Professional Documents

Culture Documents

GE Lube Oil Varnishing TIL 1528-3

Uploaded by

hebishtOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GE Lube Oil Varnishing TIL 1528-3

Uploaded by

hebishtCopyright:

Available Formats

TIL 1528-3 GE ENERGY SERVICES TECHNOLOGY CUSTOMER TECHNOLOGY SERVICES 18 NOVEMBER 2005

Compliance Category - O Timing Code - 7

TECHNICAL INFORMATION LETTER

LUBE OIL VARNISHING

APPLICATION

This TIL applies to all heavy-duty gas turbines.

PURPOSE

This TIL is to provide customers with information regarding the formation of varnish or lacquers within the lube oil system, their effects and information regarding mitigation technologies. Please note that this information represents the current information gathered to date. Compliance Category O - Optional M - Maintenance C - Compliance Required Identifies changes that may be beneficial to some, but not necessarily all, operators. Accomplishment is at customer's discretion. Identifies maintenance guidelines or best practices for reliable equipment operation. Identifies the need for action to correct a condition that, if left uncorrected, may result in reduced equipment reliability or efficiency. Compliance may be required within a specific operating time. Failure to comply with the TIL could result in equipment damage or facility damage. Compliance is mandated within a specific operating time. Failure to comply with this TIL could result in personal injury. Compliance is mandated within a specific operating time.

A Alert S Safety Timing Code 1 2 3 4 5 6 7

Prior to Unit Startup / Prior to Continued Operation (forced outage condition) At First Opportunity (next shutdown) Prior to Operation of Affected System At First Exposure of Component At Scheduled Component Part Repair or Replacement Next Scheduled Outage Optional

COPYRIGHT 2005 GE The information published in this Technical Information Letter is offered to you by GE in consideration of its ongoing sales and service relationship with your organization. However, since the operation of your plant involves many factors not within our knowledge, and since operation of the plant is in your control and ultimate responsibility for its continuing successful operation rests with you, GE specifically disclaims any responsibility for liability based on claims for damage of any type, i.e. direct, consequential or special that may be alleged to have been incurred as result of applying this information regardless of whether it is claimed that GE is strictly liable, in breach of contract, in breach of warranty, negligent, or is in other respects responsible for any alleged injury or damage sustained by your organization as a result of applying this information.

TIL 1528-3

BACKGROUND DISCUSSION

Varnish formation in lubricating oil and hydraulic systems has been present for many years in the power generation industry. Historically, varnish formation has been attributed to a singular root cause. For example, there was a #2 bearing drain line of a gas turbine was touching the inside of the exhaust strut, which caused thermal degradation of the oil and varnish formation. Varnish can be reddish brown to black in appearance, depending on the mechanism that caused the oil molecule to break and varnish to form. Recent studies have revealed that oil varnishing is usually the result of a complex string of events. To start this chain of events, oil molecules must be broken. The mechanisms that break oil molecules fall into these general categories: chemical, mechanical, and thermal. Chemical: Many chemical reactions occur as the oil ages. Oxidation of the oil leads to numerous decomposition products, including acids and insoluble particulates. Heat and the presence of metal particulates such as iron or copper accelerate the process. Additionally, highly aerated oils are far more susceptible to oxidation. Ensure that oils are compatible before adding or mixing them, as different oil additives may react adversely, further degrading the oil. Mechanical: Shearing occurs when oil molecules are torn apart as they pass between moving mechanical surfaces. Thermal: When air bubbles become entrained in the oil, severe failure of the oil may occur due to conditions known as Pressure-Induced Dieseling (PID) or Pressureinduced Thermal Degradation (PTG). These phenomenons are enabled in areas of high pressure within the hydraulic systems. Pressure Induced Dieseling, also known as micro-dieseling, occurs when air bubbles are collapsed under high pressure. This yields localized temperatures in excess of 1000 deg F (538 deg C), which in turn leads to thermal degradation and oxidation. Electrostatic charge may also cause localized thermaloxidative oil degradation and occurs in fluids systems as a result of internal molecular friction and electrostatic potential between the fluid and machine surfaces. The magnitude of the static charge within the oil will increase due to factors such as low viscosity, low conductivity, low moisture content, low levels of entrained air and high oil cleanliness. Most of these conditions are desirable attributes for an oil system and therefore cannot be eliminated. Investigations are ongoing to develop methods to prevent electrostatic discharge within the system. Static discharge can also occur due to high flow rates through main lube oil

2 of 6

filters, despite design intentions to minimize this phenomenon.

