Professional Documents

Culture Documents

AC Single Phase Induction Motor Instruction Manual Guide

Uploaded by

Dinesh Kumar MehraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AC Single Phase Induction Motor Instruction Manual Guide

Uploaded by

Dinesh Kumar MehraCopyright:

Available Formats

Ac single phase induction motor Instruction Mannual

INTRODUCTION The AC induction motor is well suited to applications requiring constant speed operation. In general, the induction motor is cheaper and easier to maintain compared to other alternatives. The induction motor is made up of the stator, or stationary windings, and the rotor. The stator consists of a series of wire windings of very low resistance permanently attached to the motor frame. As a voltage and a current is applied to the stator winding terminals, a magnetic field is developed in the windings. By the way the stator windings are arranged, the magnetic field appears to synchronously rotate electrically around the inside of the motor housing. The rotor is comprised of a number of thin bars, usually aluminum, mounted in a laminated cylinder. The bars are arranged horizontally and almost parallel to the rotor shaft. At the ends of the rotor, the bars are connected together with a shorting ring. The rotor and stator are separated by an air gap which allows free rotation of the rotor. The magnetic field generated in the stator induces an EMF in the rotor bars. In turn, a current is produced in the rotor bars and shorting ring and another magnetic field is induced in the rotor with an opposite polarity of that in the stator. The magnetic field, revolving in the stator, will then produces the torque which will pull on the field in the rotor and establish rotor rotation. In the design of the induction motor, operational characteristics can be determined through a series of calculations. Performing these calculations can help the engineer provide a motor that is best suited to a particular application. This paper will demonstrate their application. SYNCHRONOUS SPEED The speed with which the stator magnetic field rotates, which will determine the speed of the rotor, is called the Synchronous Speed (SS). The SS is a function of the frequency of the power source and the number of poles (pole pairs) in the motor. The relationship to calculate the SS of an induction motor is:

MOTOR SLIP The rotor in an induction motor can not turn at the synchronous speed. In order to induce an EMF in the rotor, the rotor must move slower than the SS. If the rotor were to somehow turn at SS, the EMF could not be induced in the rotor and therefore the rotor would stop. However, if the rotor stopped or even if it slowed significantly, an EMF would once again be induced in the rotor bars and it would begin rotating at a speed less than the SS. The relationship between the rotor speed and the SS is called the Slip. Typically, the Slip is expressed as a percentage of the SS. The equation for the motor Slip is:

EQUIVALENT CIRCUIT To analyze the operating and performance characteristics of an induction motor, an Equivalent Circuit can be drawn. We will consider a 3phase, Y connected machine, the Equivalent Circuit for the stator is as shown below:

machine, the Equivalent Circuit for the stator is as shown below:

The counter EMF (E2) is equal to the stator terminal voltage less the voltage drop caused by the stator leakage impedance.

In an analysis of an induction motor, the equivalent circuit can be simplified further by omitting the shunt reaction value, gx. The core losses associated with this value can be subtracted from the motor Power and Torque when the friction, windage and stray losses are deducted. The simplified circuit for the stator then becomes:

To complete the circuit, the component for the rotor equivalent must be added.

Simplifying the rotor component will yield the following per phase approximate Equivalent Circuit. This circuit will be used in the motor analysis in the sections following.

Solving for the Rotor Impedance in parallel with the Air Gap Impedance will yield the following simplified equivalent circuit:

You might also like

- (ELECS2) Exp5 - Class A and Class B Power Amplifier - The GWAPINGSDocument12 pages(ELECS2) Exp5 - Class A and Class B Power Amplifier - The GWAPINGSFrodolfre Reginald LazoNo ratings yet

- Study of a reluctance magnetic gearbox for energy storage system applicationFrom EverandStudy of a reluctance magnetic gearbox for energy storage system applicationRating: 1 out of 5 stars1/5 (1)

- Samsung SM-A105F - M - G Service Manual (Phonelumi - Com) PDFDocument126 pagesSamsung SM-A105F - M - G Service Manual (Phonelumi - Com) PDFJhonNo ratings yet

