Professional Documents

Culture Documents

01 RT-Flex 4 Course A Overview

Uploaded by

Aditya AryaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01 RT-Flex 4 Course A Overview

Uploaded by

Aditya AryaCopyright:

Available Formats

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.

2005 / hk

p oq=J =p=fs

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk

p oq=J =p=fs

Available Chapters of this Course:

A Short Introduction

(Philosophy of flex-technology)

B Mechanical Features

(Rail- & Supply Unit WECS modules Exhaust valve drive)

C Hydraulic Systems

(Fuel injection - Servo oil Control oil Starting air)

D Control System: WECS-9520

(System layout - Injection Exhaust valve Rail pressure misc.)

E Service Aspects

(General (Dis)Assembly Inspection intervals)

F Control diagram

G Introduction of CISERV Korea

(Mission Vision Customer satisfaction - Team Office & Workshop

Organization Workshop layout Service offered Welding repair)

`=`~

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk

p oq=J =p=fs

RT-flex Technology

Introduction Course

For Service Engineers, Ships Machinery Crew

and Engine Builders Personnel.

(Precondition: Understanding of Sulzer RTA engines.)

m~=^=l

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk

p oq=J =p=fs

Size 0:

Size 0:

RT

RT

-

-

flex50

flex50

Size I:

Size I:

RT

RT

-

-

flex58T

flex58T

-

-

B

B

RT

RT

-

-

flex60C

flex60C

Size II:

Size II:

RT

RT

-

-

flex68T

flex68T

-

-

B

B

Size IV:

Size IV:

RT

RT

-

-

flex84T

flex84T

-

-

D

D

RT

RT

-

-

flex96C

flex96C

oq=J =

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 1

p oq=J =p=fs m~=_=j~~

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 2

p oq=J =p=fs

Rail Unit(s)

WECS 9520, E 95.x

Cyl EU Terminal boxes

WECS 9520, E 90

Shipyard Interface Box

(SIB)

Supply unit

Control oil

pumps

Automatic filter

l

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 3

p oq=J =p=fs o~=r

For cylinder numbers >7

the rail unit is split in 2 parts.

(Reason: Handling during

assembly and transportation.)

Both rail-sections (fwd/aft)

are connected by fuel-, servo-

and control oil rail high press.

pipes.

-> Same pressure in the related

rails of both halfes.

WECS Cyl-EU boxes are

fitted on the outer front side

SIB (E90) Box on free end or

as shown on the left picture

E90 Shipyard Interface Box

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 4

p oq=J =p=fs

Rail Unit for flex Size IV

o~=r

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 5

p oq=J =p=fs

Fuel rail

Servo oil rail

ICU`s

VCU's/

Exhaust valve actuator

Control

Oil rail

o~=r=j~=m~

Fuel oil rail:

The fuel rail contains high pressure fuel of ~ 600 -

800 bar delivered by the fuel pumps of

the supply unit during engine operation. The rail

pressure is regulated depending on engine load.

For each cylinder, there is an Injection Control Unit

(ICU) installed on the rail.

The rail is heated by a trace heating piping system.

Servo oil rail:

The servo oil rail contains fine filtered (6-micron)

high pressure servo oil, ~ 80-190 bar, delivered by

the servo oil pumps of the supply unit, depending

on engine load. For each cylinder there is a Valve

Control Unit / exhaust valve actuator installed on

the rail.

Control oil rail:

The control oil rail contains 200 bar control oil

(constant pressure) delivered by the control oil

pumps. Control oil is used to actuate the

control pistons of the ICU`s.

Additional return/leakage piping:

- One fuel ICU-leakage pipe

- One common servo oil/control oil return pipe

- One main bearing oil supply pipe for VCU

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 6

p oq=J =p=fs

Fuel, servo oil and control oil

inlet to the rails is between the

two rail unit halves. For each

system there are two HP-pipes

coming from the supply unit.

To each rail half, there is a

separate high press. pipe (from

supply unit) connected.

For redundancy reasons there

are two HP-pipes for each system.

The cross-connection high

pressure pipes enable a direct

connection between each rail.

For two reasons:

1. Pressure equalisation

2. If one high pressure

supply pipe is broken, the

remaining one will fill up both

rails.

At each inlet, there are shut-off

valves, in order to isolate

individual HP-pipes in case of

leakages.

Cross-connections

Shut-off valves

Trace heating piping

o~=r=m

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 7

p oq=J =p=fs

Main bearing oil supply pipe for

upper side of valve control unit VCU

and exhaust valve actuator pipe.

Servo oil and control oil rail

common return pipe.

(back to crankcase/sump tank)

ICU and injection high pressure

pipe leakage drain pipe.

(connected to leakage collector

-> Alarm to Alarm System)

Trace heating

Control oil high

pressure hoses

o~=r=m

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 8

p oq=J =p=fs

Rail unit general drain piping. Possible leakages (fuel, oil, water) are collected for each rail

individually -> Alarm to Alarm System. The leakage is finally drained to sludge tank.

o~=r=m

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 9

p oq=J =p=fs

An ICU has two different sections:

Control oil side:

The rail valves (LP1-valves) control the control oil

flow to the control oil block.

Fuel side:

The fuel control valves are actuated by pistons in the

control oil block via thrust pieces. There is one valve

for one injector.

The main body of the ICU includes the injection quantity

piston. Its stroke measurement sensor with housing is

attached to the main body.

Control- and fuel oil side are entirely separated from each

other. Nevertheless, leakages of both systems have a

common drain.

Working principle: (detailed description in control systems)

Each ICU is pre-controlled by 3 rail valves (1 for each

injection valve). At a calculated crankangle, they get an

injection command impulse from WECS. The fuel control

valves will open and fuel injection will take place, while

the quantity piston measures continuously the fuel amount

injected. Once the proper amount was injected, the rail

valves will get a injection stop impulse from WECS.

Injection quantity piston

Control oil side

HFO side

Rail valves

(LP1-valves)

Fuel control

valves

Quantity piston sensor

Control oil

supply

Control oil

return

f=`=r

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 10

p oq=J =p=fs

Special measures in emergency

cases:

In case of a heavy internal or external fuel

leakage of the ICU, which cannot be fixed

immediately, the fuel supply from fuel rail to the

corresponding ICU can be shut off. The screw

plug with tool Nr.94585 can be installed instead

of the venting plug shown in the sketch. The

control oil supply and return can be shut in a

similar way. (refer to MM 0510-1/A1)

If for any other reason the injection of a unit

needs to be stopped, this can be done manually

through the WECS user interface (user

parameter), or it will happen automatically as a

consequence after other alarms.

Venting of fuel oil system:

After a major overhaul or to fill up an empty fuel

oil system, venting can be done by removing the

a.m. plug. The booster pumps will supply the

neccessary fuel pressure.

k

f=`=r

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 11

p oq=J =p=fs

Detection of leakages:

Internal leakages of all ICU`s and high pressure

injection pipes (on one rail unit half) are

monitored by one leakage sensor. In order to find

out whether the leakage actually comes from the

ICU or a injection pipe, the connection flanges

shown below have a screw plug. By opening

those plugs, the leaking pipes can be located.

If no pipe is leaking, an ICU can be the cause. In

order to locate a leaking ICU, observe the

injection time on all units, observe exhaust gas

temperatures after cylinders, or run the engine

with reduced load (i.e. < slow down speed) and

cut off the injection of all units (one by one). If the

leakage stops after a certain unit was cut off, this

ICU can be suspected.

