Professional Documents

Culture Documents

Bài viết về lập trình gia công tiện bằng MasterCam và thực tế

Uploaded by

Chu Thị YếnCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bài viết về lập trình gia công tiện bằng MasterCam và thực tế

Uploaded by

Chu Thị YếnCopyright:

Available Formats

Bi vit v lp trnh gia cng tin bng MasterCam v thc t

Gi anh em mt bi vit v gia cng tin lp trnh bng MasterCam v i vo thc t trn my tin CNC HITACHI SYSTEM 3T.

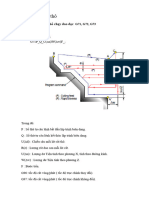

Dng sn phm :Bnh cn tole sng trn. Kch thc phi :156x78 chiu dy chun. Gia cng bng 2 loi dao tm mt loi 55 (th) v mt loi 35 (tinh). Ni mnh lm chuyn gia cng tin v cc loi bnh cn tole,bnh cn x g. C g mong anh em gp thm cng nhau pht trin vi VINAMECH. 1 Sn phm: Con ln cn tole. 2 phi : Phi thng dung cho bnh cn tole l thp C45 Kch thc phi thng c chn tu thuc cht lng,hnh dng phi. y phi c kch thc nh sau : Dy :78mm (chun) ng knh phi :156mm L :ng knh 70 3. Yu cu v chnh xc. Dung sai cho phm 0.2mm 3.Tin hnh lp trnh gia cng trn MasterCam X3: Khi ng MX v m file bn v ca chi tit :.dwg

Dng lnh Xform translate di chuyn chi tit v gc to gia cng.

M layer v n cc layer khng cn dng lp trnh,mi ng chy dao s dng mt layer duy nht :

To ng chy dao(bin dng chi tit)

Chn my tin mc nh l Generic

nh ngha phi.

nh ngha mm cp cho an ton th chng ta nn nhp cc thong s ca mm cp nh vy khi MX thc hin tnh ton gia cng s pht hin va chm vi mm cp y l iu nn lm.

Chn Rough toolpath tin hnh gia cng th.

Chn hng chy dao kiu chain

Chn kiu dao v chnh sa theo mun

Chn Insert tng ng loi cn dao (holder)

Chn v nhp cc thong s holder.

Trong parameter chn kiu b dao compensation l dao tm,nhp cc gi tr v feed rate (0.12),Plunge rate (bc tin xung dao thng gc) 0.08.,m ngui coolant (Flood),tc trc chnh (spindle speed) 650.Cc thong s ny c th nhp li trong tab Toolpath Parameter,c th b qua bc ny.

Chn kiu chy dao ZigZag,chiu su ph th 1.5 lng d cha li cho pass semi (bn tinh) l 0.2mm Trong hp thoi Senmi finish nhp lng d cha li cho gia cng tinh l 0.1 theo trc X v Z. Kiu vo dao Lead in -90,ra dao +90.Chn ch gia cng rnh nu c.

Kt qu

Gia cng tinh :

Vo toolpath chn finish : Chn Chain l ng chy dao trc Vo tab tool parameters v chnh sa cc thong s dao cho ng yu cu. y chn loi dao tm.Insert c chiu dy 4mm,bn knh nh dao 0.8mm Cc thong s v la chn khc lm ging nh dao ph th (l do cng loi cn dao tm,ch khc loi Insert)Nhp cc thong s cho toolpath l feed rate :0.12,tc trc chnh 720 vng/pht. Cc thong s cho finish parameter : Finish stepover :Chiu su ct cho Pass gia cng cui l 0.1mm. Number of finish stepover :S Pass gia cng tinh (cho bao nhiu Pass l ty ngi lp trnh), y mnh nhp l mt Pass,v lng d ca Pass gia cng trc li l 0.1mm. Stock to leave in X :Lng d cha li sau gia cng tinh. y mnh chn l 0 v l tinh. Stock to leave in Z :Lng d cha li cho phng Z l 0.tng t phng X Cc thong s khc trong hp thoi c th gii thch nh sau : Phn Tool compensation :B dng c ct Compensation type :Kiu b dao c cc la chn sau,nhng mnh bit ci no ni ci y,cc kiu khc cc bn t tm hiu . Kiu Computer :B dao bng cch phn mm t tnh tan v khi xut chng trnh ch c ta ,khng c G40,G41,G42. Kiu Control :B dao theo h iu khin ca my CNC.Khi xut chng trnh s c G40,G41,G42. Compensation direction :Hng b dao :Right :B dao phi,Left :b dao tri. Roll cutter around corners :Chn x l cnh chi tit hoc khng hoc chy theo hnh dng. Corner Break : cc kiu ph b gc cnh hoc bo cnh. Lead in/out : Nhp cc thong s cho vic vo dao ra dao.Thng thng mnh chn Lead in :-90. Vo dao thng gc. Lead out +90 .Rt dao thng gc. Plunge Parameter :Ch cho php hoc khng cho php gia cng rnh nu c trn chi tit.La chn ny thch hp vi trng hp khi s dng dao ny gia cng nhng khng cho ph rnh v loi dao khng thch hp gia cng rnh, li cho bc khc lm.

Z-234.874 Z0.000

Nhn OK tip tc.Mastercam s t ng tnh ton cho bn.

