Professional Documents

Culture Documents

Aashton T 308 T308 Short WPR 05

Uploaded by

Christina De MesaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aashton T 308 T308 Short WPR 05

Uploaded by

Christina De MesaCopyright:

Available Formats

ASPHALT

WAQTC/IDAHO

AASHTO T 308

DETERMINING THE ASPHALT BINDER CONTENT OF HOT MIX ASPHALT (HMA) BY THE IGNITION METHOD FOP FOR AASHTO T 308 (05) Scope This procedure covers the determination of asphalt binder content of hot mix asphalt (HMA) by ignition of the binder at 538C (1000F) or less in a furnace; samples may be heated by convection or direct infrared irradiation. The aggregate remaining after burning can be used for sieve analysis using the FOP for AASHTO T 30. Two methods A and B are presented. Some agencies allow the use of recycled HMA. When using recycled HMA, check with the agency for specific correction procedures. Background on Test Method Binder in the HMA is ignited in a furnace. Asphalt binder content is calculated as the difference between the initial mass of the HMA and the mass of the residual aggregate, correction factor, and moisture content. The asphalt binder content is expressed as percent of moisture-free mix mass. Sampling 1. Obtain samples of HMA in accordance with the FOP for AASHTO T 168. 2. Reduce HMA samples in accordance with the FOP for WAQTC TM 5. 3. If the mixture is not sufficiently soft to separate with a spatula or trowel, place it in a large flat pan in an oven at 125 5C (257 9F) until soft enough. 4. Test sample size shall be governed by nominal maximum aggregate size and shall conform to the mass requirement shown in Table 1. When the mass of the test specimen exceeds the capacity of the equipment used, the test specimen may be divided into suitable increments, tested, and the results appropriately combined through a weighted average for calculation of the binder content.

Note 1: Large samples of fine mixes tend to result in incomplete ignition of asphalt.

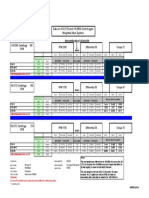

Table 1 Nominal Maximum Aggregate Size* mm (in.) 37.5 (1 ) 25.0 (1) 19.0 (3/4) 12.5 (1/2) 9.5 (3/8) 4.75 (No. 4)

T 308_short

Minimum Mass Specimen g 4000 3000 2000 1500 1200 1200

Asphalt 4-1

Maximum Mass Specimen g 4500 3500 2500 2000 1700 1700

October 2005

ASPHALT

WAQTC/IDAHO

AASHTO T 308

* One sieve larger than the first sieve to retain more than 10 percent of the material using an agency specified set of sieves based on cumulative percent retained. Where large gaps in specification sieves exist, intermediate sieve(s) may be inserted to determine nominal maximum size.

Apparatus

Note 2: The apparatus must be calibrated for the specific mix design. See Correction Factors at the end of this FOP.

There are two methods A and B. The apparatus for the two methods are the same except that the furnace for Method A has an internal balance. Forced air ignition furnace, capable of maintaining the temperature at 578C (1072F). For Method A, the furnace will be quipped with an internal scale thermally isolated from the furnace chamber and accurate to 0.1 g. The scale shall be capable of determining the mass of a 3500 g sample in addition to the sample baskets. A data collection system will be included so that mass can be automatically determined and displayed during the test. The furnace shall have a built-in computer program to calculate change in mass of the sample baskets and provide for the input of a correction factor for aggregate loss. The furnace shall provide a printed ticket with the initial specimen mass, specimen mass loss, temperature compensation, correction factor, corrected binder content, test time, and test temperature. The furnace shall provide an audible alarm and indicator light when the sample mass loss does not exceed 0.01 % of the total sample mass for three consecutive minutes.

Note 3: The furnace shall be designed to permit the operator to change the ending mass loss percentage from 0.01 percent to 0.02 percent.

For both Method A and Method B, the furnace chamber dimensions shall be adequate to accommodate a 3500 g sample. The furnace door shall be equipped so that it cannot be opened during the ignition test. A method for reducing furnace emissions shall be provided and the furnace shall be vented so that no emissions escape into the laboratory. The furnace shall have a fan to pull air through the furnace to expedite the test and to eliminate the escape of smoke into the laboratory. Sample Basket Assembly: consisting of sample basket(s), catch pan, and basket guards. Sample basket(s) will be of appropriate size allowing samples to be thinly spread and allowing air to flow through and around the sample particles. Sets of two or more baskets shall be nested. A catch pan: of sufficient size to hold the sample basket(s) so that aggregate particles and melting binder falling through the screen mesh are caught. Basket guards will completely enclose the basket and be made of screen mesh, perforated stainless steel plate, or other suitable material.

Note 4: Screen mesh or other suitable material with maximum and minimum opening of 2.36 mm (No. 8) and 600 m (No. 30) respectively has been found to perform well.

