Professional Documents

Culture Documents

Synthesis of Aspirin and Oil of Wintergreen

Uploaded by

Jason Raquin RoqueOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Synthesis of Aspirin and Oil of Wintergreen

Uploaded by

Jason Raquin RoqueCopyright:

Available Formats

Digitally signed by Jason Raquin Roque DN: cn=Jason Raquin Roque, o, ou, email=jason_mike15@yahoo.com, c=PH Date: 2012.05.

15 14:24:03 +08'00'

Synthesis of Aspirin and Oil of Wintergreen

Roque, Jason R. Frias, Abigail Pauline F. De Ramos, Jason Jalou Bachelor of Science in Biology Major in Human Biology College of Science De La Salle University Dasmarias Dasmarias, Cavite, Philippines

ABSTRACT

The foremost objective of this experiment was to formulate an aspirin. This is the combination of the salicylic acid and acetic anhydride thus forming the Aspirin also known as the Acetylsalicyclic Acid. With about 1.104 g of salicyclic acid was mixed comprehensively with 3 drops of 85% Phosphoric Acid and 2.4 mL acetic anhydride. It was placed in a water bath with a constant temperature of 90C for 5 minutes. Then a 1.0 mL of water was added to the mixed reagent and then placed in a room temperature condition to facilitate the Aspirin crystallization. After 10 minutes, the mixed reagents have been filtered using a vacuum filtration for it to separate the impurities in the Aspirin. Then the Actual yield was determined with the use of Analytical balance a modern technology used in measuring mass with precision. Through the use of the Analytical results and the theoretical results the percent yield of the synthesize Aspirin was obtained. Melting point was also determined in order to make sure that the percentage yield is accurate. Aspirins o percentage was 9.64%. On contrary, the melting point of the aspirin is 130 C. Based on the gathered results the formation of the Aspirin have gave an accurate outcome base on the true value of the Melting point of the Aspirin which is between 132C-137C. It can be hypothesize that the Aspirin made is a successful one.

INTRODUCTION

Aspirin (also known as acetylsalicylic acid) is in a group of drugs called salicylates. It works by reducing substances in the body that cause pain, fever, and inflammation. It is also known to treat mild to moderate pain, and also to reduce fever or inflammation. It is sometimes used to treat or prevent heart attacks, strokes, and angina. On the other hand, the oil of wintergreen or methylsalicylate also came from the same active ingredient, salicylic acid. Commercially, it is used as a flavoring for candies and chewing gum and in the treatment of muscular aches and pains. When synthesized and sold as the oil of wintergreen itself, it can be sold as beverage. The two compounds indicated are both organic esters. An ester is a compound that is formed when an acid (containing the COOH group) reacts with an alcohol (a compound containing an -OH group). In this experiment the experimenters will prepare two esters of o-hydroxybenzoic acid, more commonly known as salicylic acid. One of the esters, acetylsalicylic acid, is aspirin, the common analgesic. They will synthesize aspirin by mixing salicylic acid with acetic anhydride. The second ester product is oil of wintergreen, or methylsalicylate, which we prepare by allowing salicylic acid to react with

methyl alcohol. This compound, which has a familiar odor, is used as a flavoring agent and in rubbing ointments.

HO

O OH H3C O CH3

HO

O O O CH3

H+

+

O O

H3C

OH

Figure 1. Salicylic acid and acetic anhydride reacts to form acetylsalicylic acid and acetic acid

HO

O H3C OH

O H OH O H

H+

H3C

OH

Figure 2. Salicylic acid and methanol reacts to form methylsalicylate.

This experiment illustrates several properties of organic synthesis. While both product compounds in the experiment are esters of the same compound (salicylic acid), they are quite different in structure. Aspirin involves a reaction of the -OH group of salicylic acid, while methyl salicylate involves a reaction of the -COOH group of salicylic acid.

