Professional Documents

Culture Documents

Electric Power Cables

Uploaded by

VENKATESAN ROriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electric Power Cables

Uploaded by

VENKATESAN RCopyright:

Available Formats

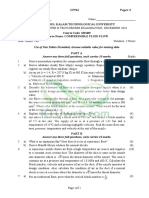

Basic components of electric power cables Power Systems

Figure 4.1 Generic representation of a electric power cable. The submarine power AC cables have an important role in offshore wind energy. Furthermore, the submarine cables are the main difference between the offshore wind farms transmission system and onshore wind farms transmission system. Therefore, a proper submarine cable model is crucial to perform accurate evaluations of the offshore wind farms collector and transmission systems. So, in the present chapter the different options to model a submarine cable are evaluated and their accuracy is discussed. Then based on an accurate and validated submarine cable model, an analysis about the reactive power management in submarine power transmission lines is carried out. Thus, taken into account active power losses, the reactive power generated in the transmission system and the voltage drop for three different reactive power management options, a reactive power compensation option is proposed. Basic components of electric power cables The purpose of a power cable is to carry electricity safely from the power source to different loads. In order to accomplish this goal, the cable is made up with some components or parts. Figure 4.1 shows a description of the cable components, which are: Conductor: The conductor is referred to the part or parts of the cable which carry the electric power. Electric cables can be made up by one conductor (mono-phase cables), three (threephase cables), four, etc.

Insulation: Dielectric material layer with the purpose of insulate conductors of different phases or between phases and ground. Shield: metal coating, which covers the entire length of the cable. It is used to confine the electric field inside the cable and distribute uniformly this field. Armor or sheath: Layer of heavy duty material used to protect the components of the cable for the external environment. Conductor Some materials, especially metals, have huge numbers of electrons that can move through the material freely. These materials have the capability to carry electricity from one object to another and are called conductors. Thus, conductor is called to the part or parts of the cable which carry electric power. The conductor may be solid or made up with various strands twisted together. The strand can be concentric, compressed, compacted, segmental, or annular to achieve desired properties of flexibility, diameter, and current density. The choice of the material as a conductor depends on: its electrical characteristics (capability to carry electricity), mechanical characteristics (resistance to wear, malleability), the specific use of the conductor and its cost. The classification of electric conductors depends on the way the conductor is made up. As a result, the conductors can be classified as Classification by construction characteristics Solid conductor: Conductor made up with only one conductor strand.

Figure 4.2 Conductor made up with Only one conductor strand. Strand conductor: Conductor made up with several low section strands twisted together. This kind of conductor has bigger flexibility than solid conductor.

Figure 4.3 Conductor made up with several low section strands twisted together. Classification by the number of conductors Mono-conductor: Conductor with only one conductive element, with insulation and with or without sheath.

Figure 4.4 Conductor with Only one conductive element. Multiple-conductor: Conductor with two or more conductive elements, with insulation and with one or more sheaths.

Figure 4.5 Conductor with multiple conductive elements. Insulation The purpose of the insulation is to prevent the electricity flow through it. So the insulation is used to avoid the conductor get in touch with people, other conductors with different voltages, objects, artifacts or other items.

Air insulated conductors A metallic conductor suspended from insulating supports, surrounded by air, and carrying electric power may be considered as the simplest case of an insulated conductor Air is not a very good insulating material since it has lower voltage breakdown strength than many other insulating materials, but it is low in cost if space is not a constraint. On the contrary, if the space is a constraint, the air is replaced as insulation material for another material with higher voltage breakdown strength . The same occurs in environments where isolation by air is not possible like submarine cables. In this case neither is possible isolation by sea water, since it is not an insulating material.

Air insulated conductor. Insulation by covering the conductor with a dielectric material In this type of insulation, the conductor is covered by an insulating material with high voltage breakdown strength (a dielectric), usually a polymer.

