Professional Documents

Culture Documents

Standardi U Oblasti Ispitivanja Metodama Bez Razaranja

Uploaded by

stefanvaljevoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standardi U Oblasti Ispitivanja Metodama Bez Razaranja

Uploaded by

stefanvaljevoCopyright:

Available Formats

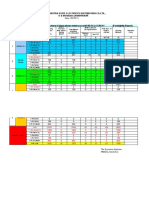

STANDARDI U OBLASTI ISPITIVANJA METODAMA BEZ RAZARANJA

Red. br. 1

Oznaka standarda SRPS EN 10160 (Idt. EN 10160:1999)

Predlog naslova standarda na srpskom jeziku Ultrazvuno ispitivanje pljosnatih proizvoda od elika debljine jednake ili vee od 6 mm (metoda refleksije) IBR elinih otkovaka - Deo 1: Ispitivanje magnetskim esticama IBR elinih otkovaka-Deo 2: Ispitivanje penetrantima IBR elinih cevi - Deo 1: Automatsko elektromagnetsko ispitivanje beavnih i zavarenih (osim zavarenih EPP postupkom) feromagnetskih elinih cevi radi provere hidraulike nepropusnosti

Naslov standarda na engleskom jeziku Ultrasonic testing of steel flat product of thickness equal or greater than 6 mm (reflection method) NDT of steel forgings-Part 1:Magnetic particle inspection NDT of steel forgings-Part 2:Penetrant testing NDT of steel tubes - Part 1: Automatic electromagnetic testing of seamless and welded (except submerged arc welded) ferromagnetic steel tubes for verification of hydraulic leaktightness NDT of steel tubes - Part 2: Automatic eddy current testing of seamless and welded (except submerged arc-welded) austenitic and austenitic-ferritic steel tubes for verification of hydraulic leaktightness NDT of steel tubes - Part 3: Automatic eddy current testing of seamless and welded (except submerged arc-welded) steel tubes for the detection of imperfections NDT of steel tubes - Part 4: Automatic full peripheral magnetic transducer/flux leakage testing of seamless ferromagnetic steel tubes for the detection of transverse imperfections NDT of steel tubes - Part 5: Automatic full peripheral magnetic transducer/flux leakage testing of seamless and welded (except submerged arc welded) ferromagnetic steel tubes for the detection of longitudinal imperfections NDT of steel tubes - Part 6: Automatic full peripheral ultrasonic testing of seamless steel tubes for the detection of transverse imperfections NDT of steel tubes - Part 7: Automatic full peripheral ultrasonic testing of seamless and welded (except submerged arc welded) tubes for the detection of

2 3

SRPS EN 10228-1 (Idt. EN 10228-1:1999) SRPS EN 10228-2 (Idt. EN 10228-2:1998) SRPS EN 10246-1

(Idt. EN 10246-1:1996) IBR elinih cevi - Deo 2: Automatsko ispitivanje beavnih i SRPS EN 10246-2 zavarenih (osim zavarenih EPP postupkom) austenitnih i (Idt. EN 10246-2:2000) austenitno-feritnih elinih cevi vrtlonim strujama radi provere hidraulike nepropusnosti IBR elinih cevi - Deo 3: Automatsko ispitivanje beavnih i SRPS EN 10246-3 zavarenih (osim zavarenih EPP postupkom) elinih cevi (Idt. EN 10246-3:1999) vrtlonim strujama radi otkrivanja nepravilnosti IBR elinih cevi - Deo 4: Automatsko ispitivanje merenjem SRPS EN 10246-4 magnetskog toka beavnih feromagnetskih elinih cevi po (Idt. EN 10246-4:1999) celom opsegu radi otkrivanja poprenih nepravilnosti IBR elinih cevi - Deo 5: Automatsko ispitivanje merenjem magnetskog toka beavnih i zavarenih (osim zavarenih EPP SRPS EN 10246-5 postupkom) feromagnetskih elonih cevi po celom opsegu radi otkrivanja uzdunih nepravilnosti (Idt. EN 10246-5:1999) SRPS EN 10246-6 9 10 (Idt. EN 10246-6:1999) SRPS EN 10246-7 (Idt. EN 10246-7:2005) IBR elinih cevi - Deo 6: Automatsko ultrazvuno ispitivanje beavnih elinih cevi po celom opsegu radi otkrivanja poprenih nepravilnosti IBR elinih cevi - Deo 7: Automatsko ultrazvuno ispitivanje beavnih i zavarenih cevi po celom opsegu (osim elektroluno zavarenih pod

