Professional Documents

Culture Documents

Cell Phone Report1

Uploaded by

sumitbhutani8Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cell Phone Report1

Uploaded by

sumitbhutani8Copyright:

Available Formats

MINOR PROJECT REPORT

CELLPHONE DETECTOR

CHAPTER -1 INTRODUCTION TO CELL-PHONE DETECTOR

1.1. INTRODUCTION

In this project we made an attempt to design a CELL-PHONE DETECTOR that can detect the both incoming and outgoing calls, SMS and video transmission even if the mobile is kept at the silent mode. Our circuit has detected the presence of an activated mobile phone even at the distance of about one-and-half meters.

R1 1M IC 3130 C1 0.22 LED R3 1M C2 47 UF

R2 100K

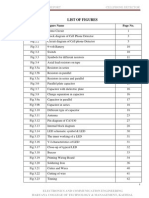

Fig 1.1 Demo Circuit

IC1 is designed as a differential amplifier Non inverting input is connected to the potential divider R1, R2. Capacitor C2 keeps the non inverting input signal stable for easy swing to + or R3 is the feedback resistor. IC1 functions as a current to voltage converter, since it converts the tiny current released by the 0.22 capacitor as output voltage. At power on output go high and LED lights for a short period. This is because + input gets more voltage than the input. After a few seconds, output goes low because the output current passes to the input through R2. Meanwhile, capacitor C1 also charges. So that both the inputs gets almost equal voltage and the output remains low. 0.22 capacitor (no other capacitor can be substituted) remains fully charged in the standby state. ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

MINOR PROJECT REPORT

CELLPHONE DETECTOR

When the high frequency radiation from the mobile phone is sensed by the circuit, 0.22 cap discharges its stored current to the + input of IC1 and its output goes high momentarily. (in the standby state, output of the differential amplifier is low since both inputs get equal voltage of 0.5 volts or more). Any increase in voltage at + input will change the output state to high.

Cell-Phone Detector Normally IC1 is off. So IC2 will be also off. When the power is switched on, as stated above, IC1 will give a high output and T1 conducts to trigger LED and Buzzer .This can be a good indication for the working of the circuit.

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

MINOR PROJECT REPORT

CELLPHONE DETECTOR

CHAPTER-2

OVERVIEW OF CELLPHONE DETECTOR

2.1. LITRETURE REVIEW

In this project we made an attempt to design a CELL-PHONE DETECTOR that can detect the both incoming and outgoing calls, SMS and video transmission even if the mobile is kept at the silent mode. Our circuit has detected the presence of an activated mobile phone even at the distance of about one-and-half meters. It gave the indication of presence of mobile by glowing the LED, according to the receiving frequency and by the buzzing the sound of a buzzer. The alarm continues until the signal transmission ceases.

2.2. BLOCK DIAGRAM OF CELLPHONE DETECTOR

FIG.2.1 BLOCK DIAGRAM OF CELLPHONE DETECTOR

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

MINOR PROJECT REPORT

CELLPHONE DETECTOR

BLOCK DIAGRAM EXPLAINATION:

There are five major block in the case of CELL PHONE DETECTOR. They are: i. ii. iii. iv. v. ANTENNA LC TUNNER CIRCUIT CURRENT TO VOLTAGE CONVERTER 555 MONOSHOT CIRCUIT OUTPUT STAGE

The first stage is the antenna stage. The transmission frequency of mobile phone ranges from 0.9 to 3 GHz with wavelength 3.3 to 10 cm. The frequency sends by an active mobile phone need to be received. This function is carried out by the receiving antenna. An ordinary RF detector using tunned circuit is not suitable for detector signals in the GHz frequency used in mobile phones. So a circuit detecting gigahertz signal is required for mobile bug. Here the circuit uses a 0.22f disk capacitor to capture RF signals from the mobile phones. The lead strength of the capacitor is fixed as 18 mm with a spacing of 8 mm between the leads to get the desired frequency. The disc capacitor along with the leads acts as a small gigahertz loop antenna to collect the RF signals from the mobile phones. This capacitor along with the lead inductance acts a transmission line to intercept the signal from the mobile. The capacitor creates a field, stores energy and transfer the stored energy in the form of minute current to the input of a current to voltage converter circuit. This form the second stage which is the lc tunner stage. The current coming to the input of the converter IC upset its balanced input and then converts the current into corresponding output voltage. When the mobile phone signals are detected by the input capacitor the output at the converter IC becomes high and low as indicated by the LED. This triggers the monostable circuit also. The low value timing components R and C produce very short time delay to avoid audio nuisance. A buzzer along with the LED forms the output stage that provide us the indication as sound and light respectively.

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

MINOR PROJECT REPORT

CELLPHONE DETECTOR

2.3. CIRCUIT DESCRIPTION

This cellular phone detector schematic circuit can sense the presence of an activated mobile cell phone from a distance of one-and-half meters. If a RF signal is detected the circuit will inform you using a sound alarm (beep sound) and a blinking LED. In this type of circuit (that use high frequency 0.9-3 GHz) you cannot use an LC circuit for frequency tuning. The circuit uses a 0.22F disk capacitor (C3) to according the RF circuit to ensure the capability of the circuit to capture the mobile phone signal.

This cellular phone detector can detect any activity of a mobile phone: incoming or outgoing SMS, video transmission or voice transmission .The C3 capacitor must have leads length of 18 mm with 8 mm spacing between leads to obtain the desired frequency. This small disk capacitor acts as a small gigahertz loop antenna to collect the RF signals. The CA3130 operational amplifier IC is used as a current to voltage converter..

CIRCUIT DIAGRAM OF CELLPHONE-DETECTOR

Fig 2.2 Circuit diagram of Cell phone-Detector

2.3.1. Purpose of the circuit

This circuit is intended to detect unauthorized use of mobile phones in examination halls, confidential rooms etc. It also helps to detect unauthorized video and audio recordings. It detects the signal from mobile phones even if it is kept in the silent mode. It also detects SMS. ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

MINOR PROJECT REPORT

CELLPHONE DETECTOR

2.3.2. WORKING OF CIRCUIT:An ordinary RF detector using tuned LC circuits is not suitable for detecting signals in the GHz frequency band used in mobile phones. The transmission frequency of mobile phones ranges from 0.9 to 3 GHz with a wavelength of 3.3 to 10 cm. So a circuit detecting gigahertz signals is required for a mobile bug. Here the circuit uses a 0.22F disk capacitor (C3) to capture the RF signals from the mobile phone. The lead length of the capacitor is fixed as 18 mm with a spacing of 8 mm between the leads to get the desired frequency. The disk capacitor along with the leads acts as a small gigahertz loop antenna to collect the RF signals from the mobile phone. Op-amp IC CA3130 (IC1) is used in the circuit as a current-to-voltage converter with capacitor C3 connected between its inverting and non-inverting inputs. It is a CMOS version using gateprotected p-channel MOSFET transistors in the input to provide very high input impedance, very low input current and very high speed of performance. The output CMOS transistor is capable of swinging the output voltage to within 10 mV of either supply voltage terminal. Capacitor C3 in conjunction with the lead inductance acts as a transmission line that intercepts the signals from the mobile phone. This capacitor creates a field, stores energy and transfers the stored energy in the form of minute current to the inputs of IC1. This will upset the balanced input of IC1 and convert the current into the corresponding output voltage. Capacitor C4 along with high-value resistor R1 keeps the non-inverting input stable for easy swing of the output to high state. Resistor R2 provides the discharge path for capacitor C4. Feedback resistor R3 makes the inverting input high when the output becomes high. Capacitor C5 (47pF) is connected across strobe of IC1 for phase compensation and gain control to optimise the frequency response. When the cell phone detector signal is detected by C3, the output of IC1 becomes high and low alternately according to the frequency of the signal as indicated by LED1. This triggers mono stable timer IC2 through capacitor C7. Capacitor C6 maintains the base bias of transistor T1 for fast switching action. The low-value timing components R6 and C9 produce very short time delay to avoid audio nuisance.

