Professional Documents

Culture Documents

Fuel Tank Ring Beam Design Calculation

Uploaded by

Dawson Preethi EACopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fuel Tank Ring Beam Design Calculation

Uploaded by

Dawson Preethi EACopyright:

Available Formats

Fuel Tank Ring Beam Design Calculation

This Design Calculation for Ring Beam Design for Fuel Tank at Bamenda Power Plant is based on

the Design Guidelines provided by "Process Industry Practices Structural: PIP

STE03020 -Guidelines for Tank Foundati on Desi gns".

Concrete Design is according to the BS 8110:1997 and ACI 318 as applies relevantly.

Loading for Fuel Tank:

Ultimate Limit State loads for foundation design work, from Fuel Tank Designer Shop Drawing,

attached in Appendix 1

permanent loads at empty and full conditions, P1e, P1f

P

1e

593kN := P

1f

6970kN :=

Operation loads at empty and full conditions, P2e, P2f

P

2e

113kN := P

2f

113kN :=

Normal Wind loads at empty and full conditions, P3e, P3f

P

3e

60kN := P

3f

60kN :=

Extreme Wind loads at empty and full conditions, P4e, P4f

P

4e

103.5kN :=

P

4f

103.5kN :=

Service Limit State loads for foundation design work, from Fuel Tank Designer Shop Drawing,

attached in Appendix 1

permanent loads at empty and full conditions, p1e, p1f

p

1e

395kN := p

1f

4648kN :=

Operation loads at empty and full conditions, p2e, p2f

p

2e

75kN := p

2f

75kN :=

Normal Wind loads at empty and full conditions, p3e, p3f

p

3e

40kN := p

3f

40kN :=

Extreme Wind loads at empty and full conditions, p4e, p4f

p

4e

69kN := p

4f

69kN :=

El Madar Engineering Projects 1 of 11 DP

Tank Geometrical Data (from vendor drawing-attached in Appendix 2):

Tank Di ameter, Dt D

t

9500mm :=

Tank Height, Ht H

t

6000mm :=

Wall Plate Thickness,WPt WP

t

6mm :=

Bottom Plate Thickness,BPt BP

t

6mm :=

Height of liquid, Hl

H

l

5500mm :=

Densities of Material contributing loads:

Density of Fuel, f

f

8.32

kN

m

3

:=

Density of Steel, .st

st

78.50

kN

m

3

:=

Density of Concrete, c

c

24

kN

m

3

:=

Soil Parameters:

Soil Repose angle and Active Pressure Coecient, ka

35deg := k

a

1 sin

( )

1 sin

( )

+

:=

Passive Coecient of Soil , Kp and Cohesion Intercept , Cs.

k

p

1

k

a

:= C

s

5

kN

m

2

:=

Soil Bearing Capacity, SBC as per Soil Investigation Report:

SBC 1.2bar :=

Density of Soil, s

s

18

kN

m

3

:=

El Madar Engineering Projects 2 of 11 DP

Concrete Design Data:

f

cu

29

N

mm

2

:=

f

y

460

N

mm

2

:=

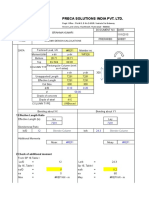

Ring Beam Dimensions:

ring beam height, hr h

r

1000mm :=

ring beam width,br b

r

400mm := > minimum ring beam width 300mm

ring beam diameter, dr D

r

9500mm := as per Tank Shop Drawi ng shell

diameter matching with ring beam

diameter to transfer load minimum

eccentricity.

Design of Ring Beam-part 1 -Soil Bearing Capacity Consideration

Soil Bearing Pressure under Ring Beam and the inll soil pressure at the same bottom level of

the foundation should be kept equal as far as possible, to avoid settlement due to punching

shear.

So for this reason rst it will be calculated the Shell Wall weight [Ww] directly transferring

onto the Ring Beam with self weight [Fsw] of the ring beam. This total Soil Pressure will be

compared against the inll soil pressure to see the dierence.