- 1-EM Section 1 Motor OperationDocument38 pages1-EM Section 1 Motor Operationmhafidz49No ratings yet

- IM (1) NotesDocument4 pagesIM (1) NotesHarshitNo ratings yet

- Three Phase Induction MotorDocument22 pagesThree Phase Induction MotorHabteNo ratings yet

- The Difference Between Asynchronous and Synchronous MotorsDocument6 pagesThe Difference Between Asynchronous and Synchronous MotorsShiva Kumar ReddyNo ratings yet

- Everything You Need to Know About Induction MotorsDocument8 pagesEverything You Need to Know About Induction Motorsdinesh11rNo ratings yet

- Module 3b (Electrical Machines)Document43 pagesModule 3b (Electrical Machines)MohammedNo ratings yet

- Magnetic Field Faraday's Law Magnetic Flux Induction Motor Resistance Magnetic Field CurrentDocument2 pagesMagnetic Field Faraday's Law Magnetic Flux Induction Motor Resistance Magnetic Field CurrentyokeshNo ratings yet

- ELE290 Chapter 6Document21 pagesELE290 Chapter 6imfendiNo ratings yet

- Ac Motors: An AC Motor Is An Driven by AnDocument18 pagesAc Motors: An AC Motor Is An Driven by AnBalamuni PsaNo ratings yet

- Induction Machine TrainerDocument29 pagesInduction Machine TrainerBabyNo ratings yet

- 3.18 Ac MotorsDocument25 pages3.18 Ac Motorsdeleted Yt acc.No ratings yet

- How three-phase induction motors convert electrical energy to mechanical motionDocument2 pagesHow three-phase induction motors convert electrical energy to mechanical motionsamyramuNo ratings yet

- Servo MechanismDocument24 pagesServo Mechanismmushahid980No ratings yet

- Servo Control Facts: Baldor Electric CompanyDocument24 pagesServo Control Facts: Baldor Electric CompanyRizwan HameedNo ratings yet

- Everything You Need to Know About Servo ControlDocument24 pagesEverything You Need to Know About Servo Controlafe2000must9083No ratings yet

- Brushless DC Motors: An Introduction to Their Construction, Working Principles and AdvantagesDocument21 pagesBrushless DC Motors: An Introduction to Their Construction, Working Principles and AdvantagesSRL MECHNo ratings yet

- Induction MotorDocument21 pagesInduction Motoragbajelola idrisNo ratings yet

- Chapter 6 - Induction Motors (Part1)Document18 pagesChapter 6 - Induction Motors (Part1)SanjanaLakshmiNo ratings yet

- #5 Module 5Document52 pages#5 Module 5anishdeshmukh108No ratings yet

- Switched Reluctance Motor Construction and Working PrincipleDocument10 pagesSwitched Reluctance Motor Construction and Working PrincipleHAMID SULIAMANNo ratings yet

- Switched Reluctance Motor PDFDocument79 pagesSwitched Reluctance Motor PDFHAMID SULIAMANNo ratings yet

- Topic 1Document20 pagesTopic 1Ʋiŋêet ḠåuṯḁmNo ratings yet

- DC Motor ControlDocument10 pagesDC Motor ControlIbrahim KhleifatNo ratings yet

- ELE290 Induction Motor GuideDocument21 pagesELE290 Induction Motor GuideHarizx SaufixNo ratings yet

- Motors and DrivesDocument23 pagesMotors and DrivesharishkumarsinghNo ratings yet

- 1 Phase Induction MotorDocument2 pages1 Phase Induction Motorjay shahNo ratings yet

- Servomotor Construction: Stator and A Rotating Magnetic FieldDocument19 pagesServomotor Construction: Stator and A Rotating Magnetic FieldctsakNo ratings yet

- Single Phase Induction MotorDocument2 pagesSingle Phase Induction Motorjay shahNo ratings yet

- Unit VDocument7 pagesUnit VMonte CarloNo ratings yet

- Skip To ContentDocument17 pagesSkip To Contentkidanemariam teseraNo ratings yet

