Professional Documents

Culture Documents

Iso 2768 English

Uploaded by

fethiaktuncOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Iso 2768 English

Uploaded by

fethiaktuncCopyright:

Available Formats

ISO Tolerances DIN ISO 2768 - 1, DIN ISO 2768 - 2.

Sayfa 1 / 3

Ramo Material AB

Din leverantr av avancerade specialartiklar

Our main activity is based on supplying specialparts to high technology companies. Our business idea is to offer our customer a wide range of special products with low production costs and complete products, based on our knowledge of quality manufactures.

Click here to visit our homepage for more information

Mycket av vr verksamhet bygger p att leverera avancerade specialartiklar till hgteknologiska fretag. Vi arbetar med ett brett kontaktnt och till lga produktions-kostnader fr att kunna erbjuda skrddarsydda och konkurrenskraftiga produkter.

Klicka hr fr mer information om Ramo Material AB

Ramo Material AB - Tel: +46 370 37 87 00 - Fax: +46 370 37 87 29

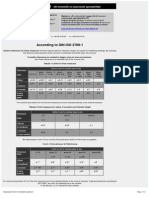

According to DIN ISO 2768-1

General tolerances for linear measures and level squares with four tolerance classes are useful for simplifying drawings. By choosing the tolerance class precision levels common in workshops should be taken into account. If smaller tolerances are needed or bigger ones are more economical, then these tolerances are indicated next to the nominal size. Tabular 1 Limits for linear measures

Limits in mm for nominal sizes in mm

Toleranceclass f (fine) m (medium) c (coarse) v (very coarce grob) 0,5 to 3 0,05 0,1 0,15 -

above 3 to 6 0,05 0,1 0,2 0,5

above 6 to 30 0,1 0,2 0,5 1

above 30 to 120 0,15 0,3 0,8 1,5

above 120 to 400 0,2 0,5 1,2 2,5

above 400 to 1000 0,3 0,8 2 4

above 1000 to 2000 0,5 1,2 3 6

above 2000 to 4000 2 4 8

For nominal sizes below 0,5 mm the limit measures are to be indicated directly at the nominal measure. Tabular 2 Limit measures for radius of curvature and chamfer height

Limits in mm for nominal sizes in mm

Tolerance class f (finne) m (medium) c (coarse) v (very coarse)

0,5 to 3 0,2

above 3 to 6 0,5

above 6

0,4

Bei Nennmassen unter 0,5 mm sind die Grenzabmasse direkt am Nennmass anzugeben. Tabelle 3 Grenzabmasse fr Winkelmasse

Limits in mm for nominal sizes in mm

Tolerance class f (fine) m (medium) c (coarse )

to 10

above 10 to 50

above 50 to 120 20 ' 30 '

above 50 to 400 10 ' 15 '

above 400

1 1 30 '

30 ' 1

5' 10 '

http://www.ramo.se/iso_2768_english.htm

28.12.2011

ISO Tolerances DIN ISO 2768 - 1, DIN ISO 2768 - 2.

Sayfa 2 / 3

v (very coarce)

30 '

20 '

For nominal sizes below 0,5 mm the limit measures are to be indicated directly at the nominal measure. If general tolerances according to ISO 2768-1 are valid, the following has to be inserted in the title box, i.e. for tolerance class medium ISO 2768 m or general tolerance ISO 2768 m For new designs only the general tolerance according to DIN ISO 2768-1 should be valid. The limit measurements of the tolerance classes m and f of DIN ISO 2768-1 are identic with those of DIN 7168-1.

General tolerances for form and position according to DIN ISO 2768-2

DIN ISO 2768-2 is for simplifying drawing and fixes general tolerances in three tolerance classes for form and position. By choosing a special tolerance class exactly the precision level common in workshops should be taken into account. If smaller tolerances are needed or bigger are more economical these tolerances should be mentioned directly according to ISO 1101. General tolerances for form and position should be used while the tolerance principle according. to ISO 8015 is valid and while this is mentioned in the drawing. This tolerance principles says that no opposite relation between measure, form and position tolerance exists (principle of superposition).