MATERIALS / REAGENTS & EXPERIMENTAL PROCEDURE

On making aspirin, he experimenters prepared a water bath that is heated in a temperature between 70-90 degrees Celsius. While heating, they prepared a salicylic acid with weigh approximately 0.150g. In a dry clean test tube, they mixed the acid with 85% H2SO4 solution and 0.3 mL acetic anhydride. They heated the reaction mixture in a water bath until the salicylic acid is dissolved and colorless. They added ice to the mixture for recrystallization. The aspirin is collected by filtering in the Buchner funnel and through washing with cold water. The aspirin was then dried overnight and weighed again for data collecting. On making methylsalicylate or oil of wintergreen, the experimenters prepared a salicylic acid with weigh approximately 0.25g. In a dry clean test tube, 2.0 mL methanol was added and mixed until the salicylic acid is dissolved. They carefully added 10 drops of concentrated H2SO4 and placed the mixture in a water bath (heated) for 15 minutes and cooled the mixture in running water afterwards. The odor of the product is then observed. On performing the FeCl3 test, the collected products were now separated in each test tube. The aspirin was dissolved first with 5 mL of distilled water. Each test tube was added with 1 drop of 1% FeCl3 and their reactions was now observed.

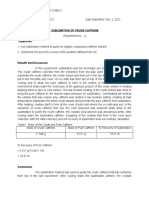

DATA & RESULTS The table below shows the percentage of aspirin which is 9.64%, it shows that the experiment was then successful in producing almost the same amount of the sample needed.

Table 1. Percentage Yield of the Aspirin Yield of Aspirin Mass of Salicylic Acid 0.1516 g Mass of Acetyl Salicylic Acid 1.6400 g % Yield 9.64%

In this reaction, acetic anhydride and salicylic acid is reacted under high temperatures. However, simply increasing the reaction temperature isnt enough. A catalyst is also needed as salicylic acid is stabilized by its benzene ring, with lone pairs from the carbonyl group and the hydroxyl group delocalizing with the electrons of the aromatic ring. In this case, we utilized sulfuric acid (H2SO4) as the reaction catalyst. While the reaction proceeded, the color of the reaction mixture changed from white to colorless. This was due to the increased heat, which increased solubility and allowed the white salicylic acid crystals to dissolve, forming a colorless mixture. Also, acetylsalicylic acid is much more soluble in water than salicylic acid, though both exist as white crystals. Thus, the disappearance of the color white in the reaction also meant that more soluble acetylsalicylic acid crystals which could dissolve were being formed, and that relatively insoluble salicylic acid crystals which couldnt dissolve were being used up. Only when there action started to cool down did white crystals of acetylsalicylic acid form, as solubility gradually dropped with the reduction in temperature. After the formation of crystals, 0.2 mL of cold deionized water was added. This was to get rid of the acetic acid by-product, either by dissociation and filtration, or by decomposition. The presence of acetic acid in the product would reduce purity and erroneously increase our yield. Furthermore, acetic acid can theoretically react with our product, leading to the production of more unwanted by-products. The water added to get rid of the acetic acid and to wash the crystals must be cold as acetylsalicylic acid is soluble in water. The reduced temperature would help to lower the solubility of our product in water, and therefore lower the amount of product lost via dissociation and filtration. Also, water can decompose our product back to salicylic acid and acetic acid via autocatalytic degradation. Using cold water instead of warm or hot water would greatly reduce such a possibility. After obtaining the white crystals of product, they were then recrystallized with a mixed solvent system of ethanol and water. In this case, a mixture of 2 solvents (solvent-pair) is much more satisfactory than a single solvent. This is because ethanol does not readily dissolve our product, unlike water. If only ethanol is used in recrystallization, very large amounts of ethanol would be needed in order to completely dissolve the crystals. On the other hand, if only water is used in recrystallization, the crystals can be completely

