaluation. The reason it is not “ideal” is because the source should be perpendicular to the

weld, and because of the flange, this is unachievable with the resources available to anyone in the

industry. If the source was placed perpendicular to the weld, the X-Rays would have to penetrate the

entire diameter of the flange. The ratio of the flange diameter compared to the diameter of the

thermowell is on average, 6 to 1. If a strong enough source of radiation or X-Ray is used to penetrate the

entire diameter of the flange then the thermowell simply disappears in the negative image of the film or

digital image. What has typically been performed to satisfy customer requests is to take shots (multiple

shots) at an angle (30° - 50°). This technique technically does not meet ASME Code and can be

somewhat costly. By performing the X-Ray at an angle, detrimental defects such as cracks can be missed

because of the superimposing of the image at an angle rather than perpendicular.

Ultrasound however has a unique technique called Shear Wave. This is an Ultrasonic Testing Method

which can scan the entire volume of the weld at an angle. Shear Wave does qualify as Volumetric NDT

and is a proven method and an extremely accurate method to inspect welds for flaws. Flanges do impose

some challenges to ultrasound because of the distance between the bolt holes and the weld, however

PANAMETRICS NDT introduced a few years back a short approach wedge, which has ultimately

eliminated this limitation. Using the short approach wedges allows the transducer to be considerably

closer to the weld being scanned by ultrasound. The surface distance is reduced by 50% or more.

Another challenge is that ultrasound may not be accurate detecting defects open to the surface and this

would be true if both sides were not scanned. Daily Thermetrics scans both sides. Shear Wave is very

effective in finding defects open to the surface from the adjacent side. However, if so desired by the

customer, Penetrant or Magnetic Particle Testing can be performed on the surface of the welds to ensure

the surface integrity of the welds. It is Daily Thermetrics Corporation’s Standard Practice to perform

ultrasonic testing by the Shear Wave technique on every full penetration weld manufactured.

Christian R. Taylor

QHSE Manager

Level II NDT UT, PT, MT, VT, LT, RTFI

Daily Thermetrics Corporation

You might also like

- ABB 3HAC050988 AM Arc and Arc Sensor RW 6-En PDFDocument238 pagesABB 3HAC050988 AM Arc and Arc Sensor RW 6-En PDForefat1No ratings yet

- Client: Pt. STBC Location: Autoclave 3 & 4 Report No.: 001-PAUT/RBT-STBC/XI/2022Document60 pagesClient: Pt. STBC Location: Autoclave 3 & 4 Report No.: 001-PAUT/RBT-STBC/XI/2022Rizal HidayatullahNo ratings yet

- PAUT - Phased Array and ToFD - V - Radiography PDFDocument14 pagesPAUT - Phased Array and ToFD - V - Radiography PDFdarouichNo ratings yet

- Guided Wave Presentation NDT Global 1Document41 pagesGuided Wave Presentation NDT Global 1Ahmed LepdaNo ratings yet

- Rexroth Trainingprogram 2022 enDocument171 pagesRexroth Trainingprogram 2022 enRavi JoshiNo ratings yet

- Daily Lrut Report: Lrut Instrument Lrut Probe TechniqueDocument1 pageDaily Lrut Report: Lrut Instrument Lrut Probe TechniqueSang Nguyen QuangNo ratings yet

- RT Level II Course Notes PDF FreeDocument169 pagesRT Level II Course Notes PDF FreeAhmad ToufailyNo ratings yet

- Ironscan - RT Study Material - FinalDocument111 pagesIronscan - RT Study Material - FinalselvamNo ratings yet

- Aubrey Debut ScriptDocument5 pagesAubrey Debut ScriptKevin Jones CalumpangNo ratings yet

- 020 L & T Hazira LTD. 25.11.2022 PI PDFDocument1 page020 L & T Hazira LTD. 25.11.2022 PI PDFAadhya engineering ServicesNo ratings yet

- Hertz Inspection Service PVT LTD Irc1Document18 pagesHertz Inspection Service PVT LTD Irc1Rahul N PatelNo ratings yet

