Professional Documents

Culture Documents

Sop of Syrup Preparation

Uploaded by

Ganesh VidhateOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sop of Syrup Preparation

Uploaded by

Ganesh VidhateCopyright:

Available Formats

Pushpam Foods & Beverages Pvt. Ltd.

Gat No. 104/2 A , Village :- Boratevasti , (Nandur), Tal: - Daund, Dist: - Pune, INDIA , Tel. No.: +91-20-2421-5162

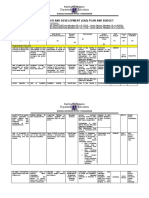

SOP FOR SUGAR SYRUP PREPARATION 1) 2) FIRST TAKE SYRUP BATCH PLANNING , CONFORM IT, ISSUE RELATED RAW MATERIAL (SUGAR, CARBON, HYFLOW,FILTER PAPERS ) FROM STORE AS PER FIFO.CARBON & BODY FEED HYFLO 0.1% OF SUGAR QUANTITY ) 3) AFTER COMPLETING RAW SYRUP TANK & FILTER PRESS CIP CERTIFY & DOCUMENTED IT. 4) AFTER RAW SYRUP TANK CIP COMPLETE OPEN BOTH STAINER OF RAW SYRUP OUT LET TANK CLEAN & WASH IT WITH WATER &FIX IT. 5) CLOSE RAW SYRUP TANK BOTTOM VALVE . 6 ) CLOSE RAW SYRUP TANK DRAIN VALVE . 7 ) CLOSE STAINER INLET , OUTLET VALVE RESPECTIVELY. 8) OPEN TREATED WATER LINE VALVE TO RAW SYRUP TANK . 9) TAKE REUIRED QTY. OF WATER ACCORDING TO BATCH SIZE & CLOSE IT. 10 ) OPEN SC-1 COOLING TO JET MIXING PUMP 11 ) OPEN VALVE NO . 18 & 19 ( JET MIXING PUMP INLET & OUTLET ) 12 ) OPEN STEAM MAIN VALVE . 0 0 13 ) SET TEMP. PROGRAM ON RAW SYRUP PID ( 85 C +/- 1 C ) 14 ) START JET MIXING PUMP. 15) WEIGH CALCULATED SUGAR BAGS, ARRANGE IT, OPEN IT.REMOVE THE LID OF BUCKET ELEVATOR, ARRANGE SUGAR HOPPER TROLLEY. 0 0 16) WHEN TEMP OF WATER IN RAW SURUP TANK REACHES 85 C +/- 1 C , START DUMPING OF SUGAR SLOWLY. 0 17) AFTER SUGAR DUMPING COMPLETE, WAIT FOR SUGAR SYRUP TEMP, REACH TO 81 C. 18) TAKE FRESH TREATED WATER IN BUCKET. DISSOLVE CALCULATED QTY. OF CARBON & HYFLOW IN BUCKET PROPERLY. REMOVE SUSPENDED MATERIAL FROM BUCKET. 0 19 ) DUMP IT IN RAW SYRUP AFTER REACHING 81 C. RINSE HOPPER WITH TREATED WATER & CLOSE HOPPER LID. 20) GIVE CARBON CONTACT TIME 30 MIN BY USING FILTER PRESS HYDROULIC PRESSURE SYSTEM. 21) LOOSE FILTER PRESS & REMOVE CIP FILTER PAPERS OF FILTER PRESS. WASH IT WITH TREATED WATER. 22) FIX NEW FILTER PAPERS ON FILTER PRESS PLATE. ENSURE FILTER PAPERS & GASKETES ARE FIXED PROPERLY. 23) CLOSE PRECOT TANK VALVE & PRECOT OUTLET & DRAIN . 24) OPEN VALVE OF TREATED WATER &TAKE WATER IN PRECOT TANK. 25) CLOSE VALVE FILTER PRESS INLET,OUTLET DRAIN VALVE 26) OPEN VALVE PRECOT TANK OUTLET ,SYRUP INLET ,OUTLET VALVE OF FILTER PRESS,PRECOT IN . OPEN /*AIR VENT VALVE. 27) OPEN SC-2 VALVE ( COOLING WATER TO RAW SYRUP PUMP ) .START RAW SYRUP CIRCULATION PUMP . AFTER REMOVING AIR FROM FILTER PRESS ,. CIRCULATE WATER 2 TO 3 MIN. & STOP RAW SYRUP CIRCULATION PUMP. 28) CLOSE VALVE OF SYRUP CIRCULATION PUMP . TAKE FRESH WATER IN PRECOAT TANK.. START PRECOAT TANK AGITATOR BY SWITCH ON FROM RAW SYRUP TANK PANAL. 29) SLOWLY ADD CALCULATED QTY. OF PRECOATING HYFLOW (3.6 kg) IN PRECOAT TANK & MAKE IT SLURRY PROPERLY. 30) NOW START RAW SURUP CIRCULATION PUMP. 31) OPEN VALVE ENSURE NO AIR TRAPPED IN FILTER PRESS & CLOSE IT.CIRCULATE THIS HYFLOW SOLUTION THROUGH FILTERPRESS TILL TURBIDITY OF FILTERPRESS OUTLET WATER LESS THAN 0.5 NTU. 32) OPEN VALVE NO. 26 . COLSE VALVE NO 27.OPEN VALVE NO.40 . ( IN THIS VALVE POSITION RAW SYRUP CIRCULATE FROM RAW SYRUP TANK TO FILTER PRESS THROGH RAW SYRUP TANK.). CIRCULATE IT TILL THE SYRUP SOLUTION QUALITY OUTLET OF FILTERPRESS IS CLEAR SOLUTION.)