11

12

prakom) radi otkrivanja podunih nepravilnosti IBR elinih cevi - Deo 8: Automatsko ultrazvuno SRPS EN 10246-8 ispitivanje zavara elektrozavarenih elinih cevi (Idt. EN 10246-8:1999) radi otkrivanja uzdunih nepravilnosti IBR elinih cevi - Deo 9: Automatsko ultrazvuno SRPS EN 10246-9 ispitivanje zavara elinih cevi zavarenih EPP postupkom radi (Idt. EN 10246-9:2000) otkrivanja uzdunih i/ili poprenih nepravilnosti IBR elinih cevi - Deo 10: Radiografsko ispitivanje zavara automatski elektroluno zavarenih elinih cevi radi otkrivanja nepravilnosti

longitudinal imperfections NDT of steel tubes - Part 8: Automatic ultrasonic testing of the weld seam of electric welded steel tubes for the detection of longitudinal imperfections NDT of steel tubes - Part 9: Automatic ultrasonic testing of the weld seam of submerged arc welded steel tubes for the detection of longitudinal and/or transverse imperfections NDT of steel tubes - Part 10: Radiographic testing of the weld seam of automatic fusion arc welded steel tubes for the detection of imperfections NDT of steel tubes - Part 11: Liquid penetrant testing of seamless and welded steel tubes for the detection of surface imperfections NDT of steel tubes - Part 12: Magnetic particle inspection of seamless and welded ferromagnetic steel tubes for the detection of surface imperfections NDT of steel tubes - Part 13: Automatic full peripheral ultrasonic thickness testing for seamless and welded (except submerged arc welded) steel tubes NDT of steel tubes - Part 14: Automatic ultrasonic testing of seamless and welded (except submerged arc-welded) steel tubes for the detection of laminar imperfections NDT of steel tubes - Part 15: Automatic ultrasonic testing of strip/plate used in the manufacture of welded steel tubes for the detection of laminar imperfections NDT of steel tubes - Part 16: Automatic ultrasonic testing of the area adjacent to the weld seam of welded steel tubes for the detection of laminar imperfections NDT of steel tubes - Part 17: Ultrasonic testing of tube ends of seamless and welded steel tubes for the detection of laminar imperfections NDT of steel tubes - Part 18: Magnetic particle inspection of tube ends of seamless and welded ferromagnetic steel tubes for the detection of laminar imperfections Iron and steel - Ultrasonic testing of H beams with parallel flanges

SRPS EN 10246-10 13 (Idt. EN 10246-10:2000) 14

15

16

17

18

19

20

21

22

IBR elinih cevi - Deo 11: Penetrantsko ispitivanje beavnih i zavarenih elinih cevi radi (Idt. EN otkrivanja povrinskih 10246-11:2000) nepravilnosti IBR elinih cevi - Deo 12: SRPS EN 10246-12 Ispitivanje beavnih i zavarenih feromagnetskih elinih cevi (Idt. EN magnetskim esticama radi 10246-12:2000) otkrivanja povrinskih nepravilnosti IBR elinih cevi - Deo 13: SRPS EN 10246-13 Automatsko ultrazvuno ispitivanje debljine beavnih i (Idt. EN zavarenih (osim zavarenih EPP 10246-13:2000) postupkom) elinih cevi po celom opsegu IBR elinih cevi - Deo 14: SRPS EN 10246-14 Automatsko ultrazvuno ispitivanje beavnih i zavarenih (Idt. EN (osim zavarenih EPP postupkom) 10246-14:1999) elinih cevi radi otkrivanja laminarnih nepravilnosti IBR elinih cevi - Deo 15: Automatsko ultrazvuno SRPS EN 10246-15 ispitivanje traka/limova koji se upotrebljavaju za proizvodnju zavarenih elinih cevi radi otkrivanja laminarnih (Idt. EN 10246-15:2000) nepravilnosti IBR elinih cevi - Deo 16: SRPS EN 10246-16 Automatsko ultrazvuno ispitivanje podruja uz zavar (Idt. EN zavarenih elinih cevi radi 10246-16:2000) otkrivanja laminarnih nepravilnosti IBR elinih cevi - Deo 17: SRPS EN 10246-17 Ultrazvuno ispitivanje krajeva beavnih i zavarenih elinih cevi (Idt. EN radi otkrivanja laminarnih 10246-17:2000) nepravilnosti IBR elinih cevi - Deo 18: SRPS EN 10246-18 Ispitivanje krajeva beavnih i zavarenih feromagnetskih (Idt. EN elinih cevi magnetskim 10246-18:2000) esticama radi otkrivanja laminarnih nepravilnosti SRPS EN 10306 Gvoe i elik - Ultrazvuno ispitivanje H profila sa paralelnim SRPS EN 10246-11