Empty Tank Load on SLS will be consi dered as the Shel l Wall loading onto the Ring Beam,

hence

approximate Actual Shell Wall Load without xing arrangements and accessories, AWw,

AW

w

WP

t

H

t

st

D

r

2

|

\

|

|

2

WP

t

st

D

r

2 + := <-lesser

value, not

considered.

AW

w

5.063

kN

m

=

Shell Wall Load at SLS,

W

w

p

1e

D

r

:= W

w

13.235

kN

m

=

for Ring Beam Design Calculation the Shell Wall loading will be considered as Ww.

El Madar Engineering Projects 3 of 11 DP

Soil Pressure calculation from Ring Beam at SLS,

Ring Beam self weight, RBsw

RB

sw

D

r

2

b

r

2

+

|

\

|

|

2

D

r

2

b

r

2

\

|

|

(

(

(

h

r

c

D

r

9.6

kN

m

= :=

Ring Beam Dimensions

Loading from the Fuel inside the tank, Wf

W

f

H

l

f

:= W

f

45.76

kN

m

2

=

soil pressure due to Ring Wall and Shell Wall loading at SLS,

Soil Bearing Pressure under ring wall,

rwsw

rwsw

W

w

RB

sw

+

( )

D

r

W

f

D

r

2

b

r

2

+

|

\

|

|

2

D

r

2

|

\

|

|

(

(

(

D

r

2

b

r

2

+

|

\

|

|

2

D

r

2

b

r

2

\

|

|

(

(

(

:=

Soil Bearing Capacity Factor of Safety at SLS:

rwsw

80.449

kN

m

2

=

SBC

rwsw

1.492 = > 1.25 ok

El Madar Engineering Projects 4 of 11 DP

FORCES ON RING BEAM

Surcharge load and inll soil load stress at Ring Beam bottom level:

Loading onto the Soil Fill as surcharge, Ss

S

s

p

1f

p

2f

+

D

r

2

b

r

2

+

|

\

|

|

h

r

s

+ 79.356

kN

m

2

= :=

Soil Bearing Pressure under tank, Ss S

s

79.356

kN

m

2

=

actual soil loading based on Tank Desi gner SLS Loading Data is higher than the pure Fuel and

Soil pressure loading, below shown, hence Ss calculation is conservative.

H

l

f

h

r

s

+ 63.76

kN

m

2

=

rwsw

S

s

1.014 = ratio between ring beam bottom soil pressure and inll soil inside,

approx =1.

at SLS the pressure under Ring Beam is approximately equal to the SLS soil pressure due to inll,

hence the Ring Beam width is sucient.

Ring Beam width, br b

r

400 mm =

El Madar Engineering Projects 5 of 11 DP

At ULS , with Fuel lled up to allowable full height of the tank, the soil pressure under Ring

Beam,

ULS

rwsw

P

1e

D

r

RB

sw

+

|

\

|

|

D

r

W

f

D

r

2

b

r

2

+

|

\

|

|

2

D

r

2

|

\

|

|

(

(

(

D

r

2

b

r

2

+

|

\

|

|

2

D

r

2

b

r

2

\

|

|

(

(

(

:=

ULS

rwsw

97.035

kN

m

2

=

SBC

ULS

rwsw

1.237 = > 1.2 ok

Ring Beam Wall Design

Lateral loading transferred into the wall are two types, one is from the inll soil lateral

pressure and the other will be from surcharge load due to the tank weight and fuel inside.

Due to inll soil,

p

1

k

a

h

r

s

:=

p

1

4.878

kN

m

2

=

due to surcharge of the Tank weight under SLS conditions,

p

2

k

a

S

s

:=

p

2

21.505

kN

m

2

=

Lateral Force on Ring Beam per unit length,

F

1

p

1

h

r

2

p

2

h

r

+ :=

F

1

23.944

kN

m

=

Hoop Tension Calculation,

H

T

F

1

D

r

2

113.732 kN = :=

H

T

0.87 f

y

12mm

2

|

\

|

|

2.513 =

to take this Hoop Tension, 3 nos of T12 bars are enough, hence check for the ULS for minimum

reinforcement requirement.