Thermometer, or other temperature measuring device, with a temperature range of 10 260C (50-500F). Oven capable of maintaining 125 5C (257 9F). Balance or scale: capacity sufficient for the sample mass and conforming to the requirements of M 231, Class G2.

Asphalt 4-2 October 2005

T 308_short

ASPHALT

WAQTC/IDAHO

AASHTO T 308

Safety equipment: Safety glasses or face shield, high temperature gloves, long sleeve jacket, a heat resistant surface capable of withstanding 650C (1202F), and a protective cage capable of surrounding the sample baskets during the cooling period. Particle mask for use during removal of the sample from the basket assembly. Miscellaneous equipment: A pan larger than the sample basket(s) for transferring sample after ignition, spatulas, bowls, and wire brushes.

Procedure Method A (Internal Balance) 1. Preheat the ignition furnace to 538C (1000F) or to the temperature determined in the Correction Factor section, Step 9 of this method. Manually record the furnace temperature (set point) prior to the initiation of the test if the furnace does not record automatically. 2. Dry the sample to constant mass, according to the FOP for AASHTO T 329; or determine the moisture content of a companion sample in accordance with the FOP for AASHTO T 329. 3. Determine and record the mass to the nearest 0.1 g of the sample basket assembly. 4. Evenly distribute the sample in the sample basket assembly, taking care to keep the material away from the edges of the basket. Use a spatula or trowel to level the sample. 5. Determine and record the total mass to the nearest 0.1 g of the sample and sample basket assembly. Calculate and record the initial mass of the sample (total mass minus the mass of the sample basket assembly) to the nearest 0.1 g. Designate this mass as (Mi). 6. 7. Record the correction factor or input into the furnace controller for the specific HMA. Input the initial mass of the sample (Mi) into the ignition furnace controller. Verify that the correct mass has been entered.

CAUTION: Operator should wear safety equipment high temperature gloves, face shield, fire-retardant shop coat when opening the door to load or unload the sample.

8.

Open the chamber door and gently set the sample basket assembly in the furnace. Carefully position the sample basket assembly so it is not in contact with the furnace wall. Close the chamber door and verify that the sample mass displayed on the furnace scale equals the total mass of the sample and sample basket assembly recorded in Step 5 within 5 g.

Note 5: Furnace temperature will drop below the set point when the door is opened, but will recover when the door is closed and ignition begins. Sample ignition typically increases the temperature well above the set point relative to sample size and binder content.

9.

Initiate the test by pressing the start button. This will lock the sample chamber and start the combustion blower.

Safety note: Do not attempt to open the furnace door until the asphalt binder has been completely burned off.

10.

Allow the test to continue until the stable light and audible stable indicator indicate that the change in mass does not exceed 0.01 % for three consecutive minutes. Press the stop button. This will unlock the sample chamber and cause the printer to print out the test results.

T 308_short

Asphalt 4-3

October 2005

ASPHALT

WAQTC/IDAHO

AASHTO T 308

Note 6: An ending mass loss percentage of 0.02 may be used, if allowed by the agency, when aggregate that exhibits an excessive amount of loss during ignition testing is used.

11.

Open the chamber door, remove the sample basket assembly, and place on the cooling plate or block. Place the protective cage over the sample basket assembly and allow it to cool to room temperature (approximately 30 minutes). Determine and record the total after ignition mass to the nearest 0.1 g. Calculate and record the mass of the sample, after ignition (total after ignition mass minus the mass of the sample basket assembly) to the nearest 0.1 g. Designate this mass as Mf. Use the asphalt binder content percentage from the printed ticket. If the sample was not oven dried and a moisture content percentage has been determined, subtract the moisture content from the printed ticket asphalt binder content and report the difference as the corrected asphalt binder content. Pb = BC M Cf (if not input in the furnace controller) where: Pb = BC = M= Cf = the corrected asphalt binder content as a percent by mass of the HMA asphalt binder content shown on printed ticket percent moisture content as determined by the FOP for AASHTO T 329 correction factor as a percent by mass of the HMA sample

12.

13.

14. Asphalt binder content percentage can also be calculated using the formula from Method B Step 16. Procedure Method B (External Balance) 1. Preheat the ignition furnace to 538C (1000F) or to the temperature determined in the Correction Factor section Step 9. Manually record the furnace temperature (set point) prior to the initiation of the test if the furnace does not record automatically. 2. Dry the sample to constant mass, according to the FOP for AASHTO T 329; or determine the moisture content of a companion sample in accordance with the FOP for AASHTO T 329. 3. Determine and record the mass to the nearest 0.1 g of the sample basket assembly. 4. Place the sample basket(s) in the catch pan. Evenly distribute the sample in the sample basket(s), taking care to keep the material away from the edges of the basket. Use a spatula or trowel to level the sample. 5. Determine and record the total mass to the nearest 0.1 g of the sample and sample basket assembly. Calculate and record the initial mass of the sample (total mass minus the mass of the sample basket assembly) to the nearest 0.1 g. Designate this mass as (Mi ). 6. Record the correction factor for the specific HMA. 7. Open the chamber door and gently set the sample basket assembly in the furnace. Carefully position the sample basket assembly so it is not in contact with the furnace wall. Burn the HMA sample in the furnace for 45 minutes or the length of time determined in Correction Factor section.