If the metallic conductor is covered with an insulating material, transmission lines can be placed close to ground or touching the ground. But in this cases when the ground plane is brought close or touches the covering, the electric field lines become increasingly distorted. Considering the equipotential lines of the electric field, these are bended due to the potential difference on the covering surface. As shown At low voltages, the effect is negligible. As the voltage increases, the point is reached where the potential gradients are enough to cause current to flow across the surface of the covering. This is commonly known as tracking. Even though the currents are small, the high surface resistance causes heating to take place which ultimately damages the covering. If this condition is allowed to continue, eventually the erosion may progress to failure

Equipotential lines of the conductors electric field when the transmission line is close to the ground. Therefore, high voltage power cables close to ground, like submarine cables, are provided with a shield to avoid this effect. Source: Energy Transmission and Grid Integration of AC

You might also like

- Power AC Transmission Lines: 3.4 Chapter ConclusionsDocument49 pagesPower AC Transmission Lines: 3.4 Chapter ConclusionsHassenNo ratings yet

- Power Cable EngineeringDocument38 pagesPower Cable EngineeringjaimeNo ratings yet

- New Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringFrom EverandNew Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringNo ratings yet

- Chapter 3 (Parameters of TX Lines)Document83 pagesChapter 3 (Parameters of TX Lines)Nati Man DejeneNo ratings yet

- Optimal Shunt Capacitor Placement for Reactive Power ImprovementDocument55 pagesOptimal Shunt Capacitor Placement for Reactive Power ImprovementKira Chakuri100% (1)

- Transmission Line Losses Explained: Copper, Dielectric, RadiationDocument1 pageTransmission Line Losses Explained: Copper, Dielectric, RadiationLG TVNo ratings yet

- LMSHarmonisationPhase2Study MEADocument38 pagesLMSHarmonisationPhase2Study MEAasawinrajaNo ratings yet

- Kelvin LawDocument6 pagesKelvin LawAbdul AlimNo ratings yet

- Cable Layout and System Design (High Voltage XLPE Cable Systems Techincal User Guide) 13-09-17Document6 pagesCable Layout and System Design (High Voltage XLPE Cable Systems Techincal User Guide) 13-09-17anamulk-1No ratings yet

- OH2UGDocument17 pagesOH2UGasawinrajaNo ratings yet

- Busbar TrunkingDocument9 pagesBusbar TrunkingCivilBoy BijayNo ratings yet

- CRGODocument15 pagesCRGOipraoNo ratings yet

- 04504772-Standardization of Benchmarks For Protective Device Time-Current CurvesDocument11 pages04504772-Standardization of Benchmarks For Protective Device Time-Current CurvesDar Win100% (1)

- Insulation Coordination Studies for a 132 kV Submarine CableDocument4 pagesInsulation Coordination Studies for a 132 kV Submarine CableJjjjpf100% (1)

- Power InverterDocument11 pagesPower Inverterriz2010No ratings yet

- GIS Vs AIS SubstationDocument2 pagesGIS Vs AIS SubstationVENKATESAN RNo ratings yet

- Capacitors: Schematic Symbols +Document5 pagesCapacitors: Schematic Symbols +lam9021No ratings yet

- Permanent / Fixed Technical LossesDocument11 pagesPermanent / Fixed Technical Lossesyogesh100% (1)

- Power Quality TechniquesDocument9 pagesPower Quality TechniquesS Bharadwaj ReddyNo ratings yet

- Design of LVDC Distribution Network Lab TrainerDocument52 pagesDesign of LVDC Distribution Network Lab TrainerAhmad TouqirNo ratings yet

- Loss Evaluation of HVAC and HVDC Transmission Solutions For Large Offshore Wind FarmsDocument11 pagesLoss Evaluation of HVAC and HVDC Transmission Solutions For Large Offshore Wind Farmsmohon_eee03100% (2)

- GTU B.E. Semester VI High Voltage EngineeringDocument3 pagesGTU B.E. Semester VI High Voltage EngineeringRavi PatelNo ratings yet

- LONG-LIFE XLPE INSULATED POWER CABLEDocument6 pagesLONG-LIFE XLPE INSULATED POWER CABLEbitconceptsNo ratings yet

- Review of Last Class: Electrical Characteristics of CablesDocument15 pagesReview of Last Class: Electrical Characteristics of CablesnnvpratapNo ratings yet

- 87 CT Class ExplanationDocument11 pages87 CT Class ExplanationdskymaximusNo ratings yet

- % Impedance of Power Transformer PDFDocument9 pages% Impedance of Power Transformer PDFtobyNo ratings yet

- Failures of Pedestal-Type (Pin and Cap) InsulatorsDocument2 pagesFailures of Pedestal-Type (Pin and Cap) InsulatorsJosé SánchezNo ratings yet

- Transmission LineDocument89 pagesTransmission LineUbaid RaufNo ratings yet

- Complete Overview of Lightning Arrester 3Document9 pagesComplete Overview of Lightning Arrester 3VENKATESAN RNo ratings yet