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

MINOR PROJECT REPORT

CELLPHONE DETECTOR

Assemble the cell phone detector circuit on a general purpose PCB as compact as possible and enclose in a small box like junk mobile case. As mentioned earlier, capacitor C3 should have a lead length of 18 mm with lead spacing of 8 mm. carefully solder the capacitor in standing position with equal spacing of the leads. The response can be optimised by trimming the lead length of C3 for the desired frequency. You may use a short telescopic type antenna. Use the miniature 12V battery of a remote control and a small buzzer to make the gadget pocket-size. The unit will give the warning indication if someone uses mobile phone within a radius of one-and-half meters. Use of capacitor A capacitor has two electrodes separated by a dielectric like paper, mica etc. The non polarized disc capacitor is used to pass AC and not DC. Capacitor can store energy and pass AC signals during discharge. 0.22f capacitor is selected because it is a low value one and has large surface area to accept energy from the mobile radiation. To detect the signal, the sensor part should be like an aerial. So the capacitor is arranged as a mini loop aerial (similar to the dipole antenna used in TV).In short with this arrangement, the capacitor works like an air core coil with ability to oscillate and discharge current.

How the capacitor senses RF? One lead of the capacitor gets DC from the positive rail and the other lead goes to the negative input of IC1. So the capacitor gets energy for storage. This energy is applied to the inputs of IC1 so that the inputs of IC are almost balanced with 1.4 volts. In this state output is zero. But at any time IC can give a high output if a small current is induced to its inputs. There a natural electromagnetic field around the capacitor caused by the 50Hz from electrical wiring. When the mobile phone radiates high energy pulsations, capacitor oscillates and release energy in the inputs of IC. This oscillation is indicated by the flashing of the LED and beeping of Buzzer. In short, capacitor carries energy and is in an electromagnetic field. So a slight change in field caused by the RF from phone will disturb the field and forces the capacitor to release energy.

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

MINOR PROJECT REPORT

CELLPHONE DETECTOR

CHAPTER -3

COMPONENTS USED

1.

VOLTAGE BATTERY

2.

SWITCH

3.

RESISTOR

4.

CAPACITOR

5.

TRANSISTOR

6.

ANTENNA

7.

IC CA3130, NE555

8.

LED

9.

PZ BUZZER

10.

PRINTING WIRING BOARD

11.

SOLDERING

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

MINOR PROJECT REPORT

CELLPHONE DETECTOR

COMPONENTS USED:

Table 3.1 Component used

Sr. No

Component

Value 2.2 M 100 K

Quantity 2 1 1 1 1 2 1 1 1 3 1 1 1 1 1 1

1 1

Resistor 1K 2K 15 K 22 f 0.22 f

Capacitor 100 f/16 V 47 f 0.1f 4.7 f/16 V CA3130

3 4 5 6

7 8

ICs NE555 Transistor Led PZ Buzzer

Printed Wiring Board Antenna

BC548

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

MINOR PROJECT REPORT

CELLPHONE DETECTOR

DETAILS OF SOME OF THE COMPONENTS 3.1 9 VOLTS BATTERY:We have used a motorcycle lead acid battery. This battery is of 9 volts. Power of this battery is used for glowing tube light when the power supply is off. Otherwise, the power supply keeps on charging the battery. 9-volt batteries are commonly used in pocket transistor radios, smoke detectors, carbon monoxide alarms, guitar effect units, and radio-controlled vehicle controllers.

Fig. 3.1 9-volt battery

3.3 RESISTOR:

Fig.3.3 Symbols for different resistors

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

10

MINOR PROJECT REPORT

CELLPHONE DETECTOR

Fig. 3.4 Axial-lead resistors on tape.

A resistor is a two-terminal electronic component designed to oppose an electric current by producing a voltage drop between its terminals in proportion to the current, that is, in accordance with Ohm's law: V = IR. The resistance R is equals to the voltage drop V across the resistor divided by the current I through the resistor. Resistors are characterized primarily by their resistance and the power they can dissipate. Other characteristics include temperature coefficient, noise, and inductance. Practical resistors can be made of resistive wire, and various compounds and films, and they can be integrated into hybrid and printed circuits. Size, and position of leads are relevant to equipment designers; resistors must be physically large enough not to overheat when dissipating their power. Variable resistors, adjustable by changing the position of a tapping on the resistive element, and resistors with a movable tap ("potentiometers"), either adjustable by the user of equipment or contained within, are also used. Resistors are used as part of electrical networks and electronic circuits. There are special types of resistor whose resistance varies with various quantities, most of which have names, and articles, of their own: the resistance of thermistors varies greatly with temperature, whether external or due to dissipation, so they can be used for temperature or current sensing; metal oxide varistors drop to a very low resistance when a high voltage is applied, making them suitable for over-voltage protection; the resistance of a strain gauge varies with mechanical load; the resistance of photo resistors varies with illumination; the resistance of a Quantum Tunneling Composite can vary by a factor of 1012 with mechanical pressure applied; and so on.

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

11

MINOR PROJECT REPORT

CELLPHONE DETECTOR

3.3.1 UNITS The ohm (symbol: ) is the SI unit of electrical resistance, named after Georg Ohm. The most commonly used multiples and submultiples in electrical and electronic usage are the milliohm, ohm, kilo ohm, and mega ohm. 3.3.2 THEORY OF OPERATION:

Ohm's law

The behaviour of an ideal resistor is dictated by the relationship specified by Ohm's law:

Ohm's law states that the voltage (V) across a resistor is proportional to the current (I), where the constant of proportionality is the resistance (R). Equivalently, Ohm's law can be stated:

This formulation states that the current (I) is proportional to the voltage (V) and inversely proportional to the resistance (R). This is directly used in practical computations.

Series and parallel resistors In a series configuration, the current through all of the resistors is the same, but the voltage across each resistor will be in proportion to its resistance. The potential difference (voltage) seen across the network is the sum of those voltages, thus the total resistance can be found as the sum of those resistances:

Fig 3.5.a Resistors in series

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

12

MINOR PROJECT REPORT

CELLPHONE DETECTOR

As a special case, the resistance of N resistors connected in series, each of the same resistance R, is given by NR. Resistors in a parallel configuration are each subject to the same potential difference (voltage), however the currents through them add. The conductance of the resistors then add to determine the conductance of the network. Thus the equivalent resistance (Req) of the network can be computed:

Fig 3.5.b Resistors in parallel

The parallel equivalent resistance can be represented in equations by two vertical lines "||" (as in geometry) as a simplified notation. For the case of two resistors in parallel, this can be calculated using:

As a special case, the resistance of N resistors connected in parallel, each of the same resistance R, is given by R/N. A resistor network that is a combination of parallel and series connections can be broken up into smaller parts that are either one or the other. For instance,

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

13

MINOR PROJECT REPORT

CELLPHONE DETECTOR

Fig 3.5.c Resistors in series and parallel

However, some complex networks of resistors cannot be resolved in this manner, requiring more sophisticated circuit analysis. For instance, consider a cube, each edge of which has been replaced by a resistor. What then is the resistance that would be measured between two opposite vertices? In the case of 12 equivalent resistors, it can be shown that the corner-tocorner resistance is 56 of the individual resistance. One practical application of these relationships is that a non-standard value of resistance can generally be synthesized by connecting a number of standard values in series and/or parallel. This can also be used to obtain a resistance with a higher power rating than that of the individual resistors used. In the special case of N identical resistors all connected in series or all connected in parallel, the power rating of the individual resistors is thereby multiplied by N.