T 308_short

Asphalt 4-4

October 2005

ASPHALT

WAQTC/IDAHO

AASHTO T 308

8. Open the chamber door, remove the sample basket assembly, and place on the cooling plate or block. Place the protective cage over the sample and allow it to cool to room temperature (approximately 30 min). 9. Determine and record the total after ignition mass to the nearest 0.1 g. Calculate and record the mass of the sample, after ignition (total after ignition mass minus the mass of the sample basket assembly) to the nearest 0.1 g. 10. 11. 12. Place the sample basket assembly back into the furnace. Burn the sample for at least 15 minutes after the furnace reaches the set temperature. Open the chamber door, remove the sample basket assembly, and place on the cooling plate or block. Place the protective cage over the sample basket assembly and allow it to cool to room temperature (approximately 30 min). Determine and record the total after ignition mass to the nearest 0.1 g. Calculate and record the mass of the sample, after ignition (total after ignition mass minus the mass of the sample basket assembly) to the nearest 0.1 g. Repeat Steps 10 through 13 until the change in measured mass, of the sample after ignition, does not exceed 0.01 percent of the previous sample mass, after ignition.

Note 7: An ending mass loss percentage of 0.02 may be used, if allowed by the agency, when aggregate that exhibits an excessive amount of loss during ignition testing is used.

13.

14.

15. 16.

Record the final value obtained as Mf, the final mass of the sample after ignition. Calculate the asphalt binder content of the sample as follows:

M Mf Pb = i 100 C f M Mi

where: Pb = Mf = Mi = Cf = M= Example Initial Mass of Sample and Basket = 5292.7 Mass of Basket Assembly Mi = 2931.5 = 2361.2 = 5154.4 = 2222.9 the corrected asphalt binder content as a percent by mass of the HMA sample the final mass of aggregate remaining after ignition the initial mass of the HMA sample prior to ignition correction factor as a percent by mass of the HMA sample percent moisture content as determined by the FOP for AASHTO T 329.

Total Mass after First ignition + basket Sample Mass after First ignition

T 308_short

Asphalt 4-5

October 2005

ASPHALT

WAQTC/IDAHO

AASHTO T 308

Sample Mass after additional 15 min ignition = 2222.7

(2222.9 2222.7) 100 = 0.009 2222.9 not greater than 0.01% so, Mf =

(2361.2 2222.7) 100 0.42 0.04 = 5.41% 2361.2

2222.7

Pb= 5.41% Gradation

1. Empty contents of the basket(s) into a flat pan, being careful to capture all material. Use a small wire brush to ensure all residual fines are removed from the baskets.

Note 8: Particle masks are a recommended safety precaution.

2. Perform the gradation analysis in accordance with the FOP for AASHTO T 30.

Report

Results shall be reported on standard forms approved by the agency. Include: Method of test (A or B) Corrected asphalt binder content, Pb Correction factor, Cf Temperature compensation factor (if applicable) Total percent loss Sample mass Moisture content Test temperature.

Attach the original printed ticket with all intermediate values (continuous tape) to the report for furnaces with internal balances.

Correction Factors Asphalt Binder and Aggregate

Asphalt binder content results may be affected by the type of aggregate in the mixture and by the ignition furnace. Asphalt binder and aggregate correction factors must, therefore, be established by testing a set of correction specimens for each Job Mix Formula (JMF) mix design. Each ignition furnace will have its own unique correction factor determined in the location where testing will be performed.

T 308_short

Asphalt 4-6

October 2005

ASPHALT

WAQTC/IDAHO

AASHTO T 308

This procedure must be performed before any acceptance testing is completed, and repeated each time there is a change in the mix ingredients or design. Any changes greater than 5% in stockpiled aggregate proportions should require a new correction factor. All correction samples will be prepared by a central / regional laboratory unless otherwise directed.

Asphalt binder correction factor: A correction factor must be established by testing a set of correction specimens for each Job Mix Formula (JMF). Certain aggregate types may result in unusually high correction factors (> 1.0%). Such mixes should be corrected and tested at a lower temperature as described below. Aggregate correction factor: Due to potential aggregate breakdown during the ignition process, a correction factor will need to be determined for the following conditions:

a. Aggregates that have a proven history of excessive breakdown b. Aggregate from an unknown source. This correction factor will be used to adjust the acceptance gradation test results obtained according to the FOP for AASHTO T 30.

Procedure

1. Obtain samples of aggregate in accordance with the FOP for AASHTO T 2. 2. Obtain samples of asphalt binder in accordance with the FOP for AASHTO T 40.

