Professional Documents

Culture Documents

Pssu Manual v.2.0

Uploaded by

gjumbo8787Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pssu Manual v.2.0

Uploaded by

gjumbo8787Copyright:

Available Formats

Release 08/2007 Ver. 2.

Installation Instructions: PSSU Control Unit

PSSU Control Unit

Installation Instructions

INTRODUCTION PSSU control units are designed to be used with Tapeswitch pressure-sensitive sensors, such as ribbon switches, sensing edges, bumpers, and presence-sensing switching mats, to form a complete safety system. A number of sensors can be connected in series. CONTROL UNIT TYPES Four versions of the control unit are available which differ only in their type of enclosure and supply voltage. The PSSU/1 control unit is housed in a DIN rail-mounting enclosure with 16 integral terminals and operates from a 110 or 240 Vac supply. The PSSU/2 control unit uses the same enclosure but operates on a 24 Vdc supply. Both of the above units are intended to be fitted inside an existing electrical enclosure on the machine. This existing enclosure must be sealed to a minimum rating of IP54. The PSSU/3 control unit uses a polycarbonate enclosure sealed to IP67 and operates from a 110 or 240 Vac supply. The PSSU/4 control unit uses the same IP67 enclosure as the PSSU/3 unit but operates from a 24 Vdc supply. Both the above units are intended to be fitted either externally or inside an existing enclosure on the machine. SAFETY INTEGRITY All PSSU control units exceed the requirements of safety integrity level 2 as defined by DIN 31006-1. The control units are self-monitoring, which means that any faults in safety critical components will be detected and will render the machine inoperative until the fault is rectified. However, the safety integrity of the system as a whole depends on the safety integrity of the sensor used, in addition to the proper installation, interface, and application. PRINCIPLE OF OPERATION The control units contain the power supply for the system, the safety output relays and the reset circuit. Figure 1 shows the principle of operation. A 24 Vdc power supply is taken from the control unit to the switching elements in the sensor(s): +ve to one conductor, -ve to the other conductor, and back to the control unit where it supplies power to the output relays. The output contacts of the safety relays are only closed when the output relays are energized. When the sensor(s) is actuated, the 24 Vdc power supply to the output relays is shorted out causing them to de-energize. Furthermore, if the power supply to the output relays is interrupted or shorted out by a fault in the sensor(s) wiring or in the switch elements, power to the output relays will be lost, the relays will deenergize and the output contacts will open. The reset circuit provides start and restart interlock functions as follows: Start Interlock - When power is applied to the system, the output relays cannot be energized until a reset signal has been applied and removed. Restart Interlock - Once the sensor(s) has been actuated and the output relays have de-energized, they cannot be energized again until a reset signal has been applied and removed. Reset will be prevented while the sensor is actuated, if there is a fault in the reset input circuit or if the two output relays are in disparity. The safety output contacts of the control unit are connected to the machine primary control element(s) in such a way that if either of the safety output relays is de-energized then the machine will be brought to rest regardless of the state of the other relay. NOTE: A machine primary control element or MPCE is defined as an electrically-controlled element which directly controls the normal operating motion of a machine such that it is the last (in time) to operate when motion is initiated or arrested. In addition, where the machine control system has two MPCEs, these devices can be monitored by connecting normally-closed auxiliary contact from each MPCE in series with the reset input. Disparity between the two MPCEs will prevent a reset. INSTALLATION WARNING Tapeswitch Safety Systems are designed to protect operators working at or near dangerous machines. They can only perform that function if they are correctly fitted and interfaced to a suitable machine. Every effort has been made to provide comprehensive and accurate information. It is the responsibility of the user to ensure that all persons involved in the installation of the product have the knowledge, training and experience necessary and that they are fully conversant with all laws, rules, regulations and codes of practice at their task.