3.4 CAPACITOR:

A capacitor is a passive electrical component that can store energy in the electric field between a pair of conductors (called "plates"). The process of storing energy in the capacitor is known as "charging", and involves electric charges of equal magnitude, but opposite polarity, building up on each plate. A capacitor's ability to store charge is measured by its capacitance, in units of farads. ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

14

MINOR PROJECT REPORT

CELLPHONE DETECTOR

Capacitors are often used in electric and electronic circuits as energy-storage devices. They can also be used to differentiate between high-frequency and low-frequency signals. This property makes them useful in electronic filters. Practical capacitors have series resistance, internal leakage of charge, series inductance and other non-ideal properties not found in a theoretical, ideal, capacitor. Capacitors are occasionally referred to as condensers. This term is considered archaic in English, but most other languages use a cognate of condenser to refer to a capacitor. A wide variety of capacitors have been invented, including small electrolytic capacitors used in electronic circuits, basic parallel-plate capacitors, mechanical variable capacitors. 3.4.1 THEORY OF OPERATION

Fig 3.6 Parallel Plate Capacitor

A capacitor consists of two conductive electrodes, or plates, separated by a dielectric, which prevents charge from moving directly between the plates. Charge may however move from one plate to the other through an external circuit, such as a battery connected between the terminals.

Fig 3.7 Capacitor with Dielectric Plate

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

15

MINOR PROJECT REPORT

CELLPHONE DETECTOR

Dielectric is placed between two conducting plates, each of area A and with a separation of d. When any external connection is removed, the charge on the plates persists. The separated charges attract each other, and an electric field is present between the plates. The simplest practical capacitor consists of two wide, flat, parallel plates separated by a thin dielectric layer. 3.4.2 CAPACITANCE

Fig 3.8 Charge Separation in Capacitor

Charge separation in a parallel-plate capacitor causes an internal electric field. A polarized dielectric spacer (orange) reduces the electric field and increase the capacitance. A capacitor's ability to store charge is measured by its capacitance of charge stored on each plate to the voltage: , For an ideal parallel plate capacitor with a plate area and a plate separation : , the ratio of the amount

In SI units, a capacitor has a capacitance of one farad when one coulomb of charge stored on each plate causes a voltage difference of one volt between its plates. Since the farad is a very large unit, capacitance is usually expressed in microfarads (F), nano farads (nF), or picofarads (pF). In general, capacitance is greater in devices with large plate areas, separated by small distances. When a dielectric is present between two charged plates, its molecules become ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

16

MINOR PROJECT REPORT

CELLPHONE DETECTOR

polarized and reduce the internal electric field and hence the voltage. This allows the capacitor to store more charge for a given voltage, so a dielectric increases the capacitance of a capacitor, by an amount given by the dielectric constant, , of the material.

3.4.3 SERIES OR PARALLEL ARRANGEMENTS Capacitors in a parallel configuration each have the same potential difference (voltage). Their total capacitance (Ceq) is given by:

Fig 3.9.a Capacitor in parallel

The reason for putting capacitors in parallel is to increase the total amount of charge stored. In other words, increasing the capacitance also increases the amount of energy that can be stored. Its expression is:

The current through capacitors in series stays the same, but the voltage across each capacitor can be different. The sum of the potential differences (voltage) is equal to the total voltage. Their total capacitance is given by:

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

17

MINOR PROJECT REPORT

CELLPHONE DETECTOR

Fig 3.9.b Capacitor in series

In parallel, the effective area of the combined capacitor has increased, increasing the overall capacitance. However, in series, the distance between the plates has effectively been increased, reducing the overall capacitance. 3.4.4 DIELECTRIC MATERIALS Most types of capacitor include a dielectric spacer, which increases their capacitance. However, low capacitance devices are available with a vacuum between their plates, which allows extremely high voltage operation and low losses. Variable capacitors with their plates open to the atmosphere were commonly used in radio tuning circuits. Later designs use polymer foil dielectric between the moving and stationary plates, with no significant air space between them.

Fig 3.10 Different type of capacitor

Capacitor materials. From left: multilayer ceramic, ceramic disc, multilayer polyester film, tubular ceramic, polystyrene, metalized polyester film, aluminum electrolytic. Major scale divisions are in centimetres. Electrolytic capacitors use an aluminum or tantalum plate with an oxide dielectric layer. The second electrode is a liquid electrolyte, connected to the circuit by another foil plate.

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

18

MINOR PROJECT REPORT

CELLPHONE DETECTOR

Electrolytic capacitors offer very high capacitance but suffer from poor tolerances, high instability, gradual loss of capacitance especially when subjected to heat, and high leakage current. The conductivity of the electrolyte drops at low temperatures, which increases equivalent series resistance. While widely used for power-supply conditioning, poor highfrequency characteristics make them unsuitable for many applications. Tantalum capacitors offer better frequency and temperature characteristics than aluminum, but higher dielectric absorption and leakage The arrangement of plates and dielectric has many variations depending on the desired ratings of the capacitor. For small values of capacitance (microfarads and less), ceramic disks use metallic coatings, with wire leads bonded to the coating. Larger values can be made by multiple stacks of plates and disks. Larger value capacitors usually use a metal foil or metal film layer deposited on the surface of a dielectric film to make the plates, and a dielectric film of impregnated paper or plastic - these are rolled up to save space. To reduce the series resistance and inductance for long plates, the plates and dielectric are staggered so that connection is made at the common edge of the rolled-up plates, not at the ends of the foil or metalized film strips that comprise the plates. A high voltage variable capacitor: Note the large spacing between the plates. One set of plates rotates on a shaft, the other set is fixed. When plates are aligned, capacitance is at maximum. As shown, the moving plates are approximately half-way between minimum and maximum capacitance, amongst other applications. 3.4.5 APPLICATIONS Capacitors have various uses in electronic and electrical systems. 3.4.6 ENERGY STORAGE A capacitor can store electric energy when disconnected from its charging circuit, so it can be used like a temporary battery. Capacitors are commonly used in electronic devices to maintain power supply while batteries are being changed. (This prevents loss of information in volatile memory.) In car audio systems, large capacitors ranging from 0.5 to over 100 farads are used to store energy for the amplifier to use on demand. ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

19

MINOR PROJECT REPORT

CELLPHONE DETECTOR

Uses can be equipped with maintenance-free capacitors to extend service life.

Table 3.2 Different Capacitor Symbol

Capacitor symbols Capacitor Polarized Variable

capacitors capacitor

3.4.7 SIGNAL COUPLING Because capacitors pass AC but block DC signals (when charged up to the applied dc voltage), they are often used to separate the AC and DC components of a signal. This method is known as AC coupling or "capacitive coupling". Here, a large value of capacitance, whose value need not be accurately controlled, but whose reactance is small at the signal frequency, is employed.

3.4.8 DECOUPLING A decoupling capacitor is a capacitor used to decouple one part of a circuit from another. Noise caused by other circuit elements is shunted through the capacitor, reducing the effect they have on the rest of the circuit. It is most commonly used between the power supply and ground. An

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

20

MINOR PROJECT REPORT

CELLPHONE DETECTOR

alternative name is bypass capacitor as it is used to bypass the power supply or other high impedance component of a circuit.

3.5 TRANSISTOR:

In electronics, a transistor is a semiconductor device commonly used to amplify or switch electronic signals. A transistor is made of a solid piece of a semiconductor material, with at least three terminals for connection to an external circuit. A voltage or current applied to one pair of the transistor's terminals changes the current flowing through another pair of terminals. Because the controlled (output) power can be much larger than the controlling (input) power, the transistor provides amplification of a signal. The transistor is the fundamental building block of modern electronic devices, and is used in radio, telephone, computer and other electronic systems. Some transistors are packaged individually but most are found in integrated circuits. 3.5.1 IMPORTANCE The transistor is considered by many to be the greatest invention of the twentieth century. It is the key active component in practically all modern electronics. Its importance in today's society rests on its ability to be mass produced using a highly automated process (fabrication) that achieves astonishingly low per-transistor costs. Although several companies each produce over a billion individually-packaged (known as discrete) transistors every year, the vast majority of transistors produced are in integrated circuits (often shortened to IC, microchips or simply chips) along with diodes, resistors, capacitors and other electronic components to produce complete electronic circuits. A logic gate consists of about twenty transistors whereas an advanced microprocessor, as of 2006, can use as many as 1.7 billion transistors (MOSFETs). The transistor's low cost, flexibility and reliability have made it a ubiquitous device. Transistorized mechatronic circuits have replaced electromechanical devices in controlling appliances and machinery. It is often easier and cheaper to use a standard microcontroller and write a computer program to carry out a control function than to design an equivalent mechanical control function.

