Professional Documents

Culture Documents

Ammonia

Uploaded by

Namye YelusCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ammonia

Uploaded by

Namye YelusCopyright:

Available Formats

- - - ~ ~ - ~ - - - - - ~ - -

Ammonia Storage:

Selection & Safety Issues

G S Lele

This article describes the advantages and disadvantages of

various structures of ammonia storage tanks. It also provides

the various codes and standards applicable for flat bottomed,

vertical and cylindrical storage tanks. The author also lists rel-

evant safety aspects to be considered for storage of

liquid ammonia.

AUTHOR

G S Lele is a chemical engineer and an alumnus of Laxminarayan Institute of Technology, Nagpur.

He is presently Deputy General Manager - Process, with Uhde India Ltd, where he is actively

involved with the Cryogenic Storage Group. He has participated in the conceptualization, design

and commisisoning of Uhde India's cryogenic storage projects.

Chemical Industry Digest. May 2008

85

' " " ' " ~ "'" Ammonia Storage

Introduction

S

torage of liquid ammonia has been done in the

chemical industry for the past several decades,

right from the time ammonia began to be com-

mercially produced. Due to the inherent physical prop-

erty of ammonia, the earlier designs for handling liq-

uid ammonia used the pressurized storage concept as

ammonia liquid could be stored at ambient tempera-

tures. However the tanks were to be designed for el-

evated pressures. To enable liquid ammonia to be

stored at near atmospheric conditions meant that am-

monia had to be cooled and refrigerated to -33C.

Inspite of the best insulation methods utilized, a re-

frigeration system is required to keep the ammonia in

liquefied form.

ally have outer tanks or walls made

from pre-stressed concrete, reinforced

concrete with an earth embankment

or one of the metals specified for the

inner tank.

Types of the ammonia

storage tanks

Primarily, there are 3 prevalent methods for stor-

ing liquid ammonia.

Pressurized storage at ambient temperature for

small capacities (up to 100 MT) in horizontal pres-

sure vessels (pressure: 12-18 kg/ cm

2

g)

Until the 1970's it was normal practice to store re-

Semi-refrigerated storage in spheres for capacities

upto 2000 MT (pressure 4-6 kg/ cm

2

g)

Atmospheric pressure storage at -33C for large ca-

frigerated ammonia in single con-

tainment tanks. Since that time it

has increasingly become the prac-

tice for the inner tank for ammonia

to be surrounded by an outer tank

or wall. The outer tank or wall is in-

tended to prevent the release of the

liquefied products into the sur-

rounding area in case of leakage

from or damage to the inner tank.

This philosophy results in in-

creased safety for the surrounding

area. Such constructions are known

as double containment and full

containment tanks. The double

~ - - - - - - - - - - . . . _ _ pacities (2000 MT and higher) with

For large scale atmo-

spheric cryogenic storages

for liquefied gases like am-

monia, design can be se-

lected from three basic types

as defined in BS 7777 taking

into account local regula-

tions, location of the storage

tank with respect to adjacent

plants, inhabitants and type

of product stored.

containment tanks and full containment tanks gener-

86

siporex

blocks

Inner cup

liqammonia

1----=san""-d-------1 siporex

foam glass

blocks

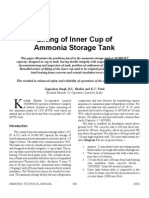

FIG- 1 Typical double containment tank

Mineral wool insulation

PUF insulation with AI cladding

.---

!+---tank

~ - - Annular space

Chemical Industry Digest. May 2008

the following types:

o Single wall tank

o Double wall tank

o Double wall full containment

tank

Disadvantages of pre-

ssurised storages

There are certain limitations in

storage of ammonia in pressurized

tanks. Some of them are outlined

below:

Limitations in terms of storage ca-

pacity (1000- 2000 MT), as present day

large capacity plants need more stor-

age space.

A major factor is the safety aspect

wherein escape of ammonia under

pressure is potentially more danger-

ous than leakage of ammonia from an

atmospheric tank.