- BPV Code Section V - Administrative Level IIIDocument24 pagesBPV Code Section V - Administrative Level IIIDanfer De la CruzNo ratings yet

- Induction Hardening - Interpretation of Drawing & Testing PDFDocument4 pagesInduction Hardening - Interpretation of Drawing & Testing PDFrajesh DESHMUKHNo ratings yet

- SRUTDocument10 pagesSRUTcakravartin servicesNo ratings yet

- Radiography of WeldsDocument15 pagesRadiography of WeldsSuphi YükselNo ratings yet

- MATH8-Relations and Functions Worksheet AnswersDocument15 pagesMATH8-Relations and Functions Worksheet AnswersRhealyn Joy Narciso100% (2)

- D p5 BV Ms 012 Msra For BorescopeDocument4 pagesD p5 BV Ms 012 Msra For BorescopeThinh NguyenNo ratings yet

- Method Statement For Near Field Test: DCSM Project 2019Document5 pagesMethod Statement For Near Field Test: DCSM Project 2019Thinh NguyenNo ratings yet

- NDT Xl-Ut-05.1 Babbit QualityDocument7 pagesNDT Xl-Ut-05.1 Babbit QualityRon KentNo ratings yet

- X-MET Presentation PDFDocument39 pagesX-MET Presentation PDFTechnical A-Star Testing & Inspection MalaysiaNo ratings yet

- Bhel UtDocument14 pagesBhel UtAnonymous 6k4VeeRNo ratings yet

- Scholly Endoscopie 1 PDFDocument80 pagesScholly Endoscopie 1 PDFAhmed shabanNo ratings yet

- BHNK Drill Pipe CatalogDocument12 pagesBHNK Drill Pipe CatalogivertianNo ratings yet

- Ultra Sound Testing: Opic:-Test Methods and TechniquesDocument23 pagesUltra Sound Testing: Opic:-Test Methods and TechniquesVarun MalanNo ratings yet

- The Dedication of the Broken Hearted SailorDocument492 pagesThe Dedication of the Broken Hearted SailorGabriele TorresNo ratings yet

- D-p5-Bv-pd-001 - RT, Issue 01, Rev 00 - Radiographic ExaminationDocument101 pagesD-p5-Bv-pd-001 - RT, Issue 01, Rev 00 - Radiographic ExaminationThinh NguyenNo ratings yet

- BR N-1594 D - Non Destructive Testing - UltrasonicDocument20 pagesBR N-1594 D - Non Destructive Testing - UltrasonicJose Alejandro Mansutti GNo ratings yet

- Level-II Course Material - UTDocument171 pagesLevel-II Course Material - UTprem aleNo ratings yet

- PT DSAW Linear Indication in API B L1 Plates ReportDocument16 pagesPT DSAW Linear Indication in API B L1 Plates ReportrichadNo ratings yet

- Vishnu Chemicals Limited FD Fan Vibration Analysis ReportDocument15 pagesVishnu Chemicals Limited FD Fan Vibration Analysis ReportSekhar Tellakula [Sands]100% (1)

- OGTC Tubular Inspection Report Format FindingsDocument1 pageOGTC Tubular Inspection Report Format FindingsMuhammad Bilal KhattakNo ratings yet

- S-022-1520-0002PM HDPE Control Procedure RevADocument10 pagesS-022-1520-0002PM HDPE Control Procedure RevAHoang Phuong NguyenNo ratings yet

- UT Level1&2Document69 pagesUT Level1&2MohaammedNo ratings yet

- 1588-1326 Hyd Jar ...Document1 page1588-1326 Hyd Jar ...khalilNo ratings yet

- Iris Inspection Report: Tube MappingDocument10 pagesIris Inspection Report: Tube MappingArief WisnuNo ratings yet

- Srihari Katari 11 Jan 2022Document50 pagesSrihari Katari 11 Jan 2022Abhishek DevarajNo ratings yet

- Engineering Company Provides Steam Pipeline SolutionsDocument14 pagesEngineering Company Provides Steam Pipeline SolutionssojeckNo ratings yet

- Coflexip Hose (Tr1-031851clm301)Document1 pageCoflexip Hose (Tr1-031851clm301)RonniNo ratings yet