Note #9: Include other additives that may be required by the JMF.

3. Prepare an initial, or butter, mix at the design asphalt binder content. Mix and discard the butter mix prior to mixing any of the correction specimens to ensure accurate asphalt content. 4. Prepare two correction specimens at the JMF design asphalt binder content. Aggregate used for correction specimens shall be sampled from material designated for use on the project. An agency approved method will be used to combine aggregate. An additional blank specimen shall be batched and tested for aggregate gradation in accordance with the FOP for AASHTO T 30. The gradation from the blank shall fall within the agency specified mix design tolerances. 5. Place the freshly mixed specimens directly into the sample basket assembly. If mixed specimens are allowed to cool prior to placement in the sample basket assembly, the specimens must be dried to constant mass according to the FOP for AASHTO T 329. Do not preheat the sample basket assembly. 6. Test the specimens in accordance with Method A or Method B of the procedure. 7. Once both of the correction specimens have been burned, determine the asphalt binder content for each specimen by calculation or from the printed oven tickets, if available. 8. If the difference between the asphalt binder contents of the two specimens exceeds 0.15%, repeat with two more specimens and, from the four results, discard the high and low result. Determine the correction factor from the two original or remaining

T 308_short

Asphalt 4-7

October 2005

ASPHALT

WAQTC/IDAHO

AASHTO T 308

results, as appropriate. Calculate the difference between the actual and measured asphalt binder contents for each specimen. The asphalt binder correction factor, Cf, is the average of the differences expressed as a percent by mass of HMA. 9. If the asphalt binder correction factor exceeds 1.0%, the test temperature must be lowered to 482 5C (900 8F).

Note 10: The temperature for determining the asphalt binder content of HMA samples by this procedure shall be the same temperature determined for the correction samples.

10. Perform a gradation analysis on the residual aggregate in accordance with the FOP for AASHTO T 30, if required. The results will be utilized in developing an Aggregate Correction Factor and should be calculated and reported to 0.1%. 11. From the gradation results subtract the % passing for each sieve, for each sample, from the % passing each sieve of the Blank specimen gradation results from Step 4. 12. Determine the average difference of the two values. If the difference for any single sieve exceeds the allowable difference of that sieve as listed in Table 2, then aggregate gradation correction factors (equal to the resultant average differences) for all sieves shall be applied to all acceptance gradation test results determined by the FOP for AASHTO T 30. If the 75 m (No. 200) is the only sieve outside the limits in Table 2, apply the aggregate correction factor to only the 75 m (No. 200) sieve.

Table 2 Permitted Sieving Difference

Sieve Sizes larger than or equal to 2.36 mm (No.8) Sizes larger than to 75 m (No.200) and smaller than 2.36 mm (No.8) Sizes 75 m (No.200) and smaller Allowable Difference 5.0% 3.0% 0.5%

T 308_short

Asphalt 4-8

October 2005

ASPHALT

WAQTC/IDAHO

AASHTO T 308

Examples:

Correction factor Blank sample % Passing 100 86.3 77.4 51.5 34.7 23.3 16.4 12.0 8.1 5.5 Correction factor sample #1 % Passing 100 87.4 76.5 53.6 36.1 25.0 19.2 11.1 9.9 5.9 Correction factor sample #2 % Passing 100 86.4 78.8 55.9 37.2 23.9 18.1 12.7 6.3 6.2 Difference 1/2 Ave. Diff. Sieves to adjust

Sieve Size mm (in.) 19.0 (3/4) 12.5 (1/2) 9.5 (3/8) 4.75 (No. 4) 2.36 (No. 8) 01.18 (No. 16) 0.600 (No. 30) 0.300 (No. 50) 0.150 (No. 100) 75 m (No. 200)

0/0 -1.1/-0.1 +0.9/-1.4 -2.1/-4.4 -1.4/-2.5 -1.7/-0.6 -2.8/-1.7 +0.9/-0.7 -1.8/+1.8 -0.4/-0.7

0.0 -0.6 -0.5 -3.2 -2.0 -1.2 -2.2 +0.1 0.0 -0.6

- 0.6

In this example all acceptance gradation test results (FOP for AASHTO T 30) performed on the residual aggregate would have an Aggregate Correction Factor. This factor would be - 0.6% on the 75 m (No. 200) sieve and would be applied to the % passing 75 m (No.200) sieve.

Sieve Size mm (in.) 19.0 (3/4) 12.5 (1/2) 9.5 (3/8) 4.75 (No. 4) 2.36 (No. 8) 01.18 (No. 16) 0.600 (No. 30) 0.300 (No. 50) 0.150 (No. 100) 75 m (No. 200)

Correction factor Blank sample % Passing 100 86.3 77.4 51.5 34.7 23.3 16.4 12.0 8.1 5.5

Correction factor sample #1 % Passing 100 87.4 76.5 55.6 36.1 25.0 19.2 11.1 9.9 5.9

Correction factor sample #2 % Passing 100 86.4 78.8 57.9 37.2 23.9 18.1 12.7 6.3 6.2

Difference 1/2

Ave. Diff.