Construction of pressurized spheri-

cal tank is much more difficult and

costly per MT of ammonia stored in

comparison with an atmospheric tank.

Atmospheric ammonia stor-

age tanks

For large scale atmospheric cryo-

genic storages for liquefied gases like

ammonia, design can be selected from

three basic types as defined in BS 7777

Ammonia Storage

(single, double and full containment design) taking

into account local regulations, location of the storage

tank with respect to adjacent plants, inhabitants and

type of product stored. Toxicity, flammability, explo-

sive limits, auto ignition temperature & density of va-

por need special attention.

Single wall tank

In this type of design, primary container (Inner

tank) is provided to hold liquid at low temperature

and vapor product under normal I design operating

conditions. Insulation is provided on the external sur-

face to minimize heat leakage.

External secondary containment is provided in the

form of low height dyke wall to contain the liquid com-

ing out due to rupture of inner tank. Emission to at-

mosphere of vaporized gas is reduced by providing

suitable foaming system. This design has been

adopted for storages of gases because of its low toxic-

vapor ammonia

OIL PUMP

AMMONIA CONO NSER OIL COOLER

q j >

)/:"

ECONOMIZER

FIG - 2 Typical screw compressor refrigeration system

RODS&BARS

FLATS & STRIPS

Stockist & Suppliers Of'

Stainless

Steel Pipe.

*

Pipe, Fitting.

*

Sheet, Coils.

*

Rods, Flats.

* Copper, Brass. sHEETs, PLATEs & co1Ls

*

P. B. Monel.

*

lnconal.

*

Hastalloy.

*

Titanium.

& PIPE FITIINGS

Of All Grades.

*

304, 304L,316,

316L, 321,310,

410,420, & 430.

REFRIGERATION QUALITY COPPER TUBE

CONTACT:

Post Box No. 3 717, 1 0/12, New Hira Building, 1st Floor,

Room No. 15, 1 st Parsiwada, Mumbai-400 004.

Tel: 022-2385 4314/2386 8818, Fax: 2387 8403

E-mail : mehta@greatmetal.com, Website : www.greatmetal.com

ity hazards. For ammonia, these designs have been

used in some plants which have been located far away

from populated areas due to safety reasons.

Double wall tank

LIQUID AMMONIA

Vapors

Inner cup

Ammonia storage tank

A double contain-

ment tank is designed

and constructed so

that both the inner &

outer tanks are ca-

pable of containing

the refrigerated liquid

stored independently.

The inner tank con-

tains the refrigerated

liquid and vapor un-

der normal operating

conditions. The outer

tank (which is located

< 6m distance from in-

ner tank) is intended

to contain refrigerated

product leakage from

the inner tank but is

not intended to con-

tain any vapor result-

Chemical Industry Digest. May 2008 87

Ammonia Storage

ing from product leakage from the in-

ner tank which means, it will be re-

leased to atmosphere.

The outer container is normally

provided in the form of "Bund Wall"

of height corresponding to hold

equivalent amount of liquid in the

storage tank. This concept again has

been used for storage of non-toxic

gases like hydrocarbons world-wide,

but not for storage of toxic material

like ammonia.

The present day tanks

are constructed on elevated

concrete foundations to

avoid the problem of ice

formation and propagation

in the soil below. Addi-

tionally, double integrity

tanks provide an extra va-

por space of 15 - 20% de-

pending on dimensions.

tures down to -165 C.

API STANDARD 620 10th edition,

Feb. 2002 -Addendum 1, June 2004

- Design and construction of large,

welded, low pressure storage tanks.

Appendix R- Low pressure storage

tanks for refrigerated products.

- DIN 4119, sheet 1 & 2, Edition 1961

for roof structure design.

