Professional Documents

Culture Documents

Plates ASTM-A240 Gr 304L

Uploaded by

abhishek198327Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plates ASTM-A240 Gr 304L

Uploaded by

abhishek198327Copyright:

Available Formats

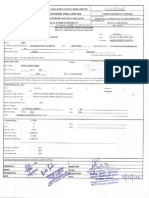

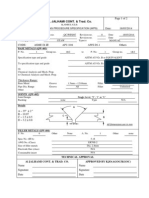

QW -482 WELDING PROCEDURE SPECIFICATION (WPS) (SEE QW 201.

.1, SECTION IX, ASME BOILER AND PRESSURE VESSEL CODE SHEET 1 OF 2

Company Name DCMS ENGINEERING CO. Welding Procedure Specification No DCMS/WPS/099 Rev-0 Date : 19/04/2012 Supporting PQR no. (S) DCMS/PQR/099 Rev - 0 Date : 7.05.2012 Welding Process (es) GTAW Type (s) Manual (Automatic, Manual, Machine or semi Automatic) JOINTS (QW-402) Joints Design Single V Groove Joint Backing Yes ___________ No ____X______ Backing Material (Type) _ARGON GAS______ (Refer to both backing & retailers). Metal Nonfusing Metal Non Metallic Other DETAILS

* BASE METAL (QW 403) P.No. 8 Group no. 1 to P.no. 8 Group no. 1 OR Specification type and grade Plates ASTM-A-240 Gr 304L To specification type and grade Plates ASTM-A-240 Gr 304L OR Chem. Analysis and Mech. Prop ___________NA___________________________ To Chem Analysis and Mech. Prop ________NA___________________________ Thickness Range :Base Metal :- Groove 1.6 to 12 mm Fillet All thickness, all sizes & all diameters Other WPS shall be applicable for both without and with backing (Stainless Steel Material) FILLER METALS (QW-404) Spec No. (SFA) AWS No. (Class) F-No. A-No Size of Filler Metals Weld Metal Thickness Range Groove Fillet Electrode-Flux (Class) Flux Trade Name Consumable Insert

Plates ASTM-A240-Gr 304L (S.S. to S.S.)

SFA-5.9 ER-308L 6 8 1.6mm

1.6 mm to 12mm All thicknesses N.A. N.A. N.A. N.A. POSITION (QW-405) POST WELD HEAT TREATMENT (QW-407) Position (s) of Groove All Positions(Test piece 1G) Temperature Range ____NA_____ Welding Progression : Up Uphill Down NA Time Range _____NA____ Position (s) of Fillet All Positions

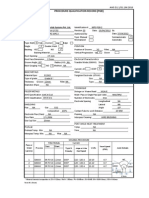

QW-482

WPS NO : DCMS/WPS/099 Dated 19/4/2012

REV : 0 SHEET 2 OF 2

PREHEAT (QW-406) Preheat Temp. Min NA__________ Interpass Temp. Max _________1250C________ Preheat maintenance _________NA__________ (Continuous or special heating where applicable should be recorded) ELECTRICAL CHARCTERISTICS (QW-409) Current AC or DC _DC_ Amp (Range) 65-85 Amp Tungsten Electrodes Size & Type Mode to metal transfer for GMAW Electrodes Wire feed speed range Polarity, Volts (Range) GAS (QW-408) Percent Composition Shielding (Mixtures) Flow Rate Shielding Argon 99.99% Pure 12-15Ltr./min Trailing Argon -Backing Argon 99.99% Pure 5-10Ltr./min

DCEN (STRAIGHT) 10-12 Volts

(Amp and volts range should be recorded for each electrode size, positions and thickness etc.)

1.6mm, 2.4mm, 2% Thoriated Tungsten Electrodes

(Pure tungsten 2% Thoriated etc.)