dissolved in a very small amount of solvent, making recrystallization difficult as the product will still being solution even after much boiling and solvent evaporation. Thus, in order to get the best of both worlds, a mixed solvent system should be used. After recrystallization, filtration and drying, our product yield was a mere 9.64%. However, after referring to several similar experiments carried out by others, I come to the conclusion that this is a rather low-yield reaction, and a yield that is larger than 60% is rather reasonable. Yields of up to 90% will rarely, if ever, be reached. The derived melting point range for our product is between 124.5C to 126.8C. This is very far from the theoretical melting point of 135.0C. However, like the reaction yield, similar replicates of this experiment done by others have results that differ greatly from theoretical values. Reported melting point temperatures for acetylsalicylic acid in scientific literature vary from 125C to137C. Our melting point range is close to the reported melting point ranges of other researchers. However, it is far from the actual melting point. Thus, we can deduce that although it is the most commonly used reaction to synthesize acetylsalicylic acid, it does have its disadvantages, such as low yield and purity. The low yield and purity that we obtained in this experiment are not only attributed to the experimental procedure and mechanism, but also to other experimental flaws. The low yields could be due to several factors, such as disturbance during crystallization, incomplete reaction and overheating. After all, crystal formation is highly dependent on critical temperature and the level of disturbance the saturated solution is subjected to. Similar to previous experiments, the usage of filter paper containing paper pulp reduced experimental yields as some product was left behind in the Buchner funnel and on the filter paper after suction filtration. Some were also stuck amongst the fibers of the filter paper that we utilized. During the synthesis and recrystallization of acetylsalicylic acid, it is preferable to maintain the temperature at a fixed 90C. This is because studies carried out have determined that this is the critical temperature for acetylsalicylic acid crystal formation. At this temperature, the formation of acetylsalicylic acid crystals is at its optimum. Maintaining a certain temperature is almost impossible when dealing with an oil bath on a hot plate. Thus, more advanced heating technology could be utilized, such as heating mantles and heat controllers. Even the common water bath can be used. Unlike the hot plate, the temperature of a water bath is not prone to fluctuations, and a water bath provides us with the exact temperature of the water it contains, unlike a hotplate. Also, with current experimental procedures it is difficult to determine whether the reaction has reached full completion. A trace amount of salicylic acid and acetic anhydride might still be present in the reaction mixture. There is a method to detect for the presence of phenols such as salicylic acid, the only phenol in this reaction. Iron (III) chloride (FeCl3) reacts with phenols to form brightly colored complexes that range from violet to red. Thus, it provides us with an easy method to test for the presence of unreacted salicylic acid. After the reaction is refluxed, 3 test tubes are labeled 1 through 3. 5 mL of distilled water is placed in each tube. A few milligrams of pure salicylic acid are then added to tube 1. Next, a few milligrams of pure acetylsalicylic acid is added to tube 2. A few milligrams of commercial aspirin were added to the last test tube. All tubes are shaken to dissolve the crystals within, and 1 drop of 1% FeCl3 is added to each of the 3 tubes. If the reaction is complete, we would expect tube 1s contents to react and change color, while the other 2 tubes remain unreacted.

REFERENCE (1) Legaspi, G. A. & Sta. Ana, S.T. 2010. Essentials of Organic Chemistry Laboratory (2) Retrieved at March 14, 2011 from http://www.britannica.com/EBchecked/topic/426191/oil-ofwintergreen (3) Retrieved on March 14, 2011 from http://science.csustan.edu/nhuy/chem1002/aspirin.htm (4) Retrieved on March 15, 2011 from http://www.reachoutmichigan.org/funexperiments/quick/csustan/aspirin.htm (5) Retrieved on March 15, 2011 from http://www.aspirin-foundation.com/cardio2.htm

You might also like

- Plant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterFrom EverandPlant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterNo ratings yet

- Full Report: Synthesis of AspirinDocument3 pagesFull Report: Synthesis of AspirinNor Ashikin IsmailNo ratings yet

- Synthesis of AspirinDocument6 pagesSynthesis of AspirinVanessaOlgaJ.Dagondon100% (1)

- Synthesis of Aspirin From Salicylic Acid and Acetic AnhydrideDocument6 pagesSynthesis of Aspirin From Salicylic Acid and Acetic AnhydrideChristine71% (7)

- Synthesize Aspirin from Salicylic AcidDocument23 pagesSynthesize Aspirin from Salicylic AcidCyrene MBolañosNo ratings yet

- Formal Report Synthesis of AspirinDocument4 pagesFormal Report Synthesis of AspirinEdrick Ramoran0% (1)

- Carboxylic Acids: Properties, Derivatives & ExperimentsDocument7 pagesCarboxylic Acids: Properties, Derivatives & ExperimentsSteffi Grace NotaNo ratings yet

- Aspirin SythesisDocument4 pagesAspirin Sythesiskramnuj92% (12)

- Synthesis of AspirinDocument4 pagesSynthesis of Aspirinホアキン 印33% (3)

- Laboratory Report CHM 153 (Inorganic Chemistry)Document9 pagesLaboratory Report CHM 153 (Inorganic Chemistry)Muhd Mirza Hizami100% (1)

- Sodium Borohydride Reduction of CyclohexanoneDocument6 pagesSodium Borohydride Reduction of CyclohexanoneMohd Nakirudin Muhamad Nor100% (5)

- Determination of The Concentration of Acetic Acid in VinegarDocument24 pagesDetermination of The Concentration of Acetic Acid in VinegarNadia Kama69% (13)