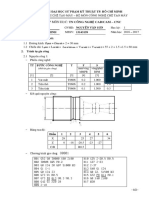

1. Xut chng trnh. Kch chn biu tng G1 trn Operation manager : Ok,chn Yes khi phn mm bo l c 2 dng c ct going nhau thc hin chu trnh gia cng v chn ng dn n th mc cn t chng trnh gia cng.Ok Kt qu chng trnh gia cng nh sau. % O0000 (PROGRAM NAME - CNC) (DATE=DD-MM-YY - 04-07-10 TIME=HH:MM - 12:12) (MCX FILE - I:\CNC.MCX) (NC FILE - I:\CNC.NC) (MATERIAL - ALUMINUM MM - 2024) G21 (TOOL - 5 OFFSET - 0) (OD ROUGH HEXAGON INSERT - NONE) G0 T0500 G18 G97 S1106 M03 G0 G54 X158.349 Z80.3 M8 G50 S3600 G96 S550 G99 G1 X154.349 F.12 Z78.324

G18 G3 X155.35 Z77. R2. G1 Z-2.837 X156.947 Z-3.253 X160.947 G0 X161.099 Z77. X159.35 G1 X155.35 G2 X153.197 Z78.774 R2. F.08 G1 X151.75 Z79.151 Z80.3 F.12 X155.75 G0 X156.5 X159.35 Z77. G1 X155.35 G3 X155.345 Z76.9 R2. F.08 X152.521 Z70.172 R22. G1 Z7.828 F.12 G3 X155.345 Z1.1 R22. X155.35 Z1. R2. G1 X159.35 X155.35 G2 X155.345 Z1.1 R2. F.08 X149.692 Z10.837 R22. G1 Z67.163 F.12 G2 X152.921 Z70.719 R22. G1 X156.921 X152.921 G3 X148.146 Z65.9 R22. F.08 G1 X146.862 Z64.925 Z13.075 F.12 X148.146 Z12.101 G3 X150.092 Z10.476 R22. G1 X154.092 X150.092 G2 X148.146 Z12.101 R22. F.08 G1 X144.033 Z15.223 Z62.777 F.12 X147.262 Z65.228 X151.262 X147.262 X141.204 Z60.629 F.08 Z17.371 F.12 X144.433 Z14.92 X148.433 X144.433 X138.375 Z19.519 F.08 Z58.481 F.12 X141.604 Z60.933 X145.604 X141.604 X135.546 Z56.333 F.08 Z21.667 F.12 X138.775 Z19.215 X142.775 X138.775

X132.717 Z23.815 F.08 Z54.185 F.12 X135.946 Z56.637 X139.946 X135.946 X129.887 Z52.037 F.08 Z25.963 F.12 X133.117 Z23.511 X137.117 X133.117 X128.654 Z26.899 F.08 G3 X127.058 Z28.208 R22. G1 Z49.793 F.12 G3 X128.654 Z51.1 R22. G1 X130.287 Z52.341 X134.287 X130.287 X128.654 Z51.101 F.08 G2 X124.229 Z46.761 R22. G1 Z31.239 F.12 G2 X127.458 Z27.86 R22. G1 X131.458 X127.458 G3 X121.4 Z39. R22. F.08 X124.629 Z47.273 R22. F.12 G1 X128.629 G0 X156.1 X159.35 Z1. G1 X155.35 G3 X153.55 Z-.671 R2. F.08 G1 Z-2.368 F.12 X155.75 Z-2.941 X159.75 X155.75 X151.75 Z-1.9 F.08 Z-1.151 F.12 X153.197 Z-.774 G2 X153.95 Z-.52 R2. G1 X157.95 G0 Z79.5 X155.55 G1 X151.55 Z79.09 X153.105 Z78.685 G3 X155.15 Z77. R1.9 X155.145 Z76.905 R1.9 X147.979 Z65.954 R21.9 G1 X128.486 Z51.156 G2 X121.2 Z39. R22.1 X128.486 Z26.845 R22.1 G1 X147.979 Z12.046 G3 X155.145 Z1.095 R21.9 X155.15 Z1. R1.9 X153.105 Z-.686 R1.9 G1 X151.55 Z-1.09 Z-1.961

X156.179 Z-3.165 X160.179 M9 G28 U0. V0. W0. M05 T0500 M01 (TOOL - 5 OFFSET - 0) (OD ROUGH HEXAGON INSERT - NONE) G0 T0500 G18 G97 S1093 M03 G0 G54 X160.179 Z79.5 G50 S3600 G96 S550 X155.35 G1 X151.35 F.12 Z78.887 X152.433 Z78.717 G18 G3 X154.95 Z77. R1.8 X154.945 Z76.91 R1.8 X147.812 Z66.01 R21.8 G1 X128.319 Z51.211 G2 X121. Z39. R22.2 X128.319 Z26.79 R22.2 G1 X147.812 Z11.991 G3 X154.945 Z1.09 R21.8 X154.95 Z1. R1.8 X152.433 Z-.716 R1.8 G1 X151.35 Z-.887 Z-2.429 X155.868 Z-3.207 X159.868 G28 U0. V0. W0. M05 T0500 M30 % Cc m lnh c t l cc m lnh cn phi chnh sa hay xa b khng cn thit. Mnh s dng my tin CNC 2 trc i SYSTEM 3T ca hng HITACHI nn cn c mt s hn ch,chng trnh khi sa phi ph hp vi iu kin ca my mc.Vic chnh sa nh sau: Cc m lnh loi b nh sau : Xa G18,G54,G99,G96.V G18 my khng hiu, my l my 2 trc ri nn hin nhin n hiu l gia cng trong mt XZ. Dng lnh G28 xa V0.V l my 2 trc,khng c trc V tng ng song song vi trc Y. Sau y l chng trnh c sa cha l c em vo s dng : % O0001 T0700 G50 X0. Z0. G97 S650 M03 G0 X190.2 Z80.3 T0707 M8 X158.349 G1 X154.349 F.12 Z78.324 G3 X155.35 Z77. R2. G1 Z-2.837 X156.947 Z-3.253 X160.947