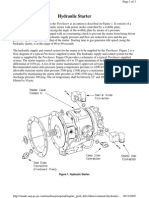

Figure 1:

Varnish on Servo Orifice

Figure 2:

Varnish on Servo Filter

Effect of Group II Base Oils Around 1990, oil suppliers started switching to Group II base oils for the manufacture of turbine oils. The oil suppliers made this change in response to stricter requirements from the automotive and transportation industry. Group II stock has much better oxidation stability as well as viscosity/temperature properties compared to the previous Group I stocks. While the highly pure nature of Group II base stocks have the properties that tend to prevent the formation of impurities, they also have a lower ability to maintain these impurities in solution once formed. For this reason, the Group II base oils are more susceptible to varnish formation once oil degradation has begun.

TIL 1528-3 Unit and System Impact While the issue of oil varnishing typically does not lead to extended forced outages, the availability and reliability of the units can be greatly affected. The varnish tends to accumulate in small, low flow passages within the hydraulic system typically in servo valves associated with hydraulically operated components. Once the varnish is established, the servo valves become sluggish or fail to operate, leading to a trip of the unit. Fleet experience indicates that turbines being operated in a peaking or cycling mode are more susceptible to oil varnishing. This is due to the thermal cycling of the oil and the time at which the systems are in a relatively cold/low flow condition. Data also shows that for a peaking/cycling turbine, the component most likely to be affected first will be the inlet guide vane (IGV) servo. Units that are base loaded may not experience varnishing until later in life. The first component affected on based loaded units is typically the gas or liquid fuel control valves. A recent study (primarily on F class GTs) suggests that as many as 1/3 of all units show some signs of oil varnishing. Methods for Detecting Varnish An oil condition-monitoring program should be part of normal maintenance including a combination of inspections and oil analysis screening tests. Inspections include viewing sight glasses for varnish and fouling, examining used filters for end-cap varnish and sludge, inspection of servo inlet ports and lastchance filters, and periodic inspection of tank bottom sediment. While there is no direct way to measure (quantify) varnish formation on servo valve surfaces, the active use of screening tests may provide an effective early warning. The patch colorimetric test can be used to trend the varnish potential of oil. Lower numbers indicate a lower risk of varnish formation. For general reference, a varnish potential rating between 0 and 40 would be considered acceptable. The range 41-60 would be a reportable condition, indicating the need to monitor the oil more frequently. Readings above 60 are considered actionable and should trigger a work plan to quickly remediate the condition. Monitoring of the sub micron particles in the oil along with the results from patch colorimetric testing can help in determining the effectiveness of removal of varnish particles. The test used to measure the sub micron particles is ASTM F 312-97 (Standard Test Method for Microscopical Sizing and Counting Particles from Aerospace Fluids on Membrane Filters) It is recommended that both of these tests be used to monitor the performance of oil conditioning equipment. Mitigation and Prevention Customers currently utilizing electrostatic type filtration, or Balanced Charge Agglomeration, have reported very good results in reducing the varnish potential of their oil. These results show that trips caused by sticking servo valves have been drastically reduced or eliminated. Unlike conventional mechanical filters, these technologies induce electrical charges on suspended particles (oxides, carbon fines, etc.) that facilitate their transfer out of the oil, either by agglomeration/filtration or simply by electrostatic precipitation onto a collection device. GE has performed extensive studies to validate the use of Balanced Charge Agglomeration technology. A recent test on seven 7FA+e turbines with this technology installed was run for 75 days while performing routine colorimetric sampling. The results of this test can be seen in Figure 3. Note that the results for two turbines are shown. The other five have been removed for clarity. All turbines exhibited similar results.

