Professional Documents

Culture Documents

Design Criteria For Concrete Foundations & Structures 2

Uploaded by

Chetan ToliaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Criteria For Concrete Foundations & Structures 2

Uploaded by

Chetan ToliaCopyright:

Available Formats

JOB SPECIFICATION Job Number-Unit Discipline

Serial

Rev.

RG

17 00

01

QATAR PETROCHEMICAL COMPANY LTD

DESIGN CRITERIA FOR CONCRETE FOUNDATIONS AND STRUCTURES

Page 1 of 24

9 8 7 6 5 4 3 2 1 0 Rev.

16/11/93 05/05/93 26/03/03 21/01/93 08/01/93

Date

Written By (Name, Initials)

Checked By (Name, Initials)

Approved By (Name, Initials)

Status

DOCUMENT REVISIONS :Revisions indicated by <>with Rev Number inside

Spec RG -1700 -01 -Rev 5 Page 1 of 24

CONTENTS 1. GENERAL 1.1. Scope 1.2. Reference documents 1.2.1. Local code, QNBS and BS codes and standards 1.2.2. Uniform Building Code 1.2.3. Other applicable specifications 2. CLIMATIC CONDITIONS 2.1. Rainfall 2.2. Snowfall 2.3. Wind 2.4. Earthquake 2.5. Temperature variations 3. LOADS ON STRUCTURES 3.1. Permanent loads 3.1.1. Dead loads of structures 3.1.2. Dead loads of equipment & machinery 3.2. Climatic loads 3.3. Live loads 3.3.1. General 3.3.2. Loads produced by persons 3.3.3. Piping loads 3.3.3.1. Vertical loads 3.3.3.2. Horizontal loads 3.3.3.3. Tie girders for elevated pipe racks 3.3.3.4. Friction factors 3.3.4. Vessels loads 3.3.5. Bridge crane & lifting appliances

Spec RG -1700 -.01-Rev.5 Page 2 of 24

3.4. Special loads 3.5. Thermal loads 3.5.1. Thermal expansion 3.5.2. Thermal loads 3.6. Trench covers loads 4. LOAD COMBINATIONS 4.1. Structures and foundations 4.2. Tall vessels 5. STRUCTURAL CONCRETE 5.1. General 5.2. Design principles 5.3. Concrete grades 5.4. Concrete protection 5.4.1. 5.4.2. Concrete paving All other concrete works

5.5. Concrete cover 5.6. Construction joints 5.7. Concrete paving 5.7.1. Paving thickness 5.7.2. Expansion joints and slab protection 5.8. Reinforcement grades 5.9. Anchor bolts and base plates 5.9.1. 5.9.2. 5.9.3. 5.10. Grouting Design Clearance Tolerance

Spec RG -1700 -.01-Rev.5 Page 3 of 24

6.

STRUCTURAL STEEL 6.1. General 6.2. Design conditions 6.2.1. Plastic design 6.2.2. Structural elements exposed to heat 6.2.3. Structural elements exposed to severe corrosion 6.2.4. Shipment subject to water filling 6.2.5. Special design conditions 6.2.6. Allowable deflections 6.3. Connections 6.3.1. Shop connections 6.3.2. Field connections 6.3.3. Minor connections 6.3.4. Black bolts 6.3.5. High strength friction grip bolts 6.3.6. Minimum bracing connection 6.3.7. Single bolt prohibited 6.4. Corrosion protection 7. SOIL CHARACTERISTICS 7.1. Ground water level 7.2. Soil bearing capacity and foundation level 8. FOUNDATIONS 8.1. 8.2. 8.3. 8.4. 8.5. Design principles Stability ratios Settlement Foundation types Foundation details

9. FIRE PROOFING 10. DESIGN AND CALCULATIONS

Spec RG -1700 -.01-Rev.5 Page 4 of 24

1. 1.1.

GENERAL Scope The purpose of this document is to define the design criteria for the concrete foundations and structure applicable to the various projects of QAPCO in their Petrochemical Complex located in UMM SAID, State of QATAR. These design criteria shall apply to all concrete foundations, concrete and steel structures and concrete paving for equipments and buildings, pipe supports and platforms at the above site. This specification is supplemented by other documents listed below and shall prevail over the listed documents.

1.2.

Reference documents The following specifications, codes and standards, in their last revisions, shall be read in conjunction with and shall be part of this specification.

1.2.1.

Local code, QNBS and BS codes and standards Local code, Q.N.B.S. and the British Standards to which it refers, - BS 4 : Part 1 : (1980) : Specification for hot-rolled section. - BS 12 : (1991) : Specification for Portland cements. - BS 449 : Part 2 : (1969) : Metric units : specification for the use of structural steel in building. - BS 639 : (1986) : Specification for covered carbon and carbon manganese steel electrodes for manual metal arc welding. - BS 648 : (1964) : Schedule of weights of building materials. (68-69) - BS 3648 : (1968) : ISO metric screw threads. (67-85) - BS 3692 : (1967) : Specification for ISO metric precision hexagon bolts, screws and nuts, Metric units. - BS 4027 : (1991) : Specification for sulphate resisting Portland cement. - BS 4165 : (1984) : Specification for electrode wires and fluxes for the submerged arc welding of carbon steel and medium tensile steel. - BS 4190 : (1967) : Specification for ISO metric black hexagon (75-78) bolts, screws and nuts. - BS 4320 : (1968) : Specification for metal washers for general engineering purposes. - BS 4360 : (1990) : Specification for weldable structural steels.