- Synthesis of Aspirin (2EMT - Group 1, 2009)Document8 pagesSynthesis of Aspirin (2EMT - Group 1, 2009)Mary Christelle90% (10)

- Che21l - Experiment 2 - Complete Lab ReportDocument4 pagesChe21l - Experiment 2 - Complete Lab ReportMishel P. FerolinoNo ratings yet

- Synthesis of AcetanilideDocument4 pagesSynthesis of AcetanilideMich Tolentino50% (2)

- Formal Report, Carboxylic Acid and DerivativesDocument4 pagesFormal Report, Carboxylic Acid and DerivativesVicente Romeo M Macatangay88% (8)

- Gravimetric Determination of Moisture and Phosphorus in Fertilizer SampleDocument6 pagesGravimetric Determination of Moisture and Phosphorus in Fertilizer SampleGelo Buligan100% (3)

- The Synthesis of AspirinDocument4 pagesThe Synthesis of AspirinMarieya Elizabeth ZantuaNo ratings yet

- Determination of Aspirin by Indirect TitrationDocument3 pagesDetermination of Aspirin by Indirect TitrationRica Marquez100% (2)

- Experiment No. 8 HydrocarbonsDocument7 pagesExperiment No. 8 HydrocarbonsMa Jessa DuntingNo ratings yet

- CE - Experiment 2 Extraction With Acid and AlkalineDocument8 pagesCE - Experiment 2 Extraction With Acid and AlkalineWeiChingNo ratings yet

- Synthesis of Methyl SalicylateDocument3 pagesSynthesis of Methyl SalicylateMartin Hernandez55% (11)

- Expt 2 BIOCHEMLABDocument5 pagesExpt 2 BIOCHEMLABEloisah Vin Santiago Ragodon100% (1)

- Synthesis of Aspirin Lab ReportDocument12 pagesSynthesis of Aspirin Lab ReportJasmeetSingh63% (8)

- Aldol Condensation Reaction Lab ReportDocument4 pagesAldol Condensation Reaction Lab ReportAvril Watson100% (3)

- Chematq 2Document5 pagesChematq 2Anonymous GO6JVW9Wud100% (5)

- Experiment 3 Lab ReportDocument10 pagesExperiment 3 Lab ReportVanessa Denise AguilarNo ratings yet

- Sublimation of Crude CaffeineDocument2 pagesSublimation of Crude CaffeineFlora Mae67% (3)

- Determination of Iron With 1,10-PhenanthrolineDocument5 pagesDetermination of Iron With 1,10-PhenanthrolineOmSilence26510% (1)

- Barfoed's Test: Specific Test For CarbohydratesDocument23 pagesBarfoed's Test: Specific Test For CarbohydratesZ ZernsNo ratings yet

- Experiment 4 Potentiometric Titration PDFDocument11 pagesExperiment 4 Potentiometric Titration PDFMohammad Izadi100% (2)

- Bials Orcinol Test Group 5 BMLS 2IDocument12 pagesBials Orcinol Test Group 5 BMLS 2ITom Anthony TonguiaNo ratings yet

- Iodine ValueDocument8 pagesIodine ValueJustyna HorodyskaNo ratings yet

- Experiment 12 (Synthesis of Acetylsalicylic Acid)Document8 pagesExperiment 12 (Synthesis of Acetylsalicylic Acid)Cheng Bauzon100% (1)

- Final Lab Report 2Document5 pagesFinal Lab Report 2api-340388320No ratings yet

- Adipic Acid SynthesisDocument3 pagesAdipic Acid SynthesisKaren Liceth BolañosNo ratings yet

- Experiment 9 Classification Tests For Hydroxyl - & Carbonyl-Containing CompoundsDocument8 pagesExperiment 9 Classification Tests For Hydroxyl - & Carbonyl-Containing CompoundsPatricia Isabel Tayag100% (7)

- Synthesis and Analysis of Aspirin via TLCDocument11 pagesSynthesis and Analysis of Aspirin via TLCRobbyNo ratings yet

- Aspirin TitrationDocument3 pagesAspirin TitrationBiancaTardecillaNo ratings yet

- Experiment 9 Formal Laboratory ReportDocument5 pagesExperiment 9 Formal Laboratory ReportNathaniel Argelio Dimaano100% (1)

- Determination of Acetic Acid in VinegarDocument15 pagesDetermination of Acetic Acid in VinegarSiti Syuhadah75% (4)