- Three Phase Induction MotorsDocument22 pagesThree Phase Induction MotorsSabiha MahbubNo ratings yet

- Speed Control of Induction Motor Using AnnDocument67 pagesSpeed Control of Induction Motor Using AnnBnr Goud50% (6)

- Three Phase Induction Motor FundamentalsDocument3 pagesThree Phase Induction Motor FundamentalsDhanashree ParanjapeNo ratings yet

- Single Phase Induction Motor and Stepper MotorDocument11 pagesSingle Phase Induction Motor and Stepper MotorManthan deshmukhNo ratings yet

- Three Phase Induction MotorDocument21 pagesThree Phase Induction MotorPrianshu JyosyulaNo ratings yet

- Induction Motor and Hydropower PlantDocument24 pagesInduction Motor and Hydropower PlantYugalal GurungNo ratings yet

- Free-Samples Amie Chapters Single Phase Induction MotorsDocument19 pagesFree-Samples Amie Chapters Single Phase Induction MotorsStitch BeatzNo ratings yet

- Single Phase Induction MotorsDocument18 pagesSingle Phase Induction MotorsAMIE Study Circle, RoorkeeNo ratings yet

- Chapter 1 - Introduction To AC MotorDocument13 pagesChapter 1 - Introduction To AC MotorJiachyi YeohNo ratings yet

- InductionDocument5 pagesInductionadarshNo ratings yet

- Stator and rotor of single phase induction motorDocument5 pagesStator and rotor of single phase induction motorjay shahNo ratings yet

- AC MachinesDocument21 pagesAC Machineskeshab pandeyNo ratings yet

- Synchronous Motor ControlDocument19 pagesSynchronous Motor ControlMohamed RashidNo ratings yet

- Synchronous Motor Control PDFDocument20 pagesSynchronous Motor Control PDFPradeep_VashistNo ratings yet

- Induction Motors: Submitted BY P.Durga Prasad 09A25A0205Document15 pagesInduction Motors: Submitted BY P.Durga Prasad 09A25A0205Suresh JillellaNo ratings yet

- BET PosterDocument4 pagesBET PosterSiddharth MohantyNo ratings yet

- SynchmtrDocument20 pagesSynchmtrmeNo ratings yet

- Synchronous Machines and SCDocument6 pagesSynchronous Machines and SCivancho04mNo ratings yet

- Ac MotorDocument17 pagesAc Motorthebeast.suazoNo ratings yet

- Basics of AC Electric Motors and PartsDocument3 pagesBasics of AC Electric Motors and PartsPankaj Kumar SinghNo ratings yet

- Induction and Synchronous Motor FundamentalsDocument9 pagesInduction and Synchronous Motor FundamentalsfitxvNo ratings yet

- A New System of Alternating Current Motors and Transformers and Other EssaysFrom EverandA New System of Alternating Current Motors and Transformers and Other EssaysRating: 5 out of 5 stars5/5 (1)

- Home-made Toy Motors: A practical handbook giving detailed instructions for building simple but operative electric motorsFrom EverandHome-made Toy Motors: A practical handbook giving detailed instructions for building simple but operative electric motorsNo ratings yet

- A New System of Alternating Current Motors and TransformersFrom EverandA New System of Alternating Current Motors and TransformersRating: 1 out of 5 stars1/5 (1)

- Electrical Machines: Lecture Notes for Electrical Machines CourseFrom EverandElectrical Machines: Lecture Notes for Electrical Machines CourseNo ratings yet

- Small Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsFrom EverandSmall Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsNo ratings yet

- Power Supply Trainer Using Lm723 IcDocument8 pagesPower Supply Trainer Using Lm723 IcDinesh Kumar MehraNo ratings yet

- Design Temperature SensorDocument2 pagesDesign Temperature SensorDinesh Kumar MehraNo ratings yet

- Analog To Digital Conversion Trainer: Instructions Manual ForDocument5 pagesAnalog To Digital Conversion Trainer: Instructions Manual ForDinesh Kumar MehraNo ratings yet