Spec RG -1700 -.01-Rev.5 Page 5 of 24

- BS 4395 :

: Specification for high strength friction grip and washers for structural engineering.

bolts and associated nuts

- BS 4449 : (1988) : Specification for carbon steel bars for the reinforcement of concrete. - BS 4466 : (1989) : Specification for bending, dimension and scheduling of reinforcement for concrete. - BS 4482 : (1985) : Specification for cold reduced steel wire for the reinforcement for concrete. - BS 4604 : (1970) : Part 1 : Specification for the use of high (71-72-82) strength friction grip bolts in structural (metric series) - general grade steelwork

- BS 5135 : (1984) : Specification for arc welding of carbon and carbon manganese steels. - BS 6399 : part 1 : (1984) : Loading for building - Code of practice for dead and imposed loads. - BS 7295 : (1990) : Fusion bonded epoxy coated carbon steel bars for the reinforcement of concrete. - BS 8004 (1986) : Code of practice for foundations. - BS 8007 : (1987) : Code of practice for design of concrete aqueous liquids. structures for retaining

- BS 8110 : Part 1 : (1985) Structural use of concrete code of practice for design and construction. - CP3 : chapter V : part 2 : (1972) : Basic data for design of buildings - Wind loads. - CP 2012 : part 1 : (1974) : Code of practice for foundations for machinery - Foundations for reciprocating machines). - BS EN 10025 (1990) : Hot-rolled products in non-alloy structural steels. Technical delivery conditions. Uniform Building Code To be used for earthquake calculation only. 1.2.3. Other applicable specifications - RG 1400.01 - Site preparation and earthworks. - RG 1700.02 - Concrete works.

1.2.2.

Spec RG -1700 -.01-Rev.5 Page 6 of 24

2. 2.1. <5> 2.2.

CLIMATIC CONDITIONS Rainfall Rainfall load should be at maximum 0.7 kN/m2 for the design. Snowfall Snowfall is not to be considered.

2.3.

Wind Wind loads shall be calculated in accordance with, CP 3 : ch. V - Part 2 : 1972 "Code of basic data for the design of buildings". The following wind speed factors shall be used : a) Topography factor S1 = 1.0. b) Ground roughness shall be category 1. Factor S2 as per CP 3, Table 3. c) Statistical factor S3 = 1.0. The wind is generally from the North, North West with occasional periods of southerly winds. Structure and equipment which extend to more than 15 meters above grade will be designed for a wind of 45 m/s. Structure and equipment which extend less than 15 meters above grade will be designed for a wind of 38m/s.

2.4.

Earthquake Zone I of UBC shall be considered.

2.5.

Temperature variations Refer to section 1.1.1. of General Specification RG 00-90-01

3.

LOADS ON STRUCTURES The design of foundations and structures will take into account the following loads. Permanent loads Dead loads of structures All structural materials, floors, stairs, covering, fire proofing and all permanent materials forming part of the structures shall be considered as dead loads.

3.1. 3.1.1.

3.1.2.

Dead loads of equipment & machinery (except bridge cranes and lifting appliances) Equipment and machinery loads without the liquid contained inside or without removable parts shall be considered as dead loads. Spec RG -1700 -.01-Rev.5

Page 7 of 24

Erection loads a) Temporary large point loads shall be considered on structural frames during the installation of equipment, such as gin pole loads on structures or foundations. b) Vertical vessel foundations shall be designed for maximum overturning loads considering vessels are at minimum vertically loaded condition. c) Large rotary equipment part loads shall be investigated on framing members (e.g. rotors during maintenance or installation). 3.2. Climatic loads Wind (refer to section 2.3). 3.3. 3.3.1. Live loads General The following loads shall be considered as live loads : - loads produced by persons, - live loads of equipment (vessels, pipe racks, etc...), - weight of liquid contained in equipment and piping during normal operation, - loads (horizontal and vertical) caused by expansion and anchor of pipes, - temporary loads such as bundle pulling loads, (for checking of ultimate load only), - loads produced by movable equipment (with dynamic effect), 3.3.2. Loads produced by persons The design live loads for floors, platforms, walkways and stairs shall be as follows : - roofs (substation) 1.20 kN/m ) for roofs not intended as ) walkways or working areas + 1.00 kN/m ) for sand 1.8 kN/m2 for canteens roof - stairs - walkways - access platforms - operating platforms - handrails 2.40 kN/m or (+ 1.5 kN concentrated at centre of thread) 2.40 kN/m 2.40 kN/m 2.40 kN/m + equipment or concentrated load 1.00 kN point load in any direction per metre. of 2.4 kN

Spec RG -1700 -.01-Rev.5 Page 8 of 24

3.3.3.

Piping loads Piping loads include all thrusts or moments due to thermal expansion or contraction of piping and the blow-out forces of expansion joints, bell and spigot pipes, safety relief valves, etc. Piping loads in general shall be considered as equipment loads. Vertical loads shall consider : - pipes empty (erection conditions), - pipes in operating conditions, - pipes in test conditions. Horizontal loads caused by pipe expansion and anchor shall be considered as operating loads.

3.3.3.1.

Vertical loads a) Vertical loads shall be computed according to size distribution and service conditions of pipes which are supported. For pipeways, use 1450 N/m as a minimum pipe load. This approximates 6 inch pipes filled with water (spacing between pipes : 12 inches). b) Pipes larger than 12 inches diameter shall be considered as concentrated loads in their actual locations. c) Live load include : . live load in operating conditions, . live load due to water while testing.

3.3.3.2.

Horizontal loads a) Main supporting girders shall be calculated to withstand horizontally, in the direction of the pipes, the greater of following thermal (friction) loads : - 10 % of the sum of all operating pipe loads acting longitudinally for pipes less or equal to 12" diameter, and - 30 % for pipes larger than 12" diameter. or - Every main supporting girder (girder which supports all diameter pipes) shall be calculated to withstand horizontally, in the direction of the pipes, friction forces as mentioned above or an arbitrary anchor force minimum 5 kN located at the most unfavourable position, whichever results in a greater member size. During refinement of the design, when location of anchors is defined the proper loads shall be considered. b) Pipe rack frames shall be calculated taking into account following horizontal thermal forces, at right angle with pipes, as a minimum : 5 % of the operating pipe loads at each concerned level.