El Madar Engineering Projects 6 of 11 DP

this conrms that reinforcement

detailing must be dominant to this

design of tension reinforcement.

k

a

P

1f

D

r

2

|

\

|

|

h

r

k

a

h

r

s

h

r

2

+

(

(

(

(

D

r

2

0.87 f

y

12mm

2

|

\

|

|

3.052 =

Minimum Reinforcement Requirement for the Ring Beam, treating it as a pure Tension

Member, as per Table 3.25 BS 8110: 1997 Part 1: Code of practice for design and construction,

A

smin

0.45% h

r

b

r

( )

:= A

smin

1800 mm

2

=

A

smin

12mm

2

|

\

|

|

(

(

15.915 = 16 bars of T12

For Vertical minimum reinforcement requirement, as per the Design Guidelines of "PIP

STE03020 -Guidelines for Tank Foundati on Desi gns" recommending ACI 318 code

requirements,

Av

smin

0.0015 h

r

b

r

( )

:= Av

smin

600 mm

2

=

Av

smin

12mm

2

|

\

|

|

(

(

5.305 = 6 bars of T12

provide 16T12 in longitudinal direction and T12@150mm in lateral direction.

Design Check for Shear

Shear Load on the Ring Beam,

s

s

W

w

b

r

0.033

N

mm

2

= :=

eective depth of the Ring Beam, d1

d

1

h

r

60mm 12mm

12mm

2

:= d

1

922 mm =

El Madar Engineering Projects 7 of 11 DP

material factor,

m

1.25 :=

Design Shear Stress calculation, considering tension r/f provided, the Design Concrete Shear Stress

C as per BS 8110: 3.5.5 Shear resistance of solid slabs,

C

0.79

100

12mm

2

|

\

|

|

2

16

b

r

d

1

(

(

(

(

1

3

400mm

d

1

|

\

|

|

1

4

f

cu

25

N

mm

2

|

\

|

|

|

|

1

3

N

mm

2

:=

C

0.425

N

mm

2

=

s

12.847 = Shear Reinforcement is not required.

Checking For Wind Loading for Stability:

Fuel Tank Diameter and Height i s withi n li mits as following that Wi nd Analysis is not required.

H

t

D

t

0.632 = which is less than 1 , no need to check for lateral loading of wind.

Even though this Fuel Tank is not anchored to the Foundati on hence check must be done for

overturning which following criteria is adopted,

reference: Saudi Aramco Best Practice, SABP-005 - 31 August, 2002/ Storage Tank Ringwal l

Foundation Design.

Overturning Moment under ULS, for extreme wind force,

M

ot

P

4f

H

t

:=

M

ot

621 kN m =

Resisting Moment under ULS, for empty tank, with 2/3 reduction,

M

r

2

3

P

1e

D

r

2

:=

M

r

1877.833 kN m =

M

r

M

ot

3.024 = hence safe.

El Madar Engineering Projects 8 of 11 DP

Soil Bearing Pressure check for ULS lateral forces:

Section Modulus for the Ring Beam Foundation, Zxx

Z

xx

D

r

b

r

+

( )

4

D

r

b

r

( )

4

32 D

r

b

r

+

( )

(

(

(

:=

Z

xx

27.256 m

3

=

due to extreme wind forces under ULS conditions, the soil stress increment due to the

over turning moment, is calculated below for upper limit and lower limit, upper limit must

be checked for Soil Bearing Capacity.

1

rwsw

M

ot

Z

xx

+ :=

1

103.234

kN

m

2

=

2

rwsw

M

ot

Z

xx

:=

2

57.665

kN

m

2

=

1

SBC < 1 = OK SBC 120

kN

m

2

=

under ULS lateral loading conditions , Fuel Tank Foundation soil pressures are safe.