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

21

MINOR PROJECT REPORT

CELLPHONE DETECTOR

Because of the low cost of transistors and hence digital computers, there is a trend to digitize information, such as the Internet Archive. With digital computers offering the ability to quickly find, sort and process digital information, increasing effort has been put into making information digital. As a result, media is often delivered in digital form before being converted and presented in analog form to the user. Areas influenced by the digital revolution include television, radio, and newspapers. 3.5.2 ADVANTAGES The key advantages that have allowed transistors to replace their vacuum tube predecessors in most applications are: Small size and minimal weight, allowing the development of miniaturized electronic devices. Highly automated manufacturing processes, resulting in low per-unit cost. Lower possible operating voltages, making transistors suitable for small, batterypowered applications. No warm-up period for cathode heaters required after power application. Lower power dissipation and generally greater energy efficiency. Higher reliability and greater physical ruggedness. Extremely long life. Some transistorized devices produced more than 30 years ago are still in service. 3.5.3 DISADVANTAGES Silicon transistors do not operate at voltages higher than about 1 kV, SiC go to 3 kV. The electron mobility is higher in a vacuum, so that high power, high frequency operation is easier in tubes. Silicon transistors, compared to vacuum tubes, are highly sensitive to electromagnetic pulses.

3.6. ANTENNA:

We use an antenna in our project for transmitting and receiving radio signal in our project. An antenna (or aerial) is an electrical device which converts electric currents into radio waves, ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

22

MINOR PROJECT REPORT

CELLPHONE DETECTOR

and vice versa. It is usually used with a radio transmitter or radio receiver. In transmission, a radio transmitter applies an oscillating radio frequency electric current to the antenna's terminals, and the antenna radiates the energy from the current as electromagnetic waves (radio waves). In reception, an antenna intercepts some of the power of an electromagnetic wave in order to produce a tiny voltage at its terminals, that is applied to a receiver to be amplified. An antenna can be used for both transmitting and receiving.

Fig 3.11 Antennas

Antennas are essential components of all equipment that uses radio. They are used in systems such as radio broadcasting, broadcast television, two-way radio, communications receivers, radar, cell phones, an antenna consists of an arrangement of metallic conductors ("elements"), electrically connected (often through a transmission line) to the receiver or transmitter. An oscillating current of electrons forced through the antenna by a transmitter will create an oscillating magnetic field around the antenna elements, while the charge of the electrons also creates an oscillating electric field along the elements. These time-varying fields radiate away from the antenna into space as a moving electromagnetic field wave. Conversely, during reception, the oscillating electric and magnetic fields of an incoming radio wave exert force on the electrons in the antenna elements, causing them to move back and forth, creating oscillating currents in the antenna. Antennas may also contain reflective or directive elements or surfaces not connected to the transmitter or receiver, such as parasitic elements, parabolic reflectors or horns, which serve to direct the radio waves into a beam or other desired radiation pattern. Antennas can be designed to transmit or receive radio waves in all directions equally (omnidirectional antennas), or transmit them in a beam in a particular direction, and receive from that one direction only (directional or high gain antennas). ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

23

MINOR PROJECT REPORT

CELLPHONE DETECTOR

Antennas are required by any radio receiver or transmitter to couple its electrical connection to the electromagnetic field. Radio waves are electromagnetic waves which carry signals through the air (or through space) at the speed of light with almost no transmission loss. Radio transmitters and receivers are used to convey signals (information) in systems including broadcast (audio) radio, television, mobile, Wi-Fi (WLAN) data networks, trunk lines and point-to-point communications links (telephone, data networks), satellite links, many remote controlled devices such as garage door openers, and wireless remote sensors, among many others. Radio waves are also used directly for measurements in technologies

including RADAR, GPS, and radio astronomy. In each and every case, the transmitters and receivers involved require antennas, although these are sometimes hidden (such as the antenna inside an AM radio or inside a laptop computer equipped with Wi-Fi). According to their applications and technology available, antennas generally fall in one of two categories: 1. Omnidirectional or only weakly directional antennas which receive or radiate more or less in all directions. These are employed when the relative position of the other station is unknown or arbitrary. They are also used at lower frequencies where a directional antenna would be too large, or simply to cut costs in applications where a directional antenna isn't required. 2. Directional or beam antennas which are intended to preferentially radiate or receive in a particular direction or directional pattern. In common usage "omnidirectional" usually refers to all horizontal directions, typically with reduced performance in the direction of the sky or the ground (a truly isotropic radiator is not even possible). A "directional" antenna usually is intended to maximize its coupling to the electromagnetic field in the direction of the other station, or sometimes to cover a particular sector such as a 120 horizontal fan pattern in the case of a panel antenna at a cell site. 3.6.1 PARAMETER Antennas are characterized by a number of performance measures which a user would be concerned with in selecting or designing an antenna for a particular application. Chief among these relate to the directional characteristics (as depicted in the antenna's radiation pattern) and the resulting gain. Even in omnidirectional (or weakly directional) antennas, the gain can often ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

24

MINOR PROJECT REPORT

CELLPHONE DETECTOR

be increased by concentrating more of its power in the horizontal directions, sacrificing power radiated toward the sky and ground. The antenna's power gain (or simply "gain") also takes into account the antenna's efficiency, and is often the primary figure of merit. Resonant antennas are expected to be used around a particular resonant frequency; an antenna must therefore be built or ordered to match the frequency range of the intended application. A particular antenna design will present a particular feed point impedance. While this may affect the choice of an antenna, an antenna's impedance can also be adapted to the desired impedance level of a system using a matching network while maintaining the other characteristics (except for a possible loss of efficiency). Although these parameters can be measured in principle, such measurements are difficult and require very specialized equipment. Beyond tuning a transmitting antenna using an SWR meter, the typical user will depend on theoretical predictions based on the antenna design and/or on claims of a vendor. An antenna transmits and receives radio waves with a particular polarization which can be reoriented by tilting the axis of the antenna in many (but not all) cases. The physical size of an antenna is often a practical issue, particularly at lower frequencies (longer wavelengths). Highly directional antennas need to be significantly larger than the wavelength. Gain Gain is a parameter which measures the degree of directivity of the antenna's radiation pattern. A high-gain antenna will preferentially radiate in a particular direction. Specifically, the antenna gain, or power gain of an antenna is defined as the ratio of the intensity (power per unit surface) radiated by the antenna in the direction of its maximum output, at an arbitrary distance, divided by the intensity radiated at the same distance by a hypothetical isotropic antenna. The gain of an antenna is a passive phenomenon - power is not added by the antenna, but simply redistributed to provide more radiated power in a certain direction than would be transmitted by an isotropic antenna. An antenna designer must take into account the application for the antenna when determining the gain. High-gain antennas have the advantage of longer range and better signal quality, but must be aimed carefully in a particular direction. Low-gain antennas have shorter range, but the orientation of the antenna is relatively inconsequential.