- Classification Tests For Carboxylic Acid and DerivativesDocument3 pagesClassification Tests For Carboxylic Acid and DerivativesJohn Emmanuel SyNo ratings yet

- Classification Tests For Carboxylic Acids and Their DerivativesDocument9 pagesClassification Tests For Carboxylic Acids and Their DerivativesAngelyka Cabalo100% (1)

- Preparation and Purification of An Alkyl HalideDocument8 pagesPreparation and Purification of An Alkyl HalideNoOneGotThisUsernameYetNo ratings yet

- Atq Experiment 8 Chem 26.1Document7 pagesAtq Experiment 8 Chem 26.1Rei Diaz Apalla100% (1)

- Pre Laboratory AssignmentDocument44 pagesPre Laboratory AssignmentJr Montero100% (3)

- Formal Report Chem 31.1Document6 pagesFormal Report Chem 31.1Elah PalaganasNo ratings yet

- Solubility of Organic CompoundsDocument4 pagesSolubility of Organic CompoundsJeremy Noceda100% (1)

- Synthesis of 1-Phenylazo-2-Naphthol SudaDocument4 pagesSynthesis of 1-Phenylazo-2-Naphthol SudaJohn ElegantNo ratings yet

- Chem 26.1 - Lab Report 7Document14 pagesChem 26.1 - Lab Report 7Gio Angelo Idos100% (1)

- CHM1024 Report 4: Reactions of AlcoholsDocument15 pagesCHM1024 Report 4: Reactions of AlcoholsAkmal Adib Fadzil83% (18)

- Chem. 14.1 - Expt. 9 Chem Lab Report - Chemical EquilibriumDocument3 pagesChem. 14.1 - Expt. 9 Chem Lab Report - Chemical EquilibriumRomi Necq S. Abuel40% (5)

- Synthesis of Salicylic AcidDocument2 pagesSynthesis of Salicylic AcidHarly Kabut100% (1)

- Identification of Alcohols and PhenolsDocument15 pagesIdentification of Alcohols and PhenolsSALIFU91% (22)

- Aspirin LabDocument3 pagesAspirin LabIbrahim AlghuzailiNo ratings yet

- Synthesis of Aspirin: 115% YieldDocument6 pagesSynthesis of Aspirin: 115% YieldStephanie ButedNo ratings yet

- Organic Chemistry - Synthesis of AspirinDocument5 pagesOrganic Chemistry - Synthesis of AspirinClarissa Macanas100% (1)

- Chemistry Lab Report 1Document10 pagesChemistry Lab Report 1karyensamNo ratings yet

- Preparation of An EsterDocument5 pagesPreparation of An EsterKojo Eghan100% (1)

- Synthesizing Aspirin: A Medicinal AgentDocument5 pagesSynthesizing Aspirin: A Medicinal Agentoussama dieselNo ratings yet

- Tracts For Contest EnglishDocument2 pagesTracts For Contest EnglishJason Raquin RoqueNo ratings yet

- History of BotanyDocument3 pagesHistory of BotanyJason Raquin RoqueNo ratings yet

- It's Not in VainDocument8 pagesIt's Not in VainJason Raquin Roque100% (8)

- I Could Not Do Without TheeDocument7 pagesI Could Not Do Without TheeJason Raquin Roque100% (6)

- Experimental Designs Research PaperDocument15 pagesExperimental Designs Research PaperJason Raquin RoqueNo ratings yet

- De La Salle University - Dasmariñas College of Science Human Biology 3-2Document3 pagesDe La Salle University - Dasmariñas College of Science Human Biology 3-2Jason Raquin RoqueNo ratings yet

- Tech Writing Proposal On The Installation of Light Emmitting Display Wall Posting in The Strategic Places at de La Sall University - Das MarinasDocument32 pagesTech Writing Proposal On The Installation of Light Emmitting Display Wall Posting in The Strategic Places at de La Sall University - Das MarinasJason Raquin RoqueNo ratings yet

- Titration of Amino Acids and PeptidesDocument10 pagesTitration of Amino Acids and PeptidesJason Raquin RoqueNo ratings yet

- The First Chief Justice Facing The Clamour of ImpeachmentDocument8 pagesThe First Chief Justice Facing The Clamour of ImpeachmentJason Raquin RoqueNo ratings yet