TAPESWITCH CORPORATION 100 Schmitt Boulevard Farmingdale, New York 11735

Phone: 631-630-0442 Fax: 631-630-0454 www.tapeswitch.com

Release 08/2007 Ver. 2.0

Installation Instructions: PSSU Control Unit

MECHANICAL PSSU/1 and PSSU/2 Control Units - should be mounted in the machine control unit on standard 'top hat' terminal rail type DIN EN 50 022-35. The machine control unit must provide sealing to IP54 according to IEC 529. The dimensions of these two units are shown in Figure 2. PSSU/3 and PSSU/4 Control Units - should be mounted on a permanent part of the machine in a position which keeps cabling to a minimum and provides sufficient protection from damage by passing traffic but allows adequate access for servicing. The dimensions of these units and the position of mounting holes are shown in Figure 3. It will be necessary to punch or drill cable entry holes in the enclosure. These holes should be made in the top and bottom surfaces of the enclosure. It is recommended that the printed circuit board (PCB) assembly be removed while these holes are made. Ensure that the PCB assembly is refitted in its original orientation. For sensors with two 2-wire cables, six holes will be required. For a sensor with a single cable, five holes will be required. See Figure 4 for hole positions. One hole should be used for (each of) the sensor cable(s), one for the mains supply cable, one for each of the safety output cables, one for the reset input cable and one for the monitor output cable. The holes should be 20 mm diameter to accept PG13.5 cable glands. Six cable glands are supplied with the unit which will accept cable of 5-9 millimeter diameter. If other cable glands are used, they must provide sealing to at least IP54 according to IEC529. The exact cabling requirements are at the discretion of the installer and depend to a large extent on the siting of the various control system elements and whether the monitor output is used. Generally it is recommended that high voltage cables are routed away from low voltage cables.

RESET INPUT DEVICE A momentary action, normally-open switch, preferably a 22mm industrial pushbutton, should be used to provide the reset input. The switch should be housed in a suitable enclosure and should be mounted in such a position that it is safe from damage by passing traffic and such that the person operating the switch can see all of the dangerous area. ELECTRICAL GENERAL - The connections for each of the control units are shown in Figures 5, 6, 7 and 8. Crimped ferrules should be fitted on all stranded wires. It is recommended that electrical installation be performed in the order described below. SENSOR(S) CONNECTION - Connect the sensor cables to the control unit taking particular care that there are no stray strands which could cause a short between adjacent terminals. A number of sensors can be connected in series, see figures 13-16 for details and limitations. When connecting a number of sensors in series, the PSSU Controller treats these "combined" sensors as a single sensor. When any one of the sensors is actuated the output relays de-energize. POWER CONNECTION - Connect mains power to the control unit. For AC operation on the PSSU/1 and the PSSU/3 units, jumpers will need to be fitted to select the appropriate voltage. The power consumption is 6 VA maximum. RESET INPUT CONNECTION - Connect the reset input to the control unit. If the machine has two MPCEs, a pair of normally closed auxiliary contacts from each MPCE can be connected in series with the reset input as shown in Figure 9. This provides cross-monitoring of the MPCEs such that if they are in disparity due to a fault, reset will be prevented until the fault is rectified. The reset input can also be used to provide a test input. This is often used in higher risk applications where the actuation of the safety device is simulated every machine cycle to reveal faults in the machine interface. This test input can be provided by connecting a normally open contact in parallel with the reset switch as shown in Figure 10.