Spare part handling/Overhaul:

Wartsila has established an exchange based

service for complete ICU`s, in case an ICU is

considered to be damaged, or if it is time for an

regular overhaul (~15`000-20`000 running hrs).

Only Wartsila approved workshops are allowed to

overhaul ICU`s!

Screw plug for leakage checking

f=`=r

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 12

p oq=J =p=fs

Main bearing oil

supply

Servo oil return

Connecting

element

Rail valve (LP1)

To exhaust valve

Components of a Valve Control Unit:

The servo oil supply from the servo oil rail to 3/2 way valve

is done via connecting element. The 3/2 way valve is pre-

controlled by one rail valve (same type as for ICU, but it

controls servo oil to actuate 3/2 way valve). The servo oil

flow into, or out of VCU cylinder is controlled by the 3/2

way valve. The servo oil return pipe has a back pressure

of ~2-3 bars, in order to dampen pressure peaks. To the

upper part of the VCU/actuator pipe, there is a main

bearing oil inlet via a non-return valve, in order to

compensate the intended oil loss through the constant

orifice in the exhaust valve drive upper housing.

Note: The servo oil itself is filtered to 6-micron by the

automatic filter, in order to reach the required oil-

cleanliness for a hydraulic system. It is taken from the

main bearing oil system of the engine.

3/2 way valve

VCU

cylinder

and piston

VCU-cover with non-return valve

s~=`=r

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 13

p oq=J =p=fs s~=`=r

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 14

p oq=J =p=fs

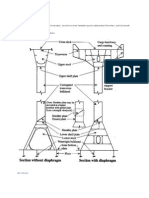

Components of an exhaust valve drive:

Main differences to a conventional RTA-valve drive:

-The exhaust valve is actuated by a double piston drive,

in order to save oil for actuation.

- Two redundant exhaust valve stroke sensors for

monitoring.

- One measuring cone for stroke sensors

- The air spring piston has now gas tight piston rings

- the disc spring package is dampening opening stroke in

case of low air spring pressure.

- The lower housing itself is the air spring cylinder.

(notice the top position)

Exhaust valve spindle

Air spring piston

Measuring cone

Double piston

drive

Damper

Disc spring package

2 exhaust valve

stroke sensors

Oil inlet from

Exhaust valve

actuator pipe

Constant orifice

b~=s~=a

Joint Ring

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 15

p oq=J =p=fs

Working principle: (Detailed description in control

systems)

The valve control unit is pre-controlled by the rail valve.

At a certain crankangle, it gets an exhaust valve open

impulse signal from WECS. Servo oil flows via rail valve

to the lower side of the 3/2 way valve spindle and moves

it up. Thus, servo oil flow to the VCU-cylinder is enabled.

Via bores in the VCU-piston, oil flows into the lower side

of the piston and moves it up to the upper end stop.

-> the exhaust valve opens.

At another calculated angle, WECS transmits an

exhaust valve close signal to the rail valve. The 3/2

way valve spindle moves down by spring pressure and

the valve control unit piston is pushed down by air

spring pressure. The servo oil underneath the piston is

drained to the servo oil return pipe. -> the exhaust valve

is closing.

The max. exhaust valve stroke is given by the upper end

stop of the piston. Due to certain control bores or

chamfers, the piston has a progressive movement.

Means, it starts to move fast and slows down, as it gets

closer to the end stop.

Note: on the upper side of the piston is main bearing oil,

on the lower side servo oil -> partition device

(alternative name for VCU). The non-return valve in the

VCU-Cover enables main bearing oil flow into, but not

out of the actuator pipe.

Rail valve

VCU piston

3/2 way valve

spindle

Actuator pipe with

main bearing oil

b~=s~=a

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 16

p oq=J =p=fs

Special measures in emergency cases:

If the injection of a certain cylinder was cut off, the exhaust

valve shall remain operational.

In case of a heavy leakage of exhaust valve actuator, actuator

pipe or valve drive, the servo oil supply can be shut off by

installing plug (Tool Nr.94586). The main bearing oil supply

can easily be interupted by a shut-off valve as well. In such a

case, the engine is operated with a closed exhaust valve and

cut - off injection.

Additionally, the exhaust valve open/close impuls signals

to the rail valve must be stopped manually (user parameter),

in order to avoid alarms from exh.valve monitoring system.

In case of exh.valve drive failure, the control impuls signals

can just be stopped manually by user parameter but only if

the injection was manually stopped previously!

The exhaust valve remains closed.

When a cylinder cooling water leakage into combustion

space occurs, the engine shall be operated with an open

exh.valve. Therefore the valve is moved open manually by

user parameter (will close by itself after a short time!), and

pins Nr.94259 can be inserted. Of course the injection is to be

cut off as well!

b~=s~=a

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 17

p oq=J =p=fs b~=s~

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 18

p oq=J =p=fs

Rail valves:

Rail valve are quick acting 3/2-way solenoid valves. Each cylinder unit has four rail valves. Three of them are pre-controlling an

ICU, one of them is pre-controlling the valve control unit.

Following an injection/return- or open/close cmd of WECS, the corresponding coils are energized by a very short time (normal

operation ~2-3 ms, max.4.5 ms), but with a high current impuls (~50-60A). This makes the valve spindle move towards the

energized coil (~0.2mm movement). The high current impuls and the short travel of the valve spindle enable a very short

actuation time, what is indispensible for precise injection- or exhaust valve control.

(Detailed description of rail valve function in control systems chapter)

Valve spindle

Coils

Iron core

Control oil/Servo oil inlet

Inlet/outlet to ICU/VCU

Outlet to common return pipe

El.sockets

The rail valves are non-

serviceable. Nevertheless, if dirt

particles are suspected to

influence proper operation, the

valves can be opened and blown

out by air. Pay attention to

assembly position of valve

spindle.

im=N=o~=s~

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 19

p oq=J =p=fs

Main components of a supply unit:

Fuel side: The jerk-type fuel oil pumps deliver

fuel into intermediate accumulator. To keep the

desired fuel rail pressure (600 - 800 bar), the pump

flow rate is regulated via regulating linkage and

el.actuators, receiving pressure setpoint signals

from WECS.

From the accumulator there are two outlets,

connecting the accumulator to the fuel rail via two

high pressure pipes.

Servo oil side: The servo oil pumps are axial

piston swashplate pumps from Bosch-Rexroth.

They deliver servo oil into servo oil collector block

to keep the operating pressure of servo oil ~ 80 -

190 bar.

There are two outlets from collector block,

connecting to the servo oil rail via two high

pressure pipes.

The number of fuel- and servo oil pumps depends

on the number of cylinders.

Fuel pumps

Servo oil pumps

Fuel intermediate

accumulator

Servo oil collector

block

Servo oil

outlet to rail

Fuel outlet

to rail

2nd intermediate

gearwheel

El.actuators

p=r

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 20

p oq=J =p=fs

Supply unit drive:

The supply unit is driven by the crankshaft, via two

intermediate gearwheels. The 2nd interm. gearwheel drives

the supply unit gearwheel, which drives the camshaft for

fuel pumps and the servo oil pumps gearwheel.

The 3-lobe cams are hydraulically fitted and can therefore

be individually replaced.

The servo oil pumps are driven by individual pinions,

having a mechanical fuse (reduced diameter in pinion), in

order to protect the gear-drive in case of a pump seizure.

The servo oil pump gearwheel is hydraulically fitted as well.