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

25

MINOR PROJECT REPORT

CELLPHONE DETECTOR

Effective area or aperture The effective area or effective aperture of a receiving antenna expresses the portion of the power of a passing electromagnetic wave which it delivers to its terminals, expressed in terms of an equivalent area. Due to reciprocity (discussed above) the gain of an antenna used for transmitting must be proportional to its effective area when used for receiving. Consider an antenna with no loss, that is, one whose electrical efficiency is 100%. It can be shown that its effective area averaged over all directions must be equal to 2/4, the wavelength squared divided by 4. Gain is defined such that the average gain over all directions for an antenna with 100% electrical efficiency is equal to 1. Therefore the effective area Aeff in terms of the gain G in a given direction is given by:

For an antenna with an efficiency of less than 100%, both the effective area and gain are reduced by that same amount. Therefore the above relationship between gain and effective area still holds. These are thus two different ways of expressing the same quantity. Efficiency Efficiency of a transmitting antenna is the ratio of power actually radiated (in all directions) to the power absorbed by the antenna terminals. The power supplied to the antenna terminals which is not radiated is converted into heat. This is usually through loss resistance in the antenna's conductors, but can also be due to dielectric or magnetic core losses in antennas (or antenna systems) using such components. Such loss effectively robs power from the transmitter, requiring a stronger transmitter in order to transmit a signal of a given strength. loss resistance will generally affect the feed point impedance, adding to its resistive (real) component. That resistance will consist of the sum of the radiation resistance Rr and the loss resistance Rloss. If an rms current I is delivered to the terminals of an antenna, then a power of I2Rr will be radiated and a power of I2Rloss will be lost as heat. Therefore the efficiency of an antenna is equal to Rr / (Rr + Rloss). Of course only the total resistance Rr + Rloss can be directly measured.

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

26

MINOR PROJECT REPORT

CELLPHONE DETECTOR

3.7 IC:

3.7. A IC CA3130:

3.7. A.1 DESCRIPTION

CA3130 are integrated-circuit operational amplifiers that combine the advantage of both CMOS and bipolar transistors on a monolithic chip. Gate-protected p-channel MOSFET (PMOS) transistors are used in the input circuit to provide very-high-input impedance, very low-input current, and exceptional speed performance. The use of PMOS field-effect transistors in the input stage results in common-mode input-voltage capability down to 0.5 volt below the negative-supply terminal, an important attribute in single-supply applications. A

complementary-symmetry MOS (CMOS) transistor-pair, capable of swinging the output voltage to within 10 millivolts of either supply-voltage terminal (at very high values of load impedance), is employed as the output circuit. The CA3130 Series circuits operate at supply voltages ranging from 5 to 16 volts, or 2.5 to 8 volts when using split supplies. They can be phase compensated with a single external capacitor, and have terminals for adjustment of offset Voltage for applications requiring offset-null capability. Terminal provisions can also made to permit strobing of the output stage. The offers superior input characteristics over those of the CA3130. 3.7. A.2 PIN DESCRIPTION

Fig 3.12 Pin Diagram of CA3130

3.7. A.3 APPLICATIONS Ground-Referenced Single Supply Amplifiers

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

27

MINOR PROJECT REPORT

CELLPHONE DETECTOR

Fast Sample-Hold Amplifiers Long-Duration Timers/Monostables High-Input-Impedance Comparators (Ideal Interface with Digital CMOS) High-Input-Impedance Wideband Amplifiers Voltage Followers (e.g. Follower for Single-Supply D/A Converter) Voltage Regulators (Permits Control of Output Voltage Down to Zero Volts) Peak Detectors Single-Supply Full-Wave Precision Rectifiers Photo-Diode Sensor Amplifiers

3.7. B IC NE555:

We use 555 timer in our project. NE555 is a highly stable controller capable of producing accurate timing pulses. With monostable operation, the time delay is controlled by one external resistor and one capacitor. With astable operation, the frequency and duty cycle are accurately controlled with two external resistors and one capacitor.

Fig 3.13 Internal Block Diagram

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

28

MINOR PROJECT REPORT

CELLPHONE DETECTOR

3.7. B.1 PINS DESCRIPTION

The connection of the pins for a DIP package is as follows:

Table 3.3 Pin Description of NE555

Pin 1 2 3

Name GND TRIG OUT

Purpose Ground, low level (0 V) OUT rises, and interval starts, when this input falls below 1/3 VCC. This output is driven to +VCC or GND.

4 5 6 7 8

RESET CTRL THR DIS V+, Vcc

A timing interval may be interrupted by driving this input to GND. "Control" access to the internal voltage divider (by default, 2/3 VCC) The interval ends when the voltage at THR is greater than at CTRL Open collector output; may discharge a capacitor between intervals Positive supply voltage is usually between 3 and 15 V.

3.7. B.2 MODES The 555 has three operating modes:

Monostable mode: in this mode, the 555 functions as a "one-shot" pulse generator. Applications include timers, missing pulse detection, bouncefree switches, touch switches, frequency divider, capacitance measurement, pulse-width modulation (PWM) and so on. Astable free running mode: the 555 can operate as an oscillator. Uses include LED and lamp flashers, pulse generation, logic clocks, tone generation, security alarms, pulse position modulationand so on. Selecting a thermistor as timing resistor allows the use of the 555 in a temperature sensor: the period of the output pulse is determined by the temperature. The use of a microprocessor based circuit can then convert the pulse period to temperature, linearize it and even provide calibration means.

Bistable mode or Schmitt trigger: the 555 can operate as a flip-flop, if the DIS pin is not connected and no capacitor is used. Uses include bounce free latched switches.

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

29

MINOR PROJECT REPORT

CELLPHONE DETECTOR

3.7. B.3 APPLICATIONS Precision Timing Pulse Generation Time Delay Generation Sequential Timing

3.8. LED:

LED displays allow for smaller sets of interchangeable LEDs to be one large display.A lightemitting-diode (LED) (pronounced), is a semiconductor diode that emits light when an electric current is applied in the forward direction of the device, as in the simple LED circuit. The effect is a form of electroluminescence where incoherent and narrow-spectrum light is emitted from the p-n junction. Light-emitting diodes are used in applications as diverse as replacements for aviation lighting, automotive lighting (particularly brake lamps, turn signals andindicators) as well as in traffic signals. LEDs have allowed new text, video displays, and sensors to be developed, while their high switching rates are also useful in advanced communications technology. Infrared LEDs are also used in the remote control units of many commercial products including televisions, DVD players, and other domestic appliances.

Fig 3.14 led schematic symbol and LED

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

30

MINOR PROJECT REPORT

CELLPHONE DETECTOR

3.8.1 PRINCIPLES:

Fig 3.15 the Inner Workings of a Led

Fig 3.16 V-I CHARACTERISTICS OF LED

I-V diagram for a diode an LED will begin to emit light when the on-voltage is exceeded. Typical on voltages are 2-3 Volt Like a normal diode, the LED consists of a chip of semiconducting material impregnated, or doped, with impurities to create a p-n junction. As in other diodes, current flows easily from the p-side, or anode, to the n-side, or cathode, but not in the reverse direction. Charge-carriers electrons and holesflow into the junction from electrodes with different voltages. When an electron meets a hole, it falls into a lower energy level, and releases energy in the form of a photon. The wavelength of the light emitted, and therefore its color, depends on the band gap energy of the materials forming the p-n junction. In silicon or germanium diodes, the electrons and holes recombine by a non-radiative transition which produces no optical emission, because these are

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

31

MINOR PROJECT REPORT

CELLPHONE DETECTOR

indirect band gap materials. The materials used for the LED have a direct band gap with energies corresponding to near-infrared, visible or near-ultraviolet light. 3.8.2 ELECTRICITY POLARITY: Unlike incandescent light bulbs, which illuminate regardless of the electrical polarity, LEDs will only light with correct electrical polarity. When the voltage across the p-n junction is in the correct direction, a significant current flows and the device is said to be forward-biased. If the voltage is of the wrong polarity, the device is said to be reverse biased, very little current flows, and no light is emitted. LEDs can be operated on an alternating current voltage, but they will only light with positive voltage, causing the LED to turn on and off at the frequency of the AC supply. Most LEDs have low reverse breakdown voltage ratings, so they will also be damaged by an applied reverse voltage above this threshold. If it is desired to drive the LED

.