- Practical Ultrasonic Inspection GuideDocument95 pagesPractical Ultrasonic Inspection GuidemohamedNo ratings yet

- Calibration and Usage Procedure for A-Scan & Digital Ultrasonic GaugeDocument8 pagesCalibration and Usage Procedure for A-Scan & Digital Ultrasonic Gaugesyasha humairaNo ratings yet

- 1303-9 Chain Sling..Document2 pages1303-9 Chain Sling..khalilNo ratings yet

- Steel Grades Material and Chemical Composition InformationDocument2 pagesSteel Grades Material and Chemical Composition InformationMitesh PhalakNo ratings yet

- Defect / Non Compliance Report: International LimitedDocument41 pagesDefect / Non Compliance Report: International LimitedMichael OkwuwaNo ratings yet

- MTM BrochureDocument8 pagesMTM BrochureMohamed100% (1)

- Audit NDT Basics PDFDocument41 pagesAudit NDT Basics PDFJindarat KasemsooksakulNo ratings yet

- Near Bit Stabilizer PDS 6716 ...Document1 pageNear Bit Stabilizer PDS 6716 ...khalilNo ratings yet

- CRYSOUND - Corporate Standard For Acoustic Imaging Partial Discharge DetectionDocument8 pagesCRYSOUND - Corporate Standard For Acoustic Imaging Partial Discharge DetectionPhương Lương TấnNo ratings yet

- SRINIVASAN CHANDRAN's ResumeDocument4 pagesSRINIVASAN CHANDRAN's ResumePaul PhiliphsNo ratings yet

- NDT Project RailwayTrackDocument9 pagesNDT Project RailwayTrackusmanNo ratings yet

- Measuring Fillet Weld Size It's Easy Right - Karsten Madsen - Pulse - LinkedInDocument5 pagesMeasuring Fillet Weld Size It's Easy Right - Karsten Madsen - Pulse - LinkedInnkvonNo ratings yet

- Z2T-DFEP003-QAM-TP-0013 - 0-Ultrasonic Test of Secondary Bottom Annular Pl...Document42 pagesZ2T-DFEP003-QAM-TP-0013 - 0-Ultrasonic Test of Secondary Bottom Annular Pl...EdAlmNo ratings yet

- Floormap3Di Training Course ProductDocument8 pagesFloormap3Di Training Course ProductTechnical A-Star Testing & Inspection MalaysiaNo ratings yet

- Report NDT Centaur 45 May 2023Document44 pagesReport NDT Centaur 45 May 2023muhamadfikri2177No ratings yet

- NDE Radiographic Exam ProcedureDocument51 pagesNDE Radiographic Exam Procedure이경훈No ratings yet

- SA27 WedgesDocument1 pageSA27 WedgesPurvi RocksNo ratings yet

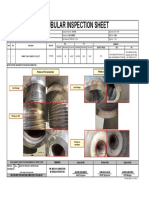

- Tubular Inspection Sheet - 2021-002 Pg.1Document1 pageTubular Inspection Sheet - 2021-002 Pg.1Aldrin HernandezNo ratings yet

- YKEPL MPI Procedure For A668 RMDocument4 pagesYKEPL MPI Procedure For A668 RMDeepak HoleNo ratings yet

- Examination Procedure For Magnetic Particle InspectionDocument21 pagesExamination Procedure For Magnetic Particle InspectionOsilonya HenryNo ratings yet

- Magnetic Particle Exam GuideDocument18 pagesMagnetic Particle Exam GuidemohamedNo ratings yet

- UT PROCEDURE TITLEDocument29 pagesUT PROCEDURE TITLESivasankarNo ratings yet

- Patels Radiography Services RT ReportDocument1 pagePatels Radiography Services RT ReportRavi patelNo ratings yet

- Jsa TubularDocument2 pagesJsa TubularRonniNo ratings yet

- Welding Inspection ToolsDocument1 pageWelding Inspection ToolsWeld Map DrawingNo ratings yet