R/F DETAIL FOR RING BEAM

El Madar Engineering Projects 9 of 11 DP

CONCRETE DETAIL

FOR RING BEAM

El Madar Engineering Projects 10 of 11 DP

APPENDIX

VENDOR SHOP DRAWING FOR FUEL TANK-PART ABSTRACTED

LOADING DETAILS FROM FUEL TANK DESIGNER SHOP DRAWING

El Madar Engineering Projects 11 of 11 DP

You might also like

- DSG-SE-02 Tank Found Concrete Ring WallDocument5 pagesDSG-SE-02 Tank Found Concrete Ring Wallmedhat145100% (1)

- Contents Specific Gravity: Calculation SheetDocument3 pagesContents Specific Gravity: Calculation SheetHui Liu100% (4)

- Revision List: No. Para. / Section No. Items Explanation / ReasonDocument17 pagesRevision List: No. Para. / Section No. Items Explanation / ReasonMayuresh KudveNo ratings yet

- Design of Storage Tank FoundationDocument14 pagesDesign of Storage Tank Foundationkoyahassan100% (1)

- Oil Storage Tank Foundation Design Spreadsheet - 2Document5 pagesOil Storage Tank Foundation Design Spreadsheet - 2Vince2686% (7)

- 3000 MT Storage Tank Foundation DesignDocument15 pages3000 MT Storage Tank Foundation DesignDeny AristyaNo ratings yet

- Ring Wall Foundation PDFDocument18 pagesRing Wall Foundation PDFAbhaysinh Shinde85% (13)

- Tank Foundation Design GuideDocument44 pagesTank Foundation Design GuideMichelle Baker65% (23)

- Ring Wall Tank Foundation DESIGNDocument6 pagesRing Wall Tank Foundation DESIGNanandamNo ratings yet

- Ring WallDocument17 pagesRing WallYunanto WidiNo ratings yet

- Tank Foundation Rev 01Document10 pagesTank Foundation Rev 01AnbalaganV100% (1)

- Concrete Ring Wall FoundationDocument16 pagesConcrete Ring Wall Foundationrao159951No ratings yet

- Design of Concrete Ring Beam For Storage TankDocument4 pagesDesign of Concrete Ring Beam For Storage Tankjiokoijiko75% (4)

- Tank Foundation Design and Load CalculationsDocument3 pagesTank Foundation Design and Load CalculationsdantevariasNo ratings yet

- Design of Concrete Ring Type Foundation For Storage TankDocument6 pagesDesign of Concrete Ring Type Foundation For Storage TankNabil Al-KhirdajiNo ratings yet

- Tank Foundation Design ProcedureDocument53 pagesTank Foundation Design ProcedureMichael Teo82% (11)

- Bottom Corrosion PreventionDocument16 pagesBottom Corrosion PreventionMayuresh Kudve100% (1)

- API 650 Storage Tank Load Computations With Ring Wall Foundation Design (8.7-m Diameter X 9.0-m Height)Document25 pagesAPI 650 Storage Tank Load Computations With Ring Wall Foundation Design (8.7-m Diameter X 9.0-m Height)AVBP100% (3)

- Jun96 Tank Foundation DesignDocument11 pagesJun96 Tank Foundation Designjuanmata26No ratings yet

- Vertical Vessel Foundation Design GuideDocument52 pagesVertical Vessel Foundation Design GuideIsrael AGNo ratings yet

- Double Deck - Floating RoofDocument7 pagesDouble Deck - Floating RoofDhia SlamaNo ratings yet

- Ring Wall Foundation Version 0Document10 pagesRing Wall Foundation Version 0vijay10484No ratings yet

- Tank FoundationDocument18 pagesTank FoundationRodrigo Fritz100% (5)