Fig3.17 Close-up of a typical LED showing the internal structure

directly from an AC supply of more than the reverse breakdown voltage then it may be protected by placing a diode (or another LED) in inverse parallel. The manufacturer will normally advise how to determine the polarity of the LED in the product datasheet. However, these methods may also be used:(*)Less reliable methods of determining polarity. It is strongly

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

32

MINOR PROJECT REPORT

CELLPHONE DETECTOR

recommended to apply a safe voltage and observe the illumination as a test regardless of what method is used to determine the polarity.

3.9 PIEZOELECTRIC BUZZER:

A buzzer or beeper is an audio signaling device, which may be mechanical, electromechanical, or piezoelectric. Typical uses of buzzers and beepers include alarm devices, timers and confirmation of user input such as a mouse click or keystroke.

Fig 3.18 Buzzer

A piezoelectric element may be driven by an oscillating electronic circuit or other audio signal source, driven with a piezoelectric audio amplifier. Sounds commonly used to indicate that a button has been pressed are a click, a ring or a beep. PRECAUTIONS FOR USE Do not apply DC bias to the piezoelectric buzzer; otherwise insulation resistance may become low and affect the performance. Do not supply any voltage higher than applicable to the piezoelectric buzzer. Do not use the piezoelectric buzzer outdoors. It is designed for indoor use. If the piezoelectric buzzer has to be used outdoors, provide it with waterproofing measures; it will not operate normally if subjected to moisture. Do not wash the piezoelectric buzzer with solvent or allow gas to enter it while washing; any solvent that enters it may stay inside a long time and damage it. A piezoelectric ceramic material of approximately 100m thick is used in the sound generator of the buzzer. Do not press the sound generator through the sound release hole otherwise the ceramic material may break. Do not stack the piezoelectric buzzers without packing.

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

33

MINOR PROJECT REPORT

CELLPHONE DETECTOR

Do not apply any mechanical force to the piezoelectric buzzer; otherwise the case may deform and result in improper operation. Do not place any shielding material or the like just in front of the sound release hole of the buzzer; otherwise the sound pressure may vary and result in unstable buzzer operation. Make sure that the buzzer is not affected by a standing wave or the like.

Be sure to solder the buzzer terminal at 350C max.(80W max.)(soldering iron trip) within 5 seconds using a solder containing silver. Avoid using the piezoelectric buzzer for a long time where any corrosive gas (H2S, etc.) exists; otherwise the parts or sound generator may corroded and result in improper operation.

Be careful not to drop the piezoelectric buzzer.

3.10 PRINTED WIRING BOARD:

When assembling an electronic circuit, a board is needed on which the components can be mounted and wired together. This board is called a Printed Wiring Board (PWB).

Fig 3.19 Printed Wiring Board

In Japan, the printed wiring board used to be called a "Printed Circuit Board." Nowadays in Japan the name "Printed Circuit Board" is not used because the initials of "Printed Circuit Board" are "PCB." PCB also stands for "Polychlorinated Biphenyls (PCBs)," which is a poison. So in Japan, we refer to the boards as "Printed Wiring Boards." In other countries, they are still referred to as "Printed Circuit Boards," or PCBs.

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

34

MINOR PROJECT REPORT

CELLPHONE DETECTOR

Making a PWB takes a lot of work, and can be very difficult. For this reason, for many handmade circuits, I often use a universal PWB. The universal PWB consists of an insulation board drilled with .8mm holes at 0.1 inch (2.54 mm) intervals. The board is completely covered with these holes from edge to edge. The insulation board is comprised of fiberglass (glass epoxy), paper epoxy, or Bakelite plastic. Centered around each hole on the bottom of the PWB is an (approximately) 2mm copper leaf (known as the "land" or "pad"). To use the board, the parts are mounted on the face of the board, and the component leads are passed through the nearest holes, to project through the bottom of the board, where the wires can be soldered together. The interval between the holes is 0.1 inches (2.54 mm), so DIP or SIP ICs can be easily mounted. The photograph shows a PWB made of glass epoxy. The color is green. Paper epoxy boards have a beige color. In case of Bakelite, the color is thin brown. There are various sizes in addition to what I have shown, so you can select a board according to your needs. The boards can also be cut to size. On the top right in the photograph, the back side is shown. The copper leaf on this board has been pre-soldered ("tinned") to make soldering easier, so it has a silver color. If the board has not been pre-soldered, then it is seen to have a copper color.

3.11 SOLDERING:

Soldering is a process in which two or more metal items are joined together by melting and flowing a filler metal into the joint, the filler metal having a relatively low melting point. Soft soldering is characterized by the melting point of the filler metal, which is below 400 C (800 F). The filler metal used in the process is called solder. Soldering is distinguished from brazing by use of a lower melting-temperature filler metal; it is distinguished from welding by the base metals not being melted during the joining process. In a soldering process, heat is applied to the parts to be joined, causing the solder to melt and be drawn into the joint by capillary action and to bond to the materials to be joined by wetting action. After the metal cools, the resulting joints are not as strong as the base metal, but have adequate strength, electrical conductivity, and water-tightness for many uses. Soldering is an

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

35

MINOR PROJECT REPORT

CELLPHONE DETECTOR

ancient technique mentioned in the Bible and there is evidence that it was employed up to 5000 years ago in Mesopotamia. 3.11.1 APPLICATIONS One of the most frequent applications of soldering is assembling electronic components to printed circuit boards (PCBs). Another common application is making permanent but reversible connections between copper pipes in plumbing systems. Joints in sheet metal objects such as food cans, roof flashing, rain gutters and automobile radiators have also historically been soldered, and occasionally still are. Jewellery components are assembled and repaired by soldering. Small mechanical parts are often soldered as well. Soldering is also used to join lead came and copper foil in stained glass work. Soldering can also be used to effect a semi-permanent patch for a leak in a container cooking vessel. 3.11.2 SOLDERS Soldering filler materials are available in many different alloys for differing applications. In electronics assembly, the eutectic alloy of 63% tin and 37% lead (or 60/40, which is almost identical in performance to the eutectic) has been the alloy of choice. Other alloys are used for plumbing, mechanical assembly, and other applications. A eutectic formulation has several advantages for soldering; chief among these is the coincidence of the liquid us and solidus temperatures, i.e. the absence of a plastic phase. This allows for quicker wetting out as the solder heats up, and quicker setup as the solder cools. A

Fig 3.20 Soldering Iron

Non-eutectic formulation must remain still as the temperature drops through the liquidus and solidus temperatures. Any differential movement during the plastic phase may result in cracks, giving an unreliable joint. Additionally, a eutectic formulation has the lowest possible melting point, which minimizes heat stress on electronic components during soldering.

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

36

MINOR PROJECT REPORT

CELLPHONE DETECTOR

Lead-free solders are suggested anywhere children may come into contact (since children are likely to place things into their mouths), or for outdoor use where rain and other precipitation may wash the lead into the groundwater. Common solder alloys are mixtures of tin and lead, respectively: 63/37: melts at 213 C (361.4 F) (eutectic: the only mixture that melts at a point, instead of over a range) 60/40: melts between 183190 C (361374 F) 50/50: melts between 185215 C (365419 F)

Lead-free solder alloys melt around 250 C (482 F), depending on their composition. For environmental reasons, 'no-lead' solders are becoming more widely used. Unfortunately most 'no-lead' solders are not eutectic formulations, making it more difficult to create reliable joints with them. Other common solders include low-temperature formulations (often containing bismuth), which are often used to join previously-soldered assemblies without un-soldering earlier connections, and high-temperature formulations (usually containing silver) which are used for high-temperature operation or for first assembly of items which must not become unsoldered during subsequent operations. Specialty alloys are available with properties such as higher strength, better electrical conductivity and higher corrosion resistance. 3.11.3 FLUX In high-temperature metal joining processes (welding, brazing and soldering), the primary purpose of flux is to prevent oxidation of the base and filler materials. Tin-lead solder, for example, attaches very well to copper, but poorly to the various oxides of copper, which form quickly at soldering temperatures. Flux is a substance which is nearly inert at room temperature, but which becomes strongly reducing at elevated temperatures, preventing the formation of metal oxides. Secondarily, flux acts as a wetting agent in the soldering process, reducing the surface tension of the molten solder and causing it to better wet out the parts to be joined.