____________ NA ________________________ (Spray arc short circulating arc etc.) ____________ NA ________________________

TECHNIQUE (QW-410) String or weave bead Root (stringer) & Final (weaving). Orifice or Gas Cup Size ceramic nozzle of Initial and Inter pass (Cleaning Brushing, Grinding etc.)Degreasing with acetone, wire brushing, if required grinding of all pass. Method of Back Gouging _____NA ______________ Oscillation 2.5 times of size of filler wire_____________ Contact Tube to Work Distance _____NA______________ Single Pass (per side) __ Multiple____________ Multiple or Single Electrode __Single_____________ Travel Speed (Range) 40-65 mm/min.__ Peening Not Allowed Other _NA__________________

FILLER METAL WELD LAYER(S) PROCESS CURRENT VOLT RANGE TRAVEL SPEED RANGE (mm/min)

CLASS

DIAMETER

TYPE / POLARITY

AMP RANGE

OTHER

Root (1st Pass) 2nd Pass 3rd & Subsequent Passes

GTAW GTAW GTAW

ER 308-L ER 308-L ER 308-L

1.6mm 1.6mm 1.6mm

DCEN DCEN DCEN

65-75 75-85 75-85

10-12 10-12 10-12

40-50 55-65 55-65

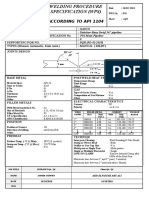

QW-483PROCEDURE QUALIFICATION RECORD

(PQR)

(SEE QW200.2, SECTION IX ASME BOILER AND PRESSURE VESSEL CODE) RECORD ACTUAL CONDITION USED TO WELD TEST COUPON

Company Name M/S. DCMS Engineering Ltd. Mumbai Procedure Qualification Record No. DCMS / PQR/099 Date : 7/5/2012 WPS No. DCM/WPS/099 Date : 19/4/2012 Welding Process(es) GTAW Types (Manual, Automatic, Semi-Automatic) Manual JOINTS (QW-402) Rev 0 Rev. 0

SHEET 1 OF 3

Plates ASTM - A -240 Gr. 304L to Plate ASTM A - 240 Gr. 304L

Groove Design of Test Coupon

BASE METAL (QW-403) Material Spec. SA - 240 Type of Grade 304 L P.No. ________8________ to P. No. ______8_________ Thickness of Test Coupon 6mm Diameter of Test Coupon NA Other Weld thickness range qualified 1.6 mm to 12 mm

POST WELD HEAT TREATMENT (QW-407) Temperature ___NA_______ Time ___NA_______ Other ___NA_______

FILLER METALS (QW-404) SFA Specification AWS Classification Filler Metal F-No

GAS (QW-408)

5.9 ER 308-L 6

Percent Composition Shielding (Mixtures) Flow Rate Shielding Argon 99.99% Pure 12-15Ltr./min Trailing ---Backing Argon 99.99% Pure 12-15Ltr./min

ELECTRICAL CHARACTERISTICS (QW-409) Current __________DC_____________ Polarity STRAIGHT (DCEN) Amps. 85-90 Amp. Volts 12 (Refer Annexure) Tungsten Electrode Size ________2.4mm ___________ Other NA____ TECHNIQUE (QW-410) Travel Speed 48.8 to 66.7 mm /min (Refer Annexure) String or Weave Bead _Root(stringer) ,Final(weave) Oscillation final pass weaving not exceeding 2.5 times dia of filler wire. Multipass or Single Pass (Per Side) ___Multipass____ Single or Multiple Electrodes _________Single ______ Other -------------------------------------

Weld Metal Analysis A-No Size of Filler Metal Other

8 1.6mm & 2mm

Weld Metal Thickness 6mm POSITION (QW-405) Position of Groove __________1G___________ Weld Progression (Uphill, Downhill) N.A. Others __________________N.A.___________ PREHEAT (QW-406) Preheat Temperature (Minimum) __N.A _ InterpassTemperature (Maximum) 1250 C Other ________________N.A._______________

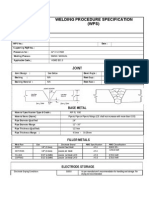

2007 SECTION IX QW -483

PQR No. DCMS/WPS/099 Dt. 8/5/2012 Rev - 0 Page 2 of 3 Type of Failure and Location weld metal weld metal

