Professional Documents

Culture Documents

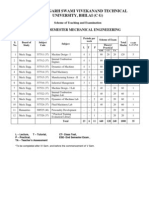

Me53 Design of Machine Elements L T P C

Uploaded by

ajithjkingsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Me53 Design of Machine Elements L T P C

Uploaded by

ajithjkingsCopyright:

Available Formats

ME53 DESIGN OF MACHINE ELEMENTS

LTPC 3104

OBJECTIVE: To familiarise the various steps involved in the Design Process To understand the principles involved in evaluating the shape and dimensions of a component to satisfy functional and strength requirements. To learn to use standard practices and standard data To learn to use catalogues and standard machine components UNIT I STEADY STRESSES AND VARIABLE STRESSES IN MACHINE MEMBERS 9 Introduction to the design process - factor influencing machine design, selection of materials based on mechanical properties -- Preferred numbers, fits and tolerances Direct, Bending and torsional stress equations Impact and shock loading calculation of principle stresses for various load combinations, eccentric loading Design of curved beams crane hook and C frame - Factor of safety - theories of failure stress concentration design for variable loading Soderberg, Goodman and Gerber relations

9

UNIT II DESIGN OF SHAFTS AND COUPLINGS 10 Design of solid and hollow shafts based on strength, rigidity and critical speed Design of keys, key ways and splines - Design of crankshafts -- Design of rigid and flexible couplings. UNIT III DESIGN OF TEMPORARY AND PERMANENT JOINTS 9 Threaded fastners - Design of bolted joints including eccentric loading, Knuckle joints, Cotter joints Design of welded joints, riveted joints for structures - theory of bonded joints. UNIT IV DESIGN OF ENERGY STORING ELEMENTS 8 Design of various types of springs, optimization of helical springs -- rubber springs -Design of flywheels considering stresses in rims and arms, for engines and punching machines. UNIT V DESIGN OF BEARINGS AND MISCELLANEOUS ELEMENTS 9 Sliding contact and rolling contact bearings -- Design of hydrodynamic journal bearings, McKee's Eqn., Sommerfield Number, Raimondi & Boyd graphs, -- Selection of Rolling Contact bearings -- Design of Seals and Gaskets -- Design of Connecting Rod. TUTORIAL: 15 TOTAL: 60 PERIODS Note: (Use of P S G Design Data Book is permitted in the University examination) TEXT BOOKS: 1. Shigley J.E and Mischke C. R., Mechanical Engineering Design, Sixth Edition, Tata McGraw-Hill , 2003. 2. Bhandari V.B, Design of Machine Elements, Second Edition, Tata McGraw-Hill Book Co, 2007. REFERENCES: 1. Sundararajamoorthy T. V, Shanmugam .N, "Machine Design", Anuradha Publications, Chennai, 2003. 2. Orthwein W, Machine Component Design, Jaico Publishing Co, 2003. 3. Ugural A.C, Mechanical Design An Integral Approach, McGraw-Hill Book Co, 2004. 4. Spotts M.F., Shoup T.E Design and Machine Elements Pearson Education, 2004. STANDARDS: 1. IS 10260 : Part 1 : 1982 Terms, definitions and classification of Plain bearings Part 1 : Construction. 2. IS 10260 : Part 1 : 1982 Terms, definitions and classification of Plain bearings Part 2 : Friction and Wear. 3. IS 10260 : Part 1 : 1982 Terms, definitions and classification of Plain bearings Part 3 : Lubrication. ME 34 FLUID MECHANICS AND MACHINERY 3104

(Common to Aeronautical, Mechanical, Automobile & Production)