23

24 25

26

27

28

29

30

31

32

stopama i IPE profila IBR-Ultrazvuno ispitivanje pljosnatih proizvoda od austenitnih i austenitno-feritnih nerajuih SRPS EN 10307 elika debljine jednake ili veeod6mm (Idt. EN 10307:2001) (metodrefl.) SRPS EN 10308 IBR-Ultrazvuno ispitivanje elinih ipki (Idt. EN 10308:2001) SRPS EN 12084 IBR-Ispitivanje vrtlonim strujama-Opti principi i uputstva (Idt. EN 12084:2001) Livarstvo - Vizuelno ispitivanje SRPS EN 12454 povrinskih diskontinuitetaelini odlivci dobijeni livenjem u (Idt EN 12454:1998) peane kalupe IBR zavarenih spojeva - Deo 1: SRPS EN 12517-1 Radiografsko ispitivanje zavarenih spojeva od (Idt. EN 12517-1:2006) elika,nikla,titana i njihovih legura - Nivoi prihvatljivosti IBR-Karakteristike fokusnih taaka u industrijskim SRPS EN 12543-1 rendgenskim sistemima za upotrebu pri ispitivanju bez (Idt. EN 12543-1:1999) razaranja - Deo 1: Metoda pretraivanja IBR-Karakteristike fokusnih taaka u industrijskim SRPS EN 12543-2 rendgenskim sistemima za upotrebu pri ispitivanju bez (Idt. EN 12543-2:2008) razaranja - Deo 2: Radiografska metoda pomou dijafragme s rupicom IBR-Karakteristike fokusnih taaka u industrijskim SRPS EN 12543-3 rendgenskim sistemima za upotrebu pri ispitivanju bez (Idt. EN 12543-3:1999) razaranja - Deo 3: Radiografska metoda kamere s prorezom SRPS EN 12543-4 IBR-Karakteristike fokusnih taaka u industrijskim rendgenskim sistemima za upotrebu pri ispitivanju bez (Idt. EN 12543-4:1999) razaranja-Deo 4: Metoda ivice IBR-Karakteristike fokusnih taaka u industrijskim rendgenskim sistemima za SRPS EN 12543-5 upotrebu pri ispitivanju bez razaranja-Deo 5: Merenje (Idt. EN 12543-5:1999) efektivne veliine fokusne take minifokusnih i mikrofokusnih rendgenskih cevi SRPS EN 12544-1 (Idt. EN 12544-1:1999) IBR-Merenje i ocena napona rendgenske cevi - Deo 1: Metoda deljenja napona

(Idt. EN 10306:2001)

and IPE beams NDT - Ultrasonic testing of austenitic and austenitic-ferritic stainless steels flat products of thickness equal to or greater than 6 mm (reflection method) NDT - Ultrasonic testing of steel bars NDT - Eddy current testing General principles and guidelines Founding - Visual examination of surface discontinuities - Steel sand castings NDT of welds - Part 1: Evaluation of welded joints in steel, nickel, titanium and their alloys by radiography - Acceptance levels NDT - Characteristics of focal spots in industrial X-ray systems for use in NDT- Part 1: Scanning method

NDT- Characteristics of focal spots in industrial X-ray systems for use in NDT- Part 2: Pinhole camera radiographic method

NDT- Characteristics of focal spots in industrial X-ray systems for use in NDT- Part 3: Slit camera radiographic method NDT- Characteristics of focal spots in industrial X-ray systems for use in NDT- Part 4: Edge method

NDT- Characteristics of focal spots in industrial X-ray systems for use in NDT- Part 5: Measurement of the effective focal spot size of mini and micro focus X-ray tubes

33

34

SRPS EN 12544-2 (Idt. EN 12544-2:2000)

35

SRPS EN 12544-3 (Idt. EN 12544-3:1999) SRPS EN 12668-1 (Idt EN 12668-1:2000+A1:200 4) SRPS EN 12668-2 (Idt. EN 12668-2:2001+A1:200

36 37

NDT- Measurement and evaluation of the X-ray tube voltage - Part 1: Voltage divider method IBR-Merenje i ocena napona NDT- Measurement and rendgenske cevi - Deo 2: Metoda evaluation of the X-ray tube provere stalnosti napona voltage - Part 2: Constancy check upotrebom debelog filtera by the thick filter meth IBR-Merenje i ocena napona NDT- Measurement and evaluation rendgenske cevi - Deo 3: of the X-ray tube voltage - Part 3: Spektrometrijska metoda Spectrometric method IBR-Karakterizacija i NDT- Characterization and proveravanje opreme za verification of ultrasonic ispitivanje ultrazvukom - Deo 1: examination equipment - Part 1: Instrumenti Instruments IBR-Karakterizacija i proveravanje NDT- Characterization and opreme za ispitivanje ultrazvukom - verification of ultrasonic examination Deo 2: Sonde equipment - Part 2: Probes