Sieves to adjust

0/0 -1.1/-0.1 +0.9/-1.4 -4.1/-6.4 -1.4/-2.5 -1.7/-0.6 -2.8/-1.7 +0.9/-0.7 -1.8/+1.8 -0.4/-0.7

0.0 -0.6 -0.5 -5.2 -2.0 -1.2 -2.2 +0.1 0.0 -0.6

0.0 -0.6

-0.5 -5.2 -2.0 -1.2 -2.2 +0.1 0.0 -0.6

In this example all acceptance gradation test results (FOP for AASHTO T 30) performed on the residual aggregate would have an Aggregate Correction Factor. The correction factor for each sieve must be applied because the average difference on the 4.75mm (No. 4) is outside the tolerance from Table 2.

T 308_short

Asphalt 4-9

October 2005

ASPHALT

WAQTC/IDAHO

AASHTO T 308

PERFORMANCE EXAM CHECKLIST DETERMINING THE ASPHALT BINDER CONTENT OF HOT MIX ASPHALT (HMA) BY THE IGNITION METHOD FOP FOR AASHTO T 308

Participant Name ______________________________

Exam Date ______________

Record the symbols P for passing or F for failing on each step of the checklist.

Procedure Element

2. Sample reduced to correct size? 3. HMA sample dried to constant mass at 105C (221F) or companion moisture sample taken per T 329? 4. Mass of sample basket assembly recorded to 0.1 g? 5. With pan below basket(s) sample evenly distributed in basket(s)? 6. Sample conforms to the required mass and mass recorded to 0.1 g?

Trial 1 Trial 2

1. Oven at correct temperature 538C (1000F) or correction Factor temperature? _____

_____ _____ _____ _____

_____ _____

_____ _____ _____

_____ _____

7. Method A a. Initial mass entered into furnace controller? b. Sample correctly placed into furnace? c. Test continued until stable indicator signals?

d.

_____ _____ _____

_____

_____ _____ _____

_____

Uncorrected binder content obtained on printed ticket? Sample mass determined to nearest 0.1 g.?

e.

_____

_____

8. Method B a. Initial temperature of sample recorded? b. Sample correctly placed into furnace? c. Sample burned for 45 min or time determined in calibration? d. Sample cooled to initial temperature? e. Sample burned to constant mass? f. Sample mass determined to nearest 0.1 g.? _____ _____ _____ _____ _____ _____ _____ _____ _____ _____ _____ _____ _____ _____

g. Uncorrected binder content calculated correctly and recorded?

OVER

T 308_short

Asphalt 4-10

October 2005

ASPHALT

WAQTC/IDAHO

AASHTO T 308

Procedure Element

9. Binder content corrected for Correction Factor if needed? 10. Binder content corrected for moisture per T 329 if needed? 11. Corrected binder content recorded to 0.01%? 12. Contents of the basket(s) carefully empted into a pan?

Trial 1 Trial 2

_____ _____ _____ _____ Second attempt: Pass _____ _____ _____ _____ Fail

Comments:

First attempt: Pass

Fail

Examiner Signature _______________________________WAQTC #:_______________

T 308_short

Asphalt 4-11

October 2005

You might also like

- 211 R83-17 PDFDocument11 pages211 R83-17 PDFjun floresNo ratings yet

- ABB 3HAC050988 AM Arc and Arc Sensor RW 6-En PDFDocument238 pagesABB 3HAC050988 AM Arc and Arc Sensor RW 6-En PDForefat1No ratings yet

- D 995 - 95b R02 - RDK5NQDocument6 pagesD 995 - 95b R02 - RDK5NQAjesh kumar0% (1)

- AASHTO T 304 Vacios en Agregado FinoDocument4 pagesAASHTO T 304 Vacios en Agregado FinoVHBH100% (1)

- Aashto t305Document3 pagesAashto t305SyahrulRamadhanNo ratings yet

- Sampling Bituminous Paving Mixtures: Standard Practice ForDocument4 pagesSampling Bituminous Paving Mixtures: Standard Practice ForAnonymous x7VY8VF7No ratings yet

- D 1754 - 97 Standard Test Method For Effects of Heat and Air On Asphaltic Materials (Thin-Film Oven Test)Document6 pagesD 1754 - 97 Standard Test Method For Effects of Heat and Air On Asphaltic Materials (Thin-Film Oven Test)Munawar IqbalNo ratings yet

- Aashto T 308 (2013)Document8 pagesAashto T 308 (2013)Stuar TencioNo ratings yet

- Embankment and Base Waqtc AASHTO T 99/T 180 In-Place DensityDocument10 pagesEmbankment and Base Waqtc AASHTO T 99/T 180 In-Place DensityFaiber CardenasNo ratings yet