OBJECTIVES a. The student is introduced to the mechanics of fluids through a thorough understanding of the properties of the fluids. The dynamics of fluids is introduced through the control volume approach which gives an integrated under standing of the transport of mass, momentum and energy. b. The applications of the conservation laws to flow though pipes and hydraulics machines are studied UNIT I INTRODUCTION 12 Units & Dimensions. Properties of fluids Specific gravity, specific weight, viscosity, compressibility, vapour pressure and gas laws capillarity and surface tension. Flow characteristics: concepts of system and control volume. Application of control volume to continuity equiation, energy equation, momentum equation and moment of momentum equation. UNIT II FLOW THROUG CIRCULAR CONDUITS 12 Laminar flow though circular conduits and circular annuli. Boundary layer concepts. Boundary layer thickness. Hydraulic and energy gradient. Darcy Weisbach equaition. Friction factor and Moody diagram. Commercial pipes. Minor losses. Flow though pipes in series and in parallel. UNIT III DIMENSIONAL ANALYSIS 9 Dimension and units: Buckinghams theorem. Discussion on dimensionless parameters. Models and similitude. Applications of dimensionless parameters. UNIT IV ROTO DYNAMIC MACHINES 16 Homologus units. Specific speed. Elementary cascade theory. Theory of turbo machines. Eulers equation. Hydraulic efficiency. Velocity components at the entry and exit of the rotor. Velocity triangle for single stage radial flow and axial flow machines. Centrifugal pumps, turbines, performance curves for pumps and turbines. UNIT V POSITIVE DISPLACEMENT MACHINES 11 Recriprocating pumps, Indicator diagrams, Work saved by air vessels. Rotory pumps. Classification. Working and performance curves. TOTAL :60 PERIODS TEXT BOOKS: 1. Streeter. V. L., and Wylie, E.B., Fluid Mechanics, McGraw Hill, 1983. 2. Rathakrishnan. E, Fluid Mechanics, Prentice Hall of India (II Ed.), 2007. REFERENCES: 1. Ramamritham. S, Fluid Mechanics, Hydraulics and Fluid Machines, Dhanpat Rai & Sons, Delhi, 1988. 2. Kumar. K.L., Engineering Fluid Mechanics (VII Ed.) Eurasia Publishing House (P) Ltd., New Delhi, 1995. 3. Bansal, R.K., Fluid Mechanics and Hydraulics Machines, Laxmi Publications (P) Ltd., New Delhi.

You might also like

- New Microsoft Word DocumentDocument3 pagesNew Microsoft Word Documentraja sekaranNo ratings yet

- Anna University Coimbatore REGULATIONS 2007-08 B.E - Mechanical EngineeringDocument28 pagesAnna University Coimbatore REGULATIONS 2007-08 B.E - Mechanical EngineeringRaajeshkrishnaNo ratings yet

- ME6352 Manufacturing Technology LTPC 3 0 0 3 ObjectivesDocument14 pagesME6352 Manufacturing Technology LTPC 3 0 0 3 ObjectivespugazhNo ratings yet

- B.Tech Machine Design SyllabusDocument25 pagesB.Tech Machine Design SyllabusSanketHedduriNo ratings yet

- Design of Machine ElementsDocument12 pagesDesign of Machine Elementssirajudeen INo ratings yet

- Text Books:: 2. Ansel Ugural, "Mechanical Design - An Integral Approach", 1 Edition, Tata Mcgraw-Hill Book Co, 2003Document6 pagesText Books:: 2. Ansel Ugural, "Mechanical Design - An Integral Approach", 1 Edition, Tata Mcgraw-Hill Book Co, 2003Liaqat ahmedNo ratings yet

- Mech 6th Sem SyllabusDocument14 pagesMech 6th Sem SyllabusArun ManoNo ratings yet

- Syllabus Automobile EngineeringDocument54 pagesSyllabus Automobile EngineeringmechanzsNo ratings yet

- Design SyllabusDocument1 pageDesign SyllabusManoj PepiNo ratings yet

- Me2302 Dynamics of Machinery L T P CDocument3 pagesMe2302 Dynamics of Machinery L T P Ckumar kmNo ratings yet

- 19me501 DmeDocument3 pages19me501 Dmesathish kumarNo ratings yet

- AutomobileDocument33 pagesAutomobilemarinerajesh3022No ratings yet

- M.E. AutomobileDocument33 pagesM.E. AutomobileJeyaram KumarNo ratings yet

- Mech 5semDocument16 pagesMech 5sembhuvansparksNo ratings yet

- Syllabus - Mech 3rd YearDocument130 pagesSyllabus - Mech 3rd YearAbhishek AmarNo ratings yet

- Black 2nd Ed Machine DesignDocument488 pagesBlack 2nd Ed Machine DesignjaysonbanlasancryptoNo ratings yet

- Transverse Loads, Vibrations of Beams With Concentrated and Distributed Loads. Dunkerly's Methods, Raleigh's MethodDocument7 pagesTransverse Loads, Vibrations of Beams With Concentrated and Distributed Loads. Dunkerly's Methods, Raleigh's Methodsanyasirao1No ratings yet