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

37

MINOR PROJECT REPORT

CELLPHONE DETECTOR

Fluxes currently available include water-soluble fluxes (no VOC's required for removal) and 'no-clean' fluxes which are mild enough to not require removal at all. Performance of the flux needs to be carefully evaluated; a very mild 'no-clean' flux might be perfectly acceptable for production equipment, but not give adequate performance for a poorly-controlled handsoldering operation. Traditional rosin fluxes are available in non-activated (R), mildly activated (RMA) and activated (RA) formulations. RA and RMA fluxes contain rosin combined with an activating agent, typically an acid, which increases the wet ability of metals to which it is applied by removing existing oxides. The residue resulting from the use of RA flux is corrosive and must be cleaned off the piece being soldered. RMA flux is formulated to result in a residue which is not significantly corrosive, with cleaning being preferred but optional. 3.11.4 BASIC SOLDERING TECHNIQUES 3.11.4.1 METHODS Soldering operations can be performed with hand tools, one joint at a time, or en masse on a production line. Hand soldering is typically performed with a soldering iron, soldering gun, or a torch, or occasionally a hot-air pencil. Sheet metal work was traditionally done with "soldering coppers" directly heated by a flame, with sufficient stored heat in the mass of the soldering copper to complete a joint; torches or electrically-heated soldering irons are more convenient. All soldered joints require the same elements of cleaning of the metal parts to be joined, fitting up the joint, heating the parts, applying flux, applying the filler, removing heat and holding the assembly still until the filler metal has completely solidified. Depending on the nature of flux material used, cleaning of the joints may be required after they have cooled. The distinction between soldering and brazing is arbitrary, based on the melting temperature of the filler material. A temperature of 450 C is usually used as a practical cut-off. Different equipment and/or fixturing is usually required since (for instance) a soldering iron generally cannot achieve high enough temperatures for brazing. Practically speaking there is a significant difference between the two processesbrazing fillers have far more structural strength than solders, and are formulated for this as opposed to maximum electrical conductivity. Brazed

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

38

MINOR PROJECT REPORT

CELLPHONE DETECTOR

connections are often as strong or nearly as strong as the parts they connect, even at elevated temperatures. "Hard soldering" or "silver soldering" (performed with high-temperature solder containing up to 40% silver) is also often a form of brazing, since it involves filler materials with melting points in the vicinity of, or in excess of, 450 C. Although the term "silver soldering" is used much more often than "silver brazing", it may be technically incorrect depending on the exact melting point of the filler in use. In silver soldering ("hard soldering"), the goal is generally to give a beautiful, structurally sound joint, especially in the field of jewellery. Thus, the temperatures involved, and the usual use of a torch rather than an iron, would seem to indicate that the process should be referred to as "brazing" rather than "soldering", but the endurance of the "soldering" appellation serves to indicate the arbitrary nature of the distinction (and the level of confusion) between the two processes. Induction soldering is a process which is similar to brazing. The source of heat in induction soldering is induction heating by high-frequency AC current. Generally copper coils are used for the induction heating. This induces currents in the part being soldered. The coils are usually made of copper or a copper base alloy. The copper rings can be made to fit the part needed to be soldered for precision in the work piece. Induction soldering is a process in which a filler metal (solder) is placed between the faying surfaces of (to be joined) metals. The filler metal in this process is melted at a fairly low temperature. Fluxes are a common use in induction soldering. This is a process which is particularly suitable for soldering continuously. The process is usually done with coils that wrap around a cylinder/pipe that needs to be soldered. Some metals are easier to solder than others. Copper, silver, and gold are easy. Iron and nickel are found to be more difficult. Because of their thin, strong oxide films, stainless steel and aluminum are a little more difficult. Titanium, magnesium, cast irons, steels, ceramics, and graphites can be soldered but it involves a process similar to joining carbides. They are first plated with a suitable metallic element that induces interfacial bonding.

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

39

MINOR PROJECT REPORT

CELLPHONE DETECTOR

3.11.4.2 DESOLDERING AND RESOLDERING Used solder contains some of the dissolved base metals and is unsuitable for reuse in making new joints. Once the solder's capacity for the base metal has been achieved it will no longer properly bond with the base metal, usually resulting in a brittle cold solder joint with a crystalline appearance. It is good practice to remove solder from a joint prior to resoldering-desoldering braids or vacuum desoldering equipment (solder suckers) can be used. Desoldering wicks contain plenty of flux that will lift the contamination from the copper trace and any device leads that are present. This will leave a bright, shiny, clean junction to be resoldered. The lower melting point of solder means it can be melted away from the base metal, leaving it mostly intact though the outer layer will be "tinned" with solder. Flux will remain which can easily be removed by abrasive or chemical processes. This tinned layer will allow solder to flow into a new joint, resulting in a new joint, as well as making the new solder flow very quickly and easily. 3.11.5 PREPARATION Step 1: Preparation If you are preparing the cable for a connector, I strongly suggest you put any connector parts on now (the screw on part of an XLR, or casing of a 1/4" jack for example). Get into the habit of sliding these on before you start on the cable, or else you can bet it won't be long before you finish soldering your connector only to discover you forgot to put the connector casing on, and have to start all over again. Once you have all the connector parts on that you need, you will need to strip your cable.

Fig 3.21 Cutter and Wires

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

40

MINOR PROJECT REPORT

CELLPHONE DETECTOR

The obvious tool to choose to strip a wire would be a wire stripper. There are many types of wire stripper, and most of them work the same. You simply put the wire in, and squeeze it and pull the end bit off. It will cut to a preset depth, and if you have chosen the right depth it will cut the insulation off perfectly. It is possible to choose the wrong depth and cut too deeply, or too shallow, but they are very easy to use. On the other hand, some people (myself included) prefer to use a knife or side cutters. I use side cutters for small cable and a Stanley knife for bigger cables...and although I have a couple of wire strippers, I haven't used them for years. This may seem odd, but I've got my side cutters and knife with me anyway, and they do the job fine. If you are using side cutters (as shown here), position them about 10mm (1/2 inch) from the end, and gently squeeze the cutters into the insulation to pierce it, but not far enough to cut the copper strands of the core. Open the cutters slightly so you can turn the wire and pierce the rest of the insulation. You may have to do this a few times to cut through all of the insulation, but it is better to cut too shallow and have to turn and cut again rather than cut the core and have to start again. Now you should be able to slide the insulation off with your cutters, or pull it off with your fingers. This may sound a tedious method, but in no time at all you will be able to do it in two cuts and a flick of the cutters. I won't explain how I use a knife to do larger cable, as I'd hate someone to slice a finger or thumb open following my instructions. Using a sharp blade like that certainly does have its risks, so stick with wire cutters or side cutters if you are at all unsure.

Fig 3.22 Cutting of Wire

If your connector has been used before, make sure you remove any remnants of wire and solder from the contacts. Do this by putting the tip of your soldering iron into the hole and flicking the

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

41

MINOR PROJECT REPORT

CELLPHONE DETECTOR

solder out when it has melted. Common Sense Alert! Please be careful when you flick melted solder flick it away from you. 3.11.6 TINNING Step 2: Tinning Whatever it is you are soldering, you should 'tin' both contacts before you attempt to solder them. This coats or fills the wires or connector contacts with solder so you can easily melt them together.