IS 4544: 2000

Double wall full containment tank

In this type both the inner and outer tanks are ca-

pable of containing the refrigerated liquid stored in-

dependently. The inner tank contains the refrigerated

liquid under normal operating conditions. T h ~ roof

is supported by the outer tank. The outer tank 1s ca-

pable of containing both the refrigerated liquid and the

vapor resulting from product leakage and is located

between 1-2 meters from the inner tank. In such tanks,

secondary containment in the form of dyke wall is not

required. The double containment tank design, also

known as the "cup-in-tank" (Double Integrity) design

is widely adopted for Ammonia Storage Tanks. The in-

ner cup of the tank is separated from the outside tank

by a suspended deck resting on the top of the inner

cup. A typical sketch of a full containment tank is

attached as Fig 1.

The present day tanks are constructed on elevated

concrete foundations to avoid the problem of ice for-

mation and propagation in the soil below (a problem

experienced with tanks resting on the surface with con-

sequences of likely damage to tank bottom plates due

to frost heaving). Additionally, double integrity tanks

provide an extra vapor space of 15 - 20% depending

on dimensions, which is very useful for maintaining

tank pressure within operating limits especially un-

der emergency conditions.

Applicable codes & standards

BS -7777- 1993

Applicable for flat bottomed, vertical and cylindri-

cal storage tanks for low temperature service.

Part 1- Guide to the general provisions for design,

construction, installation and operation.

Part 2- Specification for the design and construc-

tion of single, double and full containment metal

tanks for the storage of liquefied gas at tempera-

It is a standard for ammonia code of safety.

- Prescribes a code of safety concerning the hazards

related to ammonia.

- It also describes the properties and essential infor-

mation for safe handling and use of ammonia.

ANSI K61.1-1999

It prescribes safety requirement for the storage and

handling of anhydrous ammonia.

- This standard is intended to apply to the design,

construction, repair, alteration, location, installa-

tion, and operation of anhydrous ammonia sys-

tems including refrigerated ammonia storage sys-

tems.

- This standard does not apply to

o Ammonia manufacturing plants

. o Refrigeration systems where ammonia is used

solely as a refrigerant

o Ammonia transportation pipelines

o Ammonia barges and tankers

The above standard also prescribes guidelines for

installation of refrigerated storage tanks (above-

ground). Some of these are outlined below:

- Tanks shall be supported on suitable non combus-

tible foundations designed to accommodate the

type of tank being used.

- Adequate protection against flotation or other wa-

ter damage shall be provided wherever high flood

water might occur.

- Tanks shall be supported in such way that heat

shall be supplied to prevent the effects of freezing

and subsequent frost heaving of the soil.

Wherever dike is employed, the capacity of the dike

enclosure shall be 110% of the capacity of the larg-

est tank served.

- Each refrigerated tank container shall be equipped

with an approved liquid level gauging device and

high liquid level alarm.

- In addition to the above, this standard also gives

88 Chemical Industry Digest. May 2008

Ammonia Storage

the guidelines for,

Requirement of number of compressors

Provides guidelines for the pressure relief valves

capacity, location etc

Requirement of minimum safety equipment

Other general guidelines

Types of insulation used

As liquid ammonia is stored in refrigerated condi-

tion in the atmospheric tank, it is important to keep

heat ingress into the tank to the minimum possible.

Insulation plays a key role in this aspect. The insula-

tion type and thickness decides the overall boil off rate

from the storage tank, i.e. the kg of ammonia evapo-

rated per day per ton of tank capacity. The boil off rate

therefore is indicative of the atmospheric heat ingress

into a storage tank when other tank operations are not

taking place. The commonly used insulation for the

tanks is Polyurethane foam (PUP) which is cast in situ

on the outside tank shell and covered with aluminum

cladding. Insitu application of PUP is also used for

large bore piping and equipments. For small bore pip-

ing, pre-cast PUP split sections are available.

Other than the tank outer surface, insulation is re-

quired to be provided at various other places in and

around the tank. It can be summarized as below:

Shell bottom- foam glass (load bearing insulation)

along with sand

Below annular space between cup and shell

- Siporex block or perlite block or wooden block.