4) SRPS EN 12668-3 38 (Idt. EN 12668-3:2000+A1:200 4) SRPS EN 12679 (Idt. EN 12679:1999) 40 41 42 43 SRPS EN 12680-1 (Idt. EN 12680-1:2003) SRPS EN 12681 (Idt EN 12681:2003) SRPS EN 13068-1 (Idt. EN 13068-1:1999) SRPS EN 13068-1 (Idt EN 13068-1:1999) SRPS EN 13068-3 44 (Idt. EN 13068-3:2001) SRPS EN 13184 (Idt. EN 13184:2001+A1:2003) SRPS EN 13185 (Idt EN 13185:2001) SRPS EN 13192 47 (Idt. EN 13192:2001+AC:2003) SRPS EN 1330-3 (Idt. EN 1330-3:1997) SRPS EN 1330-4 (Idt. EN 1330-4:2000) SRPS EN 1330-7 50 51 52 53 (Idt. EN 1330-7:2005) SRPS EN 1330-8 (Idt. EN 1330-8:1998) SRPS EN 1330-10 (Idt. EN 1330-10:2003) SRPS EN 13477-1 (Idt. EN 13477-1:2001) SRPS EN 13477-2 54 (Idt. EN 13477-1:2001 SRPS EN 13554 (Idt EN 13554:2002+A1:2003) SRPS EN 13625 56 (Idt. EN 13625:2001) SRPS EN 1369 (Idt. EN 1369:1996) SRPS EN 1370 (Idt. EN 1370:1996

IBR-Karakterizacija i proveravanje opreme za ispitivanje ultrazvukom - Deo 3: Kombinovana oprema IBR-Odreivanje veliine izvora zraenja u industrijskoj radiografiji - Radiografska metoda Livarstvo-Ultrazvuno ispitivanje - Deo 1: elini odlivci za optu namenu Livarstvo - Radiografsko ispitivanje odlivaka IBR-Radioskopija - Deo 1: Kvantitativno merenje svojstava slike IBR-Radioskopija - Deo 2: Provera vremenske postojanosti radioskopskih ureaja IBR-Radioskopija - Deo 3: Opti principi radioskopskog ispitivanja metalnih materijala upotrebom X zraka i gama zraka IBR-Ispitivanje propusnosti -Metoda promene pritiska IBR-Ispitivanje propusnostiMetoda ispitnog gasa IBR-Ispitivanje nepropusnostiKalibracija referentnog etalona IBR-Terminologija - Termini koji se koriste za industrijsko radiografsko ispitivanje IBR-Terminologija - Deo 4: Termini koji se koriste za ultrazvuno ispitivanje IBR-Terminologija - Deo 7:Termini koji se koriste u ispitivanju magnetskim esticama IBR-Terminologija-Deo 8:Termini koji se koriste u ispitivanju nepropusnosti IBR Terminologija - Deo 10: Termini koji se koriste pri vizuelnom ispitivanju IBR -Akustina emisija -Karakterizacija opreme - Deo 1: Opis opreme IBR-Akustina emisijaKarakterizacija opreme - Deo 2: Verifikacija radnih karakteristika IBR-Akustina emisija - Opti principi IBR -Ispitivanje nepropusnosti -Uputstvo za selekciju instrumenata za merenje gasne nepropusnosti Livarstvo - Ispitivanje magnetskim esticama Livarstvo - Ispitivanje hrapavosti povrine komparatorima za vizuelno odreivanje

NDT- Characterization and verification of ultrasonic examination equipment - Part 3: Combined equipment NDT- Determination of the size of industrial radiographic sources Radiographic method Founding - Ultrasonic examination - Part 1: Steel castings for general purposes Founding-Radiographic examination NDT- Radioscopic testing - Part 1: Quantitative measurement of imaging properties NDT- Radioscopic testing - Part 2: Check of long term stability of imaging devices NDT- Radioscopic testing - Part 3: General principles of radioscopic testing of metallic materials by Xand gamma rays NDT- Leak testing - Pressure change method NDT- Leak testing - Tracer gas method Non destructive testing - Leak testing - Calibration of reference leaks NDT- Terminology - Part 3: Terms used in industrial radiographic testing Non destructive testing Terminology - Part 4: Terms used in ultrasonic testing NDT- Terminology - Part 7: Terms used in magnetic particle testing NDT- Terminology - Part 8: Terms used in leak tightness testing NDT- Terminology - Part 10: Terms used in visual testing NDT- Acoustic emission Equipment characterisation - Part 1: Equipment description NDT- Acoustic emission Equipment characterisation - Part 2: Verification of operating characteristic NDT- Acoustic emission - General principles NDT- Leak test - Guide to the selection of instrumentation for the measurement of gas leakage Founding - Magnetic particle inspection Founding - Surface roughness inspection by visualtactile comparators