G0 X161.099 Z77. X159.35 G1 X155.35 G2 X153.197 Z78.774 R2. F.08 G1 X151.75 Z79.151 Z80.3 F.12 X155.75 G0 X156.5 X159.35 Z77. G1 X155.35 G3 X155.345 Z76.9 R2. F.08 X152.521 Z70.172 R22. G1 Z7.828 F.12 G3 X155.345 Z1.1 R22. X155.35 Z1. R2. G1 X159.35 X155.35 G2 X155.345 Z1.1 R2. F.08 X149.692 Z10.837 R22. G1 Z67.163 F.12 G2 X152.921 Z70.719 R22. G1 X156.921 X152.921 G3 X148.146 Z65.9 R22. F.08 G1 X146.862 Z64.925 Z13.075 F.12 X148.146 Z12.101 G3 X150.092 Z10.476 R22. G1 X154.092 X150.092 G2 X148.146 Z12.101 R22. F.08 G1 X144.033 Z15.223 Z62.777 F.12 X147.262 Z65.228 X151.262 X147.262 X141.204 Z60.629 F.08 Z17.371 F.12 X144.433 Z14.92 X148.433 X144.433 X138.375 Z19.519 F.08 Z58.481 F.12 X141.604 Z60.933 X145.604 X141.604 X135.546 Z56.333 F.08 Z21.667 F.12 X138.775 Z19.215 X142.775 X138.775 X132.717 Z23.815 F.08 Z54.185 F.12 X135.946 Z56.637 X139.946

X135.946 X129.887 Z52.037 F.08 Z25.963 F.12 X133.117 Z23.511 X137.117 X133.117 X128.654 Z26.899 F.08 G3 X127.058 Z28.208 R22. G1 Z49.793 F.12 G3 X128.654 Z51.1 R22. G1 X130.287 Z52.341 X134.287 X130.287 X128.654 Z51.101 F.08 G2 X124.229 Z46.761 R22. G1 Z31.239 F.12 G2 X127.458 Z27.86 R22. G1 X131.458 X127.458 G3 X121.4 Z39. R22. F.08 X124.629 Z47.273 R22. F.12 G1 X128.629 G0 X156.1 X159.35 Z1. G1 X155.35 G3 X153.55 Z-.671 R2. F.08 G1 Z-2.368 F.12 X155.75 Z-2.941 X159.75 X155.75 X151.75 Z-1.9 F.08 Z-1.151 F.12 X153.197 Z-.774 G2 X153.95 Z-.52 R2. G1 X157.95 G0 Z79.5 S750 X155.55 G1 X151.55 F0.3 Z79.09 X153.105 Z78.685 G3 X155.15 Z77. R1.9 X155.145 Z76.905 R1.9 X147.979 Z65.954 R21.9 G1 X128.486 Z51.156 G2 X121.2 Z39. R22.1 X128.486 Z26.845 R22.1 G1 X147.979 Z12.046 G3 X155.145 Z1.095 R21.9 X155.15 Z1. R1.9 X153.105 Z-.686 R1.9 G1 X151.55 Z-1.09 Z-1.961 X156.179 Z-3.165 X160.179 M9

G0 X0. Z0. T0700 T0500 G50 X0. Z0. G97 S800 M03 G0 X180.2 Z79.5 T0505 M8 X155.35 G1 X151.35 F.12 Z78.887 X152.433 Z78.717 G3 X154.95 Z77. R1.8 X154.945 Z76.91 R1.8 X147.812 Z66.01 R21.8 G1 X128.319 Z51.211 G2 X121. Z39. R22.2 X128.319 Z26.79 R22.2 G1 X147.812 Z11.991 G3 X154.945 Z1.09 R21.8 X154.95 Z1. R1.8 X152.433 Z-.716 R1.8 G1 X151.35 Z-.887 Z-2.429 X155.868 Z-3.207 X159.868 M9 M05 G28 U0. W0. M30 %

pass bn tinh mnh tng tc trc chnh ln 750 v feed rate l 0.3 lt nhanh tit kim thi gian. Dao tinh s chy cng tc 750,feed rate 0.12 Dng lnh G50 X0. Z0. dy cu lnh sau : T0700 G50 X0. Z0. G97 S650 M03 G0 X190.2 Z80.3 T0707 M8 Mnh thc s khng hiu n c cn thit khng nhng mnh ngh l khng, cng ty mnh vn thng lm nh vy. Trong cu lnh G0 X190.2 Z80.3 T0707 M8 th X190.2 phi nh hn hoc bng gi tr X trong bng Offset/wear ca my CNC.V nu gi tr ny ln hn 195.331 chng hn th khi chy tht th s b mt c (Home).Trc Z khi ni v gi tr Z80.3 theo chng trnh gia cng, i vi my ca mnh vn hnh th gi tr OFFSET ca dao s 7 v dao s 5 nh sau. 7 X-194.311 Z-315.174 R0.000 T7 5 X-185.223 Z-317.255 R0.000 T5 Gii thch them v dng G0 X190.2 Z80.3 T0707 M8 Khi chy single block dng lnh ny th My s hiu trc tin ta phi sau s nhn hai ta X190.2 Z80.3 so vi gc ta phi ca mm cp ch khng cn so vi gc my. Trn bng Position ca my CNC s c cc thay i sau. Relative Position Absolute position Absolute position