Since the supply unit, i.e. fuel pumps and servo oil pumps

have no timing, means they just supply more or less

quantity of fuel or oil, the camshaft doesnt have to have a

determined position compared to crankshaft. However the

position of the cams relative to each other must be

respected.

3-lobe cams

Supply unit gearwheel

Servo oil

pump drive

gearwheel

and pinions

2nd intermediate

gearwheel

Camshaft bearing

covers

p=r

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 21

p oq=J =p=fs

Intermediate accumulator with

2 safety valves (1250 bar).

Fuel inlet

from

booster unit

Shutdown &

overpressur

e regulating

valve,

Fuel drain

Fuel return

to booster unit (mixing unit),

via pressure retaining

valve.

Overpressure and safety

valves:

The overpressure regulating valve

releases fuel back into return

pipe, if the fuel pressure rises

higher than 1050bar. In case of a

shutdown, the shutdown solenoid

valve is energized and the

overpressure regulating valve is

kept open -> fuel pressure drops

to 0 bar.

There are two safety valves on

each side of the intermediate

accumulator, adjusted to an

opening pressure of 1250bar.

They only open, when

overpressure regulating valve is

not limiting the pressure, due to

malfunction.

Shutdown solenoid

valve

p=r

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 22

p oq=J =p=fs

Fuel overpressure regulating valve:

In case of the fuel pressure in intermediate

accumulator rises to ~1050bar, the overpressure

regulating valve releases fuel to fuel return line.

The max. opening pressure is pre-adjusted from valve

manufacturer. Shims are used to give the right

position to knurled screw, means if the screw is fully

screwed down to shims, 1050 bar are set. The min.

opening pressure, means when knurled screw is

screwed fully out, is around 500bars (engine still

operational).

During normal operation, main bearing oil pressure

keeps the valve closed. When the opening fuel

pressure is reached, main bearing oil is released,

pressure above piston drops and fuel is released back

to fuel return line to booster unit.

Emergency operation:

In case of fuel pressure regulation failure (e.g.

woodward actuator failure), resulting in a constantly

too high fuel pressure, the max. opening pressure can

be reduced in order to remove load from fuelpump etc.

A good value will be between 600-800bar.

Drain to return pipe

Fuel

inlet

Knurled screw

and shims

Accumulator

Valve

seat and

needle

Fuel

pressure

increase/

decrease

Main bearing oil

pressure at norm.

operation

Piston

p=r

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 23

p oq=J =p=fs

Engine shutdown function:

A shutdown is initiated by energizing the solenoid

valve (energized from safety system directly). In

this way, main bearing oil pressure above piston is

released, resulting in fuel pressure drop down to 0

bar in intermediate accumulator and thus in fuel

rail. -> engine stops.

(more detailed description about shutdown in control

system chapter)

Shutdown

Solenoid

valve

MB-oil

supply

coarse

sinterfilter

Lever for

manual

activation

Piston

p=r=

Sol. Valve leakage

drain

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 24

p oq=J =p=fs

Fuel pumps:

The jerk-type fuel oil pumps deliver a

variable quantity of fuel to the intermediate

accumulator and fuel rail, in order to

maintain the demanded fuel rail pressure.

They don`t have any timing.

To change the feed quantity, the pump

plunger is turned by the regulating rack,

which is moved by regulating linkage (see

next pages).

The rollerguide/roller assembly and

regulating sleeve are lubricated by main

bearing oil.

Regulating rack

Buffer space

Non return valve

Pump plunger

Pump cylinder

Compression spring

Rollerguide

Lower housing

Upper housing

Pump cover

Regulating sleeve

c=m

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 25

p oq=J =p=fs c=m

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 26

p oq=J =p=fs

Plunger position at regulating linkage position:

Pos: 0

No delivery

Pos: 5

Half delivery

Pos: 10

Full delivery

c=m

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 27

p oq=J =p=fs

Special measures in emergency

cases:

In normal operation, all fuel pumps deliver roughly

the same quantity. If a pump is defective, it will be

detected by WECS (temperature difference at fuel

HP-outlet). The regulating linkage position will be

higher than normal at a given fuel command.

In such cases, the affected pumps need to be cut

out mechanically by lifting the roller from the cam

by excentric shaft tool. This can only be done at

engine standstill.

With one pump cut out, the engine can still be

operated at full load. If two pumps are cut out,

operation is only possible at part load.

Excentric shaft

Tool Nr:94430

Roller guide

c=m

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 28

p oq=J =p=fs

Fuel pump regulating linkage:

The regulating linkage is moved by Woodward

(ProAct IV) electric actuators, that receive a

position setpoint signal from WECS.

One actuator controls two fuel pumps (the

arrangement of actuators can differ among engine

cylinder numbers).

The torque from linkage shaft to fork lever is

transmitted in both directions via torsional springs.

If a regulating rack of a pump is stuck for some

reason, the springs will compensate, so the other

pump can still be regulated.

El. Fuel pump actuators

Local position

indication (0-10)

Torsional springs

Fork lever

o~=i~

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 29

p oq=J =p=fs o~=i~

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 30

p oq=J =p=fs

Special measures in emergency cases:

In case of one or all el.actuator fail, the corresponding

linkage stays in position or moves to full output position.

The remaining working actuators will compensate the

regulation for the failed one.

A torsional spring on each regulating shaft will pull the

linkage to full output, if the affected actuator has no torque

force anymore (el.power loss)

In addition, spacers can be installed on regulating rack of

affected pump. Depending on, how many pumps are fixed

in max. position, the fuel rail pressure cannot be regulated

properly anymore. A constantly higher fuel rail pressure

will result. The emergency overpressure regulating valve

will limit the max. pressure accordingly. For longterm

operation, the opening pressure of that one must be

reduced.

When internal actuator faults occur, the position is kept on

actual position.

Spacer

Regulating rack

o~=i~

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 31

p oq=J =p=fs

Servo oil arrangement:

The servo oil pumps are axial piston -

swashplate-type pumps from Bosch -

Rexroth. They supply oil to the collector

block, which has two high pressure outlet

pipes to the servo oil rail. A safety valve

limits the max pressure to 230 bar.

The number of servo oil pumps depends on

the number of cylinders. If one pump fails,

the engine can still be operated at full load.

When the engine turning direction is

changing, the swashplate of the pumps

needs to be reversed.

Control oil is used to move the swashplate

into position.

Servo oil

pumps

Collector Block

Servo oil high pressure

pipes

Servo oil supply

Non return valves at each inlet

Safety valve

p=rI=p=l

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 32

p oq=J =p=fs

High pressure

outlet

Anti cavitation

inlet (from

servo oil main

supply pipe)

Non return

Valve / anti

cavitation port

Control oil inlet Control oil return Case drain

Main servo oil inlet

Swashplate angle encoder

Proportional

valve position

encoder

Proportional

valve solenoid-

valves

Visual indication

Proportional

valve

HP-outlet pressure

transmitter

p=l=m

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 33

p oq=J =p=fs

Function principle of servo oil

pumps:

The Bosch-Rexroth pumps have its own

regulating system, getting pressure setpoint

signals and ahd/ast signals from WECS.

(details in Control Systems)

The anti-cavitation port avoids cavitation in the

pump body, if a pump doesn`t move the

swashplate to the appropriate engine running

direction. (pump tries to suck in from HP-outlet

pipe).