39

45 46

48 49

55

57 58

SRPS EN 1371-2 59 (Idt. EN 1371-2:1998) SRPS EN 13925-1 (Idt. EN 13925-1:2003) 61 SRPS EN 13925-2 (Idt. EN 13925-2:2003) SRPS EN 13925-3 62 63 (Idt. EN 13925-3:2005) SRPS EN 13927 (Idt. EN 13927:2003)

60

Livarstvo - Ispitivanje tenim penetrantima - Deo 2: Odlivci dobijeni preciznim livenjem IBR -Difrakcija X-zraka od polikristalnih i amorfnih materijala - Deo 1: Opti principi IBR-Difrakcija X-zraka od polikristalnih i amorfnih materijala - Deo 2: Postupci IBR-Difrakcija X-zraka od polikristalnih i amorfnih materijala-Deo 3:Instrumenti IBR-Vizuelno ispitivanje - Oprema IBR-Kvalifikacija sistema za digitalizaciju radiografskog filma - Deo 1: Definicije, kvantitativna merenja parametara kvaliteta slike, standardni referentni film i kvalitativna kontrola

Founding - Liquid penetrant inspection - Part 2: Investment castings NDT- X-ray diffraction from polycrystalline and amorphous material - Part 1: General principles NDT- X-ray diffraction from polycrystalline and amorphous materials - Part 2: Procedures Non destructive testing - X ray diffraction from polycrystalline and amorphous materials - Part 3: Instruments NDT- Visual testing - Equipment

64

SRPS EN 14096-1 (Idt. EN 14096-1:2003)

SRPS EN 14096-2 65 (Idt. EN 14096-2:2003) SRPS EN 14584 66 (Idt. EN 14584:2005) SRPS EN 14784-1 67 (Idt. EN 14784-1:2005) SRPS EN 14784-2 (Idt. EN 14784-2:2005) SRPS EN 1714 (Idt. EN 1714:1997+A1:2002) SRPS EN 444 (Idt. EN 444:1994) SRPS EN 462-1 71 (Idt. EN 462-1:1994) SRPS EN 462-2 72 (Idt. EN 462-2:1994) SRPS EN 462-3 (Idt. EN 462-3:1996) SRPS EN 462-4 74 (Idt. EN 462-4.1994) SRPS EN 462-5 75 76 (Idt. EN 462-5:1996) SRPS EN 473

IBR -Kvalifikacija sistema za digitalizaciju radiografskog filma - Deo 2: Najmanji zahtevi IBR-Akustina emisija Ispitivanje metalne opreme pod pritiskom tokom njenog potvrivanja -Poloaj izvora AE u ravni IBR -Industrijska kompjuterizovana radiografija s upotrebom fosfornih ploa - Deo 1: Klasifikacija sistema IBR-Industrijska kompjuterizovana radiografija s upotrebom fosfornih ploa - Deo 2: Osnovni principi za ispitivanje metalnih materijala upotrebom X-zraka i gama zraka Ispitivanje bez razaranja zavarenih spojeva - Ispitivanje zavarenih spojeva ultrazvukom IBR - Opti principi za radiografsko ispitivanje metalnih materijala X i gama zracima IBR -Kvalitet slike u radiografiji - Deo 1: Indikatori kvaliteta slike (tip ice) Odreivanje vrednosti kvaliteta slike IBR-Kvalitet slike u radiografiji - Deo 2: Indikatori kvaliteta slike (tip step/otvora) - Odreivanje vrednosti kvaliteta slike IBR-Kvalitet slike u radiografiji - Deo 3: Klase kvaliteta slike za gvoe i elik IBR -Kvalitet slike u radiografiji - Deo 4: Eksperimentalno ocenjivanje vrednosti kvaliteta slike i tabele kvaliteta slike IBR -Kvalitet slike u radiografiji - Deo 5: Indikatori kvaliteta slike (tip duple ice), odreivanje geometrijske vrednosti slike IBR-Kvalifikacija i sertifikacija osoblja za IBR - Opti principi