PQR

Tensile Test (QW 150) Specimen No. T-1 T-2 Width mm 19 18.80 Thickness mm 5.90 5.94 Area mm2 112.10 99.75 Ultimate Total Load N 70400 62400 Ultimate Unit Stress N/mm2 628.01 625.56

Guided Bend Tests (QW-160) Mandrel dia 24 mm (4t)

Type and Figure No. Root Bend RB -1 Root Bend RB -2 Face Bend FB -1 Face Bend FB -2 Result Satisfactory Satisfactory Satisfactory Satisfactory

Toughness Tests (QW-170)

Specimen No. Notch Location Specimen Size Test Temperature ft.lb Impact Values % Shear Mills Drop Weight Break (Y/N)

NA

Comments ________________________________________NA__________________________________

Fillet Weld Test (QW-180)

Result Satisfactory Yes _________No. _________ Penetration into Parent Metal Yes ______ No. ___ Macro Results_________________ NA ___________________________________________________ Other Tests Type of Test ___________________________________________________________________________ Deposit Analysis _________ _______________ NA __________________________________________ Other _________________________________________________________________________________ Welders Name N. MADHAVAN Stamp/ID: NMV

Test Conducted by Geo Chem Lab(P)Ltd. Laboratory Test No. M LD /12/04/2012 dt.4.5.2012

We Certify that the statement in this record are correct and that the test welds were prepared, welded, and tested in accordance with the requirements of Section IX of the ASME BOILER AND PRESSURE VESSEL CODE. Manufacture By DCMS Engg. Co. Date:7.05.2012

Details of record of tests are illustrative only and may be modified to confirm to the type and number of tests required by the Code.

Page 3 of 3 Annexure to PQR No. DCMS/PQR/099 Date: 7/5/2012 Rev: 0 Name of Welder: N. MADHAVAN Stamp/ID: NMV Process: GTAW

Numbers of Runs / Weld Passes

Electrode Th 2% (Tungsten) Filler Wire

Gas Shielding ltrs / min

Backing Gas Ltrs./min Volts

Current Amp

Speed mm/min

1 (Root) 2nd pass

st

2.4 mm

1.6 mm dia ER 308-L

14

12

11

72

48.8

2.4mm

1.6 mm dia ER 308-L

14

12

12

87

66.7

3 pass

rd

2.4mm

1.6 mm dia ER 308-L

14

12

12

87

53.04

4th pass

2.4mm

1.6 mm dia ER 308-L

14

12

12

87

49.4

Prepared By

Reviewed By

Accepted By

Abhishek Nag (QC Engineer)

P.V.Khambatkone (Ex-NPCIL QA)

Client

QW-484 MANUFACTURERS RECORD OF WELDER OR WELDING OPERATOR PERFORMANCE QUALIFICATION TESTS (SEE QW-301, SECTION XI, ASME BOILER AND PRESSURE VESSEL CODE)

WELDER NAME PURAN SINGH Welding process(es) used GTAW

Base material(s) welded SA-240 Gr 304L Thickness

Stamp/ID: PN

6mm Thick Plate Actual Values Without Range Qualified with or without

Identification of WPS followed by welder during welder during welding of test coupon : DCMS/WPS/099Rev-0 dt.15.09.11

Manual for Each Process (QW-350) Backing (Metal, weld metal, welded from both sides, flux etc.) (QW-402) ASME P.No. 8 to ASME P.No. 8 (QW-403) ( ) Plate (X ) Pipe (enter diameter, if pipe) Filler metal specification (SFA) : 5.9 and 5.1 Classification (QW-404) Filler metal F No. Filler Metal variety for GTAW, PAW (QW 404) Consumable insert for GTAW or PAW Weld deposit thickness for each welding process Welding position (1G,5G, etc) (QW-405) Progression (uphill/downhill) Backing gas for GTAW, PAW or GMAW : Fuel gas for QFW (QW-408) GMAW transfer mode (QW-409) GTAW welding current type / polarity Machine Welding Variables for the Process Used (QW-360) Direct / remote visual control Automatic voltage control (GTAW) Automatic joint tracking Welding position (1G, 5G, etc) Consumable insert Backing (metal, weld metal, welded from both sides, flux etc.)