In such a case, the non-return valve at anti-

cavitation port opens. Servo oil from main

supply pipe is sucked in via anti-cavitation port

and delivered out again via main inlet, see

schematic drawing. The oil will thus flow "idle"

through the pump.

6 ports as described are connected

B,B1 Pressure Port SAE 1 1/2 "

SB Anti Cavitation Port SAE 2 "

S Suction Port SAE 3 "

P,SP Control Pressure Port M18x1.5

Rkv Pilot Fluid Drain M22x1.5

R(L) Return (Aeration) M42x2

p=l=m

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 34

p oq=J =p=fs

HP-Inlets from pumps

2 Pressure retaining valves

2 Overpressure relief valves

3 HP-outlets for double wall

pipes control oil rails

3 shut of valves for 3 outlets

Pressure transmitter

For leakage detection

(signal to Alarm System)

Drain valve for leakage

`=l=m

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 35

p oq=J =p=fs

CAS pre-assembled with holder and data

Cable.

The 2 red lines must be in line when cyl 1

is in TDC.

`~=^=p

The Crank Angle Sensors are located on the free end of the crankshaft (or Geislinger Damper) They are separated from

the crankshaft by a special coupling. They create an exact digital signal of the momentary (= actual) crankshaft position

(0.360) The CA sensors have a resolution of 0.1

The spring loaded coupling absorbs all longitudinal and axial movement of the crankshaft. It drives a shaft which is

supported by two ball bearings. The bearings are oil lubricated. From the shaft a toothed belt drives each sensor.

Shielded BUS cables transmit the Signals to the WECS control.

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 36

p oq=J =p=fs `~=^=p

The crank angle signal is absolutely indespensable for engine operation. At least one of the sensors must be

working. If one fails, WECS can detect the failure and will keep working with the healthy signal (plausibilty

check). In case both sensors fail, at least one of them must be replaced. There is no emergency operation

possible without at least one CA sensor!

The sensor can be exchanged easily. With the flyhweel at 0.0, the two red lines on the sensor must be flush.

If not, the toothed belt is one or more teeth off its position and has to be slackened again, so the sensor

wheel can be turned freely until the two red lines are flush. Then the belt has to be pre - tensioned with a

given force (4.5 kg). Also the complete sensor drive can be exchanged, a complete drive is a standard spare.

Standard spare parts: 2 Sensors; 1 complete drive unit, assembled; coupling parts.

Experience will show whether the sensors can perfom satisfactory over a long term. The sensors are

exposed to vibrations, heat and humidity. The belts have to be exchanged after a while (estimated lifetime

max. 3 years). The belts must be free of oil!

When working on the sensors or cables, the power must be switched off before disconnecting a cable!

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 37

p oq=J =p=fs `~=^=p

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 38

p oq=J =p=fs `~=^=p

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 39

p oq=J =p=fs

Correct assembly of the crank angle

sensors and -drive is indispensable

for the operational safety.

These pages intend to sharpen the

awarness of service- and assembly people.

All necessary informations are

available in the Maintenace Manual,

chapter 9.

Dropped gear wheel collar

Gear wheel

Worn face

Sensor pully, dropped off side ring:

Consequence of overthightened belt.

`~=^=p

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 40

p oq=J =p=fs `~=^=p

Apply Molykote to

sliding surface!

Fitting of shaft encoder

1. Turn crank shaft to TDC of cyl. 1

2. Insert shaft encoder into the guide of the bearing

housing. Fasten screws slightly.

3. Push shaft encoder (with black holder plate!) inwards

4. Check whether the holder plate moves freely in the

bearing housing

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 41

p oq=J =p=fs

a= tension

~ QKR

`~=^=p

Fitting of toothed belt

1. Lay toothed belt onto the gear wheels in the position where the two red marks

of the gear wheels are flush. (The wheel of the sensor is freely movable.)

2. Push shaft encoder outwards till belt is slightly tensioned. Slightly tighten the

screws. Re - check if red marks are flush!

3. Align toothed belt in running direction and apply spring balance

4. Tension the belt slightly with the balance, loosen the screws and apply 4.5 kg.

Tighten the screws.

Cylinder No 1 must be at its actual, physical TDC during the whole installation

process! (This is NOT necessarily corresponding with the TDC signal

"tooth".!)

No tensioning by feeling!

Use the tool....

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 42

p oq=J =p=fs

It's important to recheck tension after

several engine revs. It will mostly become a

bit slack as consequence of alignement on

the wheels.

Visual check for belt tension see sketch: Belt teeth

on TDC and BDC of wheel must rest in ground.

`~=^=p

5. Turn the crankshaft for several turns to let the toothed belt find its running track.

6. If the belt tension has slackened, repeat the tensioning procedure. Check the belt tension

according the figure below.

7. Adjust and bend locking plates.

8. Tighten all screws and lock them.

Cylinder No 1 must be at its actual, physical TDC during the whole installation process!

(This is NOT necessarily corresponding with the TDC signal "tooth".!)

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 43

p oq=J =p=fs ^~=c

Servo oil and control oil is fine filtered before it enters the pumps and hydraulics. The automatic filter

has cartridges of nominal 6 m. There is an emergency bypass filter with 36 m mesh size.

The reason for filtering is to increase the lifetime and safety margin of all hydraulic components.

Control box with indications

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk Page 44

p oq=J =p=fs ^~=c

The backflushing is automatically initiated by the control box either

A) time controlled (after 1 hour) or

B) if the differential pressure across the filter becomes too high (0.35 bar)

The filter "sludge" goes back to the crankcase. It is filtered system oil which is clean enough for normal use.

In the filter control box the backflushing is initiated either by time or differential pressure. Flushing cycles are

counted. Alarms are generated if necessary (Overcurrent, differential pressure high etc)

Inside the box there is a switch with positions "Operation" and "Adjust". After switching to "Adjust" some

parameters become adjustable. Adjustable parameters are e.g. the flushing interval (1 hr 0 mins) etc

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk

p=oq=J =p=fs m~=`=e~=p

Auxiliary Functions

Auxiliary Functions

Auxiliary Functions

WECS 9500/9520

Injection Control

Exhaust Valve Control Starting Valve Control

Servo oil pressure

control

Fuel pressure control

Main Functions

Main Functions

Main Functions

Control oil pumps control

Valve stroke measurement

ICU stroke measurement

Crank angle detection

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk

p=oq=J =p=fs f=

Injection Control

(volumetric injection control)

CCM

VDM

CYL-EU

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk

p=oq=J =p=fs f=`

Schematic Layout of an Injection Unit

All components drawn in

position Return (No Injection)

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk

p=oq=J =p=fs b~=s~=`

Servo oil

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk

p=oq=J =p=fs `=^=p

`=^W

Control air is used for:

Actuation of

automatic start

valve

Oil mist detector

flushing of autom.

filter for servo oil /

control oil circuits.

air spring supply

control air for air

spring has to be

adjusted to 6.5 bar

at 23HA.

stand-by control air

has to be adjusted

to 6 bar at 19HA.

PLEASE NOTE:

Proper setting of the air

spring pressure is essential

for correct exhaust valve

timing.

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 1

p oqJ=p=fs

The RT-flex engine control is combined between the internal engine control WECS-9520

and the external Propulsion Control System, which comprises Remote Control; Safety

System, El. Governor- and Alarm Monitoring System:

1. Engine control system: WECS-9520

The WECS-9520 is the core engine control, it processes all actuation, regulation and control

directly linked to the engine:

z Common rail monitoring and pressure regulation

z Injection and exhaust- and start valve control and monitoring

z Interfacing external systems via CANopen or MOD Bus

z Engine performance tuning, IMO setting and -monitoring

The WECS modules are mounted directly on the engine and communicate via internal

System CAN Bus. An operator access to the WECS-9520 is integrated in the user interface

for the propulsion control system.