- Understanding Transformer PolarityDocument3 pagesUnderstanding Transformer PolarityVENKATESAN R100% (1)

- ELEC4611-15-Lec2 - Electric Stress in HV EquipmentDocument24 pagesELEC4611-15-Lec2 - Electric Stress in HV EquipmentPeterNo ratings yet

- Transformer DesigneDocument6 pagesTransformer Designemhm770077No ratings yet

- Report Presentation MSETCL KalwaDocument38 pagesReport Presentation MSETCL KalwaManish Kumar Bhardwaj100% (1)

- A2.24 Thermal PerformancesID55VER20Document15 pagesA2.24 Thermal PerformancesID55VER20Fajar Adi PrabowoNo ratings yet

- TOR-WG+B1 38+After+laying+tests+on+AC+and+DC+cable+systems+with+new+technologiesDocument2 pagesTOR-WG+B1 38+After+laying+tests+on+AC+and+DC+cable+systems+with+new+technologiesWalter CataldoNo ratings yet

- Theoretical Model for Assessing Zinc Layer Thickness in Overhead Power Line ConductorsDocument6 pagesTheoretical Model for Assessing Zinc Layer Thickness in Overhead Power Line Conductorsdeathjester1No ratings yet

- Early Radio Receivers, Called Crystal Radios, Used A "Cat's Whisker" of Fine Wire Pressing On A Crystal ofDocument4 pagesEarly Radio Receivers, Called Crystal Radios, Used A "Cat's Whisker" of Fine Wire Pressing On A Crystal ofPoonam bhavsarNo ratings yet

- MV Power CablesDocument32 pagesMV Power CablesMuhammad AlshafiNo ratings yet

- BalanisDocument6 pagesBalanisfabianorbNo ratings yet

- EENG611-10-Chapter 13Document17 pagesEENG611-10-Chapter 13bazzazNo ratings yet

- Trafo Spec PDFDocument56 pagesTrafo Spec PDFMohammad Fadhil KoesputraNo ratings yet

- CT ReqDocument50 pagesCT ReqRanjith KumarNo ratings yet

- Power Transmission Over Long Distances With CablesDocument8 pagesPower Transmission Over Long Distances With CablesramsesiNo ratings yet

- Design of VCBDocument14 pagesDesign of VCBAniruth100% (1)

- Total Losses in Power Distribution and Transmission Lines 1Document6 pagesTotal Losses in Power Distribution and Transmission Lines 1Muahmmad ShahzadNo ratings yet

- Mech Design - Cond-LineSupDocument16 pagesMech Design - Cond-LineSupAreyan HaqueNo ratings yet

- FIST5-14 Arc Flash Hazard Program, May 2011Document89 pagesFIST5-14 Arc Flash Hazard Program, May 2011jfejfeNo ratings yet

- BUS Ele Tech Lib Conductor Protection Wire Cable Protection 1Document3 pagesBUS Ele Tech Lib Conductor Protection Wire Cable Protection 1Víctor RojasNo ratings yet

- 10 Application of ACSR Trapezoidal Wire Conductor For A 500-KV Transmission LineDocument2 pages10 Application of ACSR Trapezoidal Wire Conductor For A 500-KV Transmission LineDante Filho100% (1)

- Lighting Circuits Guide: Selection, Dimensioning and Management With Simple SolutionsDocument76 pagesLighting Circuits Guide: Selection, Dimensioning and Management With Simple Solutionsjiwani87100% (1)

- HVDC Transmission and FACTS Devices LectureDocument22 pagesHVDC Transmission and FACTS Devices LectureKiran KunchamNo ratings yet

- Cable Impedance Calculations - Open ElectricalDocument4 pagesCable Impedance Calculations - Open Electricaludayakumart100% (1)

- Power Application TB08104003EDocument114 pagesPower Application TB08104003Eap00No ratings yet

- Zahra-HV Cables - Aug 2010Document66 pagesZahra-HV Cables - Aug 2010Yvonne TohNo ratings yet

- 2004 Doble Paper 3.16.04Document11 pages2004 Doble Paper 3.16.04KUNALJAY100% (1)

- 16 Personal Protective Grounding For Electric Power Facilities and PowerDocument89 pages16 Personal Protective Grounding For Electric Power Facilities and PowerSumer LandNo ratings yet