6 mm thk plate ER-308L A No.8 6 NA NA 1.6mm GTAW 1G N.A. Argon Gas 99.995% N.A. DCEN (GTAW) Actual Values

1.6 to 12mm Plate ER-308L A.No.8 6 N.A. N.A. 1.6 mm (GTAW)

1G & all fillet welds

N.A. Argon Gas 99.995% N.A. DCEN (GTAW) Range Qualified

NA

GUIDED BEND TEST RESULTS Guided Bend Tests Type ( ) QW- 462.2 (Side) Results ( ) QW 462.3 (a) (Trans. R & F) Type ( ) QW-462.3 (b) (Long, R & F) Results FB-1 Satisfactory RB-1 Satisfactory FB-2 Satisfactory RB-2 Satisfactory

Visual examination results (QW-302.4): Satisfactory Radiographic test results (QW-304 and QW-305): Satisfactory (For alternative qualification of groove welds by radiography) Fillet Weld Fracture test N.A. Length and percent of defects NA Macro test fusion NA Fillet leg size NA in X inch Concavity / convexity NA in. Welding test conduced by DCMS Engineering Co. Ltd. Radiographic tests conducted by M/s. Geo chem Lab, Mumbai. Laboratory Test No. MLD/11/08/06896 DT.17.9.2011 We certify that the statements in this record are correct and that the test coupons were prepared welded and tested in accordance with the requirements of Section IX of the ASME Code DCMS Engineering Co. Date __________ Date CLIENT _________________

You might also like

- WPS TITLEDocument2 pagesWPS TITLERichard Periyanayagam86% (14)

- WPS PQR A36.20Document5 pagesWPS PQR A36.20gchaves504100% (2)

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- WPSDocument3 pagesWPSKhurram Burjees100% (1)

- Val Caraig WPQTDocument1 pageVal Caraig WPQTMark Jason M. BrualNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- Welding Procedure SpecificationsDocument2 pagesWelding Procedure SpecificationsGerhard Kemp0% (1)

- Sample WPS SMAW Stainless SteelDocument7 pagesSample WPS SMAW Stainless Steeldaemsal100% (4)

- Welding Procedure Specification Pipe - 6GDocument3 pagesWelding Procedure Specification Pipe - 6Gdndudc96% (26)

- WPS & PQRDocument46 pagesWPS & PQRJohn Candidate CIns88% (8)

- WPS PQR-09Document11 pagesWPS PQR-09Ranjan KumarNo ratings yet

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Document2 pagesWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniNo ratings yet

- PQR Gmaw3gDocument4 pagesPQR Gmaw3gdevendrasingh2021100% (3)

- WPS Format For AWS D1.1 - PQR - SMAWDocument3 pagesWPS Format For AWS D1.1 - PQR - SMAWThe Welding Inspections Community100% (3)

- Wps Repair WorDocument1 pageWps Repair WorMajdi JerbiNo ratings yet

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- PQR - 152Document3 pagesPQR - 152MAT-LIONNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- Welding Procedure Specification (WPS) : According To Api 1104Document1 pageWelding Procedure Specification (WPS) : According To Api 1104Maged Lotfy Abdel-aal100% (1)

- Wps For Ss 304Document3 pagesWps For Ss 304Sajit PillaiNo ratings yet

- WPS PQR WPQ PeiplDocument16 pagesWPS PQR WPQ PeiplKrishnamurthy Panchapakesan100% (4)

- WPS-PQR (Er309l Mo)Document4 pagesWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- WPS 6G CS Pipe CorrectDocument4 pagesWPS 6G CS Pipe CorrectAla ReguiiNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Welding Procedure Specification For 24'' PipeDocument2 pagesWelding Procedure Specification For 24'' Pipeenels77100% (2)