- D1754-D1754M - 09 PDFDocument6 pagesD1754-D1754M - 09 PDFEduardo MenaNo ratings yet

- Effect of Water On Compressive Strength of Compacted Bituminous MixturesDocument3 pagesEffect of Water On Compressive Strength of Compacted Bituminous MixturesDEBOJIT NANDINo ratings yet

- Determining The Plastic Limit and Plasticity Index of Soils Fop For Aashto T 90 (07) ScopeDocument4 pagesDetermining The Plastic Limit and Plasticity Index of Soils Fop For Aashto T 90 (07) ScopejcazNo ratings yet

- AASHTO T176 Determining Sand Equivalent or Clay Content of Fine Aggregate (Finer Than No. 4)Document12 pagesAASHTO T176 Determining Sand Equivalent or Clay Content of Fine Aggregate (Finer Than No. 4)Đức Trung TrầnNo ratings yet

- Autoclave Expansion of Portland Cement: Standard Method of Test ForDocument2 pagesAutoclave Expansion of Portland Cement: Standard Method of Test ForEvert RiveraNo ratings yet

- D 692 - 00 Rdy5mi0wmaDocument2 pagesD 692 - 00 Rdy5mi0wmaRufo Casco0% (1)

- Sieve Analysis of Mineral Filler For Bituminous Paving MixturesDocument2 pagesSieve Analysis of Mineral Filler For Bituminous Paving MixturesArnold RojasNo ratings yet

- Astm D 4318Document16 pagesAstm D 4318Camilo OrozcoNo ratings yet

- Unit Weight and Voids in Aggregate: Standard Method of Test ForDocument4 pagesUnit Weight and Voids in Aggregate: Standard Method of Test ForEvert RiveraNo ratings yet

- AASHTO T 30, "Mechanical Analysis of Extracted AggregatesDocument12 pagesAASHTO T 30, "Mechanical Analysis of Extracted AggregatesĐức Trung TrầnNo ratings yet

- Astm D2726-17Document4 pagesAstm D2726-17Iranis E Lugo RodriguezNo ratings yet

- ASTM D 2041 - 03 - RdiwndetukveDocument5 pagesASTM D 2041 - 03 - RdiwndetukveharisahamedNo ratings yet

- Aashto t84 Specific Gravity and Absorption of Fine Gravity CompressDocument9 pagesAashto t84 Specific Gravity and Absorption of Fine Gravity Compressaisa syahNo ratings yet

- Astm C 618 02 1Document4 pagesAstm C 618 02 1Ciro Arnold Gonzales PauccarNo ratings yet

- Amount of Water Required For Normal Consistency of Hydraulic Cement PasteDocument3 pagesAmount of Water Required For Normal Consistency of Hydraulic Cement PasteThurain Aung KyawNo ratings yet

- Uncompacted Void Content of Fine Aggregate Test ProcedureDocument4 pagesUncompacted Void Content of Fine Aggregate Test ProcedureRianSastikaNo ratings yet

- Residue by Evaporation of Emulsified Asphalt: Standard Test Method ForDocument2 pagesResidue by Evaporation of Emulsified Asphalt: Standard Test Method ForManuel Enrique VásquezNo ratings yet

- Effects of Heat and Air On Asphaltic Materials (Thin-Film Oven Test)Document7 pagesEffects of Heat and Air On Asphaltic Materials (Thin-Film Oven Test)Kev SantiagoNo ratings yet

- Plastic Limit Plasticity Indext 090Document5 pagesPlastic Limit Plasticity Indext 090Jayson AbejarNo ratings yet

- Determining Demulsibility of Emulsified Asphalt: Standard Test Method ForDocument2 pagesDetermining Demulsibility of Emulsified Asphalt: Standard Test Method ForROBERTO MIRANDANo ratings yet

- Resistance To Plastic Flow of Bituminous Mixtures Using Marshall ApparatusDocument10 pagesResistance To Plastic Flow of Bituminous Mixtures Using Marshall ApparatusRichar DiegoNo ratings yet

- Astm Ac20Document3 pagesAstm Ac20Juan QuiñonesNo ratings yet

- Sampling Aggregates: Standard Practice ForDocument8 pagesSampling Aggregates: Standard Practice ForAbbasi HussainNo ratings yet

- WETTING AND DRYING TESTDocument12 pagesWETTING AND DRYING TESTEsteban FinoNo ratings yet

- ASTM Volume 04.03 Road and Paving MaterialsDocument7 pagesASTM Volume 04.03 Road and Paving MaterialsVenu GopalNo ratings yet

- Astm d6927Document3 pagesAstm d6927Tally AnuNo ratings yet

- Test Methods for Mineral Fillers Used in HMADocument55 pagesTest Methods for Mineral Fillers Used in HMASulaiman Musa MuhammadNo ratings yet