General tolerances for straightness and evenness in mm

Tolerance class to 10 H K L 0,02 0,05 0,1 above 10 to 30 0,05 0,1 0,2

Range of specified size in mm

above 30 to 100 0,1 0,2 0,4

above 100 to 300 0,2 0,4 0,8

above 300 to 1000 0,3 0,6 1,2

above 1000 to 3000 0,4 0,8 1,6

General tolerances for straightness and evenness in mm Tolerance class to 100 H K L 0,2 0,4 0,6 Range of specified size in mm above 100 to 300 0,3 0,6 1 above 300 to 1000 0,4 0,8 1,5 above 1000 to 3000 0,5 1 2

General tolerances for symmetry

Tolerance class

Range of specified size in mm

above 100 to 100 H K L 0,6 0,6 1 to 300 0,5

above 300 to 1000

above 1000 to 3000

0,8 1,5

1 2

General tolerances for form and position are valid for form elements for which form and position tolerances are not indicated individually. They are applicable for all characteristics of the form elements accept cylinders, profiles of any line or surfaces, inclines, coaxiality, position and total movement.

Ramo Material AB Tel: +46 370 37 87 00 Fax: +46 370 37 87 29

http://www.ramo.se/iso_2768_english.htm

28.12.2011

ISO Tolerances DIN ISO 2768 - 1, DIN ISO 2768 - 2.

Sayfa 3 / 3

Ramo Material AB ansvarar ej fr eventuella felaktigheter i ovanstende information. Ramo Material AB takes no responsibility in the eventuality of errors in the above information.

http://www.ramo.se/iso_2768_english.htm

28.12.2011

You might also like

- Sist Iso 7072 1995Document7 pagesSist Iso 7072 1995VijayGowthaman100% (1)

- International Standard 7539-2Document5 pagesInternational Standard 7539-2cao thanh quocNo ratings yet

- Royal Enfield Market PositioningDocument7 pagesRoyal Enfield Market PositioningApoorv Agrawal67% (3)

- BS4168Document10 pagesBS4168shoobi82No ratings yet

- 복사본 볼트규격표Document20 pages복사본 볼트규격표임동섭No ratings yet

- ARNOLD - Thread Forming ScrewDocument4 pagesARNOLD - Thread Forming ScrewgirishawantiNo ratings yet

- Astm A 668 A668m 2013 PDFDocument10 pagesAstm A 668 A668m 2013 PDFCarlos GuerraNo ratings yet

- Jis G4053-2008 PDFDocument14 pagesJis G4053-2008 PDFhbook100% (1)

- b1 20 1Document31 pagesb1 20 1Gustavo FamaNo ratings yet

- AISI 12L14 Steel Analysis and PropertiesDocument2 pagesAISI 12L14 Steel Analysis and PropertiessyuepiNo ratings yet

- ASTM A320-A320M-05aDocument8 pagesASTM A320-A320M-05aNadhiraNo ratings yet

- Ilnas-En Iso 19598:2016Document8 pagesIlnas-En Iso 19598:2016Victor ParvanNo ratings yet

- Mec PinDocument55 pagesMec PinManikandan VeerasekaranNo ratings yet

- Din 3760 KeçeDocument13 pagesDin 3760 KeçeUfuk YürekNo ratings yet

- Din125 WasherDocument2 pagesDin125 WasherHieu TranvanNo ratings yet

- European Standard Norme Europeenne Europaische Norm: Ultrasonic Testing of $teel BarsDocument13 pagesEuropean Standard Norme Europeenne Europaische Norm: Ultrasonic Testing of $teel BarspraveenNo ratings yet

- Chinese To DinDocument7 pagesChinese To Dindnageshm4n244No ratings yet

- Hot-rolled steel sheet standard covers chemical compositionDocument7 pagesHot-rolled steel sheet standard covers chemical compositionsiens2304No ratings yet

- Metric DIN 939 Double End Studs (1.25xD) : Visit Our For Product AvailabilityDocument4 pagesMetric DIN 939 Double End Studs (1.25xD) : Visit Our For Product Availabilitysudarshan pugaliaNo ratings yet

