Professional Documents

Culture Documents

Jsa Grinding Welding Gas Cutting

Uploaded by

Rana Waseem KhanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jsa Grinding Welding Gas Cutting

Uploaded by

Rana Waseem KhanCopyright:

Available Formats

Company Logo

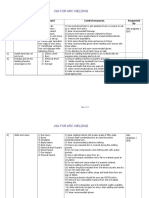

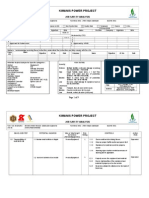

JOB SAFET ANALYSIS Grinding, Welding & Gas cutting

Project: Ref No.: Rev No.: Page: 1 of 3

Prepared by: Approved by: Step No. 1 Description of Task Step Hazard

Reviewed by: Date: Control Measures/ Preventive Measures Responsible Person

Work start-up & obtaining PTW

Unauthorized work Invalid permit Lack of competency Lack or poor communication Haste or shortcut Rotating equipment sparks. Damaged grinding disc

Obtain a hot work permit before starting the job Get the permit validated for the specific day Supervisor must ensure that all work activities are carried out by competent personnel Conduct Toolbox meeting, review the Method statement and Job safety analysis to all craftsmen involved in the work activities. Responsible person will conduct inspection, monitor the work activities and have to ensure safety standards and procedures are strictly adhered to. Make sure guards are fitted to all moving parts Ensure the proper use of guards Inspect the grinding discs prior to starting work (ring test) Make sure that disc is compatible with the grinding machine Check the RPM of disc & machine Proper PPE (Gloves + Mask). Correct installation of Grinder Wheel. Gas monitor correctly sited.

PTW applicant Supervisor PTW holder

Grinding

Supervisor

Electrocution.

Company Logo

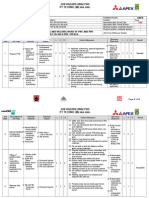

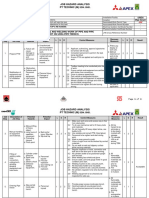

JOB SAFET ANALYSIS Grinding, Welding & Gas cutting

Project: Ref No.: Rev No.: Page: 2 of 3

Step No.

Description of Task Step

Hazard

Control Measures/ Preventive Measures

Responsible Person

High Pressure air Flying object/eye injuries

Spark containment to be used. Only experienced personnel to use the equipment. Wear a face shield while grinding Make sure an eye wash station is available nearby Proper isolation of system. All cylinders to be secured. Flame arrestor between the cylinder & torch Hoses in good condition. Proper PPE. Trained Fire Watch. Gas Monitor correctly sited. Correct Fire Extinguisher(s). Deployment of Experienced personnel. Cordoning of the area. Fire Blanket. Inspect the cylinders & hoses before starting the job Before starting welding make sure the area is clear of all types of combustible materials Provide a fire blanket on site Make sure fire extinguishers are available on site Supervisor & Workers

Gas Cutting

Burns. Fire Hazard. Explosion. Tripping. Damaged or leaking cylinders or hoses

Welding

Fire Hazard Burns.

Supervisor & Workers

Company Logo

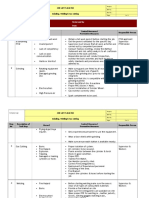

JOB SAFET ANALYSIS Grinding, Welding & Gas cutting

Project: Ref No.: Rev No.: Page: 3 of 3

Step No.

Description of Task Step

Hazard

Control Measures/ Preventive Measures

Responsible Person

Electrocution/ Spatter burns Damage cable Hot tabs end pieces of welding rods. Sparking Damage cable UV rays

Wear proper PPE for welding ie., leather jackets, Gloves, welding goggles/welding mask, Trained Fire Watch. Gas Monitor correctly sited. Certified Equipment and to be sited as near as possible to work site. Proper earthing of equipment. Certified Welder. Make sure spark containment is used such as a welding hood/fire blanket. Ensure that rod holder is in good condition. Ensure that forward and return cables are in good working condition. Use proper cable connector for extension. If cables are crossing the road then ensure proper protection. The welder & the welder helpers must wear welding goggles