NDT- Qualification of radiographic film digitisation systems - Part 1: Definitions, quantitative measurements of image quality parameters, standard reference film and qualitative control NDT- Qualification of radiographic film digitisation systems - Part 2: Minimum requirements NDT- Acoustic emission Examination of metallic pressure equipment during proof testing Planar location of AE sources NDT- Industrial computed radiography with storage phosphor imaging plates - Part 1: Classification of systems NDT- Industrial computed radiography with storage phosphor imaging plates - Part 2: General principles for testing of metallic materials using X-rays and gamma rays Non-destructive examination of welds - Ultrasonic examination of welded joints NDT- General principles for radiographic examination of metallic materials by X- and gamma-rays NDT- Image quality of radiographs Part 1: Image quality indicators (wire type) - Determination of image quality value NDT- Image quality of radiographs Part 2: Image quality indicators (step/hole type) - Determination of image quality value NDT- Image quality of radiographs Part 3: Image quality classes for ferrous metals NDT- Image quality of radiographs Part 4: Experimental evaluation of image quality values and image quality tables NDT- Image quality of radiographs Part 5: Image quality indicators (duplex wire type), determination of image unsharpness value NDT- Qualification and certification of NDT personnel - General principles

68

69 70

73

(Idt. EN 473:2008) SRPS EN ISO 12706 77 (Idt. EN ISO 12706:2000) SRPS EN ISO 9934-2 (Idt. EN ISO 9934-2:2002) SRPS EN ISO 9934-3 (Idt. EN ISO 9934-3:2002)

IBR-Terminologija - Termini koji se koriste za penetrantsko ispitivanje (ISO 12706:2000) IBR-Ispitivanje magnetskim esticama - Deo 2: Ispitna sredstva (ISO 9934-2:2002) IBR -Ispitivanje magnetskim esticama - Deo 3: Oprema (ISO 9934-3:2002)

NDT- Terminology - Terms used in penetrant testing (ISO 12706:2000) NDT- Magnetic particle testing - Part 2: Detection media (ISO 9934-2:2002) NDT- Magnetic particle testing - Part 3: Equipment (ISO 9934-3:2002)

78

79

You might also like

- J.1. Jakka - VentilatoriDocument16 pagesJ.1. Jakka - VentilatoriMilan ForgiariniNo ratings yet

- АрилјеМетал CatalogDocument10 pagesАрилјеМетал CatalogAnonymous DjWqKpZ1No ratings yet

- HRN en 9692-1 PDFDocument3 pagesHRN en 9692-1 PDFDomagoj DelačNo ratings yet

- Elektrode Jesenice KatalogDocument380 pagesElektrode Jesenice KatalogIvan Femic100% (2)

- Merne TrakeDocument90 pagesMerne TrakeenescuricNo ratings yet

- Teleoptik Gasna Oprema-KatalogDocument12 pagesTeleoptik Gasna Oprema-KatalogspahicdaniloNo ratings yet

- Bs Bozic BSCDocument75 pagesBs Bozic BSCDragan TadicNo ratings yet

- 50MN7Document2 pages50MN7Anonymous pmp0NyDNo ratings yet

- USE AND MAINTENANCE INSTRUCTIONS MANUAL FOR EVM ELECTROPUMPSDocument20 pagesUSE AND MAINTENANCE INSTRUCTIONS MANUAL FOR EVM ELECTROPUMPStrantuan74No ratings yet

- IAT - Katalog IAT - Industry of Tools, Great Quality of Tools, 50 Years of TraditionDocument252 pagesIAT - Katalog IAT - Industry of Tools, Great Quality of Tools, 50 Years of TraditionIvan AlilovicNo ratings yet

- PSA Valves CriticalDesignFeatures MARKEDDocument41 pagesPSA Valves CriticalDesignFeatures MARKEDdj22500No ratings yet

- 15 Rotating Toolholders WNT2013Document177 pages15 Rotating Toolholders WNT2013Natrajj SivakumarNo ratings yet

- 2005predavanje 0 PDFDocument42 pages2005predavanje 0 PDF2ez4rtzNo ratings yet

- Catálogo Garrafa HidráulicaDocument6 pagesCatálogo Garrafa HidráulicaELDUVINA RIBASNo ratings yet

- Elektorde WebDocument311 pagesElektorde WebMiloš JevremovićNo ratings yet

- Domestic Water SupplyDocument64 pagesDomestic Water Supplyvugili0% (1)

- MSRR 6011Document14 pagesMSRR 6011pradellesNo ratings yet

- Procesna ReduktoriDocument150 pagesProcesna ReduktoriMilenkoBogdanovic50% (2)

- Vibration Monitoring On Power TransformerDocument2 pagesVibration Monitoring On Power TransformerPriya Surya HarijantoNo ratings yet

- Elektrode Jesenice Consumables CatalogueDocument384 pagesElektrode Jesenice Consumables CatalogueValvemakerNo ratings yet

- Elster G-400 PDFDocument8 pagesElster G-400 PDFalexrm12No ratings yet

- Primer Uporednih Oznaka Čelika Prema Različitim Standardima (Normama) - Online Mašinski PriručnikDocument1 pagePrimer Uporednih Oznaka Čelika Prema Različitim Standardima (Normama) - Online Mašinski Priručnikbajica3No ratings yet