- Design Calculation For RC Ring BeamDocument19 pagesDesign Calculation For RC Ring Beamjologscresencia100% (2)

- Tank Ring Wall Foundation DesignDocument6 pagesTank Ring Wall Foundation DesignanandamNo ratings yet

- API Storage Tank DesignDocument21 pagesAPI Storage Tank DesignIndunil Prasanna Bandara Warnasooriya100% (2)

- Design of Concrete Ring Beam For Storage TankDocument6 pagesDesign of Concrete Ring Beam For Storage TankMonty MathewsNo ratings yet

- Design As Per APIDocument82 pagesDesign As Per APINeeraj BhallaNo ratings yet

- Seismic Analysis of Steel Liquid Storage Tanks by Api-650Document129 pagesSeismic Analysis of Steel Liquid Storage Tanks by Api-650haschere67% (3)

- Tank FoundationsDocument83 pagesTank Foundationsdroates100% (17)

- STAAD - Foundation Tank Ringwall Calculation SheetDocument9 pagesSTAAD - Foundation Tank Ringwall Calculation Sheetdumbadumba100% (4)

- STAAD Tank FoundationDocument17 pagesSTAAD Tank Foundationiuliandurdureanu100% (2)

- Foundation Vibration Analysis: A Strength of Materials ApproachFrom EverandFoundation Vibration Analysis: A Strength of Materials ApproachRating: 3 out of 5 stars3/5 (2)

- Design overhead water tank assessmentDocument20 pagesDesign overhead water tank assessmentBobor Emmanuel OfovweNo ratings yet

- Mathcad - Spreader Beam Design Calculations As Per DNV 5th VerDocument29 pagesMathcad - Spreader Beam Design Calculations As Per DNV 5th VerAbderraoufAffes100% (3)

- Transmission Tower Foundation DesignDocument26 pagesTransmission Tower Foundation DesignSara Nuon86% (7)

- Calculation Sheet Repot of Storage Tank Foundation Rev.2 (15mx15m)Document13 pagesCalculation Sheet Repot of Storage Tank Foundation Rev.2 (15mx15m)naser hasan fauzi100% (1)

- RCC Bund Wall With Shear KeyDocument27 pagesRCC Bund Wall With Shear Keynhulugalla100% (1)

- Member Check 60x60x5 RSA (Top & Bottom Boom)Document10 pagesMember Check 60x60x5 RSA (Top & Bottom Boom)Bobor Emmanuel OfovweNo ratings yet

- Design Verification CalculationsDocument15 pagesDesign Verification CalculationsKarthik KrNo ratings yet

- A5 SolutionDocument7 pagesA5 Solutionskata999No ratings yet

- Design of Water Pipeline Crossing Etihad Rail TrackDocument31 pagesDesign of Water Pipeline Crossing Etihad Rail TrackmrnaeemNo ratings yet

- RC Pier TabaDocument20 pagesRC Pier TabaAbera MamoNo ratings yet

- Practice in Geotechnical DesignDocument33 pagesPractice in Geotechnical DesignMaxim PaulNo ratings yet

- Water Treatment Container Calculation ReportDocument15 pagesWater Treatment Container Calculation ReportJuragan IwalNo ratings yet

- RCC Bund Wall Without Shear KeyDocument21 pagesRCC Bund Wall Without Shear Keynhulugalla100% (1)

- Design Examples For Large-Span CulvertsDocument60 pagesDesign Examples For Large-Span CulvertsAaron ChachaNo ratings yet

- Penstock Embedded DesignDocument6 pagesPenstock Embedded Designgrahazen50% (2)

- NMDC Limited 3.0 Mtpa Integrated Steel Plant: at Nagarnar, ChhattisgarhDocument9 pagesNMDC Limited 3.0 Mtpa Integrated Steel Plant: at Nagarnar, ChhattisgarhDanish AhmadNo ratings yet

- PIANC Example Fender DesignDocument8 pagesPIANC Example Fender DesignFiona Keir100% (3)