You might also like

- Jsa For Arc WeldingDocument3 pagesJsa For Arc Weldingtnssbhaskar100% (5)

- Gas Cutting and Welding JHA Safety ChecklistDocument4 pagesGas Cutting and Welding JHA Safety ChecklistSunil apexNo ratings yet

- JSA-Working at HeightDocument2 pagesJSA-Working at Heightsubhanmusadiq83% (107)

- HANDBOOK-McLean-and-Syed-2015-The Oxford Handbook of Identity Development PDFDocument625 pagesHANDBOOK-McLean-and-Syed-2015-The Oxford Handbook of Identity Development PDFEsp Success Beyond100% (13)

- Jsa CraneDocument3 pagesJsa Cranenattwa201075% (24)

- Jsa For Drilling.Document3 pagesJsa For Drilling.Belsyah Nofriyan75% (4)

- JSA Blasting and Coating KP 69.4Document5 pagesJSA Blasting and Coating KP 69.4shinto Lawrence100% (6)

- Gas Cutting JsaDocument4 pagesGas Cutting JsaMohammed Minhaj100% (1)

- JSA Material HandlingDocument11 pagesJSA Material HandlingGanga Daran100% (3)

- Staples Worklife Magazine - Winter 2019Document68 pagesStaples Worklife Magazine - Winter 2019Anonymous fq268KsS100% (1)

- JSA Fitting and Welding Work For Pipe Trench InstalationDocument6 pagesJSA Fitting and Welding Work For Pipe Trench InstalationAzmi Fauzi78% (9)

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingQomarudin Comenk100% (2)

- Job Safety Analysis (14) For Cable Laying and PullingDocument4 pagesJob Safety Analysis (14) For Cable Laying and Pullingnasar_mahsood79% (34)

- JSA G20 Scaffolding (Erection, Dismantling)Document4 pagesJSA G20 Scaffolding (Erection, Dismantling)Kanchalida Champathong92% (12)

- JSA For Welding GrindingDocument7 pagesJSA For Welding GrindingBabar78% (9)

- Welding and Grinding HazardsDocument6 pagesWelding and Grinding HazardsJeremia Samosir100% (2)

- Basic Reconnaissance Course Preparation GuideDocument6 pagesBasic Reconnaissance Course Preparation GuideJohn Leclair100% (1)

- Manual Excavation JSADocument1 pageManual Excavation JSATausif Khan100% (2)

- Job Hazard Analysis For Desalination of First Effect RetubingDocument7 pagesJob Hazard Analysis For Desalination of First Effect Retubingmc chesterNo ratings yet

- SGD SAIPEM CAMP LOADING AND UNLOADINGDocument2 pagesSGD SAIPEM CAMP LOADING AND UNLOADINGsubhanmusadiq82% (55)

- JSA CarpentryDocument2 pagesJSA Carpentrysubhanmusadiq91% (11)

- Job Safety Analysis: 1 Confined Space Entry JSA ExampleDocument7 pagesJob Safety Analysis: 1 Confined Space Entry JSA Examplerashid zamanNo ratings yet

- JSA Welding Confined SpaceDocument2 pagesJSA Welding Confined Spacegkmlal100% (4)

- Mie Hse Jha 002 - Welding, Cutting, Fabrication WorkDocument4 pagesMie Hse Jha 002 - Welding, Cutting, Fabrication WorkLuqman Osman100% (1)

- 4 JSA For Structural Fabrication and Erection WorkDocument4 pages4 JSA For Structural Fabrication and Erection WorkHappy Prajapat67% (3)

- JSA Template 2017-05-31 Cable Tray InstallationDocument19 pagesJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezNo ratings yet

- Job Safety Analysis For Scaffolding 1Document3 pagesJob Safety Analysis For Scaffolding 1nasar_mahsood71% (34)

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDocument9 pagesHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- JSA FORMAT For Materials LoadingDocument2 pagesJSA FORMAT For Materials LoadingVikky KumarNo ratings yet

- JSA For Painting Works-Hazards ControlDocument4 pagesJSA For Painting Works-Hazards Controlkaleem0% (2)

- JSA For Cable Tray Installation-Reviewed by CBREDocument10 pagesJSA For Cable Tray Installation-Reviewed by CBREPrakash Tiwari86% (7)