Spec RG -1700 -.01-Rev.5 Page 9 of 24

c) Horizontal loads on the anchor bays of pipe racks shall be taken as the greatest of : (per longitudinal file) - anchor forces from pipe stress calculation, or - 10 % of piping vertical loads from 4 bays length, or - 40 kN applied uniformly. 3.3.3.3. Tie girders for elevated pipe racks They shall be calculated, (in addition to the above), for the following : - vertical load 10 kN at mid span. 3.3.3.4. Friction factors Friction factors to be used (for local effect) : - steel/steel - PTFE/stainless steel or PTFE/PTFE 0.33 0.05 *)

*) contact pressure between PTFE and PTFE or stainless steel 15-25 N/mm. 3.3.4. Vessel loads Live loads include : - live loads due to content in operating condition, - live loads due to water while vessel is being tested : . when hydrostatic pressure testing of equipment is required at site, the weight of this equipment completely filled with water shall be incorporated in the design of the supporting structure. . when more than one vessel, etc.. is supported by one structure, the structure and the relevant foundation need to be designed on the basis that one vessel will be tested at any one time and that the others will either be empty or still in operation. 3.3.5. Bridge cranes and lifting appliances a) Bridge crane Loads applied from bridge cranes must be calculated in accordance with applicable codes and standards but should not be less than the following : Electric operation vertical loads : increase static wheel loads by horizontal force transverse to rails taken as percentage of loads + crab weight 25 % 10 % Hand operation 10 % 5%

Spec RG -1700 -.01-Rev.5 Page 10 of 24

horizontal force along the rails taken as percentage of loads + crab weight

5%

5%

b)

Monorails hoisting When hoisting by means of chain hoist, air or electric hoist, increase loads on supporting members by 50 % for impact.

3.4.

Special loads Exchanger tube bundle pulling force Provision shall be made for the pulling force required when removing (or installing) a tube bundle from a shell. The minimum horizontal force applied at the center of the bundle shall be equal to 50 % of the weight of the bundle with a 5 kN minimum. Horizontal pulling force shall be assumed to act at the centre line of the exchanger and resisted by the fixed support only. When exchangers are stocked, the force shall be taken as acting at the upper exchanger centre line, with the lower exchanger bundle having been removed.

3.5. 3.5.1.

Thermal loads Thermal expansion Due to the wide range of temperature occurring throughout the year expansion joints are to be provided at convenient locations. The following data is to be used in thermal loading calculation : maximum temperature difference concrete linear expansion factor steel linear expansion factor t = 40C -5 Ctc = 1.1 10 -5 Cts = 1.2 10

Such data can be neglected for concrete structures and for steel structure with expansion joints provided at 30 meters maximum distance. Data shall be used to determine size of expansion joint with a minimum joint width of 25 mm. 3.5.2. Thermal loads Piping, vessels, fire equipment, ducts and heat exchangers on structural supports shall be analyzed for thermal forces to be resisted by the structures and provision shall be made to relieve forces too large for the equipment or the supporting structure. For thermal loads due to piping see also para. 3.3.3. 3.6. Trench covers loads Trench covers in areas with vehicular access shall be designed for 50 kN wheel load. Contact area of wheel on covers which has been considered is : 250 x 200 mm.

Spec RG -1700 -.01-Rev.5 Page 11 of 24

4.

LOAD COMBINATIONS 4.1 . Structures and foundations

The following combination of loads shall be investigated in the design of structural members and foundations

LOAD COMBINATION

ERECTION

TEST (4)

OPERATION

EARTHQUAKE

with wind (1)

without wind (1)

Dead loads : Structures Weight of equipment Live loads: X Persons Operating vessels piping and equipment Test load Crane loads(dynamic load) Dynamic loads (machinery) Wind loads Thermal loads X X (3) X X X (2) X X X X X (2) X X X X X X (5) X X X X X X X X X X

(1) The most unfavourable load combinations shall be taken into account. (2) Crane loads with 50 % of wind pressure shall be applied on open structures and/or open sided buildings. Crane loads with full wind shall be applied on closed buildings. (3) 50 % of wind pressure shall be applied in test condition. (4) For structures supporting equipment subject to water filling, in which 90 % or more of the live load is water, applied for 72 hours or less, the basic allowable unit stresses for all loads during the filled period may be increased by 20 %. (5) Only 50 % of loads shall be taken into account.

Spec RG -1700 -.01-Rev.5 Page 12 of 24

4.2.

Tall vessels The following load combinations shall be used in assessing the design stability of tall vessels subject to overturning. a) Erection condition . Dead load Vessel without internals and attachments. . Live load Wind. b) Test condition . Dead load Vessel including test fluid, internals, platforms and ladders, piping. . Live load 50 % of wind dynamic pressure. c) Operating condition . Dead load Vessel including operating fluids at maximum level, internals, catalyst, insulation, platforms and ladders, piping. . Live load Wind, platforms, thermal, impact, vibrations. d) Shut-down condition . Dead load Vessels without operating fluids, with removable internals, platforms and ladders, insulation and piping. . Live load Wind, platforms. STRUCTURAL CONCRETE General The design and details of structural concrete shall be read in conjunction with relevant British codes (refer to paragraph 1.2).

5. 5.1.

Spec RG -1700 -.01-Rev.5 Page 13 of 24

5.2.

Design principles The allowable stress in concrete and reinforcing steel shall be in accordance with BS 8110 and BS 8007. The allowable stresses for members subjected to short time overload conditions may be increased by 20 % where short time overload is defined as follows :Short-time overload The structural and equipment operating and the piping dead loads, the design live load, lifting points load, appropriate equipment and piping contents loads resulting from short-time operational upsets (such as may occur during starting-up, shutting down, or an interruption in operation of the process). The magnitude and application of loads for the purpose of designing concrete structures and foundations subject to hydrostatic test loading shall be as follows : Case A : For small vessels where the hydrostatic test load will not be applied for more than 4 days, wind loading shall be ignored. Case B : For large vessels and small vessels where the hydrostatic test load will be applied for 5 or more days, 50 % of wind load shall be considered to act simultaneously with the hydrostatic test load. The allowable stress for members subject to hydrostatic test loads may be increased by 20 % for case A and by 25 % for case B. For the design of foundations, refer to section 8.

5.3.

Concrete grades Type I : . For plain blinding concrete . Minimum strength 15 MPa at 28 days (ref. OPC 15). . 250 kg/m3 ordinary Portland cement minimum.