X-4.131 X190.2 X190.2 Z-234.874 Z80.3 Z80.3 Machine positon Distance togo Distance togo X-4.131 X0.000 X0.000

Z-234.874 Z0.000

iu c ngha l dao s dch xung mt t l X4.131 ri chy ngang theo phng Z cch b mt phi mt v ta Z y l 80.3.iu ny tng t nh dch dao theo phng Z u tin sau mi u tin theo phng X. Gc ta y l gc ta phi,tt c cc ta u so vi gc ta phi sau khi thc hin dng lnh G0 X190.2 Z80.3 T0707 M8. Kt thc dao s 7 s c dng lnh G0 X0. Z0. T0700 Mnh vn cha hiu l ti sao l X0. Z0. Nhng khi dung G28 U0. W0. T0700 th my b mt c ngay khng xa b dao c.Nu ai hiu th gii thch gip. gn cui chng trnh cng vy,mnh phi l G28 U0. W0. ch khng th l G28 U0. W0. T0500. Trn y l ton b cc bc thc hin lp trnh gia cng trn my CNC v thc hin Trn MasteCam,Cimcoedit 4.

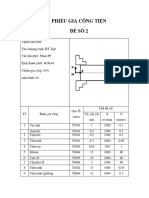

Gia cng tin : Tin vt mt :Lnh face Chi tit :Gi s chng ta gia cng chi tit nh sau. y mnh ch ni v gia cng vt mt thi nha.

Chn my gia cng. Vo machine type\lathe chn loi my l defaut,bn c th ng loi my m bn ang lm vic bng chn vo Manage list. nh ngha phi v mm cp :

Hp thoi Machine Group properties. Xut hin vi tap stock.

chn properties trong phn stock nh ngha phi.

Tap Geometry :Hnh hc ca phi.

geometry s c vi loi kiu hnh hc phi nhng mt nh l Cylinder ri nn bn khi cn chnthm,trng hp l phi c dng bt k khc mi chn loi khc,hn na

Trong gia cng CNC l gia cng hang lot nn d nhin phi phi thch hp.

Nu bn chn Make from 2 point th vic nh ngha phi s thc hin bng cch pick chn 2 im 2 gc ca hnh ch nht trn mt top tng t nh 2 gc ca chi tit. OD :nhp gi tr ng knh ngoi chi tit,nu nh ngha phi bng 2 im th y c th nh ngha li,cc bn hy th lm cho bit.

ID :chn ng knh trong nu c hy nhp them gi tr cho ng knh trong ca chi tit. Length :nhp chiu di chi tit

Axis :t gc ta phi bn phi hay phi chi tit,thong s ny c ngha quan trng, y mnh t gc ta phi bn tri chi tit.

Use margins:s dng cc lng d.Khi chn vo cc thong s lng d theo ng knh v chiu dy s hin ra,chng ta hy nhp vo nu c.

y mnh cho lng d theo ng knh l 1mm.v lng d theo chiu dy bn phi l 3mm. Chn Ok.

Xong bc to phi v quay li hp thoi Machine Group Properties. Chng ta tip tc nh ngha mm cp

Trong phn Chuck Jaws c 2 la chn l left v right ,mnh chn left spindle tc bn tri trc chnh cng l bn tri phi.V tip tc chn vo Properties.

Xut hin hp thoi : Trong phn Geometry ny s nhp cc thong s quan trng sau y :

Ok chp nhn. Ok tip tc. Nu thong s no sai ta c vo hp thoi m nhp li.

Bc tip theo to toolpath : Vo toolpath chn Face : Hin ra hp thoi :

C OK Tip tc hin ra hp thoi .

Pha bn tri hp thoi tool parameter chn dao cn gia cng hoc c th bn to mi mt dng c ct ty theo dao m bn c.Phn ny s cp sau nu nh bn no cn hi hy t vn . y mnh ch chn ly mt dao lm v d,cn nhiu vn khc lien quan n thc t chng ta s bn tip. Trn hp thoi ny s c mt s iu ta cn quan tm sau : Tool number :s th t dao Offset number :s ch v tr Offset ca dao trn my gia cng.Ci ny rt quan trng,cng cp sau nu cc bn hi. Feed rate :Bc tin dao.ci ny lien quan n nhiu th,cn kinh nghim.

Spindle speed :tc trc chnh. Max spindle speed :gii hn max ca tc trc chnh ty thuc my. Coollant :ngui,m nc ty thuc vo chc nng m nc, y mnh chn flood. Chuyn qua tap Face parameter :

Select point :chn vng b gia cng.bng cch chn 2 im gii hn. Use stock :s dng kch thc phi cn li sau gia cng.iu ny c ngha bn phi nhp chiu dy ca phi cn li sau khi thc hin vt mt. Compesation type : Computer :phn mm s t ng tnh ton v cho xut ra chng trnh l ta dao Control :b dao theo b iu khin ca my gia cng CNC.