- The Clapp Oscillator: ObjectiveDocument4 pagesThe Clapp Oscillator: ObjectiveDinesh Kumar MehraNo ratings yet

- Asynchronous Motor Operating ManualDocument4 pagesAsynchronous Motor Operating ManualDinesh Kumar MehraNo ratings yet

- Capacitor in Series and ParallelDocument3 pagesCapacitor in Series and ParallelDinesh Kumar MehraNo ratings yet

- Leakagge MethodDocument4 pagesLeakagge MethodDinesh Kumar MehraNo ratings yet

- To Measure Power Factor in A SingleDocument5 pagesTo Measure Power Factor in A SingleDinesh Kumar MehraNo ratings yet

- Series RL CircuitDocument3 pagesSeries RL CircuitDinesh Kumar MehraNo ratings yet

- Capaliiry Flow MethodDocument3 pagesCapaliiry Flow MethodDinesh Kumar MehraNo ratings yet

- Full Adder Using MultiplexerDocument3 pagesFull Adder Using MultiplexerDinesh Kumar Mehra0% (1)

- RC Phase Shift OscillatorDocument2 pagesRC Phase Shift Oscillatordinesh189100% (1)

- Oscillator Circuit Using GatesDocument8 pagesOscillator Circuit Using GatesDinesh Kumar MehraNo ratings yet

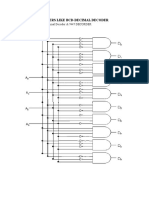

- Design of Decoders Like Bcd-Decimal Decoder Aim: Circuit DiagramDocument3 pagesDesign of Decoders Like Bcd-Decimal Decoder Aim: Circuit DiagramDinesh Kumar MehraNo ratings yet

- Analog To Digital Conversion, ADC0804Document3 pagesAnalog To Digital Conversion, ADC0804Dinesh Kumar MehraNo ratings yet

- Full Adder Using MultiplexerDocument3 pagesFull Adder Using MultiplexerDinesh Kumar MehraNo ratings yet

- Astable Multivibrator Using TransistorsDocument2 pagesAstable Multivibrator Using Transistorsdinesh189No ratings yet

- Instruction Manual of Diac CharcteristicsDocument4 pagesInstruction Manual of Diac CharcteristicsDinesh Kumar MehraNo ratings yet

- Capacitor StartingDocument3 pagesCapacitor StartingDinesh Kumar MehraNo ratings yet

- Arithmetic Logic UnitDocument7 pagesArithmetic Logic UnitDinesh Kumar MehraNo ratings yet

- AC Single Phase Induction Motor Instruction Manual GuideDocument5 pagesAC Single Phase Induction Motor Instruction Manual GuideDinesh Kumar MehraNo ratings yet

- Colpitts OscillatorDocument3 pagesColpitts OscillatorDinesh Kumar MehraNo ratings yet

- To Convert The Given Analog Input Into Its Equivalent Digital OutputDocument2 pagesTo Convert The Given Analog Input Into Its Equivalent Digital OutputDinesh Kumar MehraNo ratings yet

- Colpitts OscillatorDocument3 pagesColpitts OscillatorDinesh Kumar MehraNo ratings yet

- LOGIC GATE TRAINER MANUALDocument5 pagesLOGIC GATE TRAINER MANUALDinesh Kumar MehraNo ratings yet

- PLL 565Document6 pagesPLL 565Dinesh Kumar MehraNo ratings yet

- CLASSa Power AmpDocument1 pageCLASSa Power AmpDinesh Kumar MehraNo ratings yet

- D/A Converter: Digital to Analog ConversionDocument3 pagesD/A Converter: Digital to Analog ConversionDinesh Kumar MehraNo ratings yet

- TriacDocument7 pagesTriacDinesh Kumar MehraNo ratings yet

- Power-Cast II: Cast Transformers 112.5-13,000 kVA 2.5V Through 46 KV Primary Voltage 120V Through 15 KV Secondary VoltageDocument4 pagesPower-Cast II: Cast Transformers 112.5-13,000 kVA 2.5V Through 46 KV Primary Voltage 120V Through 15 KV Secondary Voltageingreyes7No ratings yet