- Visual Inspection Report FormDocument8 pagesVisual Inspection Report FormfriyantoNo ratings yet

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- PQRDocument2 pagesPQRalokbdasNo ratings yet

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- WPS For Smaw06-001 (Pipe 6G CS)Document10 pagesWPS For Smaw06-001 (Pipe 6G CS)walitedison100% (1)

- Joint Detail (Qw-402)Document2 pagesJoint Detail (Qw-402)Nitesh Patel100% (3)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- Sample Wps-Carbon Steel GTAW+SMAWDocument2 pagesSample Wps-Carbon Steel GTAW+SMAWchetan85100% (7)

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- Welding Procedure Specification "WPS": O O O ODocument1 pageWelding Procedure Specification "WPS": O O O OAli MoosaviNo ratings yet

- WPSDocument1 pageWPSNidhinkorothNo ratings yet

- Wps For Steel RodsDocument5 pagesWps For Steel RodsHamid MansouriNo ratings yet

- P91 Profile WpsDocument6 pagesP91 Profile WpsZead Ali Adal100% (2)

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- Welding Procedure Specification For 24'' PipeDocument2 pagesWelding Procedure Specification For 24'' Pipeenels77100% (1)

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- Sample API 1104 WpsDocument3 pagesSample API 1104 WpsMuhammadShabbir0% (1)

- WPS PQRDocument23 pagesWPS PQRHashim Khan88% (8)

- Dokumen - Tips Wqt-FormatDocument2 pagesDokumen - Tips Wqt-FormatMr Pie100% (1)

- All Position Stainless Steel Welding ProcedureDocument6 pagesAll Position Stainless Steel Welding ProcedureJaime PatrónNo ratings yet

- Everything You Need to Know About Stainless Steel Welding Procedure SpecificationDocument6 pagesEverything You Need to Know About Stainless Steel Welding Procedure SpecificationDanem HalasNo ratings yet

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- WPS GTAW pipe welding procedureDocument2 pagesWPS GTAW pipe welding procedureRichard PeriyanayagamNo ratings yet

- Welding Procedure Specification-1Document8 pagesWelding Procedure Specification-1Suresh Rathod100% (1)

- WPSDocument2 pagesWPSJuli Agus50% (2)

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- WELDING PROCEDURE AND QUALIFICATION RECORDSDocument4 pagesWELDING PROCEDURE AND QUALIFICATION RECORDSETSNo ratings yet

- Loading Unloading Temperature Welding ProgressionDocument5 pagesLoading Unloading Temperature Welding ProgressionRajesh Owaiyar71% (7)

- WPSDocument6 pagesWPSNur Wijianto100% (1)

- Automatic, Manual, Machine, or Semi-Auto.Document10 pagesAutomatic, Manual, Machine, or Semi-Auto.ChE_MattNo ratings yet

- PWPS For Piping-API 1104Document6 pagesPWPS For Piping-API 1104Nguyen Tien Luong100% (1)

- Flange Weight ChartDocument1 pageFlange Weight Chartabhishek198327No ratings yet

- Welding Rod Selection 1 PDFDocument1 pageWelding Rod Selection 1 PDFabhishek198327100% (2)

- CR Equivalent Ni Equivalent Ferrite Number 20.57 Md30 Temperature Acc. To NoharaDocument2 pagesCR Equivalent Ni Equivalent Ferrite Number 20.57 Md30 Temperature Acc. To Noharaabhishek198327No ratings yet

- Article - Stress Relieving Heat Treatments For Austenitic Stainless SteelsDocument2 pagesArticle - Stress Relieving Heat Treatments For Austenitic Stainless Steelsabhishek198327No ratings yet

- Hem PlasticsDocument3 pagesHem Plasticsabhishek198327No ratings yet

- What Every Engineer Should Know About Welding ProceduresDocument13 pagesWhat Every Engineer Should Know About Welding Proceduresarash59_4uNo ratings yet

- Standard Carbon & Stainless Steel Flange DimensionsDocument4 pagesStandard Carbon & Stainless Steel Flange Dimensionsl kishore100% (2)