Compensation direction :hng b dao,ch ny bn khi lo,khi chn hng gia cng phn mm t ng hiu hng b dao tri hoc phi,bn khi cn chn,tuy nhin cng c khi phn mm chn hng b dao sai cc bn phi chn li.

Entry amount :V tr t dao bt u gia cng..Nu dao ang v tr home th trc khi gia cng,n s thc hin chy dao nhanh n v tr sau mi thc hin gia cng.

Rough stepover :Chn vo y bn s nhp chiu dy cho mi pass gia cng th.Nu khng chn th s thc hin gia cng theo gia cng tinh.

Finish stepover :Nhp chiu dy pass tinh,pass ny phi c chiu dy gia cng cho mi pass l t hn so vi gia cng th.

Maximum number of finish passes :S pass gia cng tinh ln nht l bao nhiu.Ci ny cn ty thuc vo chiu dy ca mi pass gia cng tinh nn mi c ch MAXIMUM. Overcut amount :Nhp them khong dao i qu tm,ci ny dao ct ht qu tm phi. Retract amount :Nhp khong li dao, bt u thc hin pass tip theo. Rapid retract :Ch li dao nhanh (G0).Ci ny nu khng chn th khi ct xong mi pass dao s li v v tr bt u cho pass tip theo vi bc tin khi ct gt.Ni chung l nn chn. Stock to leave:Lng d cha li.Nu l gia cng th th cha li cn khng nhp 0 vo.

Cut away from center line :la chn ny c ngha l s thc hin vt t tm ca phi hng ra ngoi ng knh phi,ch dnh cho trng hp phn c l. Hon tt chn OK.

MasterCam s thc hin tnh ton. M phng chy th v xut chng trnh.Bc ny bi trn c ni n,nn mnh dng bi ny li

C rt nhiu iu cha c ni r y mong cc bn cho kin mnh s gii thch hoc c th hc hi thm,

Gia cng phay Pocket milling: phay hc (cavity) Cc chi tit c b mt lm p dng c 1: Chi tit M MasterCam v a chi tit vo mi trng gia cng:

2: Chn my gia cng: Trong Machine type (Loi my gia cng)-Chn Generic(my gia cng thng thng-H mt s l FANUC) nh ngha phi: M Properties trong Operation Manager chn Stock: Hin ra hp thoi:

Trn hp thoi ny s c nhng thng s v ngha nh sau: Machine group Properties: Cc thng s ca (nhm) my. Stock setup: Thit lp phi. Tool setting: Thit lp dng c ct. Safety Zone: Vng an ton. y chng ta ch quan tm n th Stock setup: Stock view: Khung nhn quan st phi. Trong phn shape (hnh dng phi) S c nhng ty chn sau: Rectangular: dng ch nht Cylindrical: Dng khi tr. Solid: phi c dng khi solid (khng c dng c bit). File: Ly phi t mt file sn c. 3 gi tr X, Y, Z trong m hnh: nhp kch thc phi bng tay. Ty chn Bounding box: Phi s t ng nhn bng gii hn bin ca chi tit. Select corners: To phi bng cch chn cc gc ca chi tit. Stock origin: Gc ca phi

In view coordinates: Trong cc h ta trong khung nhn. (cc bn nhn thy mi tn ch tm khi hp trong hp thoi y). OK kt thc qu trnh to phi. tip tc chng ta vo toolpath chn surface rough (gia cng th b mt cong) chn Pocket tin hnh bc gia cng th.

Xut hin dng nhc : Select drive surfaces (chn cc b mt cn gia cng). Trn chi tit gia cng ca chng ta c nhng b mt khng cn gia cng nn ta khng cn phi chn. Nh l chn y cc b mt ca hc chi tit, nu thiu MC s loi tr b mt v khng tnh ton gia cng cho b mt .

Trn hnh trn c ch b nhm l vng ch nht khoanh vng, bc ny khng ng, nhng khng th ch tip nn phi up i thi. Nn nh l ch chn cc b mt cn gia cng thi (hc-cavity). Enter tip tc. S hin ra hp thoi

Surface selection: Cc la chn b mt gia cng Drive: B mt cn gia cng. Tr chut nt chn l ch vo chn b mt cn gia cng, nt c du cho l hy b la chn v chn li. Nt show: Cho xem cc mt va chn, khi chn nt ny cc b mt khng c chn s n i cc bn s thy cc thiu xt nu c, hoc cc b mt chn tha, ch cn pick chut ch vo b mt cn loi b thi.