- ASSHTODocument3 pagesASSHTOmiguelangelNo ratings yet

- D2872.1207683-1 - RTFOT - NormaDocument6 pagesD2872.1207683-1 - RTFOT - NormaDenny SantanaNo ratings yet

- R67-16 Muestreo Mezcla Asfaltica Despues Compactacion (Nucleos)Document5 pagesR67-16 Muestreo Mezcla Asfaltica Despues Compactacion (Nucleos)dannychacon270% (1)

- Rutting in Asphalt Pavement Under Heavy Load and High TemperatureDocument10 pagesRutting in Asphalt Pavement Under Heavy Load and High Temperaturealiyan malkNo ratings yet

- D 4405Document5 pagesD 4405mohsenNo ratings yet

- Hydraulic Hydrated Lime For Structural PurposesDocument3 pagesHydraulic Hydrated Lime For Structural PurposesAlejandroNo ratings yet

- Compressive Strength of Molded Soil-Cement Cylinders: Standard Test Methods ForDocument4 pagesCompressive Strength of Molded Soil-Cement Cylinders: Standard Test Methods ForManuel Enrique VásquezNo ratings yet

- Memo 097.7 - 102319 - Item 450 Tunnel ExcavationDocument9 pagesMemo 097.7 - 102319 - Item 450 Tunnel ExcavationBai Alleha MusaNo ratings yet

- Constituents of Concrete Aggregates: Standard Descriptive Nomenclature ForDocument11 pagesConstituents of Concrete Aggregates: Standard Descriptive Nomenclature FormickyfelixNo ratings yet

- D4867 PDFDocument5 pagesD4867 PDFAdderly Ortega100% (1)

- Aashto T 309-15Document3 pagesAashto T 309-15William VasquezNo ratings yet

- ASTM D 545 2005, Standard TestDocument4 pagesASTM D 545 2005, Standard TestJhon100% (1)

- Astm D 2170 - 07Document10 pagesAstm D 2170 - 07m_seyedNo ratings yet

- SuperPaveFed PDFDocument96 pagesSuperPaveFed PDFNurul Syuhadah NorhasiniNo ratings yet

- Specific Gravity and Absorption of Fine Aggregate: Standard Method of Test ForDocument10 pagesSpecific Gravity and Absorption of Fine Aggregate: Standard Method of Test ForDannyChaconNo ratings yet

- Aashto Pp-14 (2018) Diseño OgfcDocument9 pagesAashto Pp-14 (2018) Diseño OgfcMario Esteban Solano RodriguezNo ratings yet

- D244Document8 pagesD244samuelNo ratings yet

- HOT MIX ASPHALT (HMA) TECHNICIAN TRAINING MANUALDocument96 pagesHOT MIX ASPHALT (HMA) TECHNICIAN TRAINING MANUALbsranjhaNo ratings yet

- Aashto T265-15Document4 pagesAashto T265-15Besha aliNo ratings yet

- Lightweight Pieces in Aggregate: NOTE 1-Caution: The Chemicals Listed inDocument2 pagesLightweight Pieces in Aggregate: NOTE 1-Caution: The Chemicals Listed inEvert RiveraNo ratings yet

- D3910-15-Design, Testing, and Construction of Slurry SealDocument8 pagesD3910-15-Design, Testing, and Construction of Slurry SealEveling Vanegas NarváezNo ratings yet

- Aashto t27Document4 pagesAashto t27binoNo ratings yet

- Aashto T0049 PDFDocument2 pagesAashto T0049 PDFram6265790No ratings yet

- Aastho T 308Document12 pagesAastho T 308Maikol Alexsis Salazar VásquezNo ratings yet

- Determining The Asphalt Binder Content of Hot Mix Asphalt (Hma) by The Ignition Method Fop For Aashto T 308 ScopeDocument14 pagesDetermining The Asphalt Binder Content of Hot Mix Asphalt (Hma) by The Ignition Method Fop For Aashto T 308 ScopeBanta SINGHNo ratings yet

- Master PlannersDocument4 pagesMaster PlannersChristina De MesaNo ratings yet

- Philippine ChurchesDocument5 pagesPhilippine ChurchesChristina De MesaNo ratings yet

- Hoa Filipino ArchitectsDocument7 pagesHoa Filipino ArchitectsJamiGadiNo ratings yet

- Rational MethodDocument49 pagesRational MethodChristina De MesaNo ratings yet

- Slump TestDocument1 pageSlump TestChristina De MesaNo ratings yet

- Field Density Test: Rubber-Balloon, Sand-Cone, Nuclear MethodsDocument2 pagesField Density Test: Rubber-Balloon, Sand-Cone, Nuclear MethodsOweida BacaroNo ratings yet

- Earthworks LangDocument11 pagesEarthworks LangChristina De MesaNo ratings yet

- JOIST AND STRUCTURAL GLOSSARYDocument29 pagesJOIST AND STRUCTURAL GLOSSARYChristina De MesaNo ratings yet