- JSA ElectricalDocument2 pagesJSA Electricalsubhanmusadiq100% (6)

- Jsa For Lifting (Crane) 016Document6 pagesJsa For Lifting (Crane) 016aliraza572270% (27)

- JSA for Erection and Removal of ScaffoldingDocument5 pagesJSA for Erection and Removal of ScaffoldingPanchdev KumarNo ratings yet

- JSA For False CeilingDocument4 pagesJSA For False CeilingJaved100% (3)

- JSA For Cutting, Grinding and WeldingDocument4 pagesJSA For Cutting, Grinding and Weldingyc safety100% (3)

- JSA - CABLE TERMINATION TITLEDocument4 pagesJSA - CABLE TERMINATION TITLESyed Yousuf Ali100% (1)

- ASHRAE Std 62.1 Ventilation StandardDocument38 pagesASHRAE Std 62.1 Ventilation Standardcoolth2No ratings yet

- Jsa For Piping and Erection RevisedDocument1 pageJsa For Piping and Erection RevisedAlvin Smith77% (26)

- Job Hazard Analysis for Pipe Fitting and WeldingDocument4 pagesJob Hazard Analysis for Pipe Fitting and WeldingShahrizatSmailKassim100% (1)

- Jsa For Civil Confined Space EntryDocument11 pagesJsa For Civil Confined Space EntryKhuda BukshNo ratings yet

- Nail Gun Pnuematic Work Method Statement SWMS V8Document5 pagesNail Gun Pnuematic Work Method Statement SWMS V8ferny.51No ratings yet

- Hot Works JSA Example - 2Document2 pagesHot Works JSA Example - 2shaheer79% (33)

- Safe Work Method Statement - Part 1: Company DetailsDocument14 pagesSafe Work Method Statement - Part 1: Company DetailsNithun DeenadayalanNo ratings yet

- Jsa Installation of Supports and Cable Racks1Document16 pagesJsa Installation of Supports and Cable Racks1loveson709100% (3)

- Erect Steel Structures SafelyDocument9 pagesErect Steel Structures SafelyLuqman Osman77% (13)

- Tie in Hot Work JHADocument4 pagesTie in Hot Work JHAmalik jahan100% (2)

- JSA PlumbingDocument2 pagesJSA Plumbingsubhanmusadiq71% (7)

- JSA For Material ShiftingDocument3 pagesJSA For Material ShiftingMohammed Minhaj100% (1)

- Civil JSA Form Block WorkDocument3 pagesCivil JSA Form Block Workdrmuhsin86% (7)

- Cement Plaster JSADocument4 pagesCement Plaster JSAMohammed Minhaj50% (2)

- JSA Cable LayingDocument2 pagesJSA Cable Layingnishanth100% (2)

- JSA WeldingDocument2 pagesJSA Weldingsubhanmusadiq100% (1)

- Hazard Full SlideDocument31 pagesHazard Full SlideRenKangWongNo ratings yet

- SGD Saipem Camp Accommodation and Building Facilities Painting JSADocument1 pageSGD Saipem Camp Accommodation and Building Facilities Painting JSAsubhanmusadiq63% (16)

- Working at HeightDocument2 pagesWorking at HeightMohamed Hichem Guesmi100% (1)

- Job Safety Analysis (Rolling For MS Plates)Document1 pageJob Safety Analysis (Rolling For MS Plates)Muhammad Ali100% (2)

- 003 JSA All Civil WorksDocument5 pages003 JSA All Civil WorksMohammed Minhaj100% (11)

- Jsa - Cutting and WeldingDocument2 pagesJsa - Cutting and WeldingSantos Rex50% (2)

- Production of Blue Ternate (Clitoria Ternatea) Flower Extracts in Hand SanitizerDocument37 pagesProduction of Blue Ternate (Clitoria Ternatea) Flower Extracts in Hand SanitizerDiane Vill100% (1)

- JSA For Fabrication WorksDocument11 pagesJSA For Fabrication Workssurendra behera100% (3)