Check: Cc b mt khng gia cng, trng hp cc bn thc hin chn cc mt drive l ton b cc b mt ca chi tit th phn check ny cc bn c th chn nt con tr chut chn cc b mt khng cn gia cng, tt nhin cc b mt cn gia cng-drive s gim i. Cc nt chn trong phn check tng t nh phn drive. Containment: Gii hn vng bin gii gia cng. y bn chn phay hc nn bc ny b, khng cn a vo, trng hp hc h th hy chn phn ny. bc ny nu bn chn vng bin l cc cnh ngoi cng ca mt bn chi tit (nhn t mt top) th Master Cam s gia cng lun phn ngoi ca chi tit. Ch ny c th gii thch sau. Entry point: Chn im vo dao. Bn nn chn im ny nm ngoi bin ca chi tit (trn cng c view chn top thy) Cc la chn khc ca phn ny tng t nh drive, check. Chn Ok. Tip tc hin hp thoi sau:

Chn Ok. Tip tc hin hp thoi sau:

Trn hp thoi s c nhng thng s sau: Toolpath parameters: Cc thng s ng chy dao. Trang bn tri xin gii thch nh sau: Ci biu tng # chnh l tool number: S th t dao Tool name:Tn dng c ct. Dia.: ng knh dao. (vit tt ca diameter) Cor. rad: -Corner radius: Bn knh gc ct dao. Ci ny mun hiu qua phn to dng c mi s thy. Length: Chiu di dng c ct. Pha bn phi s c nhng thng s sau: Tool name: tn dng c ct. Tool #: S th t dao. Len. Offset: Chiu di offset dao (thng s ny cha hiu lm). Head #: S th t u dao. Dia. Offset: gi tr ng knh offset dao. Tool dia. : ng knh dao. Corner radius: bn knh gc y dao. Coolant: M ngui. Spindle direction: hng quay ca trc chnh hay dng c ct. CW -Clock wise: Cng chiu kim ng h. CCW-Counter clock wise: Ngc chiu kim ng h. Feed rate: Bc tin dao ngang Flunge rate: Bc tin xung dao. Retract rate: Bc tin li dao. Force tool change: Thay dao bt buc (khng cht lm c th l p thay dao) Rapid retract: Li dao nhanh.

Comment: To ch thch Select library tool: Chn dng c ct trong th vin dao. Cc thng s khc mnh t dng, nn chu, bn no b sung c th post thm vy. Bc tip theo to dng c ct mi: Right click vo phn bn tri chn Create new tool Cc la chn khc khi right click: Edit tool: Chnh sa li dng c ct c. Xut hin hp thoi sau:

Hp thoai Define tool /type c nhng thng s dao sau: End mill: dao phay ngn. Spher mill: dao phay cu Bull mill: dao phay c bo R y dao. Face mill: Dao phay kha mt Rad Mill: Dao phay R: loi dao phay nh hnh bn knh b mt sau gia cng. Slot mill: Dao phay rnh nh hnh. Bore bar: Dao doa. Taper mill: Dao phay rnh cn. Drill: Mi khoan

. . . . . . . . . . Cc loi khc t dng nn cng khng r lm. Calc. Speed/Feed: Tnh ton ch ct bao gm tc v bc tin, nhng thc s cha cn thit lm, i chn dao xong, thit lp chiu su ct mi tnh n. Save to library tool: Lu vo th vin dao. Cc dao do cc bn nh ngha c th lu li dng ring. Chn spher mill: Dao phay cu v OK. Xut hin hp thoi sau:

Trn y s hin ra hp thoi hnh hc ca dng c ct: C cc thng s cn quan tm sau: Flute: Chiu di phn ct Shoulder: chiu di n vai dao. Overall: Chiu di ca dao. Corner radius: bn knh ca y cu-bng na ng knh dao. Diameter: ng knh dao. Arbor diameter: ng knh phn kp dao. Capable of: C kh nng dng cho Rough: Ch gia cng th Finish: Ch gia cng tinh. Both: Png cho c 2 trng hp. Phay th v tinh.

Rough XY Step: B rng ca phn dng c ct n phi trong mt phng XY, tnh theo % ca ng knh dng c ct. V d dao ng knh 20mm vi gi tr trong ny l 60 th b rng ct s l 12mm. Finish XY step: Tng t nh trn. rng ca phn dng c ct n vo phi khi gia cng tnh theo % ca dng c ct. Rough Z step: su ct mi pass tnh theo % ca ng knh dng c ct. Finish Z step: su lt ct tinh tnh theo % dng c ct. Required pilot dia: ng knh l dn hng dng khi khoan, ta r ren, khot l. . . Material: Vt liu ca dng c ct: - HSS: High speed steel: Thp gi hay theo cao tc. - Carbide - Ceramic: s - Borzon - Unkown: ngi dng ch nh. % of matl. cutting speed: tc ct mc nh ly theo % tc ct b mt trong d liu tnh ton ca MC. % of matl. feed per tooth: Tc ct mt nh ly theo % tc ct b mt trong d liu tnh ton ca MC, thng s ny quyt nh do vt liu ca dng c dao ct v vt liu phi b ct. Tool file name: Tn tp tin ca dng c ct. Tool name: tn dng c ct. Chuck: dng c kp, mm cp. Manufacturers tool code: m dng c ca nh sn xut. Feed rate: Bc tin dao ngang.

Plunge rate: Bc tin xung dao. Retract rate: bc tin li dao. Spindle speed: Tc trc chnh. Coolant: Ngui Off: tt ngui. Mist: dng sng m. Flood: dng dng chy. Phm chn Calc. speed/feed: Mastercam s tnh ton cho ta bc tin v tc . Phm Save to library: Lu dng c ct va nh ngha vo th vin ring. Ch ny cc bn c th to cho ring mnh nhiu loi dng c ct khc nhau, khi mt cng nh ngha li. Trn y cc bn c th nhp cc thng s sau y cc thng s khc khng cn thit lm. Rough XY Step. C th mc nh Finish XY step C th mc nh Rough Z step C th mc nh Finish Z step C th mc nh Feed rate: 200 Plunge rate: 200 Spindle speed: 1000 Tr li trang Surface rough Pocket. Mt dng c ct c to ra.Cc bn c th to ra nhiu dao phc v cho cc bc gia cng tip theo,v khng hn l chi tit ny c th gia cng c bng mt loi dao,m bng nhiu dao.