Confidential

DRAFT COPY

Prepared On :- 18.09.2011

Pushpam Foods & Beverages Pvt. Ltd.

Gat No. 104/2 A , Village :- Boratevasti , (Nandur), Tal: - Daund, Dist: - Pune, INDIA , Tel. No.: +91-20-2421-5162

33) TAKE 50ML OF SYRUP OUTLET OF FILTERPRESS, DILUTED IT TO 250 ML. CYLINDER. FILTER THIS SOLUTION THROGH 0.45 MICRN FILTER PAPER.VISUALLY CHECK NO ANY PARTICLES PRESENT ON THIS PAPER. 34) AFTER SYRUP TRANSFERD IN SIMPLE SYRUP TANK CALCULATE THE SUGAR IN KG AS.. Sugar in Kg =Sugar syrup volume x Factor (Kgs Solids /lit )

Confidential

DRAFT COPY

Prepared On :- 18.09.2011

You might also like

- Procedure For Sampling of RM and PMDocument7 pagesProcedure For Sampling of RM and PMMilan BankNo ratings yet

- SOP - Operation of Semi-Automatic Capsule Filling MachineDocument3 pagesSOP - Operation of Semi-Automatic Capsule Filling MachineKrishelle Anne Obispo75% (4)

- Sop For Operating Dry GranulatorDocument3 pagesSop For Operating Dry GranulatorsaimaNo ratings yet

- The Procedure: Cleaning ValidationDocument4 pagesThe Procedure: Cleaning ValidationYousifNo ratings yet

- Analyst Qualification (Modified)Document6 pagesAnalyst Qualification (Modified)vasant ugale75% (4)

- Tablet Section Cost DR SabDocument6 pagesTablet Section Cost DR SabAbdul SamadNo ratings yet

- Handling of Sieves and ScreensDocument4 pagesHandling of Sieves and Screensreflectprakash3610No ratings yet

- SOP Personnel HygieneDocument4 pagesSOP Personnel HygieneBejoy Karim100% (3)

- DRUG FORMULATION COMPOSITIONDocument12 pagesDRUG FORMULATION COMPOSITIONziadddNo ratings yet

- MFRDocument3 pagesMFRAlok Kumar100% (1)

- HPTLC: Factors Influencing The TLC / HPTLC Separation and Resolution of SpotsDocument8 pagesHPTLC: Factors Influencing The TLC / HPTLC Separation and Resolution of Spots0921pyNo ratings yet

- Sop For Cleaning Capsule Filling Machine C-14 in Capsulation Room 2Document5 pagesSop For Cleaning Capsule Filling Machine C-14 in Capsulation Room 2WANDERA ROBERTNo ratings yet