Each cylinder has got its own module for the cylinder-related functions. Additionally all

common functions are shared between these modules.

` p=l

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 2

p oqJ=p=fs

2. Remote control system:

Kongsberg Maritime, NABTESCO, SAM, Lyngs,

The remote control is the operator interface to the engine. Selectable control panels deliver

following manoeuvring commands to the WECS-9520 via CAN bus or MOD bus connection:

z Start, Brake Air

z Stop

z Ahead

z Astern

The remote control processes the engine telegraph command with internal settings (scaling, load

program etc.) to a speed reference signal for the governing system.

3. Electronic governor system:

Kongsberg Maritime, NABTESCO, SAM, Lyngs, ABB

The electronic governor system supplies the fuel command for the WECS-9520 and regulates the

engine speed.

The fuel command is calculated from the speed reference signal of the RC-system in relation to

the engine load. Fuel limiter in the governor system limit the fuel command depending on actual

speed and charge air pressure to avoid engine operation beyond the propeller law curve (smoke

& torque limiter).

o=`=C=d

z Air Run

z Slow Turning

z Slow Turning Failure Reset

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 3

p oqJ=p=fs

4. Safety system:

Kongsberg Maritime, NABTESCO, SAM, Lyngs

The safety system activates slowdowns and shutdowns in case of overspeed or other abnormal

conditions of the engine or its auxiliary equipment. The function with the RTflex engine is similar

to the conventional RTA engines, with some different / surplus functions:

z WECS uses redundant BUS communication with safety system to activate its slowdowns /

shutdowns

z The safety system (not the WECS!) directly activates the emergency stop solenoid via

hardwiring to depressurize the fuel common rail;

Additionally the safety system delivers some digital outputs to WECS via CAN Module Bus:

z Two inverted main bearing oil slowdown signals (size IV only 1 signal) for dry-running

protection of the control-oil pumps.

z Shutdown signal to WECS, to activate WECS-internal shutdown responses.

p~=p

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 4

p oqJ=p=fs

5. Alarm monitoring system:

Any possible system with class approval

The monitoring system receives alarm messages, divided in two groups:

z Alarm signals from WECS control system, transmitted via redundant module bus connection.

z Alarm signals hardwired via E130 for following general failures:

Leakage Alarms: Rail Unit, Supply Unit, Injection Components;

Fuel Pressure Actuator Failure;

Fuel Pump Outlet Temp Deviation Monitoring

Servo Oil Flow Monitoring

If propulsion control and alarm monitoring systems are provided by different suppliers, the

WECS9520 split version is used, and the interface is exclusively via MODbus

If propulsion control and alarm monitoring systems are provided by same supplier, the

WECS9520 integrated version is used, the interface can either be MODbus or CANopen bus.

^~=j

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 5

p oqJ=p=fs

hj=^=`OM=~=oqJ

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 6

p oqJ=p=fs

f~=b~=p=s

Control Room

WECS-9520

Service port CANopen

Crank-Angle

SSI Bus

CANopen System Bus

m

Speed ctrl. / RCS / SS

Alarm System

F

C

M

-

2

0

C

y

l

.

1

CR Pumps

Actuator

Servo oil

Pump

F

C

M

-

2

0

C

y

l

.

2

F

C

M

-

2

0

C

y

l

.

3

F

C

M

-

2

0

C

y

l

.

5

F

C

M

-

2

0

C

y

l

.

6

F

C

M

-

2

0

o

n

l

i

n

e

s

p

a

r

e

F

C

M

-

2

0

C

y

l

.

4

4..20mA

CR Pumps

Actuator

Servo oil

Pump

Servo oil

Pump

Servo oil

Pump

For engines with more

than 6 cylinders

CA

E90 SIB

E95.1

ExVa

3x EFIC

E95.6

Power

Supplies

O==OPMs^`

CR Pumps

Actuator

Engine

room

PWM

flex Engine

lmf

lmf

SAir

Ethernet

DENIS-9520 DENIS-9520

E85

CANopen

flex Engine

Local Manual Panel

C

A

N

o

p

e

n

C

A

N

o

p

e

n

ECR Manual Panel

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 7

p oqJ=p=fs

p=b~=p=s

Control Room

WECS-9520

Service

port

CANopen or

ModBus

Crank-Angle

SSI Bus

CANopen System Bus

Alarm System

F

C

M

-

2

0

C

y

l

.

1

CR Pumps

Actuator

Servo oil

Pump

F

C

M

-

2

0

C

y

l

.

2

F

C

M

-

2

0

C

y

l

.

3

F

C

M

-

2

0

C

y

l

.

5

F

C

M

-

2

0

C

y

l

.

6

F

C

M

-

2

0

o

n

l

i

n

e

s

p

a

r

e

F

C

M

-

2

0

C

y

l

.

4

4..20mA

CR Pumps

Actuator

Servo oil

Pump

Servo oil

Pump

ModBus

Servo oil

Pump

For engines with more

than 6 cylinders

CA

E90 SIB

E95.1

flex Engine

E95.6

Power

Supplies

O==OPMs^`

CR Pumps

Actuator

Engine

room

PWM

flex Engine

C

A

N

o

p

e

n

lmf

lmf

m

Speed ctrl. / RCS / SS

ExVa

3x EFIC

SAir

Local Manual Panel

DENIS-9520

ECR Manual Panel

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 8

p oqJ=p=fs

The WECS9520 system is built with a single multifunctional

electronic module FCM-20 = Flex Control Module 20

One FCM-20 is mounted per cylinder in a cabinet (E95)

below the rail unit.

An additional online spare module FCM-20 is located in the

SIB Shipyard Interface Box (E90).

The modules communicate between each other on a fast

internal CANopen system bus.

Additionally each module has got two module busses (1x

CANopen, 1x MODbus) that are used for communication to

external systems (PropCS, ALM), backup control panels,

actuators (size IV).

The internal module layout and the cable trays in the rail unit

entirely separate circuits with high EMC noise, like power

cables or pulsed current lines (PWM, rail valves) from

sensitive low power lines like databus cables and sensors.

tb`pJVROM=c~=a

Low signals, Low signals,

High signals, High signals,

Busses Busses and sensors and sensors

Power, PWM, Railvalves Power, PWM, Railvalves

E95.02

E95.01

E90 SIB

Cable tray high Cable tray high

Cable tray low Cable tray low

Box Box

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 9

p oqJ=p=fs

Hi gh Pow er I / O

Injector 1 Railvalve

Injector 2 Railvalve

Injector 3 Railvalve

Exhaust V/v Railvalve

Start Pilot Valve

24Vdc out, Start Ctrl-Oil Pps

Aut. Main Start Valve

Power Supply Man. Ctrl. Panels

Servo Oil Pump Actuator

Power Supply 24vDC OK

c`jJOM=e~~=fLl==e

FCM-20 Hardware I/O

On the upper left-hand side of the FCM-20

are the interface plugs for the high/pulsed

power outputs.

LEDs indicate I/O condition. Some change

their colour in case of failures or short

circuits. Blink codes give detailed failure

information.