Figure 3: Balanced Validation test

Charge

Agglomeration

3 of 6

TIL 1528-3 It should be noted that an initial downward trend is realized during the clean up phase followed by and upward trend as varnish that had been plated out on the system surfaces becomes reabsorbed into the oil. Over time, this varnish bloom will drop back down to desirable levels as the reclamation unit remains in service, leaving the oil systems surfaces and turbine oil clean. This technology can be used either to mitigate a current varnishing issue or to prevent the occurrence of it.

PLANNING INFORMATION

Compliance Compliance Category: O Timing Code: 7 Manpower Skills Basic skills associated with the ability to properly draw oil samples and prepare for shipment. General knowledge of lubricant testing and analysis Parts N/A Special Tooling N/A Reference Documents GEK 32568 or the latest revision of the applicable Lube Oil recommendations GEK as supplied with the turbine. Previous Modifications N/A Scope of Work N/A Contact your local GE IF&S Service Manager or Contract Performance Manager for assistance or for additional information.

NOTE: If you would like to receive future TILs by email,

RECOMMENDATIONS

Sites should fully investigate any trips involving IGVs or control valve mis-operation. Failure to eliminate all possible causes may result in a repeat occurrence. Fleet information has shown that charged particle agglomeration and electrostatic precipitator filtration technology have been successful in mitigating, as well as preventing, the effects of varnishing. These systems are typically set up as a side-stream configuration to the existing lube oil system. They can operate continuously while the turbine is online or off-line. For those customers who have not experienced trips associated with varnish formation, it is recommended that varnish removal systems be used as a preventive measure. The formation of varnish is partly dependant on the oil's age, and it is believed that all customers may experience this issue over time. Please note that the systems referenced are considered a mitigation strategy that addresses the symptoms of oil degradation and not the root cause. There are ongoing studies with oil manufacturers aimed at developing methods of prevention of oil varnishing. Contact your local GE IF&S Service Manager or Contract Performance Manager to inquire about submitting a CM&U.

contact your local GE I&FS Service Manager or Contract Performance Manager for assistance.

4 of 6

TIL 1528-3

TIL COMPLIANCE RECORD

Compliance with this TIL must be entered in local records. GE requests that the customer notify GE upon compliance of this TIL. Complete the following TIL Compliance Record and FAX it to: TIL Compliance FAX: (678) 844-3451 Toll free FAX: 1-888-896-TILS (1-888-896-8457)

TIL COMPLIANCE RECORD

Site Name: Customer Contact Information Contact Name: Address: Email: Phone: FAX: Turbine Serial Number(s):

For Internal Records Only # Customer Name: GE Contact Information Contact Name: Address: Email: Phone: FAX:

INSTALLED EQUIPMENT

Description:

TIL Completed Date: 100% TIL Completed:

Unit Numbers:

Part Description:

Part Number

MLI Number

Comments:

NOTE:

If there are any redlined drawings that pertain to this TIL implementation, please FAX the drawings along with this TIL Compliance Record. TIL Compliance FAX: (678) 844-3451 Toll free FAX: 1-888-896-TILS (1-888-896-8457)

5 of 6

FAX this form to:

TIL 1528-3

USER SATISFACTION SURVEY

GE values your opinions and comments. GE requests that you complete the User Satisfaction Survey below to help us better serve you with accurate and timely information on your equipment. Complete the following TIL Compliance Record and FAX it to: TIL Survey GE Customer Technology Services FAX: (678) 844-6737 Toll free FAX: 1-866-604-2668

USER SATISFACTION SURVEY

Serial Number: 1. How many days after TIL issue date did you receive this TIL? Date:

1 - 5 days

6 - 10 days

+ 10 days

NOTE: If you would like to receive future TILs by email, contact your local GE Energy Services representative for assistance.

Rate the following based on a scale of 1 to 5, where 1 is Excellent and 5 is Poor. 2. Please rate how well this document informed you of the technical issue.