- DIN - 17230-1980 - Ball and Roller Bearing SteelsDocument20 pagesDIN - 17230-1980 - Ball and Roller Bearing SteelswilliansakumaNo ratings yet

- Old and New DINDocument6 pagesOld and New DINDianaNo ratings yet

- F 2281 - 03 - RjiyodeDocument10 pagesF 2281 - 03 - Rjiyodekrutik100% (1)

- Astm A193 PDFDocument12 pagesAstm A193 PDFjoserodriguezherazoNo ratings yet

- Grades of Steel ChartDocument3 pagesGrades of Steel ChartKimNo ratings yet

- DIN 3015 ClampsDocument20 pagesDIN 3015 ClampsRasheshNo ratings yet

- Brochure For SAE J518 O-Ring Assortment KitsDocument1 pageBrochure For SAE J518 O-Ring Assortment KitsChristopher RuizNo ratings yet

- En10083 1Document28 pagesEn10083 1whitebrosNo ratings yet

- Astm A751Document5 pagesAstm A751Cristian OtivoNo ratings yet

- Stellite 6Document3 pagesStellite 6Jessicalba LouNo ratings yet

- Synchronous Belt Drives - Automotive PulleysDocument14 pagesSynchronous Belt Drives - Automotive Pulleystv-locNo ratings yet

- Selected ISO Fits - Hole Basis. Extract From BS 4500, Data Sheet 4500ADocument2 pagesSelected ISO Fits - Hole Basis. Extract From BS 4500, Data Sheet 4500AEngr Nayyer Nayyab MalikNo ratings yet

- DIN HANdsfsDBOOK 1 PDFDocument6 pagesDIN HANdsfsDBOOK 1 PDFsohaiblatif3No ratings yet

- Astm A194Document11 pagesAstm A194Jarek CieslakNo ratings yet

- Iso Metric 32Document2 pagesIso Metric 32rahul caddNo ratings yet

- BS 21 - Pressure Tight Pipe Thread JointsDocument8 pagesBS 21 - Pressure Tight Pipe Thread JointsHARSHANo ratings yet

- As B199-1962 Undercuts and Runouts For Screw ThreadsDocument4 pagesAs B199-1962 Undercuts and Runouts For Screw ThreadsSAI Global - APACNo ratings yet

- En1564-1 2017Document4 pagesEn1564-1 2017Dan PopaNo ratings yet

- Hexagon Socket Head Cap Screws - IsO 4762-1992Document6 pagesHexagon Socket Head Cap Screws - IsO 4762-1992Corneliu VilcuNo ratings yet

- Astm B575Document5 pagesAstm B575Jota JacquesNo ratings yet

- Hexagon Head Screws With Metric Fine Pitch Thread - Product Grades Aandb (First Revision)Document15 pagesHexagon Head Screws With Metric Fine Pitch Thread - Product Grades Aandb (First Revision)kumar QANo ratings yet

- Astm A 494Document7 pagesAstm A 494Rodrigo BarrosNo ratings yet

- 40NiCrMo7 PDFDocument2 pages40NiCrMo7 PDFAmy GriffinNo ratings yet

- BS en 10228 4 2016 Non Destructive Testi PDFDocument30 pagesBS en 10228 4 2016 Non Destructive Testi PDFDaryna KupriianovaNo ratings yet

- A723A723M-18a 1.05 PDFDocument5 pagesA723A723M-18a 1.05 PDFist93993No ratings yet

- En10083 2Document2 pagesEn10083 2Sezgin BayrakNo ratings yet

- DIN 17175 Seamless Steel Pipes, Boiler Tube, Boiler Pipe, Seamless PipeDocument3 pagesDIN 17175 Seamless Steel Pipes, Boiler Tube, Boiler Pipe, Seamless Pipeprabhatkumar_6657012No ratings yet

- DIN 7349 - Arruela Plana PDFDocument1 pageDIN 7349 - Arruela Plana PDFpierocarnelociNo ratings yet

- Material Specifications - ASTM - Werkstoff Nummer - DIN enDocument3 pagesMaterial Specifications - ASTM - Werkstoff Nummer - DIN enalomejorfofi100% (1)