The presence of ammonia vapor in the annular

space between the cup and shell acts as an insu-

lating media and helps in reducing the heat in-

gress from outside. In some cases, the annular

space is filled with a naturally occurring insulat-

ing material like perlite.

Suspended deck top - mineral wool (resin bonded

glass wool). Between the suspended deck and the

top roof, the presence of ammonia vapor acts as an

insulating media. There is no insulation required

on the top of the roof as no liquid comes in contact

with the suspended deck.

Generally a sand layer is placed between cup bot-

tom and shell bottom plate

Safety aspects for ammonia storage

system

As ammonia storage terminal and its associated fa-

cilities are generally located away from plants, follow-

ing considerations in design are made to ensure safety

ISO 9001-2000 Certified Company

Walk-in

Stability

chamber

l ~ f ~ ~ Q ~ . ~ ~ ~ ! ! ~

B- 1261127, Ansa Industrial Estate, Sakivihar Road,

Sakinaka, Andheri (E), Mumbai - 400 072. (India)

Tel: 28477547 148110111 Fax: 28475672,

www.wadegati.com

E-mail: wadegati@vsnl.com I wadegati@bom7.vsnl.net.in

Hyderabad Office: 9246528404 I 9985768860

of storage tank and connected operations:

Remote shut-off valves on liquid ammonia roam

inlet and outlet line to I from ammonia storage tank.

Dual measurement for tank level/pressure and in-

terlocking with refrigeration compressors, ammo-

nia receipt and pumping, emergency vent to flare.

Dual level measurement for the annulus portion of

the tank and annulus draining facility. This is im-

portant as there is a possibility of damage to the

cup bottom plates due to buoyancy effect (caused

when annulus level exceeds cup level).

Refrigeration system based on reliable screw com-

pressors. Optional auto loading/unloading facil-

ity for tank pressure control can be included.

Stand-by equipment for critical duties and utilities.

Closed vent and drain system for ammonia.

Redundancy in critical instrumentation & control.

Adequate fire water grid and water curtain around

ammonia pumps and road tanker loading stations.

Thermal relief valve are installed on the ammonia

lines where there is any possibility for blockage or

heat ingress.

Ammonia leak detection system for storage instal-

lation.

Chemical Industry Digest. May 2008

89

- - - - - - - - - - - - - - - - - - - - - ~ - . -----

en

Ammonia Storage

Lightening protection and earthing protection for

storage tank

Emergency power to one refrigeration holding com-

pressor to maintain tapk pressure during power

failure.

Flare for controlled venting under extreme emer-

gency situation.

Safety and vacuum relief valves on tank top (de-

signed as per API 520).

Wind direction indicator.

Emergency plant lighting.

0

You might also like

- Large Scale Ammonia Storage and HandlingDocument37 pagesLarge Scale Ammonia Storage and HandlingRainierK100% (2)

- Low Pressure and Ammonia Storage Tank: Engineering Standard Specification FORDocument11 pagesLow Pressure and Ammonia Storage Tank: Engineering Standard Specification FORHamid MansouriNo ratings yet

- 5.1 Loading UnloadingDocument66 pages5.1 Loading UnloadingMarcosGonzalezNo ratings yet

- A Study of Storage Tank Accidents InternetDocument10 pagesA Study of Storage Tank Accidents Internetfoamtrailer100% (1)

- LNG Solutions1 PDFDocument13 pagesLNG Solutions1 PDFxm861122No ratings yet

- Ammonia Storage and Filling FaciltyDocument24 pagesAmmonia Storage and Filling FaciltyRavian Lhr100% (1)

- Refrigerated Ammonia Storage Tanks For Chemical Processing PlantDocument24 pagesRefrigerated Ammonia Storage Tanks For Chemical Processing Plantkresimir.mikoc9765100% (2)

- Siemens - Provent Return For Tank Farm and TerminalDocument24 pagesSiemens - Provent Return For Tank Farm and TerminalapisituNo ratings yet