3. Please rate the overall effectiveness of this TIL.

1

Comments / Suggestions:

FAX this form to:

TIL Survey GE Customer Technology Services FAX: (678) 844-6737 Toll free FAX: 1-866-604-2668

6 of 6

You might also like

- Technical Information Letter: Lube Oil VarnishingDocument6 pagesTechnical Information Letter: Lube Oil VarnishingHeryanto SyamNo ratings yet

- 01 Tab01 130916060639 Phpapp02 PDFDocument36 pages01 Tab01 130916060639 Phpapp02 PDFajo zinzoNo ratings yet

- TIL 1132 2R1 - VIGV Inspection, Thrust WasherDocument5 pagesTIL 1132 2R1 - VIGV Inspection, Thrust WasherHernan Giraut100% (2)

- Til 1213 R1Document6 pagesTil 1213 R1Hernan GirautNo ratings yet

- TIL 476C - Exhaust Temperature Spread GuidelinesDocument2 pagesTIL 476C - Exhaust Temperature Spread GuidelinesHernan Giraut100% (1)

- T 2055 R 1Document6 pagesT 2055 R 1srinivasNo ratings yet

- GEI41042 Rev O - Washing-Cleaning PDFDocument12 pagesGEI41042 Rev O - Washing-Cleaning PDFKorcan ÜnalNo ratings yet

- TIL 1108-R1: Cast Segmented Turbine Nozzle Acceptance GuidelinesDocument10 pagesTIL 1108-R1: Cast Segmented Turbine Nozzle Acceptance GuidelinesAkramNo ratings yet

- t1068r3 IGV ClearanceDocument5 pagest1068r3 IGV ClearanceWest Damietta2100% (1)

- Til 1886 Inspection of Low Pressure Rotor Wheel Dovetails On Steam Turbines With Fossil Fueled Drum BoilersDocument6 pagesTil 1886 Inspection of Low Pressure Rotor Wheel Dovetails On Steam Turbines With Fossil Fueled Drum BoilersManuel L Lombardero100% (1)

- 04 SRL MaintenanceDocument94 pages04 SRL Maintenancerana usman100% (1)

- Technical Information Letter: Ge Power TIL 2445 Product ServiceDocument4 pagesTechnical Information Letter: Ge Power TIL 2445 Product ServiceMinhajur Rahman100% (1)

- T 2024Document4 pagesT 2024ashok100% (1)

- 000start CDDocument1,166 pages000start CDruben100% (3)

- GEK101944Document8 pagesGEK101944Nouman Saeed100% (1)

- Gas Turbine Fuel Nozzle Refurbishment Reduces Emissions and Improves ReliabilityDocument3 pagesGas Turbine Fuel Nozzle Refurbishment Reduces Emissions and Improves ReliabilityJJ100% (1)

- TIL 1819 ImplementationDocument4 pagesTIL 1819 ImplementationManuel L LombarderoNo ratings yet

- Gek 116689Document32 pagesGek 116689HANo ratings yet

- Igv 7eaDocument2 pagesIgv 7eaSamir BenabdallahNo ratings yet

- NUOVO PIGNONE Compressor Spares (2010-37)Document4 pagesNUOVO PIGNONE Compressor Spares (2010-37)sianas1706No ratings yet

- Til 1214-3R3Document7 pagesTil 1214-3R3Hernan Giraut100% (2)

- CBN Blade Tip AbradableDocument8 pagesCBN Blade Tip Abradablebehtam2407No ratings yet

- PGT25 G4 02-04-2010Document2 pagesPGT25 G4 02-04-2010Sumanth KaranamNo ratings yet

- Til 1509 R4 F-Class Front End (R0, S0, and R1) Compressor InspectionsDocument9 pagesTil 1509 R4 F-Class Front End (R0, S0, and R1) Compressor InspectionsMichael Sanchez100% (1)

- TIL 1420-2r1 Lube Oil Logic EnhancementDocument4 pagesTIL 1420-2r1 Lube Oil Logic EnhancementManuel L LombarderoNo ratings yet

- Figure 1. Hydraulic StarterDocument3 pagesFigure 1. Hydraulic StarterDenis JimenezNo ratings yet

- GE Frame Gas Turbine HGP and Combustion InspectionsDocument4 pagesGE Frame Gas Turbine HGP and Combustion InspectionsCarlos Toscano100% (1)

- CatalogoPGT25 PDFDocument4 pagesCatalogoPGT25 PDFshihabjamaan100% (4)