Fig 3.23 Tinning

To tin a wire, apply the tip of your iron to the wire for a second or two, and then apply the solder to the wire. The solder should flow freely onto the wire and coat it (if it's stranded wire the solder should flow into it, and fill the wire). You may need to snip the end off afterwards, particularly if you have put a little too much solder on and it has formed a little ball at the end of the wire. Be careful not to overheat the wire, as the insulation will start to melt. On cheaper cable the insulation can 'shrink back' if heated too much, and expose more copper core that you intended. You can cut the wire back after you have tinned it, but it's best simply not to overheat it. The larger the copper core, the longer it will take to heat up enough to draw the solder in, so use a higher temperature soldering iron for larger cables if you can. To tin a contact on an audio XLR connector, hold the iron on the outside of the the contact for a second or two, then apply the solder into the cavity of the contact. Once again, the solder should flow freely and fill the contact. Connectors such as jacks have contacts that are just holes in a flat part of the connector. To tin these you put your iron on it, and apply the solder to

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

42

MINOR PROJECT REPORT

CELLPHONE DETECTOR

where the iron is touching. The solder should flow and cover the hole. Once you have tinned both parts, you are ready to solder them together. 3.11.7 SOLDERING Step 3: Soldering This step can often be the easiest when soldering audio cables. You simply need to place your soldering iron onto the contact to melt the solder.

Fig 3.24 Soldering

When the solder in the contact melts, slide the wire into the contact. Remove the iron and hold the wire still while the solder solidifies again. You will see the solder 'set' as it goes hard. This should all take around 1-3 seconds. A good solder joint will be smooth and shiny. If the joint is dull and crinkly, the wire probably moved during soldering. If you have taken too long it will have solder spikes.

If it does not go so well, you may find the insulation has melted, or there is too much stripped wire showing. If this is the case, you should desolder the joint and start again.

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

43

MINOR PROJECT REPORT

CELLPHONE DETECTOR

3.11.8 CLEANING YOUR SOLDERING IRON You should clean your tip after each use. There are many cleaning solutions and the cheapest (and some say best) is a damp sponge. Just rub the soldering iron tip on it after each solder. Another option is to use tip cleaner. This comes in a little pot that you push the tip into. This works well if your tip hasn't been cleaned for a while. It does create a lot of smoke, so it is better not to let the tip get so dirty that you need to use tip cleaner.

Fig 3.25 Cleaning of Iron

Some solder stations come with a little pad at the base of the holder. If you have one of these, you should get into the habit of wiping the tip on the pad each time you apply solder with it. If you need to clean solder off a circuit board, solder wick is what you need. You place the wick on the joint or track you want to clean up, and apply your soldering iron on top. The solder melts and is drawn into the wick. If there is a lot of solder the wick will fill up, so gently pull the wick through the joint and your iron, and the solder will flow into it as it passes.

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

44

MINOR PROJECT REPORT

CELLPHONE DETECTOR

CHAPTER-4 APPLICATION & LIMITATION OF DETECTOR

4.1 APPLICATION

It can be used to prevent use of mobile phones in examination halls, confidential rooms, etc.

It is also useful for detecting the use of mobile phone for spying and unauthorized video transmission.

It is useful where the use of mobile phone is prohibited Like petrol pumps and gas stations, historical places, religious places and court of laws

4.2 LIMITATION

RANGE OF THE CIRCUIT

The prototype version has only limited range of 2 meters. But if a preamplifier stage using JFET or MOSFET transistor is used as an interface between the capacitor and IC, range can be increased.

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

45

MINOR PROJECT REPORT

CELLPHONE DETECTOR

CHAPTER-5

CONCLUSION & FUTURE WORKS

CONCLUSION:

In this project we made an attempt to design a CELL-PHONE DETECTOR that can detect the both incoming and outgoing calls, SMS and video transmission even if the mobile is kept at the silent mode. Our circuit has detected the presence of an activated mobile phone even at the distance of about one-and-half meters. It gave the indication of presence of mobile by glowing the LED, according to the receiving frequency and by the buzzing the sound of a buzzer. The alarm continues until the signal transmission ceases.

FUTURE ASPECTS:

Trying to increase the detecting range of mobile bug to few more meters for observing wide range of area

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

46

MINOR PROJECT REPORT

CELLPHONE DETECTOR

REFERENCES

http://www.instructables.com/ http://www.datasheet4u.com/ http://electroschematics.com/ http://www.electronics4u.com/

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

47

MINOR PROJECT REPORT

CELLPHONE DETECTOR

APPENDIX: DATASHEET of IC

IC CA3130:

DESCRIPTION

CA3130 are integrated-circuit operational amplifiers that combine the advantage of both CMOS and bipolar transistors on a monolithic chip. Gate-protected p-channel MOSFET (PMOS) transistors are used in the input circuit to provide very-high-input impedance, very low-input current and exceptional speed performance. The use of PMOS field-effect transistors in the input stage results in common-mode input-voltage capability down to 0.5 volt below the negative-supply terminal, an important attribute in single-supply applications. A

complementary-symmetry MOS (CMOS) transistor-pair, capable of swinging the output voltage to within 10 mill volts of either supply-voltage terminal (at very high values of load impedance), is employed as the output circuit. The CA3130 Series circuits operate at supply voltages ranging from 5 to 16 volts, or 2.5 to 8 volts when using split supplies. They can be phase compensated with a single external capacitor, and have terminals for adjustment of offset Voltage for applications requiring offset-null capability. Terminal provisions can also make to permit strobing of the output stage. The offers superior input characteristics over those of the CA3130.

PIN DESCRIPTION

Pin Diagram of CA3130

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

48

MINOR PROJECT REPORT

CELLPHONE DETECTOR

SPECIFICATION OF IC CA3130

Absolute Maximum Ratings DC Supply Voltage (Between V+ And V- Terminals) Differential-Mode Input Voltage DC Input Voltage Input-Terminal Current Device Dissipation: Without Heat SinkUp To 55C Above 55C With Heat SinkUp To 90C Above 90C Output Short-Circuit Duration Junction Temperature Junction Temperature (Plastic Package) Lead Temperature (Soldering) 1W Derate Linearly 16.7 mW/oC. Indefinite +175C +150C +300C 630 mW Derate Linearly 6.67 mW/oC 16V 8V (V+ +8 V) to (V- -0.5V) 1mA

Operating Conditions Operating Temperature Range Storage Temperature Range -55C to +125C -65C to +150C

FEATURES MOSFET Input Stage Provides: Very High ZI = 1.5 TW (1.5 x 1012W) Typ. Very Low II = 5pA Typ. at 15V Operation = 2pA Typ. at 5V Operation Ideal for Single-Supply Applications Common-Mode Input-Voltage Range Includes Negative Supply Rail; Input Terminals can be Swung 0.5V Below Negative Supply Rail CMOS Output Stage Permits Signal Swing to Either (or both) Supply Rails ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

49

MINOR PROJECT REPORT

CELLPHONE DETECTOR

APPLICATIONS Ground-Referenced Single Supply Amplifiers Fast Sample-Hold Amplifiers Long-Duration Timers/Monostables High-Input-Impedance Comparators (Ideal Interface with Digital CMOS) High-Input-Impedance Wideband Amplifiers Voltage Followers (e.g. Follower for Single-Supply D/A Converter) Voltage Regulators (Permits Control of Output Voltage Down to Zero Volts) Peak Detectors Single-Supply Full-Wave Precision Rectifiers Photo-Diode Sensor Amplifiers

IC NE555:

We use 555 timer in our project. NE555 is a highly stable controller capable of producing accurate timing pulses. With monostable operation, the time delay is controlled by one external resistor and one capacitor. With astable operation, the frequency and duty cycle are accurately controlled with two external resistors and one capacitor.

Internal Block Diagram

ELECTRONICS AND COMMUNICATION ENGINEERING HARYANA COLLEGE OF TECHNOLOGY & MANAGEMENT, KAITHAL

50

MINOR PROJECT REPORT

CELLPHONE DETECTOR

PIN DESCRIPTION

The connection of the pins for a DIP package is as follows:

Pin Description of NE555

Pin 1 2 3

Name GND TRIG OUT

Purpose Ground, low level (0 V) OUT rises, and interval starts, when this input falls below 1/3 VCC. This output is driven to +VCC or GND.

4 5 6 7 8

RESET CTRL THR DIS V+, Vcc