- Material Comparisons For Astm and JisDocument2 pagesMaterial Comparisons For Astm and JisNitesh GargNo ratings yet

- Estandares AstmDocument22 pagesEstandares AstmAgus HermantoNo ratings yet

- Iso 4948 2 en PDFDocument6 pagesIso 4948 2 en PDFKalpeshNo ratings yet

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987From EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNo ratings yet

- Iso Tolerances Din Iso 2768 - 1, Din Iso 2768 - 2Document3 pagesIso Tolerances Din Iso 2768 - 1, Din Iso 2768 - 2mameeran100% (2)

- Norma 2768 ToleranciasDocument2 pagesNorma 2768 Toleranciasmicheletche100% (1)

- General Tolerances - DIN ISO 2768Document2 pagesGeneral Tolerances - DIN ISO 2768Paulo Ferrari Tapie100% (2)

- According To DIN ISO 2768-1: Branco Engineering BureauDocument1 pageAccording To DIN ISO 2768-1: Branco Engineering BureauPHUONGNo ratings yet

- Toleràncies Dimensionals Iso 2768-1Document1 pageToleràncies Dimensionals Iso 2768-1carlesiemiNo ratings yet

- Iso 2768-1Document1 pageIso 2768-1Roberto Mota100% (1)

- Din Iso 2768Document3 pagesDin Iso 2768alberto.galloNo ratings yet

- DIN ISO 2768 General Tolerances T1 T2Document2 pagesDIN ISO 2768 General Tolerances T1 T2manageieNo ratings yet

- According To DIN ISO 2768-1Document2 pagesAccording To DIN ISO 2768-1Joe JoeNo ratings yet

- Jabra Storm User Manual - ENDocument19 pagesJabra Storm User Manual - ENfethiaktuncNo ratings yet

- Heat Treatment of SteelsDocument18 pagesHeat Treatment of SteelsRajeev SaiNo ratings yet

- Fuga Mobilya Katalog - Furniture Catalogue with Bedroom, Dining Room & TV Unit DesignsDocument48 pagesFuga Mobilya Katalog - Furniture Catalogue with Bedroom, Dining Room & TV Unit DesignsfethiaktuncNo ratings yet

- M 1522 Rifles CarbinesDocument38 pagesM 1522 Rifles CarbinesRyan EmbreyNo ratings yet

- Desert Eagle Semi-Automatic Pistol ManualDocument40 pagesDesert Eagle Semi-Automatic Pistol ManualMeor Amri100% (6)

- Interpane Tolerance Handbook 01-2013en PDFDocument60 pagesInterpane Tolerance Handbook 01-2013en PDFfethiaktuncNo ratings yet

- 2 Materials Charts 2010 PDFDocument42 pages2 Materials Charts 2010 PDFTrường Tùng LýNo ratings yet

- 6BA12 AR-7 Carbine Construction Guide To Full Auto SMG PDFDocument6 pages6BA12 AR-7 Carbine Construction Guide To Full Auto SMG PDFfethiaktuncNo ratings yet

- Heat Treatment GuideDocument33 pagesHeat Treatment GuidefethiaktuncNo ratings yet

- Blind Rivets VVG Fasteners 2016 2017Document58 pagesBlind Rivets VVG Fasteners 2016 2017fethiaktuncNo ratings yet

- Heat Treatment of SteelsDocument18 pagesHeat Treatment of SteelsRajeev SaiNo ratings yet

- 240LW Website Exploded ViewDocument1 page240LW Website Exploded ViewfethiaktuncNo ratings yet

- Bolt-Action Rifle Barrel and Receiver Parts ListDocument5 pagesBolt-Action Rifle Barrel and Receiver Parts ListfethiaktuncNo ratings yet

- AX50 Datasheet US 1Document2 pagesAX50 Datasheet US 1fethiaktuncNo ratings yet

- Web ManualDocument54 pagesWeb ManualfethiaktuncNo ratings yet

- Complaint Handling Policy and ProceduresDocument2 pagesComplaint Handling Policy and Proceduresjyoti singhNo ratings yet

- 2020-05-14 County Times NewspaperDocument32 pages2020-05-14 County Times NewspaperSouthern Maryland OnlineNo ratings yet