- 1420-2R1 Lube Oil Logic Enhancement PDFDocument4 pages1420-2R1 Lube Oil Logic Enhancement PDFManuel L LombarderoNo ratings yet

- lm2500 LubesupplyDocument3 pageslm2500 LubesupplyDenis Jimenez100% (2)

- SB LM2500 Ind 312 R1Document7 pagesSB LM2500 Ind 312 R1Daniil SerovNo ratings yet

- APA DOC No. 2014 PDFDocument67 pagesAPA DOC No. 2014 PDFThanapaet RittirutNo ratings yet

- GTDocument33 pagesGTowais_36100% (4)

- 6 6FA - 2019 - Rotor - Life - ManagementDocument8 pages6 6FA - 2019 - Rotor - Life - ManagementMuhammad Hasan Rafiq100% (1)

- ASME Presentation Nov 2014 PDFDocument56 pagesASME Presentation Nov 2014 PDFdf_campos33530% (2)

- (GAS TURBINE MS 5001 PA) Volume IDocument159 pages(GAS TURBINE MS 5001 PA) Volume Ihayder ahmed100% (2)

- Technical Information Letter: Thermal Engineering Product Service TIL 1108-R1Document7 pagesTechnical Information Letter: Thermal Engineering Product Service TIL 1108-R1Heryanto SyamNo ratings yet

- Technical Information Letter: GE PowerDocument6 pagesTechnical Information Letter: GE PowerHashim BukhariNo ratings yet

- GE Power Systems 7F Users Conference PresentationsDocument27 pagesGE Power Systems 7F Users Conference Presentationsatfrost4638No ratings yet

- 3 - Gas Turbine Overview 8.09Document25 pages3 - Gas Turbine Overview 8.09Sujeet Kumar100% (1)

- Procedure Repair Diaphragm PDFDocument37 pagesProcedure Repair Diaphragm PDFGian Pratama100% (1)

- Technical Information Letter: Energy Services Engineering Product Service TIL 1576Document4 pagesTechnical Information Letter: Energy Services Engineering Product Service TIL 1576Chidiebere Samuel Okogwu100% (2)

- LM 2500Document12 pagesLM 2500pramodtryNo ratings yet

- 5 Lifetime Extension For SiemensDocument21 pages5 Lifetime Extension For SiemensMohamed Omar100% (3)

- GE Energy Data Sheets Technical SpecificationsDocument7 pagesGE Energy Data Sheets Technical SpecificationsAbisholita MecaTronics100% (1)

- MS5002E NewDocument8 pagesMS5002E Newecs71100% (2)

- Comp Amp Turbine COURS 9001EDocument27 pagesComp Amp Turbine COURS 9001Enabil160874100% (1)

- t10682r1-Fr-5,6,9 VIGVDocument2 pagest10682r1-Fr-5,6,9 VIGVJEORJE100% (1)

- Til 2191 - 9e S2B Tip Shroud DistressDocument3 pagesTil 2191 - 9e S2B Tip Shroud DistressMichael SanchezNo ratings yet

- Dry Gas Seals SiemensDocument11 pagesDry Gas Seals Siemensahbabar808No ratings yet

- Steam Turbine Oil ChallengesDocument10 pagesSteam Turbine Oil Challengessevero97No ratings yet

- GE 7EA Gas Turbine DetailsDocument10 pagesGE 7EA Gas Turbine DetailsHernan GirautNo ratings yet

- Gek105054 File0007Document18 pagesGek105054 File0007outilprok22kNo ratings yet

- Oman Energy Conference - World Record Gas Turbine Service ExperiencesDocument16 pagesOman Energy Conference - World Record Gas Turbine Service ExperiencesabelsgNo ratings yet

- Til 1566-R2 Hazardous Gas Detection System RecommendationsDocument4 pagesTil 1566-R2 Hazardous Gas Detection System RecommendationsMichael Sanchez100% (2)

- Forsthoffer’s Component Condition MonitoringFrom EverandForsthoffer’s Component Condition MonitoringRating: 4 out of 5 stars4/5 (2)

- Lubrication: A Practical Guide to Lubricant SelectionFrom EverandLubrication: A Practical Guide to Lubricant SelectionRating: 5 out of 5 stars5/5 (3)