- Truck Loading Arms (D 32)Document7 pagesTruck Loading Arms (D 32)Elias EliasNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 009 Paper1eDocument10 pages009 Paper1eFaizan AhmedNo ratings yet

- Ammonia Storage Tank PDFDocument5 pagesAmmonia Storage Tank PDFAnonymous 1XHScfCI33% (3)

- Storage TankDocument10 pagesStorage TankJacekNo ratings yet

- Decommissioning Inspection and Repair of 5000 MT Ammonia Storage TankDocument17 pagesDecommissioning Inspection and Repair of 5000 MT Ammonia Storage TankGanesh NairNo ratings yet

- Lifting Ammonia Tank CupDocument12 pagesLifting Ammonia Tank Cuppcorreia_81No ratings yet

- Aiche-16-005 Ammonia Storage Design PracticeDocument5 pagesAiche-16-005 Ammonia Storage Design PracticeHsein WangNo ratings yet

- Safe decommissioning and recommissioning of an ammonia storage tankDocument11 pagesSafe decommissioning and recommissioning of an ammonia storage tankvaratharajan g rNo ratings yet

- Ammonia Storage TankDocument13 pagesAmmonia Storage Tankjfejfe100% (2)

- Recommendations For The Safe and Reliable Inspection of Atmospheric Refrigerated Amonia Storage Tanks 2002 PDFDocument32 pagesRecommendations For The Safe and Reliable Inspection of Atmospheric Refrigerated Amonia Storage Tanks 2002 PDFDaniel Puello RodeloNo ratings yet

- Ammonia storage regulations and design guidelinesDocument2 pagesAmmonia storage regulations and design guidelinesZeroRecoNo ratings yet

- In-Service Inspection of Ammonia Storage Tank WeldsDocument8 pagesIn-Service Inspection of Ammonia Storage Tank WeldsEdwinMauricioMacabeoNo ratings yet

- Anhydrous Ammonia:: Managing The RisksDocument16 pagesAnhydrous Ammonia:: Managing The RisksNeima DoualehNo ratings yet

- Fertilizers Industry Ammonia PlantDocument75 pagesFertilizers Industry Ammonia Plantnayear100% (1)

- Ammonia Storage - Guidance For Inspection of Atmospheric, Refrigerated Ammonia Storage Tanks (2008) - BrochureDocument50 pagesAmmonia Storage - Guidance For Inspection of Atmospheric, Refrigerated Ammonia Storage Tanks (2008) - BrochureGeorge Van BommelNo ratings yet

- Chemical Ammonia Report PDFDocument72 pagesChemical Ammonia Report PDFAli J. Hojeij100% (1)

- Ammonia Storage Tank Group No 18Document17 pagesAmmonia Storage Tank Group No 18Anonymous Xf4w0D2cNo ratings yet

- Linde AmmoniaDocument47 pagesLinde AmmoniaPranam BhumbarNo ratings yet

- Ammonia StorageDocument11 pagesAmmonia StorageCristina Ion100% (1)

- Scope of Inspection For Ammonia TankDocument3 pagesScope of Inspection For Ammonia TankHamid MansouriNo ratings yet

- Manage diesel safely undergroundDocument11 pagesManage diesel safely undergroundErwinApriandiNo ratings yet

- H2safety 12568330130779 Phpapp01Document80 pagesH2safety 12568330130779 Phpapp01Rommel AguillonNo ratings yet

- Liquid Storage and Handling GuidelinesDocument52 pagesLiquid Storage and Handling GuidelinesAvyan KelanNo ratings yet

- 2015 Orooji Pardis Lessons Learned From Decommissioning of A Liqud Ammonia Storage TankDocument19 pages2015 Orooji Pardis Lessons Learned From Decommissioning of A Liqud Ammonia Storage TankAdnan AliNo ratings yet

- Piping Design 5 PDFDocument9 pagesPiping Design 5 PDFSandra MArrugo100% (1)