Type II : . For plain mass concrete. . Minimum strength 25 MPa at 28 days (ref. OPC 25). . 350 kg/m3 ordinary Portland cement minimum. Type III : . For the reinforced concrete of : - the paving slab, - the foundation slab and columns under steel structures or equipment (such as exchangers, columns, drums), - the foundations of concrete structures, - all concrete structures and buildings above the ground level, - concrete trenches. . Minimum strength 30 MPa at 28 days (ref. OPC 30). . 400 kg/m3 ordinary Portland cement minimum (10-15 % of cement to be replaced by micro silica). All underground concrete surfaces to be coated with Hempel "Hempadur 1513 of DFT 125 microns, then covered with gage 1000 P.E. sheet, overlaid with 4 mm hard-board suitably fixed to retain its position. All aboveground concrete surfaced (including the internal surface of manholes) to be coated with Hempel "Sealant O 597" as a primer and Hempel "Hempadur 4523" of DFT 100 microns as a top coating.

Spec RG -1700 -.01-Rev.5 Page 14 of 24

5.4. 5.4.1.

Concrete protection Concrete paving Concrete paving shall be separated from the foundations piers with flexible material about 20 mm thick covered with heavy duty mastic 20 mm x 20 mm. The mastic must resist for water, weather and chemical. A damp-proof membrane of polythene sheet (1000 gauge) shall be provided between the subgrade and paving slab.

5.4.2.

All other concrete works The arrangements of above clause 5.3 shall be applied and for paving slab as above mentioned (clause 5.4.1.).

5.5.

Concrete cover Minimum thickness of concrete cover to principal reinforcement unless noted otherwise on the drawings is as follows :

Concrete poured against ground Formed concrete against ground Formed concrete exposed to weather

75 mm 50 mm 50 mm

Formed concrete columns, girders and beams not against 40 mm ground or not exposed to weather Formed concrete slabs and walls not against ground or not 20 mm exposed to weather The bottom of excavations for reinforced concrete bases and footings shall be blinded with a 50 mm thick layer of concrete prior to the reinforcement being fixed. 5.6. Construction joints Construction joints in columns shall be positioned at the soffit of girders, beams, haunches or column capitals and also at an appropriate 'kicker' height above slabs or bases. Construction joints in girders, beams and slabs shall be positioned at approximately a third of the span from a support. Construction joints shall be arranged to minimise the effect of shrinkage of the concrete. Generally, the distance between joints shall not exceed 10 meters. Where watertight construction is required, all construction joints shall have a continuous PVC Water bar of approved type.

Spec RG -1700 -.01-Rev.5 Page 15 of 24

5.7. 5.7.1.

Concrete paving Paving thickness Where required, a 100 mm thick reinforced concrete slab shall be used in process unit areas not subject to regular maintenance loads or other heavy loads. A 150 mm thick reinforced concrete slab shall be used in areas regularly subject to maintenance loads. Paving areas which sustain constant concentrated equipment loadings (piping assembly support, etc.) shall be properly thickened and reinforced in the loaded area to insure proper load transfer to the subgrade.

5.7.2.

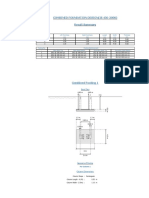

Expansion joints and slab protection In the paving slab, the expansion joints shall be spaced every 6.0 m in two directions. An horizontal dowel will be inserted in the joint every 400 mm (as per sketch below) to prevent the vertical movements but not the horizontal expansion. The joint will be filled with a 2.0 cm thick flexible material, which will be covered at the top with heavy duty mastic 20 mm x 20 mm, water, weather and chemical resistant. The dowel shall be coated as per section 5.9. It will be cast on one side in the concrete. The other half will be inserted in a closed p.v.c. pipe which will prevent the bonding of the dowel with the concrete. The dowel shall be O 16 mm and 600 mm long.

heavy duty mastic 20 mmm*20 mm flexible joint material

dowal bar closed PVC pipe

Spec RG -1700 -.01-Rev.5 Page 16 of 24

Typical expansion joint 5.8 <5> Reinforcement grades Reinforcement (re-bars) shall be coated steel Reinforcing steel shall be high yield deformed bars with a specified strength of 460 N/mm according to BS 4449. For design purpose the steel characteristic strength shall be limited to 425 N/mm. Mild steel bars may be used for links and binders. Characteristic strength shall be 250 N/mm according to BS 4449. Wire characteristic strength shall be 485 N/mm according to BS 4482.

The bending of bar reinforcement shall be carried out in accordance with BS 4466. 5.9. Anchor bolts and base plates Anchor bolts shall be in accordance with the relevant British Standards. 5.9.1 Design Anchor bolts shall be designed to cater for initial tension, induced loads and horizontal shear. The maximum allowable stresses for anchor bolts shall be based on the root area of the thread. When anchor bolts are set in concrete and are subjected to combined shear and tensile loads, the shear load shall be transmitted to the concrete by the anchor bolts and keys (if required).

When anchor bolts are to be set in sleeves, the sleeves shall be filled with grout. When required to allow the equipment expansion due to temperature, sliding plates shall be provided ; anchor bolts at sliding plates shall be hand tight only. The maximum concrete stress beneath base-plates shall be limited to 5 N/mm. A 25 % increase for stress shall be permitted for wind loading. Bolt capacities embedments and plate sizes will be based on a concrete having a strength of 28 MPa at 28 days. Clearance Minimum clearance between anchor bolts axis and the face of the foundation shall be as follows : - diameter < or equal to 30 mm : 150 mm, - 30 mm < diameter < or equal to 56 mm : 200 mm, - 56 mm < diameter < or equal to 80 mm : 300 mm. Anchor bolts shall always be located inside the reinforcement frame.

5.9.2

Spec RG -1700 -.01-Rev.5 Page 17 of 24

5.9.3

Tolerance Refer to section 16.2 of specification RG 1700.02 - Concrete works.

5.10.

Grouting Machinery shall be bedded on concrete foundations with a suitable non-shrink grout. For details, refer to Specification RG 1700.02 - Concrete works. Sand/cement grouts for use under stanchion base plates etc... shall consist in one part of Portland cement to three parts of sharp sand by volume mixed with the minimum water for workability. The minimum thickness of grout shall be 25 mm unless specified otherwise on the design drawings. All grout shall have a compressive strength at least equal to the foundation concrete.

6. 6.1.

STRUCTURAL STEEL General Structural steel shall be designed in accordance with the local Code, Q.N.B.S. and the British Standards to which it refers (in particular, BS449 Part 2). For loads, refer to section 3 and 4 of this specification. All structural steel shall be grade 43B to BS EN 10025 or equivalent.