- Turbine Oil AnalysisDocument12 pagesTurbine Oil Analysismanuelsum100% (2)

- Review Condition Monitoring and Fault Diagnosis For Diesel EnginesDocument25 pagesReview Condition Monitoring and Fault Diagnosis For Diesel EnginesNemer RaslenNo ratings yet

- Machinery Failure Analysis Troubleshooting Fourth Edition1Document7 pagesMachinery Failure Analysis Troubleshooting Fourth Edition1Juanma GarcíaNo ratings yet

- IOCL Transformer Oil DatasheetDocument1 pageIOCL Transformer Oil DatasheethebishtNo ratings yet

- Bajaj High Mast CatalogueDocument2 pagesBajaj High Mast CatalogueSuhas Acharya50% (2)

- Epoxyinsulatolavt 20131015133812.795 X PDFDocument1 pageEpoxyinsulatolavt 20131015133812.795 X PDFhebishtNo ratings yet

- IEEE STD 1185-1994, IEEE Guide For Installation Methods For Generating Station CablesDocument48 pagesIEEE STD 1185-1994, IEEE Guide For Installation Methods For Generating Station Cableshebisht100% (2)

- Vegetable Momos RecipeDocument3 pagesVegetable Momos RecipehebishtNo ratings yet

- Main Features of Electricity Act 2003Document25 pagesMain Features of Electricity Act 2003sumitsonu4uNo ratings yet

- Medium Voltage Ac DrivesDocument8 pagesMedium Voltage Ac DriveshebishtNo ratings yet

- LT Xlpe Is7098 IDocument24 pagesLT Xlpe Is7098 IChabi MongarNo ratings yet

- Epoxy InsulatorDocument1 pageEpoxy InsulatorhebishtNo ratings yet

- BusDocument14 pagesBusAnkur KalaNo ratings yet

- Airport Metro Time ScheduleDocument1 pageAirport Metro Time SchedulehebishtNo ratings yet

- 7531e en Ferro-Resonance in Voltage TransformersDocument3 pages7531e en Ferro-Resonance in Voltage TransformershebishtNo ratings yet

- Vegetable Momos RecipeDocument3 pagesVegetable Momos RecipehebishtNo ratings yet

- Delhi Metro Full Network 2021Document1 pageDelhi Metro Full Network 2021api-3729050100% (2)

- Delhi MetroDocument6 pagesDelhi MetroShafaqueAlamNo ratings yet

- Cause & Effect Diagram - BCN-2 Motor Failure: Wet Coal, Due To This Load Is On BCN-5 Is More Feed Rate Is HighDocument1 pageCause & Effect Diagram - BCN-2 Motor Failure: Wet Coal, Due To This Load Is On BCN-5 Is More Feed Rate Is HighhebishtNo ratings yet

- Ical-111 76 183 2 RVDocument4 pagesIcal-111 76 183 2 RVhebishtNo ratings yet

- Vegetable Momos RecipeDocument3 pagesVegetable Momos RecipehebishtNo ratings yet

- IS 3043 Earth Grounding CodeDocument4 pagesIS 3043 Earth Grounding CodehebishtNo ratings yet

- MV Drive IonDocument2 pagesMV Drive IonhebishtNo ratings yet

- Thermal Power PlantDocument16 pagesThermal Power PlanthebishtNo ratings yet

- Thermal Power PlantDocument16 pagesThermal Power PlanthebishtNo ratings yet

- MV Drive IonDocument2 pagesMV Drive IonhebishtNo ratings yet

- B.Tech Distance Education Academic CalendarDocument1 pageB.Tech Distance Education Academic CalendarhebishtNo ratings yet

- MGN 363Document14 pagesMGN 363Nitin PatidarNo ratings yet

- Community Health Nursing Family Nursing AssessmentDocument2 pagesCommunity Health Nursing Family Nursing AssessmentRy LlanesNo ratings yet

- Build A Tunnel: What You NeedDocument2 pagesBuild A Tunnel: What You NeedManila Business ShopsNo ratings yet

- USB and ACPI Device IDsDocument10 pagesUSB and ACPI Device IDsKortiyarshaBudiyantoNo ratings yet