- MG 411Document12 pagesMG 411Trần Khắc ĐộNo ratings yet

- Corwire Katalog YiceDocument54 pagesCorwire Katalog YiceAlexandar Marinkovic100% (1)

- Fidic Crvena Knjiga BosanskiDocument68 pagesFidic Crvena Knjiga BosanskiNamik HadziibrahimovicNo ratings yet

- USK UT EquipmentDocument2 pagesUSK UT EquipmentOhomina JoshNo ratings yet

- Tolerancije Limova I CeviDocument4 pagesTolerancije Limova I CeviZoran Tanja JarakovićNo ratings yet

- 04 ZavrtnjeviDocument54 pages04 ZavrtnjeviBaneMarkovicNo ratings yet

- PressedDocument36 pagesPressedJovanRadisicNo ratings yet

- Uputstvo Central 17 23 24 28 24M 28MDocument19 pagesUputstvo Central 17 23 24 28 24M 28Mserzo75100% (1)

- Catalog Strunguri Pentru Lemn - August 2013Document11 pagesCatalog Strunguri Pentru Lemn - August 2013Expert Masini UnelteNo ratings yet

- Utp 86 FNDocument1 pageUtp 86 FNc131508No ratings yet

- Cold Drawn Seamless For Heat Exchangers and BoilersDocument12 pagesCold Drawn Seamless For Heat Exchangers and BoilersmuhammadsaliNo ratings yet

- Valvula de MariposaDocument12 pagesValvula de MariposaErick HdezNo ratings yet

- Table of Bolt SizesDocument5 pagesTable of Bolt Sizesnagaraj108No ratings yet

- Book 1Document7 pagesBook 1Milan MilojevicNo ratings yet

- Catalog Universaluri, Bacuri, Flanse BERNARDO - Austria - eMasiniUnelteDocument22 pagesCatalog Universaluri, Bacuri, Flanse BERNARDO - Austria - eMasiniUnelteExpert Masini UnelteNo ratings yet

- SRPS U.n4.035 1994Document42 pagesSRPS U.n4.035 1994makimagNo ratings yet

- Quality steel E295 technical data sheetDocument1 pageQuality steel E295 technical data sheetNunoAfonsoNo ratings yet

- Prirubnice I Prirubnički SetoviDocument26 pagesPrirubnice I Prirubnički SetovisinisamaticNo ratings yet

- ASTM MaterialDocument4 pagesASTM MaterialEr Moosa MohammedNo ratings yet

- Aixam SV41AF Owner's Manual PDFDocument49 pagesAixam SV41AF Owner's Manual PDF1210tango1971No ratings yet

- Gorenje E2704WDocument13 pagesGorenje E2704WBoban TimotijevicNo ratings yet

- Universal WPS Packages for MIG/MAG and MMA Welding ProcessesDocument6 pagesUniversal WPS Packages for MIG/MAG and MMA Welding ProcessesAdmir TalicNo ratings yet

- Thermit CatalogueDocument20 pagesThermit CatalogueJboy SchlossNo ratings yet

- TH043D Parts CatalogDocument17 pagesTH043D Parts CatalogMarko CmukNo ratings yet

- Autodesk Mehanikal DesktopDocument348 pagesAutodesk Mehanikal DesktopMedina HodzicNo ratings yet

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesFrom EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Welded Pipes Made of Thermomechanically Rolled Materials 13 PDFDocument1 pageWelded Pipes Made of Thermomechanically Rolled Materials 13 PDFqc_531040655No ratings yet

- European Standards Fro Metallic MaterialsDocument3 pagesEuropean Standards Fro Metallic MaterialsVivi GouriotiNo ratings yet

- 77.040.20 - Non-Destructive Testing of MetalsDocument4 pages77.040.20 - Non-Destructive Testing of MetalsIsmailNo ratings yet

- List of NDT Standards 10 2015 CorrDocument16 pagesList of NDT Standards 10 2015 CorrAymeeen100% (2)

- NDT of helically welded pipesDocument13 pagesNDT of helically welded pipes_ARCUL_No ratings yet

- Ultrasonic Testing Standards and Practices GuideDocument3 pagesUltrasonic Testing Standards and Practices GuideChoy De VillaNo ratings yet

- ISO Specifications for Non-Destructive TestingDocument4 pagesISO Specifications for Non-Destructive Testingskynyrd75No ratings yet

- ISO Standards List for Non-Destructive TestingDocument5 pagesISO Standards List for Non-Destructive TestingAlfredo Bigolotti100% (6)