- SQ - HD Plug For HeaderDocument1 pageSQ - HD Plug For Headerabhishek198327No ratings yet

- Packed Bed Column MS DWG ModelDocument1 pagePacked Bed Column MS DWG Modelabhishek198327No ratings yet

- Air TankDocument1 pageAir Tankabhishek198327No ratings yet

- Specialist in Carbon, Stainless, Alloy Steel & FittingsLb0.3 0.70.4 0.90.5 1.10.7 1.50.9 21.2 2.61.5 3.32 4.4Lb0.20.30.40.50.70.91.21.40.40.70.91.11.522.63.1Document1 pageSpecialist in Carbon, Stainless, Alloy Steel & FittingsLb0.3 0.70.4 0.90.5 1.10.7 1.50.9 21.2 2.61.5 3.32 4.4Lb0.20.30.40.50.70.91.21.40.40.70.91.11.522.63.1Carlos Abril FlorezNo ratings yet

- Specialist in Carbon, Stainless, Alloy Steel & FittingsLb0.3 0.70.4 0.90.5 1.10.7 1.50.9 21.2 2.61.5 3.32 4.4Lb0.20.30.40.50.70.91.21.40.40.70.91.11.522.63.1Document1 pageSpecialist in Carbon, Stainless, Alloy Steel & FittingsLb0.3 0.70.4 0.90.5 1.10.7 1.50.9 21.2 2.61.5 3.32 4.4Lb0.20.30.40.50.70.91.21.40.40.70.91.11.522.63.1Carlos Abril FlorezNo ratings yet

- ModulesDocument5 pagesModulesabhishek198327No ratings yet

- Welcome To Our WebsiteDocument5 pagesWelcome To Our Websiteabhishek198327No ratings yet

- Dish Drg. - 2.9.2014Document1 pageDish Drg. - 2.9.2014abhishek198327No ratings yet

- Nozzle THKDocument6 pagesNozzle THKabhishek198327No ratings yet

- DCMS Engineering CompanyDocument1 pageDCMS Engineering Companyabhishek198327No ratings yet

- ASTM Flange DimensionsDocument2 pagesASTM Flange DimensionsjacquesmayolNo ratings yet

- Grain SizeDocument2 pagesGrain Sizeprabhjot singh1No ratings yet

- App - Copy WPSDocument2 pagesApp - Copy WPSabhishek198327No ratings yet

- Basics of Stress RelievingDocument5 pagesBasics of Stress Relievingabhishek198327No ratings yet

- Kjlced09 Sec01 Pages129-145 Bellowstubing&WeldfittingsDocument17 pagesKjlced09 Sec01 Pages129-145 Bellowstubing&Weldfittingsabhishek198327No ratings yet

- 06 - Weld Ability and Defects in WeldmentsDocument50 pages06 - Weld Ability and Defects in Weldmentsamitjee138463No ratings yet

- Jyoti Architectural Products PVT LTDDocument1 pageJyoti Architectural Products PVT LTDabhishek198327No ratings yet

- Helium Leak Testing FundamentalsDocument2 pagesHelium Leak Testing Fundamentalsabhishek198327100% (1)

- Heat Treatment of Welded JointsDocument4 pagesHeat Treatment of Welded Jointsabhishek198327No ratings yet

- Crude Oil Storage Tanks-BasicsDocument176 pagesCrude Oil Storage Tanks-BasicsPandipperumal Sankaralingam100% (44)

- Expansion JointsDocument15 pagesExpansion Jointsaop10468No ratings yet

- Helium TestingDocument1 pageHelium Testingabhishek198327No ratings yet

- Stress Concentration Factors and Design GuidelinesDocument4 pagesStress Concentration Factors and Design Guidelinesabhishek198327No ratings yet

- Changes in ISO 5817Document15 pagesChanges in ISO 5817Binoj Nair67% (3)

- c5 Lathe 120203152613 Phpapp02Document30 pagesc5 Lathe 120203152613 Phpapp02Preavin Kutty Thamotharan100% (1)