- IPAMS Healthcare and Medical Services Evaluation FormDocument2 pagesIPAMS Healthcare and Medical Services Evaluation FormManases VelasquezNo ratings yet

- Job Safety Analysis (Jsa)Document11 pagesJob Safety Analysis (Jsa)Noraini Binti Osman50% (2)

- JSA Roof Sheeting V3 16 July 06Document6 pagesJSA Roof Sheeting V3 16 July 06Walt Flowers80% (5)

- Project Name: Proposed Icomc & BMC Building Complex Phe Design ReportDocument19 pagesProject Name: Proposed Icomc & BMC Building Complex Phe Design ReportAmit Kumar MishraNo ratings yet

- JSA PaintingDocument1 pageJSA PaintingjonesNo ratings yet

- Sendai Framework For Disaster Risk ReductionDocument34 pagesSendai Framework For Disaster Risk ReductionDavid GarciaNo ratings yet

- Ultratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSADocument5 pagesUltratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSATFattah100% (1)

- Safety Signs and SymbolsDocument5 pagesSafety Signs and Symbolsjon pantz100% (1)

- Crowding Boarding and Patient Through PutDocument9 pagesCrowding Boarding and Patient Through PutMarwa El SayedNo ratings yet

- JSA For Flue Gas Duct Height WorkDocument4 pagesJSA For Flue Gas Duct Height Worksubhadipmanna8No ratings yet

- Safe Haven Thesis StatementDocument5 pagesSafe Haven Thesis Statementangelabaxtermanchester100% (2)

- Corn SpecDocument4 pagesCorn SpecJohanna MullerNo ratings yet

- Secrets of AntimonyDocument9 pagesSecrets of AntimonyNCSASTRONo ratings yet

- Beddtiot ORTHO / Orthodontic Courses by Indian Dental AcademyDocument60 pagesBeddtiot ORTHO / Orthodontic Courses by Indian Dental Academyindian dental academyNo ratings yet

- 2018 Intervention Session Template 3Document4 pages2018 Intervention Session Template 3api-404544260No ratings yet

- Mumps Guide: Causes, Symptoms, Treatment & PreventionDocument14 pagesMumps Guide: Causes, Symptoms, Treatment & PreventionChristian JonathanNo ratings yet

- Phenol Hazards and PrecautionsDocument3 pagesPhenol Hazards and PrecautionsMarnel Roy MayorNo ratings yet

- MadRiverUnion01 13 21editionDocument8 pagesMadRiverUnion01 13 21editionMad River UnionNo ratings yet

- Essay On Current Poverty State of India After COVID-19: KeywordsDocument10 pagesEssay On Current Poverty State of India After COVID-19: KeywordsMALLI ROYALNo ratings yet

- Chymoral Plus'Document3 pagesChymoral Plus'Neha SureshNo ratings yet

- Anti-epileptic drugs: Types, Mechanisms & TreatmentDocument7 pagesAnti-epileptic drugs: Types, Mechanisms & TreatmentSampada ghodkiNo ratings yet

- Mechanical Syllabus PDFDocument225 pagesMechanical Syllabus PDFshashiNo ratings yet

- Nutrition Care Plan - DysphagiaDocument1 pageNutrition Care Plan - DysphagiaElaine ArsagaNo ratings yet

- Hortatory Exposition Humaira AssahdaDocument4 pagesHortatory Exposition Humaira Assahdaaleeka auroraNo ratings yet

- Nurse Licensure Examination Review Center for Allied Professions (RCAPDocument15 pagesNurse Licensure Examination Review Center for Allied Professions (RCAPnikko0427No ratings yet

- Which Is More Effective in Treating Chronic Stable Angina, Trimetazidine or Diltiazem?Document5 pagesWhich Is More Effective in Treating Chronic Stable Angina, Trimetazidine or Diltiazem?Lemuel Glenn BautistaNo ratings yet

- Testing Antibiotics with Disk Diffusion AssayDocument3 pagesTesting Antibiotics with Disk Diffusion AssayNguyễn Trung KiênNo ratings yet

- UntitledDocument221 pagesUntitledlaljadeff12No ratings yet

- Mini BalanzaDocument146 pagesMini Balanzaisaac_elvisNo ratings yet