- Typical Noise Levels in Power SubstationDocument2 pagesTypical Noise Levels in Power SubstationVENKATESAN RNo ratings yet

- AIS - Air Insulated SubstationsDocument3 pagesAIS - Air Insulated Substationssandeep_03638No ratings yet

- Gas Insulated Transmission Line GILDocument3 pagesGas Insulated Transmission Line GILVENKATESAN RNo ratings yet

- Moving Iron InstrumentsDocument5 pagesMoving Iron InstrumentsVENKATESAN RNo ratings yet

- Complete Overview of Lightning Arrester 3Document9 pagesComplete Overview of Lightning Arrester 3VENKATESAN RNo ratings yet

- Primary DistributionDocument6 pagesPrimary DistributionVENKATESAN RNo ratings yet

- Current TransformersDocument4 pagesCurrent TransformersVENKATESAN R100% (1)

- AC Adjustable Speed DriveDocument5 pagesAC Adjustable Speed DriveVENKATESAN RNo ratings yet

- Complete Overview of Lightning Arrester 2Document7 pagesComplete Overview of Lightning Arrester 2VENKATESAN RNo ratings yet

- CT PT Metering SetDocument5 pagesCT PT Metering SetVENKATESAN RNo ratings yet

- Improve Power Transfer With Shunt Capacitor BanksDocument2 pagesImprove Power Transfer With Shunt Capacitor BanksVENKATESAN RNo ratings yet

- Difference Between Power Transformer and Distribution TransformerDocument2 pagesDifference Between Power Transformer and Distribution TransformerMidhun VargheseNo ratings yet

- Protective Grounding RequirementsDocument1 pageProtective Grounding RequirementsVENKATESAN RNo ratings yet

- Understanding Transformer PolarityDocument3 pagesUnderstanding Transformer PolarityVENKATESAN R100% (1)

- What Is The Difference Between MCBDocument7 pagesWhat Is The Difference Between MCBVENKATESAN RNo ratings yet

- GIS Vs AIS SubstationDocument2 pagesGIS Vs AIS SubstationVENKATESAN RNo ratings yet

- What Is The Static Var CompensatorDocument3 pagesWhat Is The Static Var CompensatorVENKATESAN RNo ratings yet

- Reasons For Substation Grounding SystemDocument1 pageReasons For Substation Grounding SystemVENKATESAN RNo ratings yet

- What Is The Resonance PhenomenaDocument2 pagesWhat Is The Resonance PhenomenaVENKATESAN RNo ratings yet

- CT'sDocument11 pagesCT'selectricalrakeshNo ratings yet

- Transformer Vector GroupDocument11 pagesTransformer Vector GroupVENKATESAN RNo ratings yet

- Neutral Grounding ResistorsDocument1 pageNeutral Grounding ResistorsVENKATESAN RNo ratings yet

- Tan Delta TestingDocument2 pagesTan Delta TestingNillutpal BoruahNo ratings yet

- Power SysDocument2 pagesPower SysVivek GuptaNo ratings yet

- Motor StartingDocument16 pagesMotor StartingVENKATESAN RNo ratings yet

- System Neutral GroundingDocument4 pagesSystem Neutral GroundingVENKATESAN RNo ratings yet

- Fault Analysis On LVDocument15 pagesFault Analysis On LVVENKATESAN RNo ratings yet

- Short Circuit CalculationDocument18 pagesShort Circuit CalculationVENKATESAN RNo ratings yet

- Understanding Vector Group of Transformer FullDocument14 pagesUnderstanding Vector Group of Transformer FullVENKATESAN R100% (2)

- AHRI Standard 350-2015 - (R2021)Document17 pagesAHRI Standard 350-2015 - (R2021)TamNo ratings yet

- BMX DAI 1604 Input Modules: Subject of This SectionDocument6 pagesBMX DAI 1604 Input Modules: Subject of This SectionLeonardo NeiraNo ratings yet

- ITI Basics - 2-09Document66 pagesITI Basics - 2-09peloquin1349391No ratings yet

- Hydraulic LabDocument14 pagesHydraulic LabAbdallah AlhasanNo ratings yet

- 2SK2876-01MR: FAP-IIS SeriesDocument3 pages2SK2876-01MR: FAP-IIS Seriesgilberto gutierrezNo ratings yet

- Universiti Malaysia Pahang: Faculty of Mechanical EngineeringDocument13 pagesUniversiti Malaysia Pahang: Faculty of Mechanical EngineeringFirdaus IliasNo ratings yet