- 30M - ConocoPhillips Optimized CascadeDocument11 pages30M - ConocoPhillips Optimized CascadeX-Titan Wan de Pirates100% (1)

- Atmospheric Storage Tank Types and Design FeaturesDocument112 pagesAtmospheric Storage Tank Types and Design FeaturesS Balamuthu Manickam100% (1)

- Storage Tank Safety and Emissions ManagementDocument96 pagesStorage Tank Safety and Emissions ManagementenggmohanNo ratings yet

- FlareDocument10 pagesFlareAgus SuriptoNo ratings yet

- RP 108Document15 pagesRP 108Vasant Kumar VarmaNo ratings yet

- Ammonia Production and Storage 1Document4 pagesAmmonia Production and Storage 1rajaraghuramvarmaNo ratings yet

- ATM Storage TankDocument10 pagesATM Storage TankSteve WanNo ratings yet

- ISO TC 197 Hydrogen Standards UpdateDocument14 pagesISO TC 197 Hydrogen Standards Updatejkhgvdj mnhsnjkhgNo ratings yet

- Ammonia Plant 2520Location&LayoutDocument4 pagesAmmonia Plant 2520Location&Layoutapi-3714811100% (1)

- Operation Instruction of PSA UnitDocument83 pagesOperation Instruction of PSA UnitAbassyacoubouNo ratings yet

- Cryogenic Spill Protection and MitigationDocument9 pagesCryogenic Spill Protection and MitigationypzoNo ratings yet

- CCCCC C: C À C × C Î C C !C C!C #C $!C %&"C "C#%!Document11 pagesCCCCC C: C À C × C Î C C !C C!C #C $!C %&"C "C#%!bejoise100% (2)

- What Is The Low Temperature TankDocument64 pagesWhat Is The Low Temperature TankAhmed ELmlahy100% (1)

- MDEA Safety Data SheetDocument8 pagesMDEA Safety Data SheetGhifaris VashaNo ratings yet

- Technical Aspect of Storage Tank LossDocument9 pagesTechnical Aspect of Storage Tank LossAnuj GuptaNo ratings yet

- Ammonia Storage Tank Pre-Commissioning ProcessDocument13 pagesAmmonia Storage Tank Pre-Commissioning ProcessUnknownNo ratings yet

- LNG Tank Design Analysis with LUSASDocument7 pagesLNG Tank Design Analysis with LUSASMelvin MagbanuaNo ratings yet

- Storage Tanks Emissions and Emission Reductions 201312Document50 pagesStorage Tanks Emissions and Emission Reductions 201312yamakunNo ratings yet

- Ammonia Properties and HandlingDocument25 pagesAmmonia Properties and HandlingJohn Harken100% (2)

- Oisd192 PDFDocument68 pagesOisd192 PDFpmcmbharat264No ratings yet

- Essential Practices for Managing Chemical Reactivity HazardsFrom EverandEssential Practices for Managing Chemical Reactivity HazardsNo ratings yet

- Storage Tank Design: Email:moemen - Hussein@alexu - Edu.egDocument58 pagesStorage Tank Design: Email:moemen - Hussein@alexu - Edu.egahmadhatakeNo ratings yet

- Ammonia tank specDocument4 pagesAmmonia tank specsajalkk25No ratings yet

- 1 - Storage Tanks - Training Course - EzzatDocument185 pages1 - Storage Tanks - Training Course - EzzatSaeed Abdel GhanyNo ratings yet

- STORAGE TANKS FOR REFINERIESDocument10 pagesSTORAGE TANKS FOR REFINERIESSiddharth Sridhar100% (1)

- General Rules Aboveground Tanks DesignDocument5 pagesGeneral Rules Aboveground Tanks Designpiolinwalls100% (1)

- Hd115 - Pressur GaugeDocument2 pagesHd115 - Pressur GaugeKumararaja KonikkiNo ratings yet