Figure 3

TAPESWITCH CORPORATION 100 Schmitt Boulevard Farmingdale, New York 11735

Phone: 631-630-0442 Fax: 631-630-0454 www.tapeswitch.com

Release 08/2007 Ver. 2.0

Installation Instructions: PSSU Control Unit

SAFETY OUTPUT CONNECTION Two normally-open safety outputs are provided. In low to medium risk applications, the machine is normally provided with a single MPCE. In such cases, both safety outputs should be connected in series with the MPCE coil as shown in Figure 11. If the machine is fitted with two MPCEs one safety output should be connected in series with each MPCE coil as shown in Figure 12. To protect the contacts of the safety output relays from the effects of switching inductive loads, arc suppressors should be fitted in parallel with the MPCE coils as shown in Figures 11 and 12. Arc suppressors must not be fitted across the safety relay contacts. To protect against the possibility of both safety outputs welding in, due to an overcurrent fault in the machine circuit, 2A fuses should be fitted in series with the MPCE coils as shown in Figures 11 and 12. This limits the current through the safety output contacts to well below that which could cause the contacts to weld. MONITOR OUTPUT (PSSU/3 and PSSU/4) The monitor output is a change-over volt-free relay output. The monitor relay is energized when the safety output relays are energized. The monitor output can be used as an input to a machine control device such as a programmable logical controller (PLC) to signal that the sensor has been actuated. NOTE: The monitor output is not a safety output and must not be used in the machine stop circuit. INITIAL CHECKING The system can be checked at this point as follows: (a) Check that the sensor is clear. (b) Apply power to the control unit. DO NOT APPLY POWER TO THE MPCEs. The POWER ON (RED) and SENSOR CLEAR (GREEN) indicators should be lit. The RESET ON and OUTPUT ON indicators should be off. (c) Press and hold the reset button. The RESET ON (AMBER) indicator should illuminate. The reset relay should be heard energizing. (d) Release the reset button. The RESET ON indicator should go off, and the OUTPUT ON (GREEN) indicator should illuminate. (e) Actuate the sensor. The SENSOR CLEAR and the OUTPUT ON indicators should go off.

Reset Input Neutral Earth Live

1 16 15 14 13 12 11 10 9 B A D C Reset Output 1 Output 2

Sensor see Table 1

Sensor see Table 1

2 3 4

For 240VAC: Jumper 12-13 For 110VAC: Jumper 12-14 and 11-13

5 6 7 8

N eutral Earth Live

Figure 5 PSSU/1 Connection Details

For 240VAC: Jumper 6-7 For 110VAC: Jumper 5-7 & 6-8

Output 2

10 9 8 7 6 5 4 3 2 1

X1

1 2 3 4 5 6 7 8 9

A B C D

N/O Common Monitor Output

Output 1

X2

Figure 7 PSSU/3 Connection Details

TAPESWITCH CORPORATION 100 Schmitt Boulevard Farmingdale, New York 11735

Sensor See Table 1

If the system operates as described above, the installation can be completed.

Phone: 631-630-0442 Fax: 631-630-0454 www.tapeswitch.com

N/C

Release 08/2007 Ver. 2.0

Installation Instructions: PSSU Control Unit

1 2

Sensor see Table 1

B A

D C

Sensor see Table 1

MPCE 1

MPCE 2

16 15 14 13 12 11 10 9

3 4 5 6 7 8

Reset Output 1

Res et Term inals

OV +24V

Res et Switch

Output 2

Tes t Input

Figure 6 PSSU/2 Connection Details

Figure 10 Connection of Test Input

Output 2

+24V

OV

Output 1

Machine Control Volts Output 1 Safety Fuse 2A Output 2 Arc Suppressor

10 9 8 7 6 5 4 3 2 1

X1

MPCE 1

Figure 11 Safety Output Connection (single MPCE)

X2

1 2 3 4 5 6 7 8 9

A B C D

N/O Common

N/C

Machine Control Volts

Reset Input

Output 1

Arc Suppress or

Sensor See Table 1

Safety Fus e 2A

Figure 8 PSSU/4 Connection Details

Output 2 Safety Fus e

Monitor Output

MPC E 1

MPCE 1

MPCE 2

Arc Suppress or

MPC E 2

Res et Term inals

2A

Res et Switch

Figure 12 Safety Output Connection (two MPCE)

Figure 9 Cross-monitoring of MPCE's

TAPESWITCH CORPORATION 100 Schmitt Boulevard Farmingdale, New York 11735 Phone: 631-630-0442 Fax: 631-630-0454 www.tapeswitch.com

