Professional Documents

Culture Documents

Sugar Plant

Uploaded by

hemant_ghugeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sugar Plant

Uploaded by

hemant_ghugeCopyright:

Available Formats

1he bas|c process

Sugar cane musL be crushed Lo exLracL Lhe [ulce 1he crushlng process musL break up Lhe

hard nodes of Lhe cane and flaLLen Lhe sLems 1he [ulce ls collecLed fllLered and someLlmes

LreaLed and Lhen bolled Lo drlve off Lhe excess waLer 1he drled cane resldue (bagasse) ls

ofLen used as fuel for Lhls process 1he remalnlng llquld ls allowed Lo seL lnLo a solld mass

known as [aggery gur chancaca or panela (Cur ls used ln Lhe resL of Lhls documenL)

|e|ds

1he yleld of gur from sugar cane depends mosLly on Lhe quallLy of Lhe cane and Lhe efflclency

of Lhe exLracLlon of [ulce

Plgh quallLy cane has a good [ulce conLenL wlLh hlgh sugar levels (20+) oor quallLy cane

or cane LhaL has been harvesLed early may have slmllar [ulce conLenL buL Lhe sugar levels wlll

be reduced

1he efflclency wlLh whlch [ulce can be exLracLed from Lhe cane ls llmlLed by Lhe Lechnology

used 1he slmple Lhree roller crushers used by mosL arLlsanal producers wlll never exLracL

more Lhan 30kg of [ulce from each 100kg of cane

?lelds are also lmproved by careful conLrol of Lhe bolllng process 8olllng should be

compleLed as rapldly as posslble and Lhe condlLlons kepL as clean as posslble

rush|ng

Cane must be crushed within 24 hours of being cut. After this time the sugar begins to 'invert' into

different sugars that will not set solid.

Crushing efficiency is the most important factor in good sugar yields. Every possible amount of juice

needs to be squeezed from the cane.

Mass baIance

You might also like

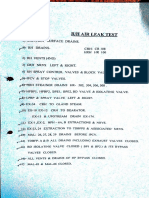

- Air Leak Test PDFDocument1 pageAir Leak Test PDFhemant_ghugeNo ratings yet

- Overflow: PWM ControllerDocument1 pageOverflow: PWM Controllerhemant_ghugeNo ratings yet

- NomenclatureDocument1 pageNomenclaturehemant_ghugeNo ratings yet

- ATM Block Ticket No.Document1 pageATM Block Ticket No.hemant_ghugeNo ratings yet

- ElectivesDocument1 pageElectiveshemant_ghugeNo ratings yet

- Posible Exam QuestionsDocument3 pagesPosible Exam Questionshemant_ghugeNo ratings yet

- Assignment 4Document3 pagesAssignment 4hemant_ghugeNo ratings yet

- P&ID Equipment List for System PreparationDocument1 pageP&ID Equipment List for System Preparationhemant_ghugeNo ratings yet

- Weirs 2Document3 pagesWeirs 2hemant_ghugeNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)