- Hd112 - Revolving NozzleDocument2 pagesHd112 - Revolving NozzleKumararaja KonikkiNo ratings yet

- Hd116 - Restriction NozzleDocument1 pageHd116 - Restriction NozzleKumararaja KonikkiNo ratings yet

- Hd115 - Pressur GaugeDocument2 pagesHd115 - Pressur GaugeKumararaja KonikkiNo ratings yet

- HD173Document2 pagesHD173Kumararaja KonikkiNo ratings yet

- Hd117 - Retarding NozzleDocument1 pageHd117 - Retarding NozzleKumararaja KonikkiNo ratings yet

- Master Stream Nozzle For Monitor: DescriptionDocument2 pagesMaster Stream Nozzle For Monitor: DescriptionKumararaja KonikkiNo ratings yet

- Master Stream Nozzle For Monitor: Model - Varsha - 40Document2 pagesMaster Stream Nozzle For Monitor: Model - Varsha - 40Kumararaja KonikkiNo ratings yet

- Hd117 - Retarding NozzleDocument1 pageHd117 - Retarding NozzleKumararaja KonikkiNo ratings yet

- Vajra 322P: Technical DataDocument4 pagesVajra 322P: Technical DataKumararaja KonikkiNo ratings yet

- Hd112 - Revolving NozzleDocument2 pagesHd112 - Revolving NozzleKumararaja KonikkiNo ratings yet

- VAJRA 536: Electric DC Remote Controlled MonitorDocument4 pagesVAJRA 536: Electric DC Remote Controlled MonitorKumararaja KonikkiNo ratings yet

- Hd184 - Foam Chamber Model - FDocument6 pagesHd184 - Foam Chamber Model - FKumararaja KonikkiNo ratings yet

- Hd116 - Restriction NozzleDocument1 pageHd116 - Restriction NozzleKumararaja KonikkiNo ratings yet

- Master Stream Nozzle For Monitor: Model - Varsha - 40Document2 pagesMaster Stream Nozzle For Monitor: Model - Varsha - 40Kumararaja KonikkiNo ratings yet

- HD173Document2 pagesHD173Kumararaja KonikkiNo ratings yet

- Vajra 322P: Technical DataDocument4 pagesVajra 322P: Technical DataKumararaja KonikkiNo ratings yet

- Hd185 - Foam DeflectorDocument2 pagesHd185 - Foam DeflectorKumararaja KonikkiNo ratings yet

- Master Stream Nozzle For Monitor: DescriptionDocument2 pagesMaster Stream Nozzle For Monitor: DescriptionKumararaja KonikkiNo ratings yet

- VAJRA 536: Electric DC Remote Controlled MonitorDocument4 pagesVAJRA 536: Electric DC Remote Controlled MonitorKumararaja KonikkiNo ratings yet

- Cargo ShipsDocument36 pagesCargo ShipsKumararaja KonikkiNo ratings yet

- Ucalgary 2017 Sofekun GabrielDocument123 pagesUcalgary 2017 Sofekun GabrielKumararaja KonikkiNo ratings yet

- Specifiers Guide To Steel ProtectionDocument6 pagesSpecifiers Guide To Steel ProtectionKumararaja KonikkiNo ratings yet

- Standards Spec Brochure ME WEBDocument44 pagesStandards Spec Brochure ME WEBReza TambaNo ratings yet

- Chemcad Sizing ToolsDocument48 pagesChemcad Sizing Toolsparedanil100% (1)

- Marine Geotechnics PDFDocument28 pagesMarine Geotechnics PDFwidayat810% (1)

- Technical Specification Pile Foundation Transmission LinesDocument35 pagesTechnical Specification Pile Foundation Transmission LinesAnonymous YN4aNlNo ratings yet

- SpotQAassessments 2Document25 pagesSpotQAassessments 2l_aguilar_mNo ratings yet

- 10 1 1 1018 7352 PDFDocument10 pages10 1 1 1018 7352 PDFKumararaja KonikkiNo ratings yet