- "60 Tips On Object Oriented Programming" BrochureDocument1 page"60 Tips On Object Oriented Programming" BrochuresgganeshNo ratings yet

- (SIRI Assessor Training) AM Guide Book - v2Document19 pages(SIRI Assessor Training) AM Guide Book - v2hadeelNo ratings yet

- Weibull Statistic and Growth Analysis in Failure PredictionsDocument9 pagesWeibull Statistic and Growth Analysis in Failure PredictionsgmitsutaNo ratings yet

- E2 PTAct 9 7 1 DirectionsDocument4 pagesE2 PTAct 9 7 1 DirectionsEmzy SorianoNo ratings yet

- Instrumentos de Medición y Herramientas de Precisión Starrett DIAl TEST INDICATOR 196 A1ZDocument24 pagesInstrumentos de Medición y Herramientas de Precisión Starrett DIAl TEST INDICATOR 196 A1Zmicmarley2012No ratings yet

- The Human Resource Department of GIK InstituteDocument1 pageThe Human Resource Department of GIK InstitutexandercageNo ratings yet

- 1st Exam Practice Scratch (Answer)Document2 pages1st Exam Practice Scratch (Answer)Tang Hing Yiu, SamuelNo ratings yet

- QSK45 60 oil change intervalDocument35 pagesQSK45 60 oil change intervalHingga Setiawan Bin SuhadiNo ratings yet

- Chapter 6: Structured Query Language (SQL) : Customer Custid Custname OccupationDocument16 pagesChapter 6: Structured Query Language (SQL) : Customer Custid Custname OccupationSarmila MahendranNo ratings yet

- Nature of ConversionDocument18 pagesNature of ConversionKiranNo ratings yet

- Fundamental of Investment Unit 5Document8 pagesFundamental of Investment Unit 5commers bengali ajNo ratings yet

- Business Case - Uganda Maize Export To South SudanDocument44 pagesBusiness Case - Uganda Maize Export To South SudanInfiniteKnowledge33% (3)

- Peter Wilkinson CV 1Document3 pagesPeter Wilkinson CV 1larry3108No ratings yet

- Variable Displacement Closed Circuit: Model 70160 Model 70360Document56 pagesVariable Displacement Closed Circuit: Model 70160 Model 70360michael bossa alisteNo ratings yet

- ASCE - Art Competition RulesDocument3 pagesASCE - Art Competition Rulesswarup babalsureNo ratings yet

- ECON Value of The FirmDocument4 pagesECON Value of The FirmDomsNo ratings yet

- Leases 2Document3 pagesLeases 2John Patrick Lazaro Andres100% (1)

- Notes On Lesson: Faculty Name Code Subject Name CodeDocument108 pagesNotes On Lesson: Faculty Name Code Subject Name CodeJeba ChristoNo ratings yet

- De Thi Chuyen Hai Duong 2014 2015 Tieng AnhDocument4 pagesDe Thi Chuyen Hai Duong 2014 2015 Tieng AnhHuong NguyenNo ratings yet

- Terms and Condition PDFDocument2 pagesTerms and Condition PDFSeanmarie CabralesNo ratings yet

- Compressive Strength Beam DesignDocument70 pagesCompressive Strength Beam DesignDjuned0% (1)

- Learning HotMetal Pro 6 - 132Document332 pagesLearning HotMetal Pro 6 - 132Viên Tâm LangNo ratings yet

- 1990-1994 Electrical Wiring - DiagramsDocument13 pages1990-1994 Electrical Wiring - Diagramsal exNo ratings yet

- Benchmarking Guide OracleDocument53 pagesBenchmarking Guide OracleTsion YehualaNo ratings yet

- Beams On Elastic Foundations TheoryDocument15 pagesBeams On Elastic Foundations TheoryCharl de Reuck100% (1)

- Biggest Lessons of 20 Years InvestingDocument227 pagesBiggest Lessons of 20 Years InvestingRohi Shetty100% (5)

- Chapter 1 Qus OnlyDocument28 pagesChapter 1 Qus OnlySaksharNo ratings yet