- Site Master FileDocument16 pagesSite Master Fileshrikantmsd0% (1)

- 2-O&c of Paam Af 90 TDocument6 pages2-O&c of Paam Af 90 Tananth100% (1)

- Process Validation of Ointment/Cream FormulationDocument40 pagesProcess Validation of Ointment/Cream FormulationGursharanjit Singh Shinh100% (2)

- Standard Operating Procedure - CapsuleDocument7 pagesStandard Operating Procedure - CapsuleIntan NajiihahNo ratings yet

- Procedure For Operational and Cleanning of Automatic Single Head Tube Filling and & Sealing Mc-6Document5 pagesProcedure For Operational and Cleanning of Automatic Single Head Tube Filling and & Sealing Mc-6asit_m80% (5)

- THAI COATER Spec PDFDocument4 pagesTHAI COATER Spec PDFConfundo Paa DuroNo ratings yet

- Standard Operating Procedure (Sop) Collecting Swab or Rinse Samples For Chemical and Microbiological AnalysisDocument11 pagesStandard Operating Procedure (Sop) Collecting Swab or Rinse Samples For Chemical and Microbiological AnalysisAbuNo ratings yet

- 2017-02-08 Flow Process Chart SyrupsDocument1 page2017-02-08 Flow Process Chart Syrupsreflectprakash361075% (4)

- Tablet Tooling in Compression MachineDocument32 pagesTablet Tooling in Compression Machinesubirme0% (1)

- OQ Protocol Capsulating MachineDocument11 pagesOQ Protocol Capsulating MachineNadine LilleNo ratings yet

- Master Formula and Manufacturing RecordsDocument7 pagesMaster Formula and Manufacturing RecordsTrilochan AyurvedaNo ratings yet

- Revital SOP membrane cleaningDocument4 pagesRevital SOP membrane cleaningMusyoka Urbanus100% (1)

- RM-Method Validation ProtocolDocument12 pagesRM-Method Validation ProtocolShagorShagorNo ratings yet

- SOP For Operation of Carton Coding MachineDocument3 pagesSOP For Operation of Carton Coding MachineJayant Kumar JhaNo ratings yet

- BMR Cephracap 500 Cap Checked 1Document16 pagesBMR Cephracap 500 Cap Checked 1jordan7half7don100% (1)

- Vatakulantka Rasa TabletDocument7 pagesVatakulantka Rasa Tabletreflectprakash3610No ratings yet

- Sop of Cleaning and Operation of Dispensing BoothDocument3 pagesSop of Cleaning and Operation of Dispensing BoothRainMan75100% (2)

- SOP On Operation and Cleaning of Paste KettleDocument3 pagesSOP On Operation and Cleaning of Paste KettleRakesh RauniyarNo ratings yet

- Masterformularecord 180319024817Document20 pagesMasterformularecord 180319024817Mucharla Praveen KumarNo ratings yet

- Table For Cleaning SolutionsDocument1 pageTable For Cleaning Solutionsreflectprakash3610No ratings yet

- Line Clearance ProcedureDocument3 pagesLine Clearance ProcedurePrince Moni67% (3)

- Calibration For GlaswaresDocument6 pagesCalibration For GlaswaresKhrystin BerdosNo ratings yet

- DESIGN QUALIFICATION AUTOMATIC CAPSULE FILLING MACHINE - Pharmaceutical Guidance PDFDocument14 pagesDESIGN QUALIFICATION AUTOMATIC CAPSULE FILLING MACHINE - Pharmaceutical Guidance PDFShoaib BiradarNo ratings yet

- SOP of Cleaning of Sampling ToolsDocument2 pagesSOP of Cleaning of Sampling ToolsYousifNo ratings yet

- SOP of Sanitation of PW SystemDocument6 pagesSOP of Sanitation of PW Systemanon_350461302100% (1)

- Prepared by Production: Approved by QA/QC:: NVIDAZOLE® 2500 BolusDocument17 pagesPrepared by Production: Approved by QA/QC:: NVIDAZOLE® 2500 BolusLegese HailuNo ratings yet

- Acitral Syrup 1000litDocument4 pagesAcitral Syrup 1000litAhmad HussainNo ratings yet