Release 08/2007 Ver. 2.0

Installation Instructions: PSSU Control Unit

Table 1 SENSOR CONNECTION B C D

Red White 1 Yellow Black 2 White

TECHNICAL SPECIFICATIONS

Safety Grade Power Consumption Response Time 2 (DIN 31006-1) 6 VA 10 ms 0 to 50 degrees C -20 to 70 degrees C Fitted as Standard 110/240 Vac 24 Vdc Safety Relay, Force-Operated Contacts 2 x Normally Open 5 A @ 240 Vac 5 A @ 24 Vdc 0.75 A @ 50 Vdc Resistive } Load 1 A @ 24 Vdc Inductive 0.35 A @ 50 Vdc } Load Switching Frequency Monitor Output (PSSU/3 & PSSU/4 Only) Device Type Contact Type/Quantity Contact Rating Enclosure: Protection Rating PSSU/1 & PSSU/2 PSSU/3 & PSSU/4 Terminal Capacity Material 5 Hz

SENSOR TYPE

CKP and Armormats Mats, Edges, and Ribbon Switch

Black Black 1

White 2

Any Edge or Ribbon Switch Ribbed 1 Smooth 1 Ribbed 2 Smooth 2

Temperature Range: Operating Storage Reset Function Supply Voltage: PSSU/1, PSSU/3 PSSU/2, PSSU/4

Table 2

A PSSU/1 & 2 PSSU/3 & 4 15 3 B 16 4 C 2 5 D 1 6

Safety Outputs: Device Type Contact Type/Quantity Contact Rating

Terminal Numbers

Standard Relay 1 x Changeover 5 A @ 240 Vac

IP20 IP67 2 2.5 mm Polycarbonate

INTERCONNECT DIAGRAMS, DAISY CHAINED/SERIES CONNECTION

Multiple Mats with 4 Conductor Standard Color Coded Lead Wire - Figure 13

MAT 1

MAT 2

MAT 3

MAT N

A B C D

BLACK RED YELLOW WHITE

YELLOW WHITE

BLACK RED

YELLOW WHITE

BLACK RED

YELLOW WHITE

BLACK RED

NOTE: Maximum Number of Mats Limited to 100 Square Feet

TAPESWITCH CORPORATION 100 Schmitt Boulevard Farmingdale, New York 11735

Phone: 631-630-0442 Fax: 631-630-0454 www.tapeswitch.com

Release 08/2007 Ver. 2.0

Installation Instructions: PSSU Control Unit

Multiple Mats with Optional 2 Conductor Standard Color Coded Lead Wire - Figure 14

MAT 1

MAT 2

MAT 3

MAT N

A B C D

BLACK WHITE BLACK WHITE

BLACK WHITE

BLACK WHITE

BLACK WHITE

BLACK WHITE

BLACK WHITE

BLACK WHITE

Multiple Sensing Edges, Bumpers and Ribbon Switches with Color Coded Wire - Figure 15

A B C D

BLACK Edge/sensor 1 W HITE BLACK W HITE

BLK W HT

BLK Edge/sensor 2 W HT

BLK W HT

BLK Edge/sensor N W HT

W HITE BLACK

Edges and Bumpers Can Be Ordered with Lead Wire Exiting Both Ends to Facilitate Easy Series Connection NOTE: Maximum Number of Edges, Bumpers, and Ribbon Switches Limited to 200 Feet

Multiple Sensing Edges, Bumpers and Ribbon Switches with Non-Color Coded Zip Cord Wire - Figure 16

RIBBED Edge/sensor 1 SMOOTH RIBBED SMOOTH SMO SMO RIB

A B C D

RIB

Edge/sensor 2

RIB SMO

RIB Edge/sensor N SMO

SMOOTH RIBBED

TAPESWITCH CORPORATION 100 Schmitt Boulevard Farmingdale, New York 11735

Phone: 631-630-0442 Fax: 631-630-0454 www.tapeswitch.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Asterisk BrochureDocument7 pagesAsterisk BrochureOmar WaheedNo ratings yet

- 54 - Fuller FSO 6109A Transmission Service Manual PDFDocument134 pages54 - Fuller FSO 6109A Transmission Service Manual PDFJulio OrtegaNo ratings yet

- Experienced DGM seeks senior roleDocument5 pagesExperienced DGM seeks senior rolekavas26No ratings yet