- Lipids Vitamins and SteroidsDocument3 pagesLipids Vitamins and SteroidsJason Raquin RoqueNo ratings yet

- Product Manual The Font PenDocument6 pagesProduct Manual The Font PenJason Raquin RoqueNo ratings yet

- Draft of The Revised Student Election Code of DLSU 3Document36 pagesDraft of The Revised Student Election Code of DLSU 3Jason Raquin RoqueNo ratings yet

- Reaction of LipidsDocument5 pagesReaction of LipidsJason Raquin Roque89% (9)

- Mission Without Limit BookletDocument10 pagesMission Without Limit BookletJason Raquin RoqueNo ratings yet

- Jason R. Roque - ResumeDocument7 pagesJason R. Roque - ResumeJason Raquin RoqueNo ratings yet

- Isolation and Characterization of Egg ProteinsDocument6 pagesIsolation and Characterization of Egg ProteinsJason Raquin Roque100% (4)

- CucurbitaceaeDocument1 pageCucurbitaceaeJason Raquin RoqueNo ratings yet

- Dna Sequencing and Human Genome ProjectDocument24 pagesDna Sequencing and Human Genome ProjectJason Raquin RoqueNo ratings yet

- Determination of The Acid Dissociation ConstantDocument3 pagesDetermination of The Acid Dissociation ConstantJason Raquin RoqueNo ratings yet

- Compilation of Technical Writing MaterialsDocument11 pagesCompilation of Technical Writing MaterialsJason Raquin RoqueNo ratings yet

- Genetic DisordersDocument12 pagesGenetic DisordersJason Raquin RoqueNo ratings yet

- Dna ReplicationDocument9 pagesDna ReplicationJason Raquin RoqueNo ratings yet

- Community Immersion OutputDocument5 pagesCommunity Immersion OutputJason Raquin Roque100% (2)

- CellDocument2 pagesCellJason Raquin Roque100% (1)

- Carbonyl Compounds Aldehyde and KetonesDocument7 pagesCarbonyl Compounds Aldehyde and KetonesJason Raquin Roque100% (1)

- Calculus Research PaperDocument6 pagesCalculus Research PaperJason Raquin RoqueNo ratings yet

- Brochure MethampethamineDocument2 pagesBrochure MethampethamineJason Raquin RoqueNo ratings yet

- Brochure CFCDocument2 pagesBrochure CFCJason Raquin RoqueNo ratings yet

- Brochure Lung CancerDocument2 pagesBrochure Lung CancerJason Raquin Roque50% (2)

- Problem set 1 covers energy, heat, gases, and thermodynamicsDocument15 pagesProblem set 1 covers energy, heat, gases, and thermodynamicsFikret BazNo ratings yet

- Advantages and Disadvantages of Social MediaDocument2 pagesAdvantages and Disadvantages of Social MediaCeleste GalvanNo ratings yet

- Properties of Skeletal MuscleDocument72 pagesProperties of Skeletal MuscleAakash GohilNo ratings yet

- Maths ReportDocument3 pagesMaths ReportShishir BogatiNo ratings yet

- Sick GM31Document54 pagesSick GM31Magdy SalehNo ratings yet

- Energy Conservation Opportunities Sugar Industry IDocument8 pagesEnergy Conservation Opportunities Sugar Industry INikhil MohiteNo ratings yet

- IEC 60793-1-30-2001 Fibre Proof TestDocument12 pagesIEC 60793-1-30-2001 Fibre Proof TestAlfian Firdaus DarmawanNo ratings yet

- Series Portable Oscilloscopes: Keysight DSO1000A/BDocument15 pagesSeries Portable Oscilloscopes: Keysight DSO1000A/BNestor CardenasNo ratings yet

- Dav Public School, Berhampur, Odisha Summer Holiday HomeworkDocument3 pagesDav Public School, Berhampur, Odisha Summer Holiday HomeworkOmNo ratings yet

- A Simple Method To Transfer The SelectedDocument2 pagesA Simple Method To Transfer The SelectedrekabiNo ratings yet

- A Study On Consumer Preference Towards Skincare With Special Reference To Himalaya Herbal Products in Nilambur at Malappuram District of KeralaDocument4 pagesA Study On Consumer Preference Towards Skincare With Special Reference To Himalaya Herbal Products in Nilambur at Malappuram District of Keralaarcherselevators50% (2)

- Sdo385 50hz Doosan GeneratorDocument4 pagesSdo385 50hz Doosan GeneratorsunshinemachineryNo ratings yet