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 10

p oqJ=p=fs

Low Pow er I / O

FCM/20 Cylinder # Identification Error

Fuel Qty. Feedback ok / Failure

Exhaust V/v Position 1 FB ok / Failure

Exhaust V/v Position 2 FB ok / Failure

Analogue In 1 (Rail Pressure, Charge Air) / Failure

Analogue In 2 (Rail Pressure, Charge Air) / Failure

Analogue in 3 (Spare) / Failure

CA Sensor 1 Short Circuit Power Supply

CA Sensor 2 Short Circuit Power Supply

CA-Sensor 1 Master / Clock or Data Failure

CA-Sensor 2 Master / Clock or Data Failure

CAN System Bus 1 Master / Bus Failure

CAN System Bus 2 Master / Bus Failure

CAN Module Bus 1 Traffic / Bus Failure

MODbus Traffic

Digital Input 1 (Turning Gear Engaged; TDC Pick-up)

Digital Input 2 (Pressure Switches)

Analogue Out (Fuel Actuator Setpoint)

Power Supply Failure

Module ready, SW ok

Failure on Module

Not Applicable

c`jJOM=e~~=fLl==i

FCM-20 Hardware I/O

On the lower right-hand side are the

interface plugs for low power signals and

databusses.

LEDs indicate FCM-20 module & I/O

condition. Some change their colour in

case of failures or short circuits. Blink

codes give detailed failure information.

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 11

p oqJ=p=fs

The internal FCM-20 functions within the WECS-9520 can be separated in two groups:

Common Funct i ons & Cy l i nder Funct i ons

1. Common functions:

Fuel- and servo oil rail pressure regulation and monitoring, control oil pumps control.

Storage and processing of tuning data (IMO, engine-specific and global settings)

Internal WECS monitoring (power supply, SW-watchdog, CRC- & HW-checks)

Calculation and processing of common control variables (VIT, VEC, VEO, engine state)

Interface to propulsion control system and to backup panels in CR and LC.

Failure indications with help of module LED`s.

2. Cylinder related functions:

Start-, injection- and exhaust valve control according to settings in data container and commands

and parameters received across CANopen System bus.

For synchronizing the valve control timing with the crank angle, each FCM-20 reads and

processes the crank angle signals from the SSI-Bus and calculates speed, angle and rotational

direction of its cylinder.

c`jJOM=j=c

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 12

p oqJ=p=fs `=c=f~

F

C

M

-

2

0

C

y

l

.

1

F

C

M

-

2

0

C

y

l

.

2

F

C

M

-

2

0

C

y

l

.

3

F

C

M

-

2

0

C

y

l

.

5

F

C

M

-

2

0

C

y

l

.

4

Fuel Rail

Servo Oil Rail

Control Oil Rail

Control Oil

Flow

(4-20mA)

Servo Oil Pumps (CAN Module bus)

Fuel Supply Actuator (4-20mA)

Turning Gear Disengaged (Dig. In)

P Charge Air (4-20mA)

TDC Pickup (Dig. In)

1 2

1 2

1 2 3

1 2 3

Autom.

Start

Valve

(Dig. Out)

1 2

How external units are

divided between FCM-

20 #1 to FCM #5

Control Oil

Pumps

(Dig. Out)

Servo Oil

Inlet Press.

(4-20mA)

Local MCP (CAN Module bus) ECR MCP

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 13

p oqJ=p=fs `=c=f~

Injection Control Unit

3 Railvalves

Exhaust Control Unit

1 Railvalve

Start Pilot Valve

Exhaust Valve

Position Feedback

4-20 mA

Fuel Quantity

Feedback

4-20 mA

24Vdc out

Crank Angle Sensors

Each

1 Clockbus 1 Databus

E85

Power

Supply

24Vdc

Crankangle SSI Bus 2

Crankangle SSI Bus 1

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 14

p oqJ=p=fs

The railvalves are ultra-fast responding (~2ms) bi-stable solenoid valves.

Due to the high actuation current and the thermal load on the solenoid coils they

may not be energized for more than 4ms. This on-time is sampled, monitored and

limited by the WECS-9520.

After installing or replacing a bi-stable valve, its

position open/close is unknown.

To make sure the valves are always in the safe

No injection and Exhaust valve closed

position when the engine is stopped, WECS-

9520 sends setpulses to all railvalves in regular

intervals (~10s).

o~~

Wire Coil Magnet Piston

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 15

p oqJ=p=fs

Crank angle detection :

Without direct mechanical crank angle transmission to the control elements for fuel

injection and exhaust valves it is necessary to measure the actual crank angle

electrically. The WECS-9520 measuring principle provides an absolute angle

resolution to make sure, the exact crank angle value is present immediately after

powering up (without having to initialize the angle transmitters before a vacant output

is present).

Two such angle transmitters are connected with

serrated belts to a specially designed drive

shaft. This application prevents transmission of

axial and radial crankshaft movements to the

sensors.

`~=^=a

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 16

p oqJ=p=fs

To synchronize the messages between FCM-20 modules and CA-sensors, each

sensor has an own SSI-Clock Bus. (SSI = Synchronous Serial Interface Bus).

For every clock bus one of two redundant FCM-20 supplies a clock pulse to the

sensor and the other modules. These modules are the clock bus masters.

Each crank angle sensor (or shaft encoder) supplies angle data signals in a bit

frame to all FCM-20 modules via its SSI-Data Bus.

Signals from both CA sensors are processed and checked for errors within each

FCM-20. A final master angle is calculated from the measured angles.

The final master angle value is compared with a TDC pulse signal from a pick-

up on the flywheel. If the difference between master angle and TDC signal is too

large, an alarm, slowdown or shutdown is initiated by the WECS-9520

(depending on the deviation angle).

The final master angle value is used to determine crankangle, engine speed and

direction of engine rotation.

`~=^=a

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 17

p oqJ=p=fs

Normal operation

Some degrees before the piston reaches TDC, the FCM-20 calculates the correct

injection begin angle, taking VIT and FQS into consideration. Further a deadtime is

added to compensate the time-difference between the injection command from the

control system and the real injection begin. The deadtime is measured during the

injection cycle by comparing the elapsed time between command release and begin

of movement fuel quantity sensor. The fuel quantity sensor further gives a feedback

of the amount of injected fuel and is compared with the scaled fuel command.

Injection begin and end are triggered and actuated by the FCM-20.

Injection Control

(volumetric injection control)

Each FCM-20 calculates the necess-

ary injection timing for its own cylinder

by processing the crank angle signal

and the fuel command received from

the speed control.

FCM-20

f=`

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 18

p oqJ=p=fs

Schematic Layout of an Injection Unit

When the railvalves are switched to

Injection, fuel is supplied from

volume through injection control

valves 3.41 to the fuel nozzles.

During fuel displacement the fuel

quantity piston moves inwards and

delivers a feedback signal analogue

to the injected fuel quantity to the

FCM, which compares this value

with the necessary amount (= LI).

Once the desired amount of fuel has been injected,

the FCM-20 switches the railvalves to return

position. Immediately the injection control valves

interrupt the fuel rail pressure from the fuel nozzles.

Due to the rising pressure in space the fuel

quantity piston moves back to its initial position.

Injection Control Valves

Rail Valves

Fuel Quantity Signal

Fuel oil side

Ctrl. oil side

All components drawn in position

Return (No Injection)

f=`=r

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 19

p oqJ=p=fs

At very low load two of the three injection valves are cut out. This is used to avoid visible

smoke emission and to reduce fuel consumption.