- Transmission Tower Foundation DesignDocument26 pagesTransmission Tower Foundation Design14pcash100% (1)

- Engineering Calculations Template-White Cellar 2 5mDocument36 pagesEngineering Calculations Template-White Cellar 2 5mThaiNguyenNo ratings yet

- Sound: Wall de IgnDocument36 pagesSound: Wall de IgnHundeejireenyaNo ratings yet

- Main FileDocument9 pagesMain FileSyed Munawar AliNo ratings yet

- Abutment Design Example To BD 30Document32 pagesAbutment Design Example To BD 30Elton MaroNo ratings yet

- Rectangular Tank MathcadDocument37 pagesRectangular Tank Mathcadelixnz100% (1)

- Chimney DesignDocument13 pagesChimney DesignUhong Lai100% (1)

- Design of Pile Foundations Static FormulaDocument8 pagesDesign of Pile Foundations Static FormulaSasha NewmanNo ratings yet

- Calculation For Box Culvert Rev.ADocument45 pagesCalculation For Box Culvert Rev.AZulfikar N JoelNo ratings yet

- Saddle AnalysisDocument17 pagesSaddle AnalysisvishalsatheNo ratings yet

- Finite Elements For Infinite ComplexitiesDocument1 pageFinite Elements For Infinite ComplexitiesDawson Preethi EANo ratings yet

- Finite Element Method For IdeasDocument1 pageFinite Element Method For IdeasDawson Preethi EANo ratings yet

- Colorless Tsukuru TazakiDocument1 pageColorless Tsukuru TazakiDawson Preethi EANo ratings yet

- Ring Foundation Design CriteriaDocument1 pageRing Foundation Design CriteriaDawson Preethi EANo ratings yet

- Rehabilitation of Leaking ManholesDocument1 pageRehabilitation of Leaking ManholesDawson Preethi EANo ratings yet

- Marvelous RevitDocument1 pageMarvelous RevitDawson Preethi EANo ratings yet

- Why I Should Record My Dreams PDFDocument1 pageWhy I Should Record My Dreams PDFDawson Preethi EANo ratings yet

- Time History and History of TimeDocument1 pageTime History and History of TimeDawson Preethi EANo ratings yet

- Dynamics of Structures Vs Schrodinger EquationDocument1 pageDynamics of Structures Vs Schrodinger EquationDawson Preethi EANo ratings yet

- Canopy DesignDocument1 pageCanopy DesignDawson Preethi EANo ratings yet

- Passion For An Earthquake!Document2 pagesPassion For An Earthquake!Dawson Preethi EANo ratings yet

- Steinbrenner, Amen!Document1 pageSteinbrenner, Amen!Dawson Preethi EANo ratings yet

- 27-04-2011 Cross Beam and Support Column Design For TrenchDocument3 pages27-04-2011 Cross Beam and Support Column Design For TrenchDawson Preethi EANo ratings yet

- Fixing Bolt Design Calculation For TransformerDocument7 pagesFixing Bolt Design Calculation For TransformerDawson Preethi EA100% (1)

- Trench Design 17-04-2011Document12 pagesTrench Design 17-04-2011Dawson Preethi EANo ratings yet

- Chumbana Kanda-Jayahtilaka Kammellaweera A Review by Dawson PreethiDocument11 pagesChumbana Kanda-Jayahtilaka Kammellaweera A Review by Dawson PreethiDawson Preethi EANo ratings yet

- Uqp, Skao Dmamh: Ksraudk Ix.%YhDocument52 pagesUqp, Skao Dmamh: Ksraudk Ix.%YhDawson Preethi EA100% (2)

- Friction Mini LabsDocument3 pagesFriction Mini Labsapi-298716691No ratings yet

- Weymouth EquationDocument7 pagesWeymouth EquationCHANADASNo ratings yet

- Scientific American - Angrist - Perpetual Motion MachinesDocument10 pagesScientific American - Angrist - Perpetual Motion MachinestisafkNo ratings yet