- 9608/21/M/J/15 © Ucles 2015Document57 pages9608/21/M/J/15 © Ucles 2015Asilbek AshurovNo ratings yet

- Vehicle and Driver Vibration - PPTDocument16 pagesVehicle and Driver Vibration - PPTAnirban MitraNo ratings yet

- The Housekeeping Department: Learning Activity #1Document4 pagesThe Housekeeping Department: Learning Activity #1Limar Geoff G. RosalesNo ratings yet

- Chapter 2 - Cross-Cultural Management SkillsDocument26 pagesChapter 2 - Cross-Cultural Management Skillsfatematuj johoraNo ratings yet

- Win Top Prizes in Investizo's SuperTrader ContestDocument3 pagesWin Top Prizes in Investizo's SuperTrader ContestJafrid NassifNo ratings yet

- A.3s Scheme Used in Managing Epp ClassDocument35 pagesA.3s Scheme Used in Managing Epp Classpixie02100% (2)

- Bid ProcessDocument85 pagesBid ProcessRobiatol Adawiah Mohammad ShamsidiNo ratings yet

- Gradient of A Scalar Field and Its Geometrical InterpretationDocument3 pagesGradient of A Scalar Field and Its Geometrical InterpretationMichael100% (1)

- Philips 170v7fbDocument95 pagesPhilips 170v7fbaposticaaNo ratings yet

- PPST OrientationDocument66 pagesPPST OrientationRaymund Dagdag100% (1)

- AssignmentDocument15 pagesAssignmentWahab MirzaNo ratings yet

- Design of A Neural Network Function Block For Insertion Into The Function Block Library of A Programmable Logic ControllerDocument4 pagesDesign of A Neural Network Function Block For Insertion Into The Function Block Library of A Programmable Logic ControllerArmando Fermin PerezNo ratings yet

- Jda Connects The Dots at Its 209821Document5 pagesJda Connects The Dots at Its 209821Gerardo LujanNo ratings yet

- Stress Amongst Healthcare Professionals and Migrant Workers During Covid-19 PandemicDocument6 pagesStress Amongst Healthcare Professionals and Migrant Workers During Covid-19 PandemicIJAR JOURNALNo ratings yet

- AGITAN Defoamer Technologies PDFDocument15 pagesAGITAN Defoamer Technologies PDFMarco Lopez100% (1)

- Porter's Five Forces: Submitted by Subham Chakraborty PGDMDocument5 pagesPorter's Five Forces: Submitted by Subham Chakraborty PGDMSubham ChakrabortyNo ratings yet

- Original Prusa I3 MK2S To MK3 Upgrade Parts ListDocument2 pagesOriginal Prusa I3 MK2S To MK3 Upgrade Parts ListLuan AlvesNo ratings yet

- What Happens To Load at YieldingDocument14 pagesWhat Happens To Load at YieldingWaqas Anjum100% (2)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlFrom EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlRating: 4 out of 5 stars4/5 (4)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Guidelines for Siting and Layout of FacilitiesFrom EverandGuidelines for Siting and Layout of FacilitiesNo ratings yet

- Operational Excellence: Journey to Creating Sustainable ValueFrom EverandOperational Excellence: Journey to Creating Sustainable ValueNo ratings yet

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- Guidelines for Developing Quantitative Safety Risk CriteriaFrom EverandGuidelines for Developing Quantitative Safety Risk CriteriaNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Bow Ties in Risk Management: A Concept Book for Process SafetyFrom EverandBow Ties in Risk Management: A Concept Book for Process SafetyNo ratings yet

- Guidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisFrom EverandGuidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisNo ratings yet

- Perfume Engineering: Design, Performance and ClassificationFrom EverandPerfume Engineering: Design, Performance and ClassificationRating: 4 out of 5 stars4/5 (5)

- Fragrance Chemistry: The Science of the Sense of SmellFrom EverandFragrance Chemistry: The Science of the Sense of SmellRating: 3 out of 5 stars3/5 (2)

- Practical Process Control for Engineers and TechniciansFrom EverandPractical Process Control for Engineers and TechniciansRating: 5 out of 5 stars5/5 (3)

- Temperature-Responsive Polymers: Chemistry, Properties, and ApplicationsFrom EverandTemperature-Responsive Polymers: Chemistry, Properties, and ApplicationsNo ratings yet