- Chhattisgarh Technical University B.E. Mechanical 5th Sem Subject SchemeDocument14 pagesChhattisgarh Technical University B.E. Mechanical 5th Sem Subject Schemeveer_sNo ratings yet

- B.Tech II Year Mechanical Engineering Study Scheme for Sem IVDocument6 pagesB.Tech II Year Mechanical Engineering Study Scheme for Sem IVRoshan Virat PandeyNo ratings yet

- General Ability Test (Common For All Streams EC, ME, Ee, Ce) Part A: General English: TheDocument18 pagesGeneral Ability Test (Common For All Streams EC, ME, Ee, Ce) Part A: General English: ThevqxknpnkNo ratings yet

- Me2204 Fluid Mechanics and Machinery SyllabusDocument1 pageMe2204 Fluid Mechanics and Machinery SyllabusrajapratyNo ratings yet

- DTS Syllabus12122011Document1 pageDTS Syllabus12122011ntsdharmaNo ratings yet

- Machine Design SyllabusDocument2 pagesMachine Design SyllabusssjNo ratings yet

- Fluid Mechanics and Machinery: Understanding Flow in Pumps & TurbinesDocument3 pagesFluid Mechanics and Machinery: Understanding Flow in Pumps & TurbinesTHIRUMALAINo ratings yet

- Devi Ahilya Vishwavidyalaya, I Dore I Stitute of E Gi Eeri G & Tech OlogyDocument20 pagesDevi Ahilya Vishwavidyalaya, I Dore I Stitute of E Gi Eeri G & Tech OlogySonal MahajanNo ratings yet

- ME 314 Design of Machine Elements (3-0-0-6) : TextsDocument9 pagesME 314 Design of Machine Elements (3-0-0-6) : TextsKrishna MurthyNo ratings yet

- Gas Power Cycles: Carnot Cycle, Diesel Cycle, Dual Cycle, Brayton Cycle, Cyclecalculations & Analysis Unit-IiiDocument6 pagesGas Power Cycles: Carnot Cycle, Diesel Cycle, Dual Cycle, Brayton Cycle, Cyclecalculations & Analysis Unit-Iiiapi-19815017No ratings yet

- Design of Fluid Power Systems for Industrial ApplicationsDocument2 pagesDesign of Fluid Power Systems for Industrial ApplicationsMurugan ShanmugamNo ratings yet

- 073 - ME6601 Design of Transmission Systems - Anna University 2013 Regulation SyllabusDocument2 pages073 - ME6601 Design of Transmission Systems - Anna University 2013 Regulation SyllabusM A JomahNo ratings yet

- B Tech Semester 5 2015-19Document30 pagesB Tech Semester 5 2015-19api-294538209No ratings yet

- Course Module (VI Sem)Document7 pagesCourse Module (VI Sem)Vijay KumawatNo ratings yet

- Machine Elements Design GuideDocument248 pagesMachine Elements Design GuideKrishnan P MNo ratings yet

- Design of Machine ElementDocument1 pageDesign of Machine ElementUjjwal ShuklaNo ratings yet

- B.Tech. Mechanical Engineering IV Semester S.No Subject Name and CodeDocument8 pagesB.Tech. Mechanical Engineering IV Semester S.No Subject Name and CodeGuru MaheshNo ratings yet

- r17 III-i SyllabusDocument19 pagesr17 III-i SyllabusAvinash RNo ratings yet

- Mechanical Engineering Department, NIT Srinagar: 5 SemesterDocument8 pagesMechanical Engineering Department, NIT Srinagar: 5 SemesterBISMA ZARGARNo ratings yet

- Semester VDocument14 pagesSemester VAbhishek GuptaNo ratings yet

- dESIGN OF MC ELEMENTS PDFDocument46 pagesdESIGN OF MC ELEMENTS PDFlogeshboy007No ratings yet

- Syllabus PDFDocument66 pagesSyllabus PDFPardeep KumarNo ratings yet

- 6TH SEM SyllabusDocument35 pages6TH SEM Syllabussrujangowdasj2002No ratings yet

- B. Tech. 8 Semester Mechanical Engineering: Theory Sessional TotalDocument10 pagesB. Tech. 8 Semester Mechanical Engineering: Theory Sessional TotalAbhishek MeNo ratings yet