- Manual Apollo FireDocument156 pagesManual Apollo FireAgnaldo JuniorNo ratings yet

- IqaDocument3 pagesIqaPamela ColemanNo ratings yet

- Rac Inspection ReportDocument13 pagesRac Inspection ReportDaniel DevineNo ratings yet

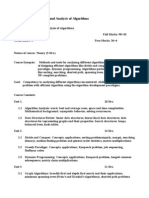

- 5th Sem Syllabus:design and Analysis of AlgorithmsDocument3 pages5th Sem Syllabus:design and Analysis of AlgorithmsAmit MantriNo ratings yet

- 0901 B 8038093 D 8 EbDocument3 pages0901 B 8038093 D 8 EbAshraf El-AttarNo ratings yet

- CV - Edson C Ayuste - Senior Instrument Engineer - March2018Document8 pagesCV - Edson C Ayuste - Senior Instrument Engineer - March2018Edson AyusteNo ratings yet

- GE Carescape V100 Monitor - Service ManualDocument178 pagesGE Carescape V100 Monitor - Service ManualGIGNo ratings yet

- Repeater Installation and CommissioningDocument34 pagesRepeater Installation and CommissioningTuan TocdaiNo ratings yet

- GSM Principles and Block Diagram ExplainedDocument3 pagesGSM Principles and Block Diagram ExplainedNirmal AnilkumarNo ratings yet

- Telenor (Introduction)Document22 pagesTelenor (Introduction)Bilal SayalNo ratings yet

- Interfacing The MCP215X To A Host Controller: Author: Mark Palmer Microchip Technology, IncDocument38 pagesInterfacing The MCP215X To A Host Controller: Author: Mark Palmer Microchip Technology, IncglizNo ratings yet

- Model LD - Large DC Volt/Current/Process Display: General Description SpecificationsDocument16 pagesModel LD - Large DC Volt/Current/Process Display: General Description SpecificationsRafael LinarezNo ratings yet

- Safety Instruction Sheets For Plant Piping and Cross-Country PipelinesDocument35 pagesSafety Instruction Sheets For Plant Piping and Cross-Country PipelinesRaj Bindas50% (2)

- Understanding Wired and Wireless Networks: Lesson 3Document32 pagesUnderstanding Wired and Wireless Networks: Lesson 3Guadalupe SantiagoNo ratings yet

- Belden 9463 PDFDocument3 pagesBelden 9463 PDFtr0184No ratings yet

- Genstat Workshop 1Document13 pagesGenstat Workshop 1Syamsul ArifinNo ratings yet

- Iso 05815-1-20031547185181297Document22 pagesIso 05815-1-20031547185181297Hakeem Shahzad100% (1)

- Acision MCO IPSM Gateway Fact Sheet v10Document2 pagesAcision MCO IPSM Gateway Fact Sheet v10jrashev100% (1)

- Electrical Distribution and Transmission Systems Analyses and Design ProgramsDocument44 pagesElectrical Distribution and Transmission Systems Analyses and Design ProgramsgovindarulNo ratings yet

- Telegram Listing Nav350Document82 pagesTelegram Listing Nav350caskibNo ratings yet

- YD Series Three Phase Asynchro Conveyor MotorDocument18 pagesYD Series Three Phase Asynchro Conveyor MotorAditya SafarudinNo ratings yet

- Asme B56.1Document88 pagesAsme B56.1Ana María FernándezNo ratings yet

- LPS Earth Test Report of Liberty Knitwear LTD 30.10.2022.docx222Document22 pagesLPS Earth Test Report of Liberty Knitwear LTD 30.10.2022.docx222roniNo ratings yet

- Sound Sources Used For Testing Open Office Components and SystemsDocument2 pagesSound Sources Used For Testing Open Office Components and SystemsNada KhlifNo ratings yet

- 38hds Installation ManualDocument8 pages38hds Installation Manualdelmar02No ratings yet

- NRC12 VarlogiDocument2 pagesNRC12 VarlogiNima MahmoudpourNo ratings yet