6.2.

Design conditions Design shall be in accordance with the above standards with the following modifications :

6.2.1.

Plastic design shall not be used for structures

6.2.2.

For structural elements continuously exposed to heat above 260C (500F), allowable design stresses shall be reduced in proportion to reductions in yield strength of the steel at the design temperatures. Special materials protection or material thickness allowance shall be employed for structural elements subjected to severe corrosion or wear conditions. For structures supporting equipment subject to water filling, in which 90% or more of the live load is water, applied for 72 hours or less, the basic allowable unit stresses for all loads during the filled period may be increased of 20%.

Spec RG -1700 -.01-Rev.5 Page 18 of 24

6.2.3. 6.2.4.

6.2.5.

Where special design conditions require higher strength materials, they may be used but shall be submitted to Engineering Contractor or to QAPCO for approval and must be designed, designated and detailed accordingly. Allowable deflections Design vertical deflections on structural steel members under the effect of dead loads, equipment loads, live loads, crane loads and wind loads shall not exceed the following values : . purlins and girders . floor beams - without equipments - with equipments . runway and monorail beams . cantilever beams (L equals the span of beams) L/200 L/300 L/500 L/750 L/400

6.2.6.

Design horizontal deflections on structural steel frames under the effect of equipment loads, live loads, crane loads and wind loads shall not exceed the following values : . frames without equipment . frames with equipment or crane(s) - without wind allowance - with wind allowance (H equals the height of frames) H/200 H/300 H/200

Spec RG -1700 -.01-Rev.5 Page 19 of 24

In case of pipe racks design deflection under the effect of dead loads and imposed loads shall not exceed the following values : . main supporting beams (L equals the span of beams) . combined deflections of intermediate beams and longitudinal tie beams L/200 (L equals the span of the intermediate beams) L/400

6.3. 6.3.1. 6.3.2.

Connections Shop connections may be welded or bolted with high strength friction grip type bolts. Field connections are to be bolted with high strength friction type bolts, conforming to BS 4604. No field welding shall be permitted for structural steelwork unless approved by the Engineering Contractor. The welding procedure specification and welders qualification test certificates will have to be submitted to the Engineering Contractor for approval. If approved, field welding may be used if facilities are available and if so, field welding shall be designed, detailed and specified. Minor connections such as handrail, floor plate, etc..., may be bolted with common black bolts of grade 4.6, conforming to BS 4190 or welded if required on drawings. Minimum diameter to be used : Walkway structures, joints, grits, etc... : 16 mm Handrails and ladders : 12 mm

6.3.3.

6.3.4. 6.3.5. 6.3.6. 6.3.7. 6.4.

Black bolts connecting members supporting vibrating equipment shall have lock-washer or other equivalent system. High strength bolts friction type shall be tightened in accordance with the minimum tension specified in BS 4604. The minimum bracing connection shall be made using two 20 mm (3/4 inch) diameter high strength bolts or be capable of resisting to 59 kN if welded. Connections by a single bolt is prohibited in all cases. Corrosion protection Structural steel shall be painted as per applicable painting specification.

Spec RG -1700 -.01-Rev.5 Page 20 of 24

7. 7.1.

SOIL CHARACTERISTICS Ground water level For design purposes, the maximum height of the ground water shall be taken as follows : Ethylene Plant area : 0.700 m above QNHD (Reference level 97.450), Other areas : 1.000 m above QNHD (Reference level 97.750).

7.2.

Soil bearing capacity and foundation level For ethylene plant area, design will be performed with 0,3 MPa at 2 meters depth on soil substitution for foundations not less than 1 m wide. For foundations less than 1 m wide, the bearing pressure will be reduced prorata. For new plants like LDPE Unit N 2 and utility generation facilities extension, a specific soil survey will be made.

8. 8.1. 8.1.1. 8.1.2.

FOUNDATIONS Design principles Foundations subject to static loads only, shall be designed generally in accordance with the British Code of Practice for foundations BS 8004. Foundations subject to overturning moments, shear or uplift forces, shall be proportioned so that under any condition of loading the Factor of Safety against overturning and shear, shall not be less than described in section 8.2. The weight of earth superimposed over foundations may be used in computing the resisting moment or load. Foundations and structures for reciprocating machinery subject to vibration shall be designed generally in accordance with the British Code of Practice for foundations for machinery, CP 2012 : Part 1 : 1974 or equivalent. Foundations and structures for rotating machines. Rotating machinery may be supported either directly on a rigid foundation or on an e levated structure.

Spec RG -1700 -.01-Rev.5 Page 21 of 24

8.1.3.

8.1.4.

The horizontal eccentricity in any direction, between the centroid of mass of the machine-foundation system and centroid of the base contact area, shall not exceed 5 % of the respective dimension. The center of gravity of the machine-foundation system should be as close as possible to the lines of action of the unbalanced forces. Elevated structures for rotating machinery shall be as follows : a) machinery loads shall be directly over vertical supports, where possible, b) beams and slabs shall have a span as short as possible, c) within the weight requirements of the foundation, the upper table and the foundation slab shall be as rigid as possible in the horizontal plane. Dynamic design shall show that the natural frequencies of foundation-soil system are either less than 80 % or greater than 120 % of the operating frequency of the machine. In case such a provision is impracticable, it shall be shown that the amplitudes are within the allowable values indicated in fig. 1. A reasonable amount of damping shall be estimated. 8.1.5. 8.1.6. 8.1.7. 8.2. Pump foundation block shall be reinforced only on exposed faces, however appendages to such foundations shall be reinforced to ensure integral action. Masonry walls shall be supported on either grade beams or continuous strip footings. Allowance must be made for buoyancy where any foundations are submerged by ground water. Stability ratios Foundations and structures shall be checked for resistance to overturning and sliding. The minimum factors of safety shall be as follows : a) 1.5 times the overturning moment for erection condition or test condition. b) 2.0 times the overturning moment for operating condition or shut-down condition. c) Sliding resistance to be 1.5 times maximum sliding force. 8.3. Settlement Except for vibrating machinery a maximum settlement of any one foundation should be 25 mm with maximum differential settlement of 12 mm from one foundation to another after hydrostatic tests. 8.4. Foundation types In general, foundations for equipment, structures, buildings etc...shall be shallow type (refer to section 7.2. here above). 8.5. Foundation details