Qua trang Surface parameter: Cc thng s b mt gia cng.

Trn trang ny s c nhng thng s sau: Clearance: Mt phng an ton. L mt phng m sau khi kt thc gia cng ca con dao , dao s rt v v tr ny. Absolute: Ly theo ta tuyt i Incremental: Ly theo ta tng i. Tip comp (tip compensation): cc kiu b dao. Retract: Li dao. Ch nh mt phng li dao sau mi ln chuyn dao gia cng lt ct tip theo. Feed plane: mt phng n phi. Hay l mt phng gia cng, t y dao s bt u thc hin gia cng. Regen (regenerate ): Xut li thng s b mt. Qua th Rough parameter: Cc thng s gia cng th.

Total tolerance: Dung sai tng ca b mt sau gia cng. Maximum stepdown: Chiu su ct ln nht cho mi lt ct Climb: Phay thun Conventional: Phay nghch. Hai thng s climb v conventional cn phi hiu r, khi cn s up hnh ln gii thch, vn ny c nhiu ti liu gii thch nhng cha r rng. Entry options: Cc ty chn vic vo dao thc hin ct gt kL. Use entry: S dng chc nng vo dao. Align plunge entries for start holes: Chnh hng xung dao theo cc l khoan bt u. Qua th Pocket parameters: Cc thng s gia cng ti hc.

Phn rough: Cutting methods: Cc phng php ct gt, hay cc kiu chin lc chy dao. Nh hnh hin th, khng gii thch thm phn ny. Stepover percentage: Phn trm b rng ct ngang so vi ng knh dao. Spiral inside to outside: Chy xon c t trong ra ngoi. Use quick zigzag: S dng kiu chy zigzag nhanh. Roughing angle: Gc ct th so vi phng X. Finish: gia cng tinh. Nu chn vo y, sau gia cng th s thc hin lun gia cng tinh bng dao ny. Pass: s lt ct tinh. Cutter compensation: B dao. Lead in/out: thit lp vo v ra dao. Xong th pocket parameter: Chn OK kt thc hp thoi Surface rough pocket. MasterCam s thc hin tnh ton ng chy dao trong khong thi gian 30s. V kt qua cui cng

You might also like

- Báo Cáo CNCDocument23 pagesBáo Cáo CNCPhong ĐặngNo ratings yet

- CHU TRINH TIỆN G71.G70Document26 pagesCHU TRINH TIỆN G71.G70dongate79No ratings yet

- BaocaocadcamDocument32 pagesBaocaocadcamBilson mcpeNo ratings yet

- Đỗ Nhật Quang MẪU BÁO CÁO GC3 207154Document13 pagesĐỗ Nhật Quang MẪU BÁO CÁO GC3 207154Trần Anh TríNo ratings yet

- Đáp Án Cad Cam 2015Document4 pagesĐáp Án Cad Cam 2015Huynh Nhat HaoNo ratings yet

- 2 - BT Dich CTDocument7 pages2 - BT Dich CTkhach laNo ratings yet

- (104 Dap An de Thi Hoc Ky I Nam Hoc 2015 2016 Mon Cong Nghe Cadcam CNC Co Ban Dot 2 DH Su Pham Ky ThuatDocument10 pages(104 Dap An de Thi Hoc Ky I Nam Hoc 2015 2016 Mon Cong Nghe Cadcam CNC Co Ban Dot 2 DH Su Pham Ky ThuatTrangNo ratings yet

- 1617-1 - CNC CB - BT Tien XeDocument2 pages1617-1 - CNC CB - BT Tien XeNguyen Anh MinhNo ratings yet

- Ly Thuyet - TIEN CNCDocument11 pagesLy Thuyet - TIEN CNCNhật NguyễnNo ratings yet

- 2 - BT Dich CTDocument7 pages2 - BT Dich CT20143224No ratings yet

- GiacongDocument30 pagesGiacongcasyboy1996No ratings yet

- Các lệnh G-code cơ bản cho máy CNC - 970508Document5 pagesCác lệnh G-code cơ bản cho máy CNC - 970508Trương Văn TrọngNo ratings yet

- BTN2 03 Xaydung mayphayCNC3trucDocument19 pagesBTN2 03 Xaydung mayphayCNC3trucMinh VõNo ratings yet

- Chương IiDocument17 pagesChương IiHoàng NguyễnNo ratings yet

- DondoanDocument8 pagesDondoanTrưởng NgôNo ratings yet

- Chương ViiiDocument5 pagesChương ViiiNguyễn ChungNo ratings yet

- Mẫu Báo Cáo Gc3 (207154)Document11 pagesMẫu Báo Cáo Gc3 (207154)Nguyễn Văn TâmNo ratings yet