- Ultrasonic Tank Floor Corrosion AssessmentDocument6 pagesUltrasonic Tank Floor Corrosion AssessmentleonciomavarezNo ratings yet

- NDT Methods for Weld Inspection - Radiography and UltrasonicsDocument2 pagesNDT Methods for Weld Inspection - Radiography and Ultrasonicshayder1920No ratings yet

- PDLAMMPS - made easy: An introductionDocument8 pagesPDLAMMPS - made easy: An introductionSaeed AbdNo ratings yet

- DGPS Sensor JLR-4331W Instruction ManualDocument42 pagesDGPS Sensor JLR-4331W Instruction ManualantonioNo ratings yet

- Weber Grills - FinalDocument12 pagesWeber Grills - FinalDIVYANSHU SHEKHARNo ratings yet

- 19 - Speed, Velocity and Acceleration (Answers)Document4 pages19 - Speed, Velocity and Acceleration (Answers)keyur.gala100% (1)

- News Writing April 2019Document39 pagesNews Writing April 2019Primrose EmeryNo ratings yet

- Fund. of EnterpreneurshipDocument31 pagesFund. of EnterpreneurshipVarun LalwaniNo ratings yet

- Uji Deteksi Biofilm Dari Isolat Klinik Kateter Urin Bakteri Entercoccus Dibandingkan Dengan Tube MethodDocument27 pagesUji Deteksi Biofilm Dari Isolat Klinik Kateter Urin Bakteri Entercoccus Dibandingkan Dengan Tube MethodIyannyanNo ratings yet

- 2021 - Tet Purchase Behavior Report - INFOCUSDocument15 pages2021 - Tet Purchase Behavior Report - INFOCUSGame AccountNo ratings yet

- Deforestation Management System Using Force and SoundDocument4 pagesDeforestation Management System Using Force and SoundManeesh SvsNo ratings yet

- IotDocument88 pagesIotLalithyaNo ratings yet

- Module 37 Nur 145Document38 pagesModule 37 Nur 145Marga WreatheNo ratings yet

- Tipologie Break in OutDocument17 pagesTipologie Break in OutGiorgio FantauzziNo ratings yet

- History: Ludwig Hunger: About Us: Home - Ludwig Hunger GMBHDocument3 pagesHistory: Ludwig Hunger: About Us: Home - Ludwig Hunger GMBHPatrizio MassaroNo ratings yet

- Retired Car Jacker Screen PlayDocument4 pagesRetired Car Jacker Screen Playapi-633948182No ratings yet

- Semen RetentionDocument3 pagesSemen RetentionMattNo ratings yet

- Sample Field Trip ReportDocument6 pagesSample Field Trip ReportBILAL JTTCNo ratings yet

- Request Letter Group 7Document1 pageRequest Letter Group 7Brent PatarasNo ratings yet

- The Grey Nomads Guide To AustraliaDocument3 pagesThe Grey Nomads Guide To AustraliaFreerangecamping60% (5)

- Ebook Drugs and The Neuroscience of Behavior An Introduction To Psychopharmacology 2Nd Edition Prus Test Bank Full Chapter PDFDocument62 pagesEbook Drugs and The Neuroscience of Behavior An Introduction To Psychopharmacology 2Nd Edition Prus Test Bank Full Chapter PDFeffigiesbuffoonmwve9100% (10)

- ME 2141 - Complete ModuleDocument114 pagesME 2141 - Complete ModuleNICOLE ANN MARCELINONo ratings yet

- Gps Vehicle Tracking System ProjectDocument3 pagesGps Vehicle Tracking System ProjectKathrynNo ratings yet

- BMW Mini COoper Installation InstructionsDocument1 pageBMW Mini COoper Installation InstructionsEdiJonNo ratings yet

- Tec Relay 52GDocument3 pagesTec Relay 52Gimmer nainggolanNo ratings yet

- 4thinternationalconferencetheimportanceofplace Proceedings 2017 PDFDocument428 pages4thinternationalconferencetheimportanceofplace Proceedings 2017 PDFnerko86No ratings yet

- 10risk Assessment and ComahDocument25 pages10risk Assessment and ComahHansraj RahulNo ratings yet