- Syllabus Mechanical Automobile Eng Guj For Advt 12 2012 13Document6 pagesSyllabus Mechanical Automobile Eng Guj For Advt 12 2012 13sandeep198989No ratings yet

- Automobile 5th Syllabus CsvtuDocument9 pagesAutomobile 5th Syllabus CsvtuTejasvi AnantNo ratings yet

- Iii Mech Vi Sem QB 2013 2014 Even PDFDocument137 pagesIii Mech Vi Sem QB 2013 2014 Even PDFSiva RamanNo ratings yet

- Ce6451 Fluid Mechanics and Machinery L T P C 3 0 0 3: ObjectivesDocument3 pagesCe6451 Fluid Mechanics and Machinery L T P C 3 0 0 3: Objectiveskumar kmNo ratings yet

- Production ElectivesDocument20 pagesProduction ElectivesAdhi ThyanNo ratings yet

- Design of Machine Members - Syllabus PDFDocument3 pagesDesign of Machine Members - Syllabus PDFVAIBHAV TIWARINo ratings yet

- Sem 6 SyllabusDocument6 pagesSem 6 SyllabusRangan SrinivasanNo ratings yet

- Syllabus - BE Mech II Wef 2012-13 PDFDocument28 pagesSyllabus - BE Mech II Wef 2012-13 PDFPavan KishoreNo ratings yet

- Design Machine ElementsDocument7 pagesDesign Machine ElementsNinad PawarNo ratings yet

- Mech Engg Syllabus Modified (R10) 11.3.2012Document57 pagesMech Engg Syllabus Modified (R10) 11.3.2012Srimanthula SrikanthNo ratings yet

- Track/Train Dynamics and Design: Advanced TechniquesFrom EverandTrack/Train Dynamics and Design: Advanced TechniquesGerald J. MoyarNo ratings yet

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Fea RDocument21 pagesFea RajithjkingsNo ratings yet

- RSM Based Comparative Experimental Study of Sustainable Biodiesel Synthesis From Different 2G Feedstocks Using Magnetic Nanocatalyst Cafe ODocument1 pageRSM Based Comparative Experimental Study of Sustainable Biodiesel Synthesis From Different 2G Feedstocks Using Magnetic Nanocatalyst Cafe OajithjkingsNo ratings yet

- L.R. Monisha Miriam, Ajith J. Kings, R. Edwin Raj, M. Adhi ViswanathanDocument1 pageL.R. Monisha Miriam, Ajith J. Kings, R. Edwin Raj, M. Adhi ViswanathanajithjkingsNo ratings yet

- Sustainable Biodiesel Production From Ceiba Penandra, Mahua Longifolia, and Azadirachta Indica Using Cao-Tio Nano CatalystDocument1 pageSustainable Biodiesel Production From Ceiba Penandra, Mahua Longifolia, and Azadirachta Indica Using Cao-Tio Nano CatalystajithjkingsNo ratings yet

- Carbohydrate Polymer Technologies and Applications: Enterobacter CloacaeDocument1 pageCarbohydrate Polymer Technologies and Applications: Enterobacter CloacaeajithjkingsNo ratings yet

- Energy Conversion and Management: Ajith J. Kings, R. Edwin Raj, L.R. Monisha Miriam, M. Adhi VisvanathanDocument1 pageEnergy Conversion and Management: Ajith J. Kings, R. Edwin Raj, L.R. Monisha Miriam, M. Adhi VisvanathanajithjkingsNo ratings yet

- Energy Conversion and Management: L.R. Monisha Miriam, R. Edwin Raj, Ajith J. Kings, M. Adhi VisvanathanDocument1 pageEnergy Conversion and Management: L.R. Monisha Miriam, R. Edwin Raj, Ajith J. Kings, M. Adhi VisvanathanajithjkingsNo ratings yet

- Net Zero Co2 Emissions of CHP, GHP and Biogas Plant - SierikovaDocument19 pagesNet Zero Co2 Emissions of CHP, GHP and Biogas Plant - SierikovaGogyNo ratings yet

- Newtonian Fluids PDFDocument5 pagesNewtonian Fluids PDFengineer bilalNo ratings yet

- ASHRAE Standard 22-2007 - Methods of Testing For Rating Water-Cooled Refrigerant CondensersDocument10 pagesASHRAE Standard 22-2007 - Methods of Testing For Rating Water-Cooled Refrigerant CondensersDžana KadrićNo ratings yet