- Myo Cny 2023 MenuDocument12 pagesMyo Cny 2023 Menulihanyong17No ratings yet

- Return On Marketing InvestmentDocument16 pagesReturn On Marketing Investmentraj_thanviNo ratings yet

- Louise Bedford Trading InsightsDocument80 pagesLouise Bedford Trading Insightsartendu100% (3)

- Bank 12Document19 pagesBank 12Shivangi GuptaNo ratings yet

- Human Resource Planning and Corroporate Strategies: Meaning and Definition of StrategyDocument19 pagesHuman Resource Planning and Corroporate Strategies: Meaning and Definition of StrategyRashmi KhublaniNo ratings yet

- Chapter 3 Theoretical ConsiderationsDocument8 pagesChapter 3 Theoretical Considerationsapi-3696675No ratings yet

- Appetizers Fire-Grilled Gourmet Burgers: Red Robin'S Finest Burgers Red'S Tavern MenuDocument2 pagesAppetizers Fire-Grilled Gourmet Burgers: Red Robin'S Finest Burgers Red'S Tavern MenufruitfuckNo ratings yet

- Lista 30 JulioDocument2 pagesLista 30 JulioMax Bike MartinezNo ratings yet

- STTH2002C: High Efficiency Ultrafast DiodeDocument16 pagesSTTH2002C: High Efficiency Ultrafast DiodeAseng saputraNo ratings yet

- Role of MicrofinanceDocument1 pageRole of MicrofinanceuttamsudhirNo ratings yet

- Grade 5 PPT English Q4 W3 Day 2Document17 pagesGrade 5 PPT English Q4 W3 Day 2Rommel MarianoNo ratings yet

- tmp1AE2 TMPDocument8 pagestmp1AE2 TMPFrontiersNo ratings yet

- 28 GHZ Millimeter Wave Cellular Communication Measurements For Reflection and Penetration Loss in and Around Buildings in New York CityDocument5 pages28 GHZ Millimeter Wave Cellular Communication Measurements For Reflection and Penetration Loss in and Around Buildings in New York CityJunyi LiNo ratings yet

- Martek Navgard BnwasDocument4 pagesMartek Navgard BnwasСергей БородинNo ratings yet

- Image Authentication ENFSIDocument43 pagesImage Authentication ENFSIIolanda OprisanNo ratings yet

- KD.7.1-WPS OfficeDocument9 pagesKD.7.1-WPS OfficePratista TyasNo ratings yet

- Syllabus: Android Training Course: 1. JAVA ConceptsDocument6 pagesSyllabus: Android Training Course: 1. JAVA ConceptsVenkata Rao GudeNo ratings yet

- Fundamental Powers of The State (Police Power) Ynot v. IAC Facts: Ermita Malate v. City of Manila 20 SCRA 849 (1967)Document18 pagesFundamental Powers of The State (Police Power) Ynot v. IAC Facts: Ermita Malate v. City of Manila 20 SCRA 849 (1967)Ella QuiNo ratings yet

- ATV600 - Communication - Parameters - EAV64332 - V1.3Document46 pagesATV600 - Communication - Parameters - EAV64332 - V1.3Sugeng WahyudiNo ratings yet

- Bid Document Vol. II Attachment BOQDocument6 pagesBid Document Vol. II Attachment BOQHrityush ShivamNo ratings yet

- E-Leadership Literature ReviewDocument36 pagesE-Leadership Literature ReviewYasser BahaaNo ratings yet

- Urinary: Rachel Neto, DVM, MS, DACVP May 28 2020Document15 pagesUrinary: Rachel Neto, DVM, MS, DACVP May 28 2020Rachel AutranNo ratings yet

- ChE 4110 Process Control HW 1Document6 pagesChE 4110 Process Control HW 1MalloryNo ratings yet

- Char Chapori Sahitya ParishadDocument2 pagesChar Chapori Sahitya ParishaddescataNo ratings yet

- What Is InterpolDocument5 pagesWhat Is InterpolJimmy Jr Comahig LapeNo ratings yet

- Install CH340 driver for ArduinoDocument8 pagesInstall CH340 driver for Arduinosubbu jangamNo ratings yet