- Line Clearance Procedure at Pharma ManufacturingDocument3 pagesLine Clearance Procedure at Pharma ManufacturingRainMan75No ratings yet

- Batch Manufacturing Record - Capsule FinalDocument6 pagesBatch Manufacturing Record - Capsule FinalAkik Sasmal100% (1)

- SOP For Cleaning of StirrerDocument2 pagesSOP For Cleaning of StirrerPrince Moni100% (1)

- What Is BMR (Batch Manufacturing Record)Document2 pagesWhat Is BMR (Batch Manufacturing Record)Prince Moni100% (1)

- SOP Cleaning and SanitizingDocument1 pageSOP Cleaning and SanitizinggiyandNo ratings yet

- ACF SOP Medical Supplies201611Document29 pagesACF SOP Medical Supplies201611Mohammed Abdullah100% (1)

- GMPDocument38 pagesGMPFree Escort Service0% (1)

- In Process Quality Control Pharma PathwayDocument6 pagesIn Process Quality Control Pharma PathwayDeepakNo ratings yet

- Scale Up and Post Approval Changes in ADocument29 pagesScale Up and Post Approval Changes in ADaruvuri Vaidehi Chowdary100% (2)

- Manufacturing Formula: PRODUCT: Medgel Suspension (Sucralfate)Document5 pagesManufacturing Formula: PRODUCT: Medgel Suspension (Sucralfate)Mohammed ZubairNo ratings yet

- SOP For Cleaning of Drum MixerDocument1 pageSOP For Cleaning of Drum MixerAmit SharmaNo ratings yet

- ASEAN Guideline Process OnDocument7 pagesASEAN Guideline Process OnVipin GuptaNo ratings yet

- Procedure For Line ClearanceDocument1 pageProcedure For Line ClearanceSairam EdupugantiNo ratings yet

- Sop For Operating Tray DryerDocument3 pagesSop For Operating Tray Dryersaima0% (1)

- Analysis of Vitamins A and E by HPLCDocument9 pagesAnalysis of Vitamins A and E by HPLCamit545No ratings yet

- SOP For Laminar Air Flow Workbench - PharmaguidelineDocument2 pagesSOP For Laminar Air Flow Workbench - PharmaguidelineGopi NathNo ratings yet

- Sop-Receiving Raw MaterialsDocument3 pagesSop-Receiving Raw MaterialsSiti Alyani MatNo ratings yet

- Cleaning Guidelines for 30” Vibratory SifterDocument1 pageCleaning Guidelines for 30” Vibratory SifterananthNo ratings yet

- Pretreatment Equipment Manual: Portable ExchangeDocument5 pagesPretreatment Equipment Manual: Portable ExchangeMira FazziraNo ratings yet

- Amine Cylinder Scrubber Decon PlanDocument2 pagesAmine Cylinder Scrubber Decon Planmichelle.forriderNo ratings yet

- Summer InternshipDocument50 pagesSummer InternshipDev MathurNo ratings yet

- Hypothyroidism Web BookletDocument25 pagesHypothyroidism Web BookletalbinutaNo ratings yet

- Incoftech 2013 BrochureDocument12 pagesIncoftech 2013 BrochureGanesh VidhateNo ratings yet

- On The Kerala Karnataka BorderDocument8 pagesOn The Kerala Karnataka BorderGanesh VidhateNo ratings yet

- IndiaDocument37 pagesIndiaapi-19800939No ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Fssa 2006Document69 pagesFssa 2006Kartik SinghNo ratings yet

- Sibilla Della Zingara Gypsy-Oracle-Cards PDFDocument26 pagesSibilla Della Zingara Gypsy-Oracle-Cards PDFAnastasia100% (7)

- Indra: Total SheetDocument633 pagesIndra: Total SheetPHAM PHI HUNGNo ratings yet

- 2022 Mechanical Properties of UNS S39274 Superduplex Stainless Steel Work Hardened and Solution AnnealedDocument10 pages2022 Mechanical Properties of UNS S39274 Superduplex Stainless Steel Work Hardened and Solution Annealedvander alkminNo ratings yet