- Process Dynamics and ControlDocument7 pagesProcess Dynamics and ControlTitilope Oreoluwa MorolariNo ratings yet

- KWU Steam Turbine Governing System 210 X 4 MW HtpsDocument86 pagesKWU Steam Turbine Governing System 210 X 4 MW HtpsAneesh CR100% (1)

- 24장 연습문제 풀이Document8 pages24장 연습문제 풀이전찬이No ratings yet

- Wet Compression Boosts Combustion Turbine CapacityDocument11 pagesWet Compression Boosts Combustion Turbine CapacityMario TermicaNo ratings yet

- 312CL Hyd SchematicDocument2 pages312CL Hyd SchematicEmmanuel solomon100% (1)

- Ametek Model 3050OLVRev2Document2 pagesAmetek Model 3050OLVRev2Yanto Hasudungan LumbantobingNo ratings yet

- AE8404 Propulsion I 2Document3 pagesAE8404 Propulsion I 2Chris Lenard92No ratings yet

- Vacuum Pump Systems BrochureDocument10 pagesVacuum Pump Systems BrochureMelissa WilliamsNo ratings yet

- Relief Valves For Centrifugal Pumps According To NFPA 20 - Fire Protection SpecialistsDocument1 pageRelief Valves For Centrifugal Pumps According To NFPA 20 - Fire Protection SpecialistsMohamed Abou El hassanNo ratings yet

- 9th Physics FloatationDocument4 pages9th Physics FloatationMuzaFar100% (1)

- SJV-EP-IA-011-VP-003 - DATA SHEET - 190117 - 최종Document15 pagesSJV-EP-IA-011-VP-003 - DATA SHEET - 190117 - 최종Jahangir AlamNo ratings yet

- Venturi Type Flow Meter: SubmittalDocument1 pageVenturi Type Flow Meter: SubmittalrajuNo ratings yet

- Cyclones and Inertial SeparatorsDocument36 pagesCyclones and Inertial SeparatorsShashank SrivastavaNo ratings yet

- Updated Al Brashdi CV April 2023Document4 pagesUpdated Al Brashdi CV April 2023Mohammed BrashdiNo ratings yet

- ONLINE LAB - ME LAB1 EXPT 7 FLOW MEASUREMENT PITOT TUBE MS TEAMSbDocument8 pagesONLINE LAB - ME LAB1 EXPT 7 FLOW MEASUREMENT PITOT TUBE MS TEAMSbJessray RepunteNo ratings yet

- FM200 ADS Engineering ManualDocument142 pagesFM200 ADS Engineering Manualhasanmnh100% (1)

- NIT TIRUCHIRAPPALLI PROCESS CALCULATIONS END SEMESTER EXAMDocument2 pagesNIT TIRUCHIRAPPALLI PROCESS CALCULATIONS END SEMESTER EXAMSujalNo ratings yet

- Ethylene Glycol Production From Synthesis GasDocument1 pageEthylene Glycol Production From Synthesis GasBramJanssen76100% (3)

- Melyza Funes - Cycles of Matter VocabularyDocument3 pagesMelyza Funes - Cycles of Matter Vocabularyapi-450782149No ratings yet

- (AIAA Education Series.) Brian J. Cantwell-Aircraft and Rocket Propulsion-Stanford University (2010)Document335 pages(AIAA Education Series.) Brian J. Cantwell-Aircraft and Rocket Propulsion-Stanford University (2010)awarialocksNo ratings yet

- Form 1325Document7 pagesForm 1325Alex HateganNo ratings yet

- Chemical Conversion of Steel Mill Gases To Urea - An Analysis of Plant CapacityDocument8 pagesChemical Conversion of Steel Mill Gases To Urea - An Analysis of Plant CapacityNestor TamayoNo ratings yet

- CSA Group Hazloc GuideDocument1 pageCSA Group Hazloc GuideMátyás DalnokiNo ratings yet

- Pisoilx 02 en PDFDocument4 pagesPisoilx 02 en PDFJuan BarrientosNo ratings yet

- F 2012081Document2 pagesF 2012081Ahmed SalamaNo ratings yet

- Shell and Tube Heat ExhangerDocument31 pagesShell and Tube Heat ExhangerRohit PhalakNo ratings yet