- FDM 3D Printing Technology OverviewDocument20 pagesFDM 3D Printing Technology Overviewrahmat iwan100% (1)

- Properties and Application of High Strength Concrete: Prof. Dr. Md. Abdus SalamDocument31 pagesProperties and Application of High Strength Concrete: Prof. Dr. Md. Abdus SalamMd.Ahasan Ullah NoyonNo ratings yet

- ProGradu JennyHollander 21061Document124 pagesProGradu JennyHollander 21061ahmed titoNo ratings yet

- Astm A479Document8 pagesAstm A479Orlando Rojas100% (3)

- Press Felt Cleaning in A Paper Machine - Paper Machine Clothing & Filter BeltsDocument11 pagesPress Felt Cleaning in A Paper Machine - Paper Machine Clothing & Filter BeltsvenkNo ratings yet

- SC832 Reference Card 203-104-063Document2 pagesSC832 Reference Card 203-104-063Sitec Industrial AutomationNo ratings yet

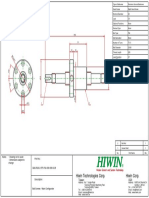

- Precision Ground 20mm Ballscrew with 2.5mm LeadDocument1 pagePrecision Ground 20mm Ballscrew with 2.5mm LeadRadovan KnezevicNo ratings yet

- NL - NL FactSheet - Main 01Document1 pageNL - NL FactSheet - Main 01ronaldb322No ratings yet

- Draft Executive Summary of Beekay SteelsDocument6 pagesDraft Executive Summary of Beekay SteelsSuryakanta PradhanNo ratings yet

- Project Report On Fabrication of Scaffolding MaterialsDocument7 pagesProject Report On Fabrication of Scaffolding MaterialsEIRI Board of Consultants and Publishers100% (1)

- DS 164 02 ZincAnode304 MZSDocument2 pagesDS 164 02 ZincAnode304 MZSPower PowerNo ratings yet

- Membrana - 10KDO AMIDocument1 pageMembrana - 10KDO AMIAlejandro Ibañez CortésNo ratings yet

- Astm A105Document5 pagesAstm A105mahamad AziNo ratings yet

- Salient Features of LHB CoachesDocument3 pagesSalient Features of LHB CoachesVijay AnandNo ratings yet

- ASME B31.3-2016 Postweld Heat Treatment TableDocument1 pageASME B31.3-2016 Postweld Heat Treatment TableSumner TingNo ratings yet

- Form 1 AWS D1.1Document2 pagesForm 1 AWS D1.1Bui Chi TamNo ratings yet

- JUNE 2022 Surplus Record Machinery & Equipment DirectoryDocument718 pagesJUNE 2022 Surplus Record Machinery & Equipment DirectorySurplus Record100% (1)

- Is 277Document10 pagesIs 277Santosh Chaudhari67% (3)

- Non Traditional Machining MCQDocument3 pagesNon Traditional Machining MCQRohit Ghulanavar79% (14)

- FITTING SHOP AssignmentDocument24 pagesFITTING SHOP AssignmentAli Raza100% (3)

- Avesta 3D ElectrodesDocument2 pagesAvesta 3D ElectrodesOndrej PelešNo ratings yet

- Welding PresentationDocument18 pagesWelding PresentationFasil ParuvanathNo ratings yet

- Touchwood AC Colour: Architectural CoatingsDocument2 pagesTouchwood AC Colour: Architectural CoatingsmuthukumarNo ratings yet

- Astm Sa 234 PDFDocument11 pagesAstm Sa 234 PDFarifin rizalNo ratings yet

- IkssssDocument6 pagesIkssssVikas GowdaNo ratings yet

- Product Data Sheet: Bisalloy Protection 400 SteelDocument1 pageProduct Data Sheet: Bisalloy Protection 400 SteelAli TalebiNo ratings yet

- Chromium PlatingDocument22 pagesChromium PlatingKodeboyina ChandramohanNo ratings yet

- RollingDocument9 pagesRollingFiq IskandarNo ratings yet