Spec RG -1700 -.01-Rev.5 Page 22 of 24

Foundation plinths for structural columns and equipment leg supports shall extend not less than 50 mm from the edges of base-plates 0.2 m sq. and less in area, and 75 mm for base-plates over 0.2 m sq in area. Foundations for equipment such as pumps and compressors shall extend not less than 75 mm from the edge of base-plates except when otherwise specified on the manufacturer's drawings. Foundations, for vessels supported on skirts, shall have the area within the skirt sloped for drainage to a 50 mm pipe drain, cast in the foundation and directed to the paving or ground. Unless otherwise specified, exposed edges of concrete above grade shall have a 25 mm chamfer. All reinforced concrete foundations shall be constructed on mass concrete blinding. The thickness of blinding shall be 50 mm. 9. <5> 10. FIREPROOFING See specification Rg 1700-03 Rev2 DESIGN AND CALCULATIONS Detail of design and calculations shall be shown on sketches showing structure arrangements, loads, member sizes, etc... Computer printout shall supplement sketches whenever computers are utilised. All calculations shall be in English language, using S.I. units.

Units to be used shall be : . Length . Area . Volume . Force . Distributed loads . Stress m, mm m, mm m3, mm3 N, kN kN/m N/mm (MPa)

Spec RG -1700 -.01-Rev.5 Page 23 of 24

Spec RG -1700 -.01-Rev.5 Page 24 of 24

You might also like

- Blast Resistant StructuresDocument3 pagesBlast Resistant Structuresprabhay123456No ratings yet

- Architecture Yr2 Industrial TrainingDocument33 pagesArchitecture Yr2 Industrial TrainingKintu Philly100% (2)

- Cap Screws: Sae J429 Grade IdentificationDocument6 pagesCap Screws: Sae J429 Grade IdentificationHomer SilvaNo ratings yet

- Truss Connections AISC ManualDocument8 pagesTruss Connections AISC ManualBun KunNo ratings yet

- Design Water TankDocument83 pagesDesign Water TankHemant Sonawadekar100% (2)

- Blast Resistant Design of Steel StructuresDocument116 pagesBlast Resistant Design of Steel StructuresPetr KonupčíkNo ratings yet

- Lateral Load Capacity of Piles - Short Piles - Davisson - BromsDocument9 pagesLateral Load Capacity of Piles - Short Piles - Davisson - BromsGeorge KaraspNo ratings yet

- ST7013-Design of Steel Concrete Composite StructuresDocument11 pagesST7013-Design of Steel Concrete Composite StructuresPraveen KumarNo ratings yet

- Universal Beams and Columns Imperial UnitsDocument1 pageUniversal Beams and Columns Imperial UnitsPratama YogaNo ratings yet

- CT2 2006 Foundation Analysis DesignDocument4 pagesCT2 2006 Foundation Analysis DesignKroya HunNo ratings yet

- Connection Design (With Moment) - T26Document10 pagesConnection Design (With Moment) - T26Li ChianNo ratings yet

- ASD Vs LRFDDocument5 pagesASD Vs LRFDUsman AfzalNo ratings yet

- Openings in BeamsDocument57 pagesOpenings in BeamsNguyen Ngoc Hoa100% (1)

- IEEE693 Tutorial3-2007c (Compatibility Mode) PDFDocument145 pagesIEEE693 Tutorial3-2007c (Compatibility Mode) PDFjinjin0205No ratings yet

- 1.1 Design of Pipe Racks Writeup PDFDocument5 pages1.1 Design of Pipe Racks Writeup PDFCarlosAlbertoGrimaldoBarajasNo ratings yet

- Bearing Capacity of SoilsDocument138 pagesBearing Capacity of SoilsMuqeem Khan100% (1)

- Bearing Design PDFDocument48 pagesBearing Design PDFNon Etabas GadnatamNo ratings yet

- Zhong Design of Foundations For Large Dynamic Equipment in A High Seismic Region 2013 PDFDocument12 pagesZhong Design of Foundations For Large Dynamic Equipment in A High Seismic Region 2013 PDFasgharNo ratings yet

- Shear Strength of High-Strength BoltsDocument61 pagesShear Strength of High-Strength Boltsloox600No ratings yet

- Notes On Pre-Stressed Concrete.Document10 pagesNotes On Pre-Stressed Concrete.Chetan ToliaNo ratings yet

- Columns DesignDocument60 pagesColumns DesignifsrebraNo ratings yet

- 2011 CV3201 Columns (EC2) 1Document40 pages2011 CV3201 Columns (EC2) 1sunilarunaNo ratings yet

- Shear Wall Design and BehaviorDocument34 pagesShear Wall Design and BehaviorRacharla Narasimha Raju Varma100% (1)

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- Slab Raft FoundationDocument46 pagesSlab Raft Foundationankit kadam100% (3)

- Floor Vibration Analysis in STAAD ProDocument10 pagesFloor Vibration Analysis in STAAD Procsreeniv0% (1)

- Modeling of Vibratory Pile DrivingDocument12 pagesModeling of Vibratory Pile DrivingAlberto AguilarNo ratings yet

- The Study of The Effects of Web Openings On The Concrete BeamsDocument10 pagesThe Study of The Effects of Web Openings On The Concrete BeamsChetan ToliaNo ratings yet

- Sharma Et Al-2017-Structural Concrete As PublishedDocument9 pagesSharma Et Al-2017-Structural Concrete As PublisheddebiNo ratings yet

- Alamathy 400kV CB (Dyn DN) (NC)Document8 pagesAlamathy 400kV CB (Dyn DN) (NC)Rajan_2010No ratings yet

- A Comparison of Frame Stability Analysis Methods in ANSI/AISC 360-05Document12 pagesA Comparison of Frame Stability Analysis Methods in ANSI/AISC 360-05MugamputhagamNo ratings yet

- Flat SlabDocument38 pagesFlat SlabRicky Gunawan100% (1)

- SG Rule of Thumb For RC DesignDocument13 pagesSG Rule of Thumb For RC DesignRsjBugtongNo ratings yet