- CE-203 LAB File Engineering Mechanics Nishant Sharma 2K20/CE/102Document10 pagesCE-203 LAB File Engineering Mechanics Nishant Sharma 2K20/CE/1022K2O-A17-11 Vishal GuptaNo ratings yet

- Assignment-2 - Engg Mech PDFDocument8 pagesAssignment-2 - Engg Mech PDFNiteshNo ratings yet

- Manual Me ProDocument414 pagesManual Me ProJavier Gaete ObrequeNo ratings yet

- Fundamentals of ThermodynamicsDocument55 pagesFundamentals of Thermodynamicsudoye kachiNo ratings yet

- (Amaleaks - Blogspot.com) Phyc-121 Week 1-10Document84 pages(Amaleaks - Blogspot.com) Phyc-121 Week 1-10Amanda Dinah RamilNo ratings yet

- AP Physics Work Energy Power PDFDocument17 pagesAP Physics Work Energy Power PDFAli khan7No ratings yet

- Applied Mathematical Modelling: Mahesh Prakash, Paul W. ClearyDocument15 pagesApplied Mathematical Modelling: Mahesh Prakash, Paul W. ClearyDeepak Kumar SinghNo ratings yet

- BITS Pilani AssignmentDocument9 pagesBITS Pilani AssignmentNaresh SehdevNo ratings yet

- Ocean Waves and Oscillating Systems PDFDocument287 pagesOcean Waves and Oscillating Systems PDFMerrel Ross100% (1)

- Physicsaholics Circular Motion Exercise Level 1Document5 pagesPhysicsaholics Circular Motion Exercise Level 1Gaurav KumarNo ratings yet

- Flexural Strength Masonry PrismsDocument10 pagesFlexural Strength Masonry PrismsMuhammadAboubakarFarooqNo ratings yet

- Chassis Design Validation of A Baja CarDocument6 pagesChassis Design Validation of A Baja CarConrad54No ratings yet

- Center of Mass and Moment of InertiaDocument31 pagesCenter of Mass and Moment of InertiaLakshNo ratings yet

- Thesis On Steel Fibre Reinforced ConcreteDocument8 pagesThesis On Steel Fibre Reinforced Concretedenisemillerdesmoines100% (2)

- OpenFoam Solvers ListDocument4 pagesOpenFoam Solvers ListAbhishek VermaNo ratings yet

- Vehicle Suspension Design and DynamicsDocument70 pagesVehicle Suspension Design and DynamicsDrBalaramakrishna NizampatnamNo ratings yet

- EarthquakeDocument49 pagesEarthquakeNupur BhadraNo ratings yet

- Fire Engine - Loading Appendix - G - 293Document46 pagesFire Engine - Loading Appendix - G - 293Shivaranjan HJNo ratings yet

- Handbook of Spring Design Part 1Document51 pagesHandbook of Spring Design Part 1senthilkumar D0% (1)

- Aich Le M3 4Document22 pagesAich Le M3 4El CamotitoNo ratings yet

- IG GeophysicsDocument50 pagesIG Geophysicssukri arjunaNo ratings yet

- Assessing defects in pressure vessel nozzlesDocument27 pagesAssessing defects in pressure vessel nozzlesvenkatrangan2003No ratings yet

- Blast Loading & Blast Effect On StructuresDocument16 pagesBlast Loading & Blast Effect On StructuresSuhas Joshi100% (1)

- Mechanical Systems: Translational RotationalDocument30 pagesMechanical Systems: Translational RotationalHussainNo ratings yet

- Projectile Motion 1Document52 pagesProjectile Motion 1Ayman EidNo ratings yet

- Thermo NotesDocument12 pagesThermo NotesSamriddha Das GuptaNo ratings yet

- Waves ExcerciseDocument3 pagesWaves Excerciseleelee1127No ratings yet