- Albany 03 05 08 - RefDocument2 pagesAlbany 03 05 08 - RefJulio VergaraNo ratings yet

- I-Theory: Modal AnalysisDocument6 pagesI-Theory: Modal AnalysispedramNo ratings yet

- HV Insulations Comp.190310Document24 pagesHV Insulations Comp.190310M V Ravindra MutyalaNo ratings yet

- Technical Reference: Advanced Printing SystemsDocument13 pagesTechnical Reference: Advanced Printing Systemsgadacz111No ratings yet

- Service Manual: Microwave Oven TC 2250/WHDocument8 pagesService Manual: Microwave Oven TC 2250/WHTóth LászlóNo ratings yet

- Sirius 3rb2 DatasheetDocument25 pagesSirius 3rb2 DatasheetCesar IgamiNo ratings yet

- Laser Based Voice and Data CommunicationDocument41 pagesLaser Based Voice and Data Communicationanshu_ranjan180% (5)

- CPE 329 Final Project ReportDocument13 pagesCPE 329 Final Project ReportChris PolisNo ratings yet

- Scitronics - Metal - Detector - TMD1080 1Document4 pagesScitronics - Metal - Detector - TMD1080 1Fernando BarrosNo ratings yet

- Photoelectric Effect: Figure 1: Constituents of The Atom A. Photoelectric EffectDocument5 pagesPhotoelectric Effect: Figure 1: Constituents of The Atom A. Photoelectric EffectMahnoor SiddiqiNo ratings yet

- 8200A-Audiolab Service Manual V01Document35 pages8200A-Audiolab Service Manual V01teniNo ratings yet

- Mechanical Test Report (51252731-Ea)Document14 pagesMechanical Test Report (51252731-Ea)Nguyen ngoc thongNo ratings yet

- Alamada Electrical PlanDocument17 pagesAlamada Electrical PlanFedilino P. FornollesNo ratings yet

- Preamplifiers: Matching The Preamplifier To The Detector and The ApplicationDocument8 pagesPreamplifiers: Matching The Preamplifier To The Detector and The ApplicationsuryaNo ratings yet

- Advanced sensor systems pressure sensor specificationsDocument5 pagesAdvanced sensor systems pressure sensor specificationsIrfhanNo ratings yet

- Fujitsu - ASIC/COT - 40nm CMOS Technology CS302 SeriesDocument2 pagesFujitsu - ASIC/COT - 40nm CMOS Technology CS302 SeriesFujitsu Semiconductor EuropeNo ratings yet

- Andrew FXL-780Document4 pagesAndrew FXL-780AbeSalNo ratings yet

- ANFIS Paper PresentationDocument16 pagesANFIS Paper PresentationghulamNo ratings yet

- Extended Life Computer Grade CapacitorDocument2 pagesExtended Life Computer Grade CapacitorАндрей ПоляковNo ratings yet

- Electricity and MagnetismDocument12 pagesElectricity and MagnetismTrisha Bonita Restauro100% (1)

- Transline Part 2Document97 pagesTransline Part 2Haw-ChyunNo ratings yet

- LAC 65.1 Load Cell Amplifier ModuleDocument2 pagesLAC 65.1 Load Cell Amplifier ModulerngNo ratings yet

- MX28F1000P: Features 1M-Bit (128K X 8) Cmos Flash MemoryDocument33 pagesMX28F1000P: Features 1M-Bit (128K X 8) Cmos Flash MemorymustafaNo ratings yet

- Electrical Engineering and InstrumentationDocument11 pagesElectrical Engineering and InstrumentationKrishnan DandapaniNo ratings yet

- Module 7Document17 pagesModule 7jimmyboyjr50% (2)

- Resistors in Series and in ParallelDocument4 pagesResistors in Series and in ParallelAtif MehfoozNo ratings yet

- Feedback vs feedforward CM control: comparative studyDocument4 pagesFeedback vs feedforward CM control: comparative studysuryaNo ratings yet