- Phay CNC - ĐHBKDocument6 pagesPhay CNC - ĐHBKDũng Châu ChíNo ratings yet

- Tien FanucDocument4 pagesTien FanucdamphuongNo ratings yet

- Chế tạo ống lótDocument10 pagesChế tạo ống lótTrần NamNo ratings yet

- Lập trình gia công tiện (Lathe70) với MasterCam X4 tiếng việtDocument18 pagesLập trình gia công tiện (Lathe70) với MasterCam X4 tiếng việtTruonglanaNo ratings yet

- Cad/cam Co BanDocument6 pagesCad/cam Co Bantranvutuananh01032003No ratings yet

- DUCDocument13 pagesDUCĐức NhậtNo ratings yet

- Dương Gia Kiệt_21146117_Đề 1Document4 pagesDương Gia Kiệt_21146117_Đề 1Vu Nguyen Manh HungNo ratings yet

- Hướng dẫn sử dụng G-Code Lập trình CNCDocument21 pagesHướng dẫn sử dụng G-Code Lập trình CNCdaocongdablNo ratings yet

- Bài tập 1.1Document27 pagesBài tập 1.1Quốc PhongNo ratings yet

- Phay CNCDocument51 pagesPhay CNCHiệp Trần NgọcNo ratings yet

- Tien - Cncfagor Maycnc7 t8050Document67 pagesTien - Cncfagor Maycnc7 t8050Phương Hoàng VănNo ratings yet

- Báo cáo BTL Công nghệ CNCDocument25 pagesBáo cáo BTL Công nghệ CNCHiệp Trần NgọcNo ratings yet

- CNC Autosaved AutosavedDocument131 pagesCNC Autosaved AutosavedVăn NhạtNo ratings yet

- Chuong2 CNgiacongCNCDocument79 pagesChuong2 CNgiacongCNCPháp Sư Giấu MặtNo ratings yet

- BT3 Đào Đ C Anh 1410052Document12 pagesBT3 Đào Đ C Anh 1410052lam cuongNo ratings yet

- Bù DaoDocument29 pagesBù Daogd1901100% (2)

- Tinh Toan Moi Ghep ThenDocument384 pagesTinh Toan Moi Ghep ThenBùi Văn HợpNo ratings yet

- chế đọ cắt tuần 3Document6 pageschế đọ cắt tuần 3Thắng NguyễnNo ratings yet

- Các lệnh lập trình CNCDocument198 pagesCác lệnh lập trình CNCTran HoangNo ratings yet

- Báo Cáo CADCAMCNCDocument27 pagesBáo Cáo CADCAMCNCNguyễn Thế VũNo ratings yet

- Các lệnh CNC cơ bảnDocument3 pagesCác lệnh CNC cơ bảnSơn HảiNo ratings yet

- BÀI TẬP TIỆN REN - Nguyễn Phương Thảo 18104042Document4 pagesBÀI TẬP TIỆN REN - Nguyễn Phương Thảo 18104042Nguyễn Phương ThảoNo ratings yet

- Bai Giang TIENDocument54 pagesBai Giang TIENThanh PhướcNo ratings yet

- Nguyễn Việt Thắng 101200374Document11 pagesNguyễn Việt Thắng 101200374thắng nguyễnNo ratings yet

- Thuyết Minh Dao-Thầy Long Góp ý.Document5 pagesThuyết Minh Dao-Thầy Long Góp ý.Khiêm Nguyên GiaNo ratings yet

- Bài tập 1Document27 pagesBài tập 1Hữu NghịNo ratings yet

- MÃ LỆNH G CODEDocument2 pagesMÃ LỆNH G CODEĐạt ThànhNo ratings yet

- Lochppc04957 Lab1Document14 pagesLochppc04957 Lab1Na BuiNo ratings yet

- GCode List PDFDocument3 pagesGCode List PDFduongfxNo ratings yet

- Tìm hiểu về GDocument55 pagesTìm hiểu về GcuongnxcuongNo ratings yet

- Lachnngcinv HpgimtcDocument35 pagesLachnngcinv HpgimtcT.K KỳNo ratings yet

- 41.2001.QD - BCN PhulucDocument11 pages41.2001.QD - BCN Phuluctrilinh2k3No ratings yet

- Tinh Toan Co Ban (14.11.21)Document15 pagesTinh Toan Co Ban (14.11.21)Nam HoaiNo ratings yet

- Báo cáo thí nghiệm môn cadDocument12 pagesBáo cáo thí nghiệm môn cadTrí NguyễnNo ratings yet

- Thông Cad Cam 15-5Document46 pagesThông Cad Cam 15-5hoangvujr9No ratings yet

- Báo Cáo Đ Án I Hà Văn CDocument11 pagesBáo Cáo Đ Án I Hà Văn CBangNo ratings yet

- GVHD: thầy Nguyễn Văn Thành SVTH: Nguyễn Đăng Khoa MSSV: 1711778 Lớp: A02Document49 pagesGVHD: thầy Nguyễn Văn Thành SVTH: Nguyễn Đăng Khoa MSSV: 1711778 Lớp: A02Khoa KhoaNo ratings yet

- Lực kẹp khi gia côngDocument6 pagesLực kẹp khi gia côngHạ Xuân ThuNo ratings yet

- PHIẾU CÔNG NGHỆDocument2 pagesPHIẾU CÔNG NGHỆmỹ vănNo ratings yet

- System DataDocument22 pagesSystem DataNam NguyễnNo ratings yet