Injecting with one (or two) nozzles a certain fuel volume takes longer than with 3 (or 2)

nozzles. This longer injecting time allows a more constant injection pressure and thus

improved atomization for an optimal combustion.

To avoid thermal stress to cylinder liners, the active nozzles are switched over every 20

minutes.

Special injection patterns

Also injection spray interruptions (multi-shooting patterns), register injection patterns are

possible to optimize atomization. This feature is not yet used on the current engines.

Low Load operation

At low engine load

the WECS-9520

cuts out one of the

three injection

valves per cylinder.

p=k=`

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 20

p oqJ=p=fs

Exhaust Valve Control

The exhaust valve is opened by servo oil pressure and closed by an air spring, same as

with conventional Sulzer engines. A partition device (VCU, valve control unit) isolates

the (fine-filtered) servo oil for the rail valve loop from the normal bearing oil for the

exhaust valve actuation. The stroke of the valve spindle is measured by 2 analogue

position sensors for a feedback to the WECS-9520.

Partition Device

Exhaust Control Valve

Exhaust Rail Valve

p=

b~=s~=`

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 21

p oqJ=p=fs

Detailed functional description of the exhaust valve control:

The valve opening angle is calculated in each FCM-20 according to measured

crank angle, nominal opening angle and VEO: Variable Exhaust-Valve Opening.

The exhaust rail valves are triggered to the Open position.

Servo oil pressure operates the control piston inside the valve control unit. This

movement builds up oil pressure for opening the exhaust valve spindle.

The time between the Open command and the initial movement of the spindle is

measured. It is called opening deadtime.

At the next revolution this deadtime will be considered by switching the rail valve a

little earlier (or later) for compensation of hydraulic delays.

Analogue to the above mentioned, the valve closing angle is determined and

controlled by the FCM-20 including the VEC: Variable Exhaust-Valve Closing and

a closing deadtime.

b~=s~=`

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 22

p oqJ=p=fs

FQS, VIT:

These functions are known from the contemporary RTA engines:

FQS: Fuel Quality Setting

z Manual offset for the injection timing

VIT: Variable Injection Timing

z Advance / retard injection according to engine load for optimized fuel

consumption and NO

x

emission.

Different from the RTA engines, the injection angles for the RT-flex are no more

related to the firing pressure (advanced injection begin => +, retarded => -), but

to the

Crankangle (CA) between 0- 360.

As a result an advanced injection begin or FQS setting [higher firing pressure] (e.g.

+1.0 according to RTA philosophy) is now -1.0 in relation to the earlier injection

angle (e.g. 2instead of 3CA).

cnpI=sfq

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 23

p oqJ=p=fs

-2.0

-1.0

0.0

1.0

2.0

3.0

4.0

0 10 20 30 40 50 60 70 80 90 100 110 120

Engine Speed [%]

I

T

B

A

n

g

l

e

[

C

A

]

-3.0

-2.0

-1.0

0.0

1.0

2.0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2

Charge Air Pressure [-]

I

T

A

A

n

g

l

e

[

C

A

]

-4.0

-3.0

-2.0

-1.0

0.0

1.0

2.0

3.0

4.0

0 200 400 600 800 1000 1200 1400 1600

Fuel Rail Pressure [bar]

I

T

C

A

n

g

l

e

[

C

A

]

FQS, VIT:

The VIT angle calculation for the RT-flex

depends on RPM, charge air pressure

and (new) fuel rail pressure.

This 3rd parameter is introduced to

compensate differences in injection timing

resulting from different injection pressures.

Higher fuel pressure causes advanced

injection and higher P max.

Thus the injection begin angle is retarded a

bit with increasing fuel pressure.

Fuel Rail pressure at CMCR

VIT A

VIT B

VIT C

cnpI=sfq

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 24

p oqJ=p=fs

VEO, VEC:

The VEC (variable exhaust-valve closing) is known from the contemporary RTA 84T

B/D engines:

VEC: Variable Exhaust-valve Closing

Adopting compression pressure to keep the

firing ratio (P

max

/ P

compr

) within permitted range

during advanced injection.

VEO: Variable Exhaust-valve Opening

Keeps the exhaust gas pressure blowback

constant by earlier valve opening at higher

speed for fuel economy and less deposits at

piston underside.

-35

-30

-25

-20

-15

-10

-5

0

5

0 10 20 30 40 50 60 70 80 90 100 110 120

Engine Speed [%]

V

E

C

A

n

g

l

e

[

C

A

]

-5

0

5

10

15

20

0 10 20 30 40 50 60 70 80 90 100 110 120

Engine Speed [%]

V

E

O

A

n

g

l

e

[

C

A

]

VEC

VEO

VEC and VEO are calculated by WECS, they cant be changed manually

sblI=sb`

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 25

p oqJ=p=fs c=m=`

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 26

p oqJ=p=fs

Starting

Before and at begin of an engine start, the fuel actuators are set to a value defined in

the WECS-9520 parameters, normally it is 95% of the actuator output.

As soon as engine running is detected, the rail pressure is regulated to the desired

value (~700 bar).

Engine Running

FCM-20 #3 or #4 calculates the necessary rail pressure and the output signal to

the actuators (4-20 mA signal range).

2 transmitters supply the actual value from the fuel rail. For faster response of the

dynamic pressure regulation, any change of the fuel command for the speed

control is additionally transmitted as feed forward to the control loop.

The fuel pumps charge up the fuel rail pressure via intermediate fuel accumulator.

The resulting pressure in the rail depends on the quantity of supplied oil coming

from the supply unit and the outgoing fuel to the injectors.

c=m=`

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 27

p oqJ=p=fs

Pressure Regulation

For faster response of the dynamic pressure regulation any change of the fuel

command is additionally transmitted as feed forward to the control loop.

Feed forward

c=c~

r

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 28

p oqJ=p=fs

Shutdown

A shutdown from the Safety System is performed as follows:

RTflex size I (58TB/60C): The safety system releases the pressurized fuel rail to

the overflow tank by opening the pneumatic fuel shutdown valve 3.07 via

emergency stop solenoid 3.08 (ZV7061S).

RTflex size IV (84TD/96C): The safety system releases the pressurized

intermediate fuel accumulator to the fuel return line by opening the hydraulic fuel

shutdown valve 3.07 via emergency stop solenoid 3.08 (ZV7061S).

WECS-9520 triggers the fuel actuator output to zero for terminating fuel feed to

the rail unit, while the engine is not yet stopped.

Injection commands are blocked by the WECS-9520.

c=m=`=

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 29

p oqJ=p=fs p=C=`=l=`

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 30

p oqJ=p=fs

The servo oil rail pressure is

controlled depending on the engine

load. At part load the pressure is

reduced, because due to the lower

firing pressure, the servo oil pressure

must be adopted to adjust the

opening speed of the exhaust valve

accordingly.

0

50

100

150

200

250

0 10 20 30 40 50 60 70 80 90 100 110 120

Engine Load (MEP x n) [%]

S

e

r

v

o

O

i

l

P

r

e

s

s

u

e

[

b

a

r

]

A FCM-20 uses the fuel command as engine load reference to calculate the

necessary setpoint for the servo oil pressure.

Each servo oil pump is controlled by a different FCM. A pulse-width modulated

current signal is supplied to solenoids mounted on the control plate of the pumps.

This signal is setting the output of the axial pumps and accordingly the servo oil

supply to the rail.