- Design of Anchor Reinforcement A Petrolium Project Papers 199Document20 pagesDesign of Anchor Reinforcement A Petrolium Project Papers 199walidNo ratings yet

- BY Pooja Pingle: Structwel Designers & ConsultantsDocument23 pagesBY Pooja Pingle: Structwel Designers & ConsultantssachinapkarNo ratings yet

- Anchor Bolt DesignDocument26 pagesAnchor Bolt Designdwicahyo_as100% (1)

- Pour StripsDocument2 pagesPour StripsChetan Tolia100% (1)

- FOUNDATIONS FOR VIBRATING MACHINESDocument13 pagesFOUNDATIONS FOR VIBRATING MACHINESAJBAJBNo ratings yet

- Codeofpracticefor Designandconstructionof MachinefoundationsDocument6 pagesCodeofpracticefor Designandconstructionof MachinefoundationsMalar ManoharanNo ratings yet

- Qap-15-23 - rg1700 01 Rev-5 Design Criteria For Concrete Foundations and StructuresDocument23 pagesQap-15-23 - rg1700 01 Rev-5 Design Criteria For Concrete Foundations and StructuresAnonymous uLAATWpfNo ratings yet

- Example II.C-5 HSS Chevron Brace Connection: F F F FDocument5 pagesExample II.C-5 HSS Chevron Brace Connection: F F F FVasilica BarbarasaNo ratings yet

- CaissonDocument12 pagesCaissonjohnnyoliveiraNo ratings yet

- Designing Foundations for Pumps and CompressorsDocument38 pagesDesigning Foundations for Pumps and CompressorsAmrut BhattNo ratings yet

- Concrete Building ElementDocument2 pagesConcrete Building ElementsheikNo ratings yet

- Dokumen - Tips - X848ebook Download PDF Marine Structural Design A El Reedys BackgroundDocument7 pagesDokumen - Tips - X848ebook Download PDF Marine Structural Design A El Reedys BackgroundRaviNo ratings yet

- IS.11639.Part 2.1995Document13 pagesIS.11639.Part 2.1995imadhuryya5023No ratings yet

- (Eng) Steel Code Check 2011.0 v1Document123 pages(Eng) Steel Code Check 2011.0 v1chhouch100% (1)

- Calculating Wind Load on a Dish AntennaDocument1 pageCalculating Wind Load on a Dish AntennadovermanNo ratings yet

- Optimum Tail Shapes For Bodies of Revolution PDFDocument7 pagesOptimum Tail Shapes For Bodies of Revolution PDFnaro0101No ratings yet

- Shear Behavior of Headed Anchors With Large Diameters and Deep Embedments - Discussion Title 107-S14 - Mar-Apr 2010Document6 pagesShear Behavior of Headed Anchors With Large Diameters and Deep Embedments - Discussion Title 107-S14 - Mar-Apr 2010ehab.attalaNo ratings yet

- Installation and Bending of Underground PE PipingDocument1 pageInstallation and Bending of Underground PE PipingWalter Calle AranaNo ratings yet

- Design Plate Girders for Buildings & BridgesDocument109 pagesDesign Plate Girders for Buildings & BridgesFahd Abdul RahmanNo ratings yet

- Connection Design - CTL ObservationDocument1 pageConnection Design - CTL ObservationnvnagarajuNo ratings yet

- 1999 OMAE99 PIPE-5037 Bai - Bending Moment Capacity of PipesDocument13 pages1999 OMAE99 PIPE-5037 Bai - Bending Moment Capacity of Pipesdmlsfmm100% (1)

- Problem 1-015 PDFDocument3 pagesProblem 1-015 PDFOscar SanchezNo ratings yet

- Proposed Design Criteria For Stiffened Seated Connections To Column WebsDocument25 pagesProposed Design Criteria For Stiffened Seated Connections To Column WebsBùi Văn HợpNo ratings yet

- Technical Note - Effective Length Factors For Gusset Plates in Chevron Braced FramesDocument4 pagesTechnical Note - Effective Length Factors For Gusset Plates in Chevron Braced FramesJosh Wrase0% (1)

- Analysis Done in LPILE Plus v5.0Document9 pagesAnalysis Done in LPILE Plus v5.0Afzal WaseemNo ratings yet

- IS 802 Part-1 Sec-2 DRAFT 12oct11 PDFDocument18 pagesIS 802 Part-1 Sec-2 DRAFT 12oct11 PDFRohit DeraNo ratings yet

- Biaxial Bending of Steel Angle Section PDFDocument3 pagesBiaxial Bending of Steel Angle Section PDFImam NakhrowiNo ratings yet

- ACI 350.3/350.3R seismic design standard for liquid-containing concrete structuresDocument111 pagesACI 350.3/350.3R seismic design standard for liquid-containing concrete structuresmike wilsonNo ratings yet

- Schaeffler Diagram PDFDocument16 pagesSchaeffler Diagram PDFrajesh_14No ratings yet

- ASTM A307 Bolts ASTM A325 BoltsDocument21 pagesASTM A307 Bolts ASTM A325 BoltsprimasukmayuanaNo ratings yet

- Stability Analysis of Pipe Rack in Petrochemical Facilities-IJAERDV04I0264348Document11 pagesStability Analysis of Pipe Rack in Petrochemical Facilities-IJAERDV04I0264348Editor IJAERDNo ratings yet

- BS Iec Iee-56486979874967Document25 pagesBS Iec Iee-56486979874967ramasamy2012No ratings yet

- Bottom LugDocument7 pagesBottom LugAjiri IvoviNo ratings yet

- Astm d2015 1996 PDFDocument11 pagesAstm d2015 1996 PDFJeffersonCárdenasNo ratings yet

- The Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsDocument12 pagesThe Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsMiguelNo ratings yet

- G DavitarmsDocument30 pagesG Davitarmsosvald97No ratings yet

- Biaxial Bending and Torsion of Steel Equal Angle Section BeamsDocument29 pagesBiaxial Bending and Torsion of Steel Equal Angle Section Beamsp_meulendijks108No ratings yet

- ACI code requirements for structural concrete parametersDocument5 pagesACI code requirements for structural concrete parametersOscarCVNo ratings yet