- NDT PDFDocument13 pagesNDT PDFAaron QuinnNo ratings yet

- BS en 10225 - 2009Document81 pagesBS en 10225 - 2009Md Azahary100% (3)

- Tiêu Chuẩn AstmDocument12 pagesTiêu Chuẩn AstmMartynas PreisaitisNo ratings yet

- Synopsis Mobile Banking AdministrationDocument24 pagesSynopsis Mobile Banking AdministrationRaj BangaloreNo ratings yet

- Exam 1 With SolutionsDocument11 pagesExam 1 With SolutionsSsebass PozzoNo ratings yet

- 16BBG - Sec17 - NPR NPRHD NQR NRR Diesel Cab Chassis Electrical Revision 3 100115 FinalDocument34 pages16BBG - Sec17 - NPR NPRHD NQR NRR Diesel Cab Chassis Electrical Revision 3 100115 FinalJou Power50% (2)

- Flow Chart Fixed Column BasesDocument4 pagesFlow Chart Fixed Column BasesstycnikNo ratings yet

- Carrier LDU ManualDocument123 pagesCarrier LDU Manualdafrie rimbaNo ratings yet

- B406-4 Rev. DDocument86 pagesB406-4 Rev. Danshit1No ratings yet

- Ficha Tecnica Viking PDFDocument11 pagesFicha Tecnica Viking PDFRichie ChicolNo ratings yet

- Perencanaan Produksi Dan Kebutuhan Material: Modul 4Document48 pagesPerencanaan Produksi Dan Kebutuhan Material: Modul 4Ivanca Earltina Miranda SimanungkalitNo ratings yet

- TSQL Coding Standards ChecklistDocument5 pagesTSQL Coding Standards ChecklistSaman AzeemNo ratings yet

- TENDERSCHEDULE309532Document2 pagesTENDERSCHEDULE309532heavens indiaNo ratings yet

- Manual de Teatro en Casa Nuevo PanasonicDocument56 pagesManual de Teatro en Casa Nuevo PanasonicMiguel Angel Aguilar BarahonaNo ratings yet

- Vanos E36Document68 pagesVanos E36Jorge SepulvedaNo ratings yet

- Hytherm 500, 600Document2 pagesHytherm 500, 600Oliver OliverNo ratings yet

- Noise Fundamentals ExplainedDocument26 pagesNoise Fundamentals ExplainedMuhamad FuadNo ratings yet

- Nuke 9.0v1 ReleaseNotesDocument32 pagesNuke 9.0v1 ReleaseNotesFlavioNo ratings yet

- Maharashtra State Electricity Distribution Co - LTD., O & M Division, NANDURBARDocument3 pagesMaharashtra State Electricity Distribution Co - LTD., O & M Division, NANDURBARPuru BornareNo ratings yet

- Be 2K OEM's Manual: Bernini Design SRL - ItalyDocument48 pagesBe 2K OEM's Manual: Bernini Design SRL - ItalySergio Ricardo IbañezNo ratings yet

- Download Descargar libro de geometria analitica de ricardo figueroa bookDocument3 pagesDownload Descargar libro de geometria analitica de ricardo figueroa bookJuniorNo ratings yet

- Câtlo ABB PDFDocument288 pagesCâtlo ABB PDFquocthinh_09No ratings yet

- Manual (4906-9127)Document6 pagesManual (4906-9127)LuisCabreraOroscoNo ratings yet

- Procedure For Management ReviewDocument3 pagesProcedure For Management ReviewMAYMODERN STEELNo ratings yet

- 01 Introduction To Programming ConceptsDocument34 pages01 Introduction To Programming ConceptsPoolparty LuluNo ratings yet

- Iphone 6 Full schematic+IC BoardDocument86 pagesIphone 6 Full schematic+IC BoardSIDNEY TABOADANo ratings yet

- Strategic Human Resource Development I SlidesDocument26 pagesStrategic Human Resource Development I SlidesAbhiman Behera50% (2)

- The Future of HovercraftDocument3 pagesThe Future of Hovercrafthovpod6214100% (4)

- Sda-02-Dd-02 - Pile & Pile Cap - Sheet-1 - R0Document1 pageSda-02-Dd-02 - Pile & Pile Cap - Sheet-1 - R0Himani PatelNo ratings yet

- Generador de Vapor Cu360Document36 pagesGenerador de Vapor Cu360Jonatan medran ochoaNo ratings yet

- Datasheet TachogeneratorDocument4 pagesDatasheet TachogeneratorNurulHidayatNo ratings yet

- SuperStr 14Document1 pageSuperStr 14Poshan DhunganaNo ratings yet

- SwephprgDocument94 pagesSwephprgAbhisekAcharyaNo ratings yet