With engine at standstill, the control oil circuit feeds the servo oil rail with

approximately 50 bar, adjusted at pressure reducing valve 4.27.

p=l=m=`

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 31

p oqJ=p=fs

Control oil pressure control:

The control oil pump(s) supply an oil pressure of 200 bar to operate injection rail

valves and to prime the servo oil rail (with reduced pressure), when the engine is at

standstill. The high actuation pressure for the injection rail valves is required for a fast

valve response and precise injection timing.

One control oil pump starts up, as soon as main bearing oil pressure is available.

(Size IV: both pumps are starting up).

During starting and in low speed range both pumps are running.

At higher engine speed one of the pumps is switched off and restarts only if the

control oil pressure delivered by the remaining pump drops below 170 bar.

At engine stop, one pump is switched off again after a time delay. The other pump

keep on running as long as main bearing oil pressure is available. (Size IV: both

pumps keep on running).

Control oil pressure is adjusted at pressure retaining valves inside rail unit.

A dry-run protection in case of low bearing oil pressure is provided within the WECS

software.

`=l=m=`

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 32

p oqJ=p=fs

The opening and closing of the starting pilot valves 2.07 is

controlled by the corresponding FCM, depending on the

crank angle.

The nominal opening angle is 0, closing angle is 110

For engines with a large cylinder number the closing angle

can be reduced in order to save starting air.

The automatic starting valve 2.03 is activated by solenoids

ZV70113C and ZV7014C via FCM-20 #1 and #2, if the

remote control sends a constant START signal over the bus.

For slow turning and slow turning failure reset the remote

control sends pulsed signals to FCM-20 #1 and #2. The slow

turning speed can be adjusted in the WECS-9520

parameters by adopting pulse cycles.

Additionally an Air Run signal enables to blow the engine

with start air, if required.

p~=s~=`

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 33

p oqJ=p=fs p~=s~=`

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 34

p oqJ=p=fs

Redundancy, emergency operation with damaged control parts :

Flex Control Module FCM-20

If a FCM-20 fails, the corresponding cylinder is cut out, all other cylinders remain

operative.

Any FCM-20 module can be exchanged with the online spare. The respective

software and parameters are already stored within the online spare module and no

software download or reprogramming is necessary.

When introducing a FCM-20 module from stock as online spare in the system it

will load up the software and parameters from the modules already present in the

system. If installed as online spare without affecting operation. If installed in any

other place without valid software, the module function will only be activated after

completing data transfer to the new module.

j=o~

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 35

p oqJ=p=fs

System CAN Bus, Module Bus (CANopen or MODbus) and SSI Bus (CA)

Always two busses are active. If one bus is interrupted, shortened or else, the

second bus is still available for communication. Engine operation is not

interrupted.

WECS-9520 power supply (E85)

All modules have redundancy by doubled primary and/or secondary power

supplies.

Sensors

All vital sensors and transmitters are existing twice and their mean values are

used for controlling the engine. If one sensor fails, WECS-9520 indicates the

specific sensor failure and continues to work with the remaining one.

p=o~

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 36

p oqJ=p=fs p=o~

Crank angle sensor

If one of the two crank angle sensors is out of order, WECS stays operational with

the remaining crank angle sensor.

If both sensors are damaged, the engine can not be operated! It is necessary

to replace at least one sensor.

TDC- Pick-up

A damaged TDC sensor is signaled by the WECS monitoring system, but will not

stop or slow down the engine operation.

Fuel quantity sensor

With a damaged fuel quantity sensor, the FCM uses a fixed deadtime to calculate

the injection begin angle and an artificial fast ramp signal for the fuel quantity,

which results in less injected fuel on the affected unit than at normal operation.

Exhaust valve position sensor

Each exhaust valve has two redundant position sensors. If both fail, the FCM

controls the exhaust opening and closing valve angles with optimised, fixed

opening and closing times

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 37

p oqJ=p=fs

Fuel pumps and actuators

If a fuel pump / actuator is damaged, the connected regulating linkage(s) can be

blocked manually in full delivery position. The corresponding fuel pumps deliver

max. pressure. The (second) actuator(s) regulate(s) at a lower output and the fuel

pressure control valve 3.06 limits the rail-pressure to 950 bar.

Servo oil pumps

With one damaged servo oil pump the engine remains operational at full load, with

2 damaged pumps operation is only possible in lowest part load.

Control oil pumps

If a control oil pump fails, the servo oil rail feeds the control oil circuit via non-return

valve 4.29, until the second control oil pump builds up pressure. With both control oil

pumps damaged, emergency operation is possible with exclusive oil supply from

servo oil rail.

m=o~

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 38

p oqJ=p=fs

Fuel shut down valve / Em. Stop valve

With fuel shutdown valve 3.07 or the emergency stop solenoid 3.08 damaged, any

stop commands are processed by only blocking injections commands and

triggering fuel actuator output to zero. Stopping the engine is always possible.

Remote Control / Speed Control System

With damaged remote control or speed control, the engine can still be operated

from the back-up panel in the engine control room or from the local control panel.

If the speed control is still operational, the new WECS-9520 panels allow either

fuel control mode or speed control mode from the manual control panels.

The manual control panels are a part of the WECS-9520 control system and offer

one specified functionality, independent from the propulsion system manufacturer.

l=o~

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 39

p oqJ=p=fs j~~=`=m~

Selector buttons for manoeuvring

commands.

Start Air is released as long as AH / AS

buttons are pressed. The engineer can

decide, when and for how long start- or

brake air is supplied.

Select Speed or fuel control

Speed and fuel commands are set with

a dial button on the RC supplier part of

the CR / LC panels.

Last command is stored, when taking

over to other panel or from remote to

manual control.

Similar panels are installed in ECR and

Local Control Panel.

All necessary information is shown on the

display:

Speed and / or Fuel Command

Start Interlocks

Safety events (SHD, SLD, OVSPD)

Rail pressures

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 05.2005 / JKU Page 40

p oqJ=p=fs j~~=`=m~

If the Ackn. button is pressed for more

than 5 seconds, WECS-9520 SW info

and all necessary IMO check values are

indicated in the screen for 10 seconds.

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk

p oq=J =p=fs

Chapter F: Service and Operation

Intention:

Introducing Service Engineers and Operating Engineers in some of the specialties

of daily life with the Common Rail Sulzer.

What to think of and look at on daily rounds.

What do to if there's trouble.

Which parts to overhaul...

f

Training Makes A Difference @ Wrtsil Training Center Winterthur / issue 01.2005 / hk

p oq=J =p=fs

- Normal Operation; Things to Consider.

The flex part of the engine requires different treatment from other engines: The following list

mentions some thoughts. It can be extended:

- Trace heating of rail unit, supply unit and rising pipes (all fuel parts). To avoid sticking

HFO the trace heating shall be on at all times. Especially important in port. The fuel inside

rising pipes and rail does not circulate and must be kept warm. To avoid starting difficulties

it is recommended to turn on the heating at least 4 hours before engine starting if it needed

to be stopped for some reason. All rail unit covers shall be kept close.

WARNING: When changing over bunker to MDO the trace heating must by all means be

stopped early enough to avoid overheating of the diesel oil.

- WECS: The WECS system shall always be kept on, there is no need of stopping it in port.

It is recommended to stop WECS power when unplugging sockets from modules,

when disconnecting the sockets of the crank angle sensors and when welding on

the engine. Power supply to a single cylinder can be stopped even with running engine,