- New Design Criteria For Gusset Plates in TensionDocument18 pagesNew Design Criteria For Gusset Plates in TensiongullipalliNo ratings yet

- 4.2bearing Type ConnectionsDocument6 pages4.2bearing Type ConnectionsMani KumarNo ratings yet

- Transverse Plate-To-squarerectangular Hss ConnectionsDocument7 pagesTransverse Plate-To-squarerectangular Hss Connectionsdeepak_dce_meNo ratings yet

- NCh2369.Of2003 (English April 25 2005) Seismic Design of Industrial Struct and FacilDocument131 pagesNCh2369.Of2003 (English April 25 2005) Seismic Design of Industrial Struct and FaciliagpconceNo ratings yet

- Arch Mechanism in Prestressed Concrete Beams With Web OpeningsDocument9 pagesArch Mechanism in Prestressed Concrete Beams With Web OpeningsChetan ToliaNo ratings yet

- Reinforcement Detailing For Openings in Beams 103Document5 pagesReinforcement Detailing For Openings in Beams 103stefengoNo ratings yet

- NCSCM Campus Tender DocumentsDocument498 pagesNCSCM Campus Tender Documentssadi3013No ratings yet

- Specification For Hollow Metal Pressed Steel Doors PDFDocument7 pagesSpecification For Hollow Metal Pressed Steel Doors PDFChetan ToliaNo ratings yet

- Site Grading Specs PDFDocument2 pagesSite Grading Specs PDFChetan ToliaNo ratings yet

- Basic Functions and The Right TriangleDocument15 pagesBasic Functions and The Right TriangleChetan Tolia100% (1)

- uPVC Pressure Grey Pipes BS PDFDocument3 pagesuPVC Pressure Grey Pipes BS PDFChetan ToliaNo ratings yet

- StructuresDocument33 pagesStructuresChetan ToliaNo ratings yet

- Basics of Engg MechanicsDocument10 pagesBasics of Engg MechanicsKumar RaviNo ratings yet

- RCC Member Design TipsDocument5 pagesRCC Member Design TipsChetan ToliaNo ratings yet

- 27 Shape of ArchesDocument20 pages27 Shape of ArchesChetan ToliaNo ratings yet

- Dia GridDocument16 pagesDia GridAshok VarmaNo ratings yet

- SL Chan FacadeDocument29 pagesSL Chan FacadeKayBee DatilesNo ratings yet

- Greatest Gift TimeDocument21 pagesGreatest Gift TimeChetan ToliaNo ratings yet

- Base Isolation For Increased Earthquake Resistance of BuildingsDocument9 pagesBase Isolation For Increased Earthquake Resistance of BuildingsChetan ToliaNo ratings yet

- Architects Guide 2010-03-18 PDFDocument47 pagesArchitects Guide 2010-03-18 PDFSharath JagadeeshanNo ratings yet

- SL Chan FacadeDocument29 pagesSL Chan FacadeKayBee DatilesNo ratings yet

- JBS Conceptual DesignDocument11 pagesJBS Conceptual DesignChetan ToliaNo ratings yet

- Buloane PeikkoDocument16 pagesBuloane Peikkovladimir8_addressNo ratings yet

- Cover Contents Preface Acknowledgements - DG12Document9 pagesCover Contents Preface Acknowledgements - DG12Eng TrNo ratings yet

- Maintenance of Building ElementsDocument10 pagesMaintenance of Building ElementsaremyulNo ratings yet

- Comparative Estimation of Underground Water Tank and Elevated Storage Tank of JunnarDocument7 pagesComparative Estimation of Underground Water Tank and Elevated Storage Tank of JunnarCE19M014 Gugulothu SurendarNo ratings yet

- Ram Concrete AnalysisDocument94 pagesRam Concrete AnalysisTom CurryNo ratings yet

- 3D-Dynamic Design For Reinforced Versus Prestress Concrete For Al-Huriya BuildingDocument36 pages3D-Dynamic Design For Reinforced Versus Prestress Concrete For Al-Huriya BuildingCahyadi SetiawanNo ratings yet

- Finall Structurall Report For PrintDocument66 pagesFinall Structurall Report For Printpoojitha100% (1)

- Design and Fabrication of Bambara Groundnut Vigna Subterranea L Verdc Combined Sorter Sheller and Cleaning Machine PDFDocument25 pagesDesign and Fabrication of Bambara Groundnut Vigna Subterranea L Verdc Combined Sorter Sheller and Cleaning Machine PDFFiraol GudisaNo ratings yet

- Small Craft Power PredictionDocument32 pagesSmall Craft Power Predictionaeromexpower2009No ratings yet

- 4 - Compression Members and Column Base PlatesDocument25 pages4 - Compression Members and Column Base Platesبشیر عبدالقادر چلبیNo ratings yet

- Metals Building Tech NotesDocument11 pagesMetals Building Tech Notescorazon philNo ratings yet

- MED162 Notes 7Document4 pagesMED162 Notes 7JOHN ANDREW HITOSISNo ratings yet

- Progressive Collapse Analysis of RC Buildings Using Non - Linear Static and Non - Linear Dynamic MethodDocument5 pagesProgressive Collapse Analysis of RC Buildings Using Non - Linear Static and Non - Linear Dynamic MethodMr PolashNo ratings yet

- Design of Over Head Water TankDocument20 pagesDesign of Over Head Water TankRomyMohan100% (1)

- Eval 5 Review Nov 2020Document5 pagesEval 5 Review Nov 2020criscab12345No ratings yet

- Ir Pc-1: Pre-Check (PC) Design Criteria For Freestanding Signs and Scoreboards: 2019 CBCDocument15 pagesIr Pc-1: Pre-Check (PC) Design Criteria For Freestanding Signs and Scoreboards: 2019 CBCAbrar AhmadNo ratings yet

- Combined Foundation Design (Is 456-2000) Result SummaryDocument30 pagesCombined Foundation Design (Is 456-2000) Result Summaryarchetype designNo ratings yet

- Brochure Final 29.06.2021-CompressedDocument36 pagesBrochure Final 29.06.2021-CompressedDuraid FalihNo ratings yet

- Bridge Continuous GirderDocument35 pagesBridge Continuous GirderGinald SantosNo ratings yet