- D6528-07 ASTM Standard Consolidated Undrained Direct Simple Shear Testing of Cohesive SoilsDocument9 pagesD6528-07 ASTM Standard Consolidated Undrained Direct Simple Shear Testing of Cohesive SoilsDayana HernandezNo ratings yet

- Pentecostal Ecclesiology: Simon K.H. Chan - 978-90-04-39714-9 Via Free AccessDocument156 pagesPentecostal Ecclesiology: Simon K.H. Chan - 978-90-04-39714-9 Via Free AccessStanley JohnsonNo ratings yet

- 6b530300 04f6 40b9 989e Fd39aaa6293aDocument1 page6b530300 04f6 40b9 989e Fd39aaa6293attariq_jjavedNo ratings yet

- Ebrosur Silk Town PDFDocument28 pagesEbrosur Silk Town PDFDausNo ratings yet

- Module 37 Nur 145Document38 pagesModule 37 Nur 145Marga WreatheNo ratings yet

- Introduction 3-12-86Document13 pagesIntroduction 3-12-86Roshdy AbdelRassoulNo ratings yet

- 1 John 2:15-27 - Bible Commentary For PreachingDocument6 pages1 John 2:15-27 - Bible Commentary For PreachingJacob D. GerberNo ratings yet

- Company Profile 2Document7 pagesCompany Profile 2R Saravana KumarNo ratings yet

- Hairpin tube arrangements and multiple-bend designs for superheatersDocument2 pagesHairpin tube arrangements and multiple-bend designs for superheatersMArifHidayahNo ratings yet

- Sample Field Trip ReportDocument6 pagesSample Field Trip ReportBILAL JTTCNo ratings yet

- HS-2172 Vs HS-5500 Test ComparisonDocument1 pageHS-2172 Vs HS-5500 Test ComparisonRicardo VillarNo ratings yet

- Com Statement (HT APFC22 - 02)Document2 pagesCom Statement (HT APFC22 - 02)SOUMENNo ratings yet

- IruChem Co., Ltd-Introduction of CompanyDocument62 pagesIruChem Co., Ltd-Introduction of CompanyKhongBietNo ratings yet

- Uji Deteksi Biofilm Dari Isolat Klinik Kateter Urin Bakteri Entercoccus Dibandingkan Dengan Tube MethodDocument27 pagesUji Deteksi Biofilm Dari Isolat Klinik Kateter Urin Bakteri Entercoccus Dibandingkan Dengan Tube MethodIyannyanNo ratings yet

- Mitchella Partridge Berry Materia Medica HerbsDocument3 pagesMitchella Partridge Berry Materia Medica HerbsAlejandra GuerreroNo ratings yet

- Fendering For Tugs: Mike Harrison, Trelleborg Marine Systems, UKDocument5 pagesFendering For Tugs: Mike Harrison, Trelleborg Marine Systems, UKRizal RachmanNo ratings yet

- The Creators College of Science & Commerce: 1 TermDocument2 pagesThe Creators College of Science & Commerce: 1 TermJhangir Awan33% (3)

- Tap Yourself FreeDocument134 pagesTap Yourself Freenguyenhavn100% (2)

- Citric Acid Passivation of Stainless SteelDocument41 pagesCitric Acid Passivation of Stainless Steelnqh2009100% (2)

- Schaeffler - Account Insights - Mar 2020Document13 pagesSchaeffler - Account Insights - Mar 2020mohit negiNo ratings yet

- EiaDocument14 pagesEiaRamir FamorcanNo ratings yet

- Shanidham - In-Shanidham Pacify Lord ShaniDocument3 pagesShanidham - In-Shanidham Pacify Lord ShanisubramanyaNo ratings yet

- Specifications Sheet ReddyDocument4 pagesSpecifications Sheet ReddyHenry CruzNo ratings yet

- The Quill Vol. LVIII Issue 1 1-12Document12 pagesThe Quill Vol. LVIII Issue 1 1-12Yves Lawrence Ivan OardeNo ratings yet

- Presentation For Partial Fulfillment of The Diploma in Occupational Safety and HealthDocument16 pagesPresentation For Partial Fulfillment of The Diploma in Occupational Safety and HealthmarinaNo ratings yet

- IIT2019 RIT-1-CPM Chemistry TestDocument15 pagesIIT2019 RIT-1-CPM Chemistry TestPRAKHAR GUPTANo ratings yet

- BS en 12201 5 2011Document20 pagesBS en 12201 5 2011fatjon31100% (4)

- CBSE Worksheet-01 Class - VI Science (The Living Organisms and Their Surroundings)Document3 pagesCBSE Worksheet-01 Class - VI Science (The Living Organisms and Their Surroundings)Ushma PunatarNo ratings yet

- OE Spec MTU16V4000DS2250 3B FC 50Hz 1 18Document6 pagesOE Spec MTU16V4000DS2250 3B FC 50Hz 1 18Rizki Heru HermawanNo ratings yet