- Coupling GuardsDocument10 pagesCoupling Guards최승원No ratings yet

- CHCDIV001 Work With Diverse People: Student Questions Case Study/ Scenarios Observations Oral Questions OtherDocument14 pagesCHCDIV001 Work With Diverse People: Student Questions Case Study/ Scenarios Observations Oral Questions OtherHardeep kaur0% (1)

- Guide Fortran 77Document60 pagesGuide Fortran 77acid94No ratings yet

- Ulangan SMSTR 1Document2 pagesUlangan SMSTR 1obito 22No ratings yet

- Form 340 - Feb 2021Document11 pagesForm 340 - Feb 2021PREM MURUGANNo ratings yet

- Raphael L. Chua, Estefen Emerson R. Contreras, Zahra Mikael M. French, Katrina Angela B. Pangilinan, Janah Andrea W. TibudanDocument32 pagesRaphael L. Chua, Estefen Emerson R. Contreras, Zahra Mikael M. French, Katrina Angela B. Pangilinan, Janah Andrea W. TibudanALFONSO LUIS DUQUENo ratings yet

- Katalog ELKADocument44 pagesKatalog ELKAflash_90697638No ratings yet

- Fluvial Process and Landforms Notes 26th MarchDocument22 pagesFluvial Process and Landforms Notes 26th Marchcgmalia100% (1)

- RSCH111-110 Week1-20Document61 pagesRSCH111-110 Week1-20Julia AcostaNo ratings yet

- User S Manual: Pellin PellinDocument14 pagesUser S Manual: Pellin PellinnicehornetNo ratings yet

- Purchasing, Receiving and Storing Food SupplyDocument36 pagesPurchasing, Receiving and Storing Food SupplySharmine Rose BradmanNo ratings yet

- Applying For A Job: Eats RestaurantDocument3 pagesApplying For A Job: Eats RestaurantJuniorChancoNo ratings yet

- 2020-Botao NHS Gad Budget-RevisedDocument5 pages2020-Botao NHS Gad Budget-RevisedJoseph Caballero CruzNo ratings yet

- Seminiferous TubuleDocument9 pagesSeminiferous TubuleOLASUNMBO OWOLABINo ratings yet

- 7 Rotary Lock Motor Instructions PDFDocument216 pages7 Rotary Lock Motor Instructions PDFthanhNo ratings yet

- F1-27 Instruction ManualDocument39 pagesF1-27 Instruction ManualMohamed LhocineNo ratings yet

- The Hunters: Anthropologists' Misconceptions of the !Kung PeopleDocument4 pagesThe Hunters: Anthropologists' Misconceptions of the !Kung PeopleSimba GlynNo ratings yet

- Office of The Deputy Commissioner Mirpurkhas: SubjectDocument1 pageOffice of The Deputy Commissioner Mirpurkhas: SubjectFaisalJRahujoNo ratings yet

- Overtime Pay-DOLEDocument1 pageOvertime Pay-DOLEJun CanilloNo ratings yet

- Case Study FormatDocument4 pagesCase Study FormatNeru RoriNo ratings yet

- Minumum Wages Karnataka 2017 18 PDF Download MW Kar S Estt 2017Document2 pagesMinumum Wages Karnataka 2017 18 PDF Download MW Kar S Estt 2017Aditya BorkarNo ratings yet

- Medtronic 630G Pump FDA User GuideDocument312 pagesMedtronic 630G Pump FDA User GuideSzekeres-Csiki KatalinNo ratings yet

- ORION P4 Cell Phone Interceptor ManualDocument16 pagesORION P4 Cell Phone Interceptor ManualislombekNo ratings yet

- Post Graduate Diploma in EMERGENCY Medical Services (Pgdems)Document39 pagesPost Graduate Diploma in EMERGENCY Medical Services (Pgdems)Chaitali ChorgheNo ratings yet

- Metals and Its Alloys MCQDocument2 pagesMetals and Its Alloys MCQsrj sNo ratings yet

- All Star Bulk DescriptionDocument3 pagesAll Star Bulk DescriptionSamrandNo ratings yet

- Globalization Challenged by Covid-19Document1 pageGlobalization Challenged by Covid-19jasslyne100% (1)