- 400A Diesel Welding MachineDocument3 pages400A Diesel Welding MachineSuristiono WidjayaNo ratings yet

- HP SondeDocument12 pagesHP SondeNamik HadziibrahimovicNo ratings yet

- Use of Gas Tables Permitted, Assume Suitable Value For Missing DataDocument2 pagesUse of Gas Tables Permitted, Assume Suitable Value For Missing DataVenkitaraj K PNo ratings yet

- Morocco-UK Power Project - XlinksDocument11 pagesMorocco-UK Power Project - XlinksLouis gaoNo ratings yet

- Electrostatic and Electromagnetic Forces: Electronic Address: Tim - Henley@mail - Utoronto.caDocument9 pagesElectrostatic and Electromagnetic Forces: Electronic Address: Tim - Henley@mail - Utoronto.caTimothy Murray HenleyNo ratings yet

- Technical Data: 1300 Series Edi 1306C-E87Tag4Document8 pagesTechnical Data: 1300 Series Edi 1306C-E87Tag4mahmoud khtaNo ratings yet

- GENPHY2 - Lesson - Ohm's Law and ResistanceDocument3 pagesGENPHY2 - Lesson - Ohm's Law and ResistanceJazmaine SimbulanNo ratings yet

- 10th Physics Chapter 10 (PTB +FTB)Document10 pages10th Physics Chapter 10 (PTB +FTB)mayarali2112006No ratings yet

- Lecture 7Document23 pagesLecture 7Shahab HassanNo ratings yet

- Kinetic Theory of GasDocument4 pagesKinetic Theory of GasTawhidul AlamNo ratings yet

- Mhi FD & KX Error Codes - R410aDocument5 pagesMhi FD & KX Error Codes - R410atvassilopoulosNo ratings yet

- D16.7 Relative Motion Analysis - AccelerationDocument5 pagesD16.7 Relative Motion Analysis - AccelerationAbdullah AlotaibiNo ratings yet

- Three-phase motor data sheetDocument1 pageThree-phase motor data sheetatlas tajhizNo ratings yet

- (2001) (Sun) (Two-Group Interfacial Area Transport Equation For A Confined Test Section)Document367 pages(2001) (Sun) (Two-Group Interfacial Area Transport Equation For A Confined Test Section)Erol BicerNo ratings yet

- BahanKuliah 2BDocument74 pagesBahanKuliah 2BAsep RNo ratings yet

- Module 1 PhysicsDocument12 pagesModule 1 PhysicsCasimero CabungcalNo ratings yet

- LaGrange Method Finds Sphere Terminal VelocityDocument10 pagesLaGrange Method Finds Sphere Terminal Velocityotis-a2No ratings yet

- 2020 03 Maintworld AdashDocument2 pages2020 03 Maintworld AdashaabejaroNo ratings yet

- EE 370 Electronic Instrument Assignment 3Document1 pageEE 370 Electronic Instrument Assignment 3vineet mishraNo ratings yet

- 300/500ma Low Dropout Linear Voltage Regulator: General Description FeaturesDocument11 pages300/500ma Low Dropout Linear Voltage Regulator: General Description FeaturesPedro RodriguezNo ratings yet

- Testing and Performance Assessment of 1KWp Solar Rooftop SystemDocument5 pagesTesting and Performance Assessment of 1KWp Solar Rooftop Systemsoumen sardarNo ratings yet

- Lab Mannual Melde's ExperimentDocument13 pagesLab Mannual Melde's Experimentheartwinner50% (18)

- (Power Electronics and Applications Series) Bianchi, Nicola - Electrical Machine Analysis Using Finite Elements-CRC Press (2005)Document298 pages(Power Electronics and Applications Series) Bianchi, Nicola - Electrical Machine Analysis Using Finite Elements-CRC Press (2005)Prince KumarNo ratings yet

- AB1019 Supercapacitors in Smart MetersDocument2 pagesAB1019 Supercapacitors in Smart MeterseyadNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeFrom EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeRating: 4 out of 5 stars4/5 (130)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- ISO 50001: A strategic guide to establishing an energy management systemFrom EverandISO 50001: A strategic guide to establishing an energy management systemNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Solar Electricity Basics: Powering Your Home or Office with Solar EnergyFrom EverandSolar Electricity Basics: Powering Your Home or Office with Solar EnergyRating: 5 out of 5 stars5/5 (3)